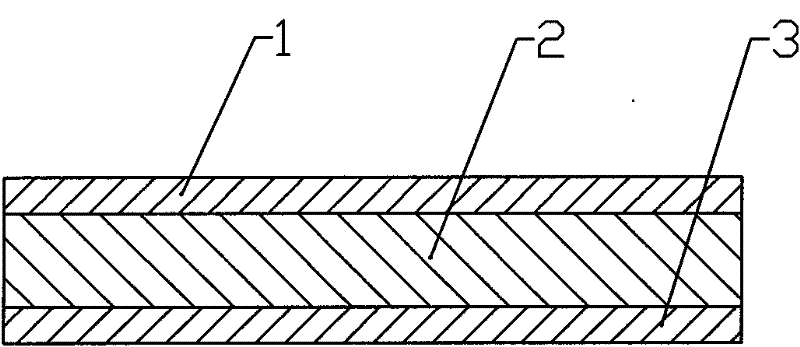

Oriented chipboard and processing technology

A technology of oriented strand board and preparation process, which is applied in the field of particle board, oriented strand board and preparation process, can solve the problems such as the limitation of particle length, and achieve the effects of reducing production cost, improving bearing capacity, and increasing static bending strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw materials: leftover dry / wet rotary cut veneer leftovers from plywood processing

[0033] Equipment: guillotine cutting machine, crusher, conveyor belt, dryer, winnowing machine, hot press, paving machine.

[0034] Reagents: modified melamine resin glue (produced by Zibo Aowei Adhesive Co., Ltd.), wax emulsion waterproofing agent (produced by Shanghai Jiaoer Chemical Products Co., Ltd.), industrial phosphoric acid (mass percentage concentration 85%, Shifang Hongyu Chemical Industry Co., Ltd. Co., Ltd.), industrial ammonium chloride (mass percentage concentration 99.5%, produced by Shandong Kangte Weiye Chemical Co., Ltd.), water (industrial water).

[0035] step:

[0036] (1) material preparation

[0037] Raw materials: Dry / wet rotary cut veneer scraps left over from plywood processing, with a thickness of 0.4-0.9mm;

[0038] The moisture content of the wet veneer is 30% to 50%, and the moisture content of the dry veneer is 15% to 20%.

[0039] (2) guillotine cut...

Embodiment 2

[0074] Raw materials: leftover dry / wet rotary cut veneer leftovers from plywood processing

[0075] Equipment: guillotine cutting machine, crusher, conveyor belt, dryer, winnowing machine, hot press, paving machine.

[0076] Reagents: phenolic resin glue (manufactured by Qingdao Jingweite Chemical Co., Ltd.), water.

[0077] step:

[0078] (1) material preparation

[0079] Raw materials: Dry / wet rotary cut veneer scraps left over from plywood processing, with a thickness of 0.4-0.9mm;

[0080] The moisture content of the wet veneer is 30% to 50%, and the moisture content of the dry veneer is 15% to 20%.

[0081] (2) guillotine cutting

[0082] Use guillotine cutter to cut wet veneer and dry veneer separately, the length of shavings cut by guillotine is ≤170mm, and try to avoid horizontal feeding.

[0083] (3) Broken

[0084] Use a crusher to crush the shavings so that the width of the shavings is ≤40mm and the length is ≤170mm. Separate the shavings with a length greater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com