Soybean-based formaldehydeless adhesive used for chipboards, and application method thereof

An adhesive and soybean technology, which is applied in the application, adhesive, adhesive additive and other directions, can solve the problems of high water absorption thickness expansion rate, poor preformability, and the inability of soybean glue to uniformly sizing the moisture content of shavings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

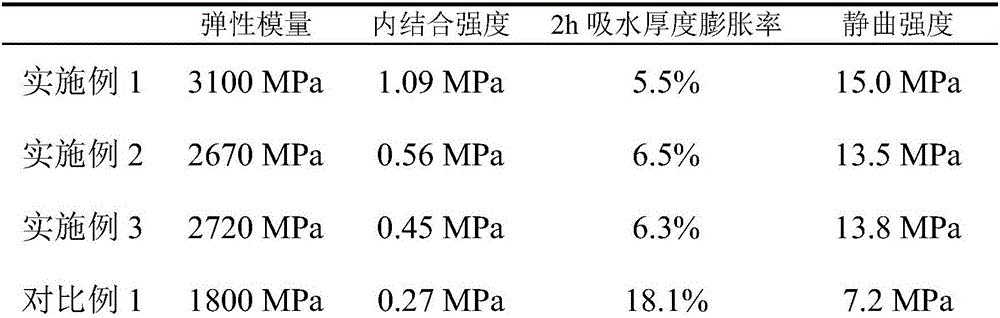

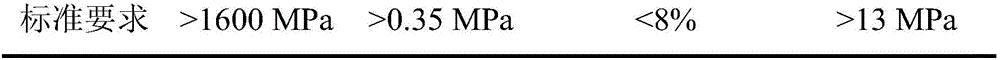

Examples

Embodiment 1

[0030] In this example, the soybean-based formaldehyde-free adhesive consists of the following raw material components in parts by weight:

[0031] Defatted soy flour: 20 servings

[0032] Sodium hydroxide (acid-base regulator): 0.2 parts

[0033] Epoxy resin (crosslinking agent, commercially available): 20 parts

[0034] Casson (antifungal agent, commercially available): 0.5 parts

[0035] Polyether modified polysiloxane (leveling agent, commercially available, Jiangxi Tiansheng New Material Co., Ltd., model QS302): 0.5 parts

[0036] Water: 30 parts

[0037] Rosin emulsion (tackifier, commercially available, Xiamen Baixu Chemical Co., Ltd., model J7009, solid content 50%): 28.8 parts.

[0038] When applying, mix sodium hydroxide, epoxy resin, carthone, polyether modified polysiloxane and water evenly to form a suspension as the liquid component, defatted soybean powder as the powder component, and rosin emulsion as the third Components, mix the powder components and sha...

Embodiment 2

[0040] In this example, the soybean-based formaldehyde-free adhesive consists of the following raw material components in parts by weight:

[0041] Defatted soy flour: 25 servings

[0042] Citric acid (acid-base regulator): 0.4 parts

[0043] Silane coupling agent (crosslinking agent, model KH560): 2.5 parts

[0044] Didodecyldimethylammonium chloride (antifungal agent): 0.3 parts

[0045] Polyether modified polysiloxane (leveling agent): 0.7 parts

[0046] Water: 30 parts

[0047] Terpene resin emulsion (tackifier, commercially available, Guangzhou Songbao Chemical Co., Ltd., model 8218, solid content 60%): 41.1 parts.

[0048] In application, stir citric acid, silane coupling agent, quaternary ammonium salt derivatives, polyether modified polysiloxane with water to form a uniform liquid as the liquid component, defatted soybean powder as the powder component, terpene resin Emulsion is used as the third component. While mixing the powder component and shavings, evenly sp...

Embodiment 3

[0050] In this example, the soybean-based formaldehyde-free adhesive consists of the following raw material components in parts by weight:

[0051] Defatted soy flour: 27 parts

[0052] Oxalic acid (acid-base regulator): 0.3 parts

[0053] Silane coupling agent (crosslinking agent): 3 parts

[0054] Copper sulfate (mold inhibitor): 0.5 parts

[0055] Polyether modified polysiloxane (leveling agent): 0.6 parts

[0056] Water: 30 parts

[0057] Polyvinyl alcohol solution (tackifier, commercially available, solid content 22%): 38.6 parts.

[0058] In application, stir oxalic acid, silane coupling agent, copper sulfate, polyether modified polysiloxane, polyvinyl alcohol solution with water to form a homogeneous liquid as a thickening liquid component, defatted soybean powder as a powder component, While mixing the powder component and the shavings, evenly spray the viscosifying liquid component, adjust the moisture content of the surface layer to 13%, and the moisture content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Internal binding strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com