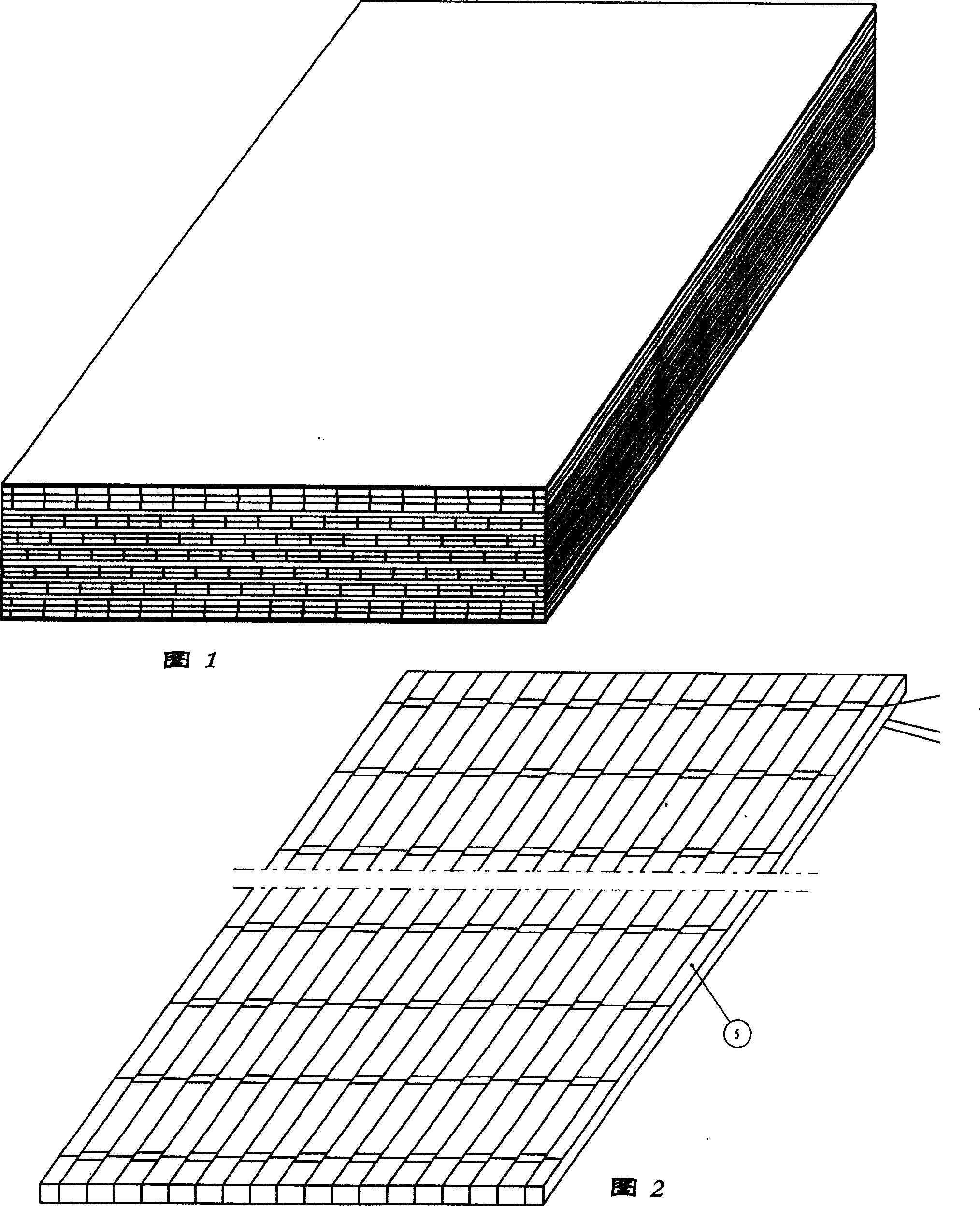

Bamboo and wood alternately arranged composite board and its manufacturing method

A manufacturing method and technology of composite boards, applied in the direction of manufacturing tools, joining of wooden veneers, wood processing appliances, etc., can solve the problems of wood shortage, product strength decline, cost increase, etc., and achieve the effect of reducing wood consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

