Impregnation densified veneer enhanced laminated veneer lumber and a manufacturing method thereof

A technology of laminated veneer lumber and manufacturing methods, applied in the direction of impregnated wood, manufacturing tools, wood impregnation, etc., to achieve the effects of protecting the ecological environment, saving resources and harvesting, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The fast-growing poplar section is rotary-cut by a rotary cutter to obtain a veneer with a thickness of 2.0-4.0mm, and dried to a moisture content of 6%-10%;

[0029] Take a part of the poplar veneer with a thickness of 4.0mm and put it into the impregnating phenolic resin glue with a weight concentration of 15% for 30 minutes, take it out and dry it to a moisture content of 10%;

[0030] Then put the impregnated veneer into a hot plate hot press for high temperature compression, the temperature of the hot plate is 150°C, the compression time is 5.0min, the compression rate of the veneer is 50%, take it out and cool it to room temperature;

[0031] The veneer is coated with phenolic resin glue, and the amount of glue on one side is 150g / m2 2 ;

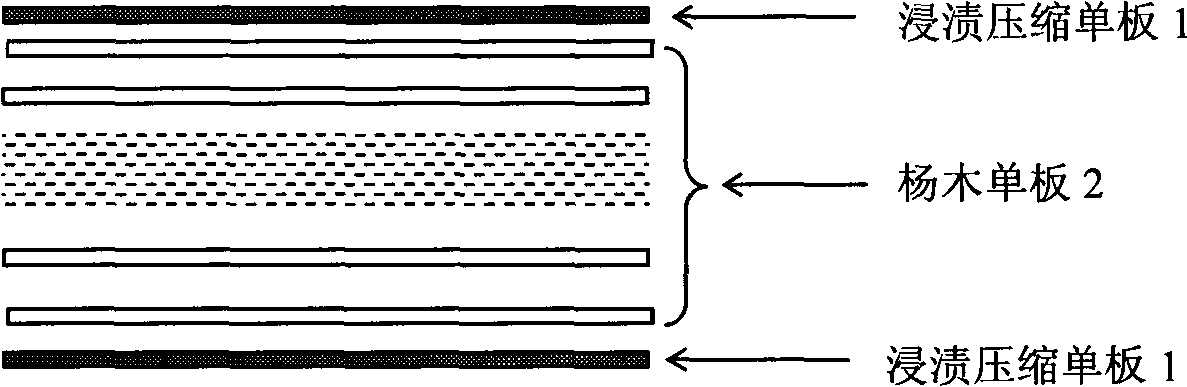

[0032] Glue-coated veneers are artificially assembled. The number of slab layers is 10. The method of assembly is that the upper and lower surfaces of the slab are each a layer of impregnated and compressed veneer, and the midd...

Embodiment 2

[0036] The fast-growing poplar section is rotary-cut by a rotary cutter to obtain a veneer with a thickness of 2.0-4.0mm, and dried to a moisture content of 6%-10%;

[0037] Take a part of the 2.0mm poplar veneer and put it into the impregnation phenolic resin glue with a weight concentration of 25% for 60 minutes, take it out and dry it to a moisture content of 10%;

[0038] The unimpregnated veneer is coated with phenolic resin glue, and the amount of glue on one side is 150g / m2 2 ;

