Bamboo wood composite plywood for concrete form panel and manufacturing method thereof

A bamboo-wood composite and manufacturing method technology, which is applied in the direction of manufacturing tools, wood layered products, and the joining of wooden veneers, which can solve the problems of poor overall performance of the board, large sawing road loss, and difficult boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Embodiment 1, moso bamboo, fir composite concrete building template

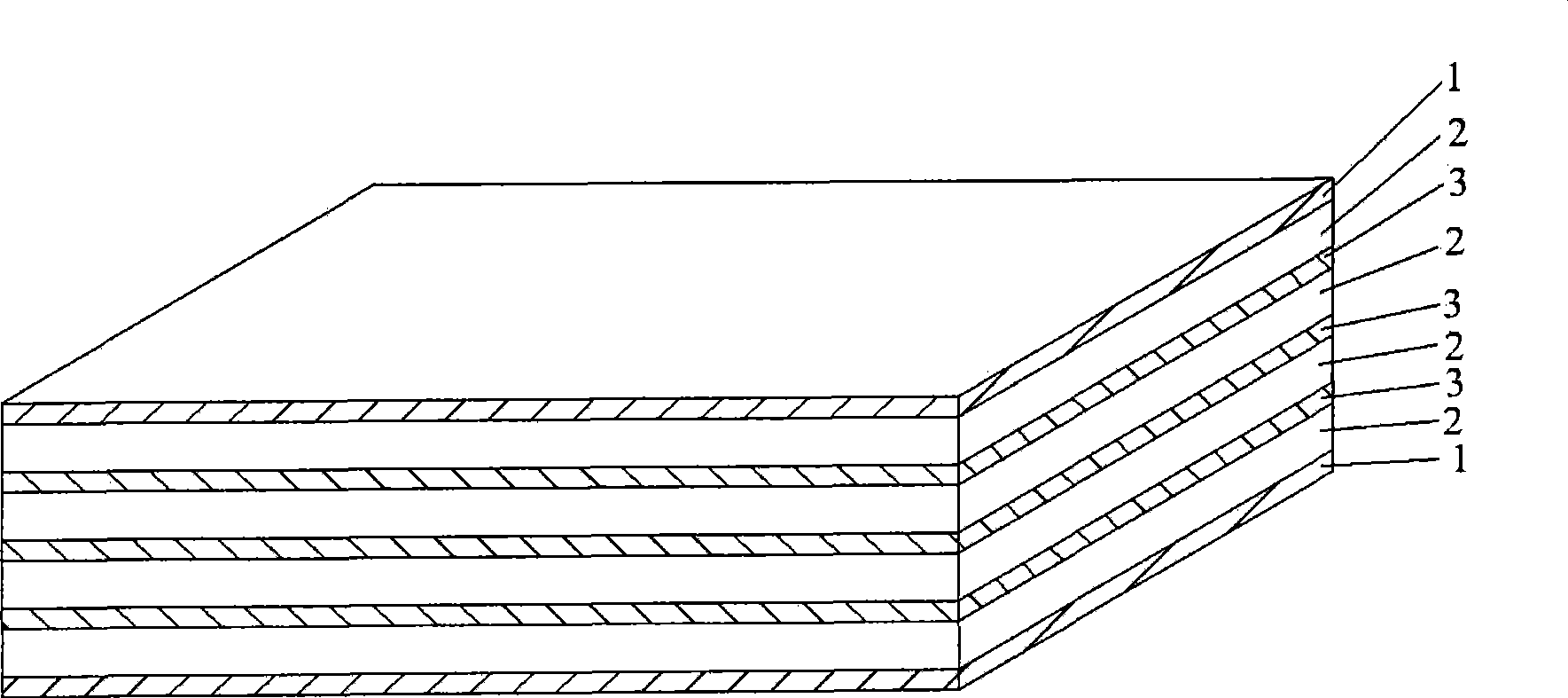

[0096] Such as figure 1 As shown, the concrete building template (that is, bamboo-wood composite plywood, also known as bamboo-fir composite concrete building template) includes nine layers, the surface layer of the slab is a 1.1 mm thick bamboo mat 1, and the subsurface layer is a 2.5 mm thick bamboo mat. Chinese fir veneer (the first log rotary cut veneer) 2, the middle five layers (core layer) are 1.1 mm thick bamboo curtain 3 and 2.5 mm thick fir veneer 2, the material of each layer can be seen from the cross section The thickness of the concrete building template obtained by hot pressing the slab is 12 millimeters.

[0097] The production method of the composite concrete building template provided by the present embodiment may include the following specific steps:

[0098] 1. Saw cutting and rotary cutting: Saw Chinese fir into fir wood sections according to a predetermined size, and rotary cut...