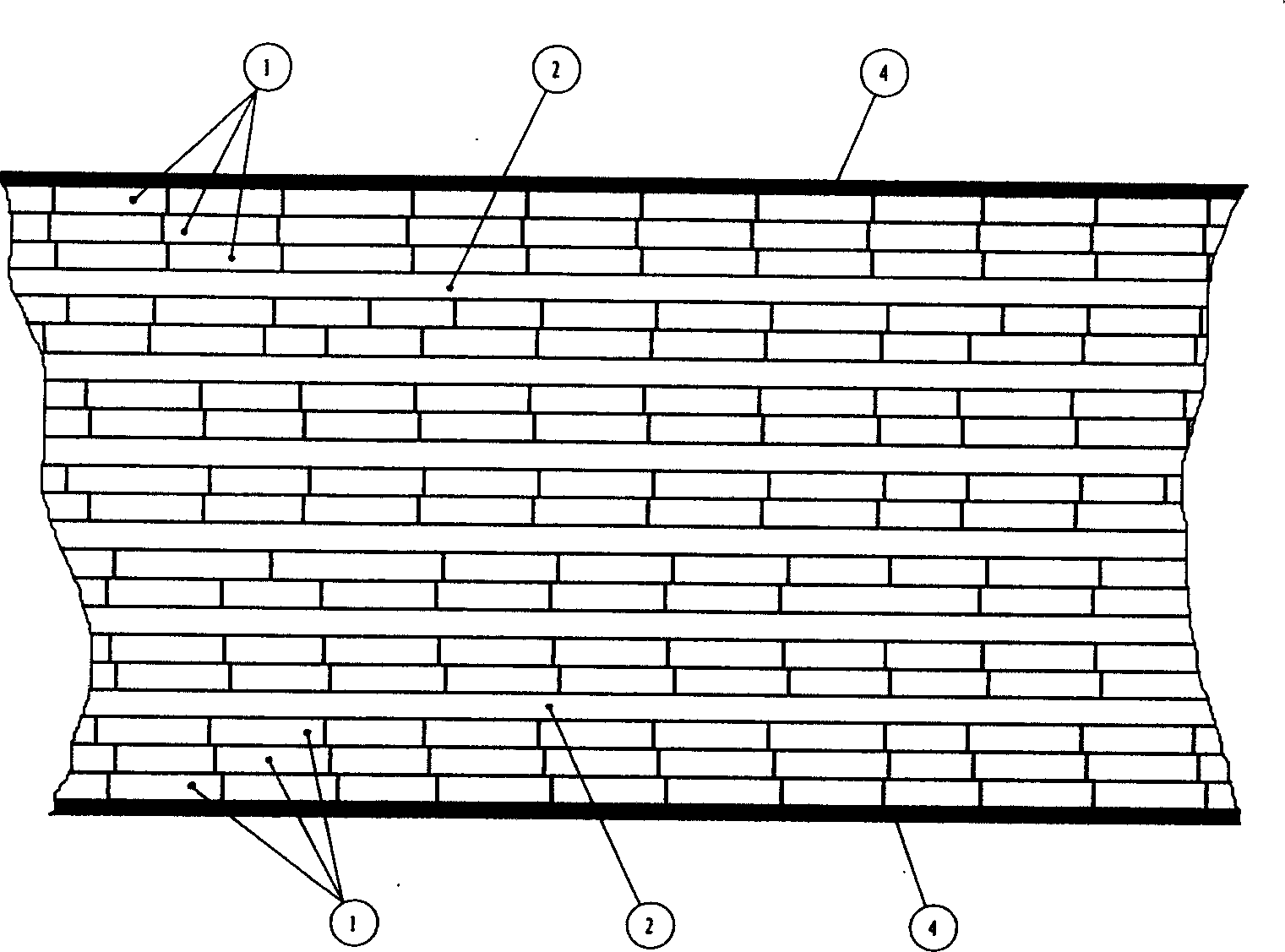

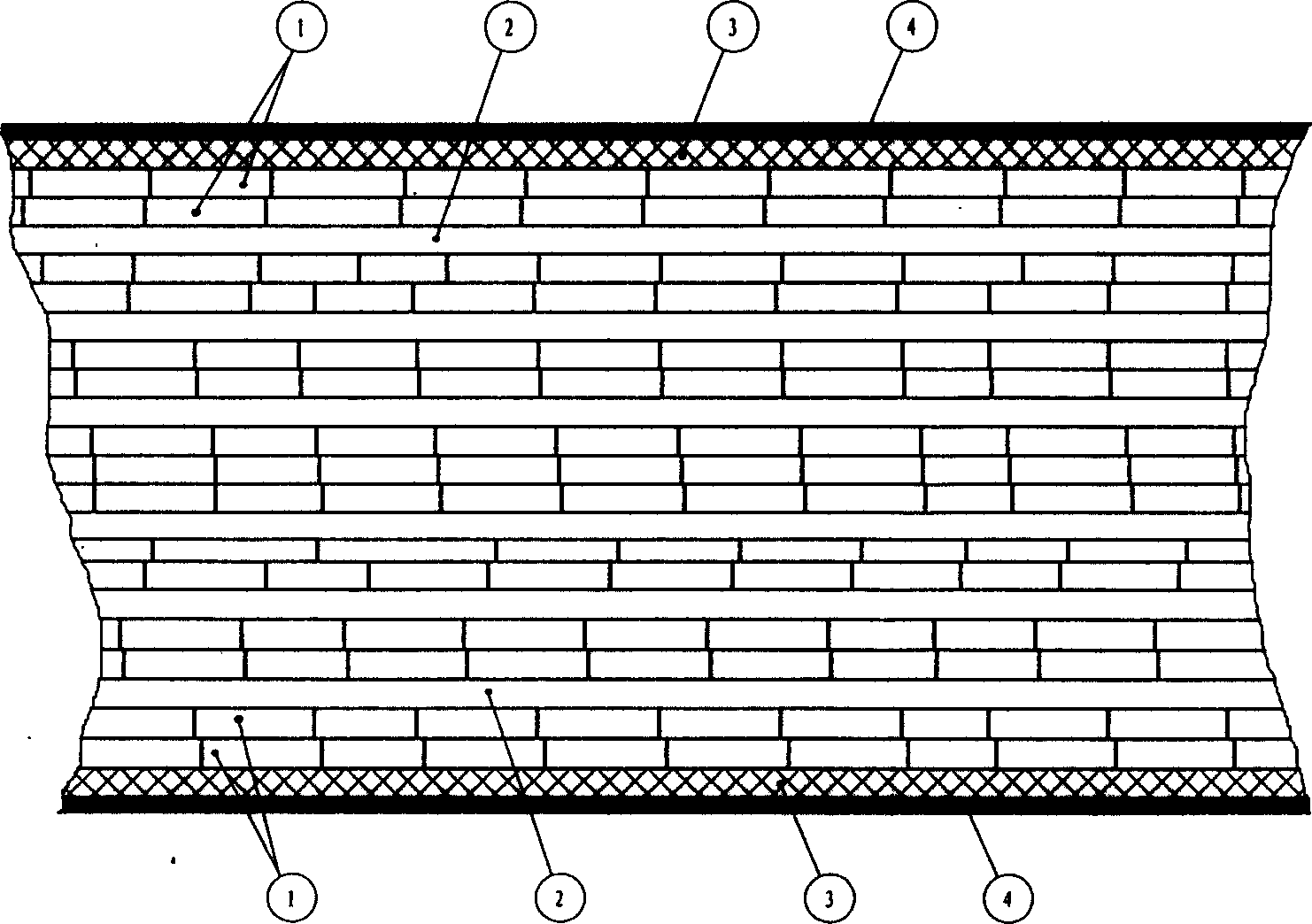

Embodiment Construction

[0028] The present invention utilizes ready-made bamboo machinery, improves and deepens its function, combines and arranges into a continuous production line, and moso bamboo is continuously made into high-quality bamboo sticks, specifically:

[0029] 1. Bamboo slip cutting machine: Cut the original bamboo into bamboo tubes according to the length of the product.

[0030] 2. Bamboo tube opening machine: Push the bamboo tube to the "multi-cutter" mold along the fiber direction, and break it into multiple bamboo strips at one time.

[0031] 3. Continuous milling machine: use multiple sets of wheels to cooperate with milling cutters and cutters, under the continuous pushing of materials, the knots of bamboo strips are flattened, green, yellowed and trimmed, making it into flat and thick bamboo strips. Its average thickness can be pre-adjusted to be equal to the multiple of the final thin bamboo sheet, for example 8mm thick.

[0032] 4. Medium chipping machine: it breaks the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com