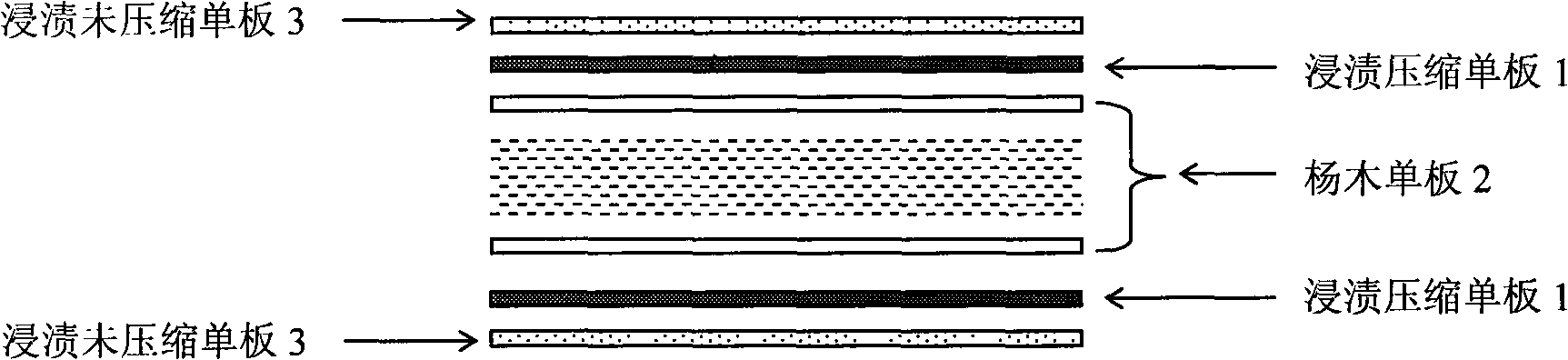

[0039] Glue-coated veneers are artificially assembled. The number of slab layers is 15. The method of assembly is that the upper and lower sides of the slab are 2 layers of phenolic glue impregnated veneers, and the middle 11 layers are poplar veneers with a thickness of 4.0mm; all veneers The slabs are assembled along the grain, and the formed slabs are aged at room temperature for 45mim;

[0040] Then send it into a hot press for hot pressing, the hot pressing temperature is 180°C, the hot ...

Embodiment 3

[0042] The fast-growing poplar section is rotary-cut by a rotary cutter to obtain a veneer with a thickness of 2.0-4.0mm, and dried to a moisture content of 6%-10%;

[0043] Take a part of 4.0mm poplar veneer and put it into urea-formaldehyde resin glue with a weight concentration of 30% for 90 minutes, take it out and dry it until the water content is 10%;

[0044] Then put the impregnated veneer into a flat plate hot press for high temperature compression, the temperature of the hot plate is 130°C, the compression time is 1.0min, the compression rate of the veneer is 30%, take it out and cool it to room temperature;

[0045] Take a part of the 2.0mm poplar veneer and put it into the impregnation phenolic resin glue with a weight concentration of 25% for 60 minutes, take it out and dry it to a moisture content of 10%;

[0046] Apply phenolic resin glue to the undipped veneer, and the amount of glue on one side is 220g / m 2 ;

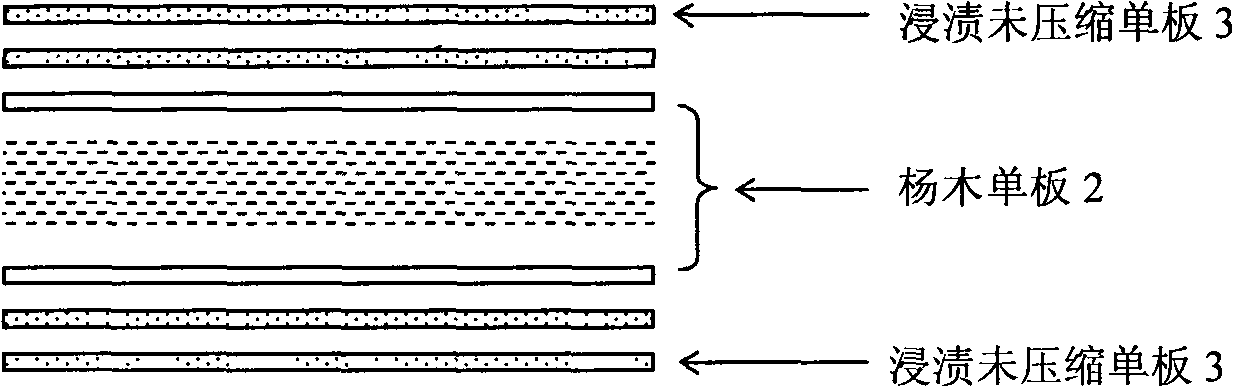

[0047] Glue-coated veneer is artificially assemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com