Glued bamboo board and preparation method thereof

A technology for gluing bamboo boards and plywood, which is applied in the direction of manufacturing tools, chemical instruments and methods, and wood layered products, can solve the problems of fragile products and achieve high impact strength, high density, and high static bending strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

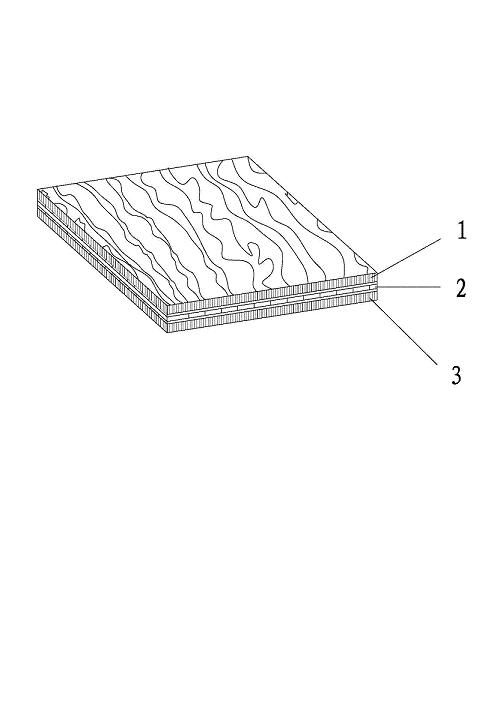

[0036] Such as figure 1Shown, a kind of glued bamboo board comprises upper layer 1, middle layer 2, lower layer 3; Described upper layer 1 and lower layer 3 are recombined bamboo boards, and the bamboo silk arrangement direction of described recombined bamboo boards and self board The surface is vertical; the density of the a kind of glued bamboo board is 1.5g / cm 3 , the water content is 8.0%, the 24-hour water absorption thickness expansion rate is 2.0%, the static bending strength is 120MPa, and the surface hardness is 90MPa. The bamboo filaments of the recombined bamboo board include carbonized and non-carbonized bamboo filaments, which form irregular patterns after hot pressing. The degree of carbonization of carbonized bamboo filaments is also different. The middle layer 2 is a three-layer bamboo flat-pressed plywood, and the direction of the bamboo filaments of two adjacent bamboo flat-pressed plywood is vertical.

[0037] The bamboo sheet flat-pressed plywood refers ...

Embodiment 2

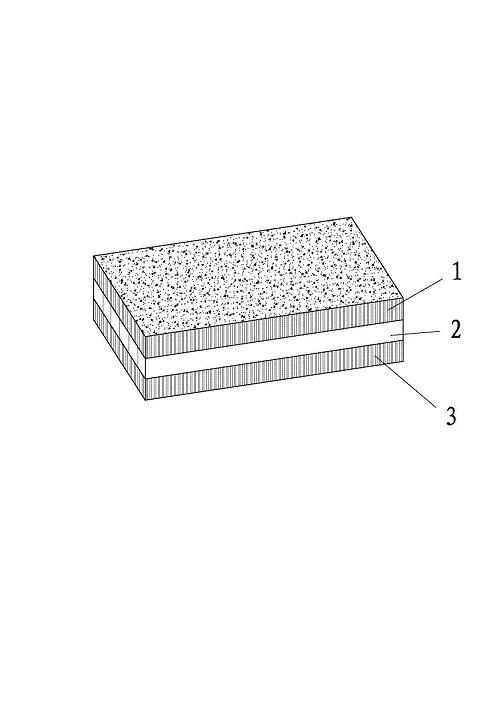

[0048] Such as figure 2 Shown, a kind of glued bamboo board comprises upper layer 1, middle layer 2, lower layer 3; Described upper layer 1 and lower layer 3 are recombined bamboo boards, and the bamboo silk arrangement direction of described recombined bamboo boards and self board The surface is vertical; the density of the a kind of glued bamboo board is 1.4g / cm 3 , the water content is 8.0%, the 24-hour water absorption thickness expansion rate is 2.0%, the static bending strength is 120MPa, and the surface hardness is 90MPa. The bamboo filaments of the recombined bamboo board are all uncarbonized bamboo filaments. The middle layer 2 is bamboo side-pressed plywood.

[0049] The bamboo side-pressed plywood refers to cutting the moso bamboo into slices, removing the green and yellowing, and then making bamboo slices of predetermined specifications. The press is used for cold pressing or hot pressing.

[0050] The thickness of the recombined bamboo board is 7mm; the thick...

Embodiment 3

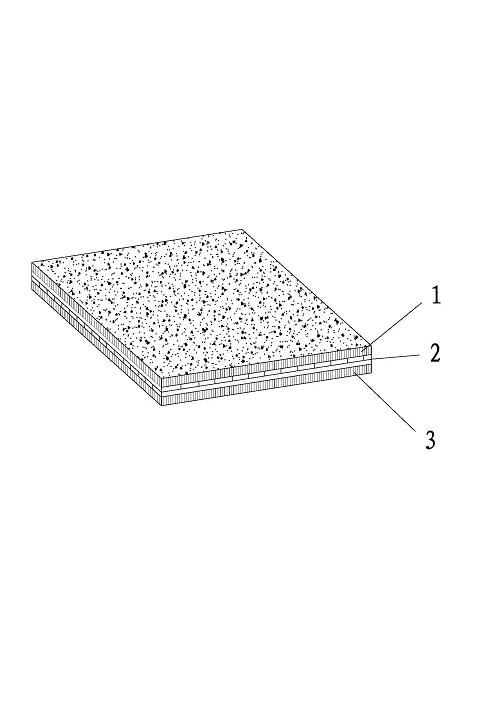

[0059] Such as image 3 Shown, a kind of glued bamboo board comprises upper layer 1, middle layer 2, lower layer 3; Described upper layer 1 and lower layer 3 are recombined bamboo boards, and the bamboo silk direction of described recombined bamboo boards and its own board surface vertical; the density of the a kind of glued bamboo board is 1.6g / cm 3 , the water content is 14.0%, the 24-hour water absorption thickness expansion rate is 2.0%, the static bending strength is 180MPa, and the surface hardness is 140MPa. The bamboo filaments of the recombined bamboo board are all non-carbonized bamboo filaments. The middle layer 2 is a two-layer bamboo flat-pressed plywood, and the direction of the bamboo filaments of the adjacent two-layer bamboo flat-pressed plywood is vertical. The thickness of the recombined bamboo board is 10mm; the single layer thickness of the two-layer bamboo plywood is 4mm.

[0060] Above-mentioned a kind of glued bamboo board is manufactured as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com