Embodiment 2

[0113] Embodiment 2, moso bamboo, poplar composite concrete building template

[0114] Such as figure 1 As shown, the concrete building formwork (i.e. bamboo-wood composite plywood, also known as bamboo-poplar composite concrete building formwork) includes nine layers, the surface layer of the slab is a 1.1 mm thick bamboo mat 1, and the subsurface layer is a 2.5 mm thick bamboo mat. Poplar veneer (the first log rotary-cut veneer) 2, the middle five layers (core layer) are 1.1 mm thick bamboo curtain 3 and 2.5 mm thick poplar veneer 2, each layer can be seen from the section The material; the thickness of the plywood obtained by hot pressing the slab is 12 mm.

[0115] The production method of the composite concrete building template provided by the present embodiment may include the following specific steps:

[0116] 1. Sawing and rotary cutting: the poplar is sawed into poplar wood sections according to the predetermined size, and rotary cut into poplar veneer (the first l...

Embodiment 3

[0131] Embodiment 3, moso bamboo, fir composite concrete building template

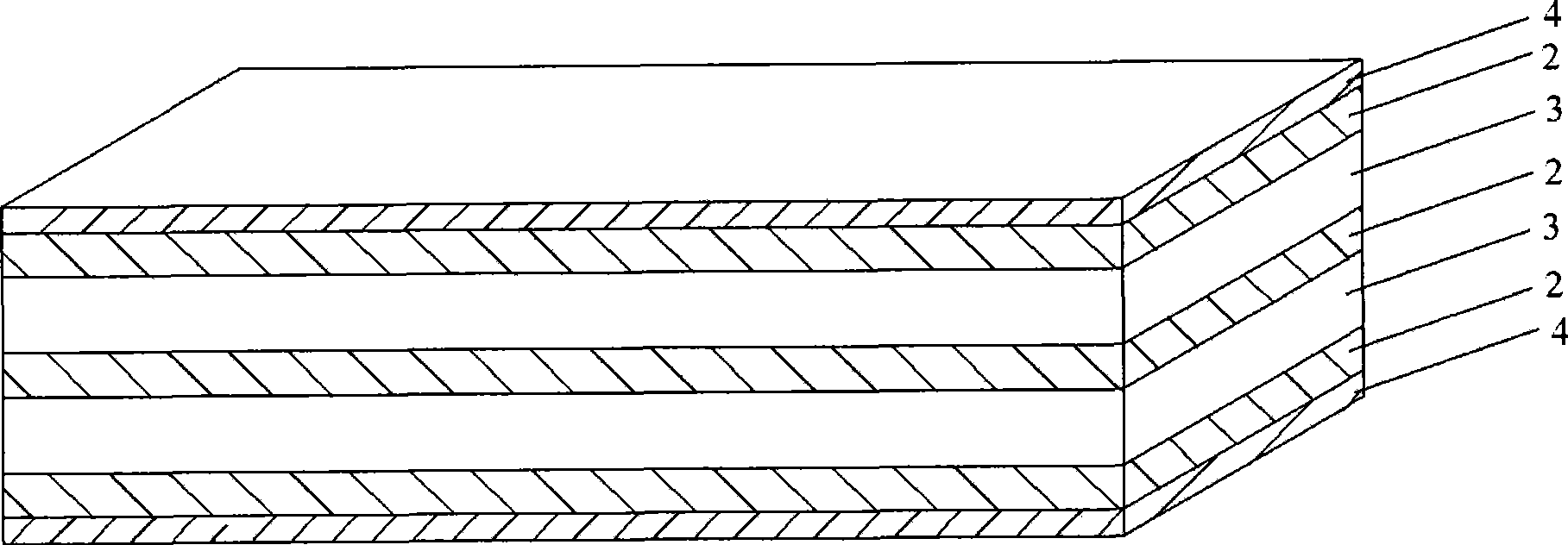

[0132] Such as figure 2 As shown, the concrete building template (that is, bamboo-wood composite plywood, also known as bamboo-fir composite concrete building template) includes seven layers, and the surface layer of the slab is a 1.5 mm thick fir veneer (the second log rotary-cut veneer ) 4, the subsurface layer is 2.5 mm thick fir veneer (the first log rotary cut veneer) 2, the middle three layers (core layer) are two layers of 4.3 mm thick bamboo curtain 3 and a layer of 2.5 mm thick fir veneer Slab 2, the material of each layer can be seen from the section; the thickness of the concrete building formwork obtained by hot pressing the slab is 15 mm.

[0133] The production method of the composite concrete building template provided by the present embodiment may include the following specific steps:

[0134] 1. Saw cutting and rotary cutting: the Chinese fir is sawed into fir wood sections accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com