Starch based biomass functional adhesive and preparation method thereof

A biomass and adhesive technology, applied in the field of papermaking, can solve the problems of immaturity of biomass functional adhesives, and achieve the effects of excellent rheology, good rheology and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

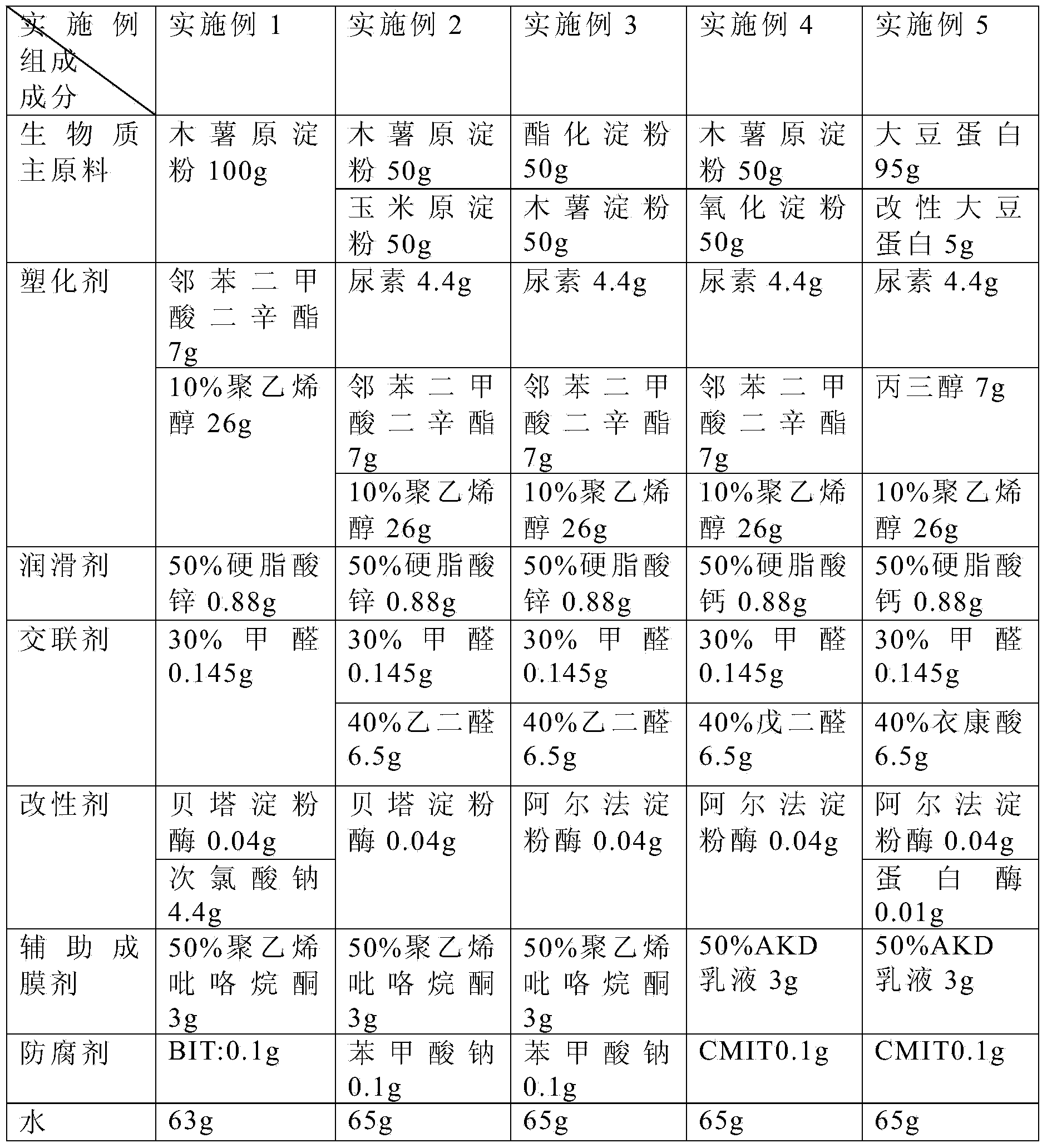

Examples

Embodiment 1

[0033] Weigh the raw materials according to the composition and mass percentage of the starch-based biomass functional adhesive described in Table 1, Example 1, add the weighed biomass main raw material, modifier and water to the reactor, and heat up to 80°C, react for 40 minutes;

[0034] Pump the above-mentioned reacted material to a three-stage steam ejector for steaming, and the steam temperature is 140°C;

[0035] Send the above-mentioned treated materials to the mixing tank, add the weighed lubricant, plasticizer, and crosslinking agent under stirring, react at 70°C for 50 minutes, and add the preservative after the reaction is complete;

[0036] Add a pH regulator to the above-mentioned treated material to adjust the pH to 6-7, then add an auxiliary film-forming agent and mix evenly, cool the mixed material to 40-50°C and discharge it, and finally filter to remove impurities to obtain the final product Starch-based biomass functional adhesive.

Embodiment 2

[0038] Weigh the raw materials according to the composition and mass percentage of the starch-based biomass functional adhesive described in Table 1, Example 2, add the weighed biomass main raw material, modifier and water to the reactor, and heat up to 90°C, react for 50min;

[0039] Pump the above-mentioned reacted materials to a three-stage steam ejector for steaming, and the steam temperature is 130°C;

[0040] Send the above-mentioned treated materials to the mixing tank, add the weighed lubricant, plasticizer, and cross-linking agent under stirring, react at 80°C for 40 minutes, and add the preservative after the reaction is complete;

[0041] Add a pH regulator to the above-mentioned treated material to adjust the pH to 6-7, then add an auxiliary film-forming agent and mix evenly, cool the mixed material to 45°C and discharge it, and finally filter to remove impurities to obtain the final product biostarch Matrix functional adhesives.

Embodiment 3

[0043] Weigh the raw materials according to the composition and mass percentage of the starch-based biomass functional adhesive described in Table 1, Example 3, add the weighed biomass main raw material, modifier and water to the reactor, and heat up to 70°C, react for 40 minutes;

[0044] Pump the above-mentioned reacted material to a three-stage steam ejector for steaming, and the steam temperature is 120°C;

[0045] Send the above-mentioned treated materials to the mixing tank, add the weighed lubricant, plasticizer, and crosslinking agent under stirring, react at 70°C for 40 minutes, and add the preservative after the reaction is complete;

[0046]Add a pH regulator to the above-mentioned treated material to adjust the pH to 6-7, then add an auxiliary film-forming agent and mix evenly, cool the mixed material to 40°C and discharge it, and finally filter to remove impurities to obtain the final product starch-based Biomass functional adhesives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com