Wood-plastic floorboard and manufacturing method

A technology for wood-plastic flooring and wood-plastic composite materials, which is applied in the field of wood-plastic flooring and its manufacturing, can solve the problems of instability, low mechanical properties, poor water resistance, wear resistance and aging resistance, and is conducive to popularization and application. Simple manufacturing process and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

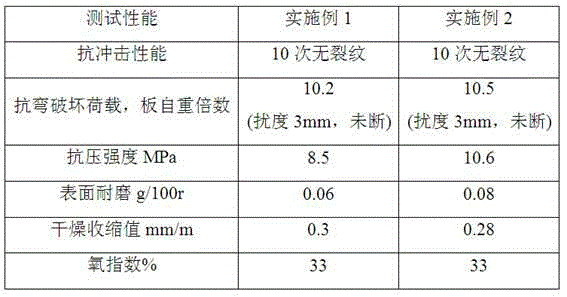

Embodiment 1

[0017] A wood-plastic floor is composed of two layers of PVC-based wood-plastic composite materials, the bottom layer of the floor is PVC-based wood-plastic composite material A, and the upper layer is PVC-based wood-plastic composite material B.

[0018] PVC-based wood-plastic composite material A is prepared from the following raw materials in parts by mass: 100 parts of PVC powder, 200 parts of plant fiber, 40 parts of plasticizer, 5 parts of heat stabilizer, 10 parts of coupling agent, and 50 parts of inorganic filler.

[0019] PVC-based wood-plastic composite material B is prepared from the following raw materials in parts by mass: 100 parts of PVC powder, 100 parts of plant fiber, 30 parts of plasticizer, 5 parts of heat stabilizer, 9 parts of coupling agent, and 1 part of anti-aging agent , 2 parts of reinforcing agent, 0.5 part of coloring agent.

[0020] PVC-based wood-plastic composite materials are formed by extrusion, injection molding or calendering.

[0021] The...

Embodiment 2

[0026] A wood-plastic floor is composed of three layers of PVC-based wood-plastic composite materials. The bottom layer of the floor is PVC-based wood-plastic composite material A, the middle layer is PVC-based wood-plastic composite material A, and the upper layer is PVC-based wood-plastic composite material B.

[0027] PVC-based wood-plastic composite material A is prepared from the following raw materials in parts by mass: 100 parts of PVC powder, 300 parts of plant fiber, 80 parts of plasticizer, 10 parts of heat stabilizer, 15 parts of coupling agent, and 80 parts of inorganic filler.

[0028] PVC-based wood-plastic composite material B is prepared from the following raw materials in parts by mass: 100 parts of PVC powder, 150 parts of plant fiber, 50 parts of plasticizer, 7 parts of heat stabilizer, 12 parts of coupling agent, and 5 parts of anti-aging agent , 5 parts of reinforcing agent, 2.0 parts of coloring agent.

[0029] PVC-based wood-plastic composite materials a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com