Tunnel inspection image acquisition device and tunnel inspection system

A technology of image acquisition device and inspection system, which is applied in mining devices, measuring devices, mining equipment, etc., can solve the problems of low overall efficiency of tunnel inspection operations, complex structure of large-scale flaw detection vehicles, and low timeliness of flaw detection vehicles. Facilitate real-time processing, reduce exposure differences, and improve timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

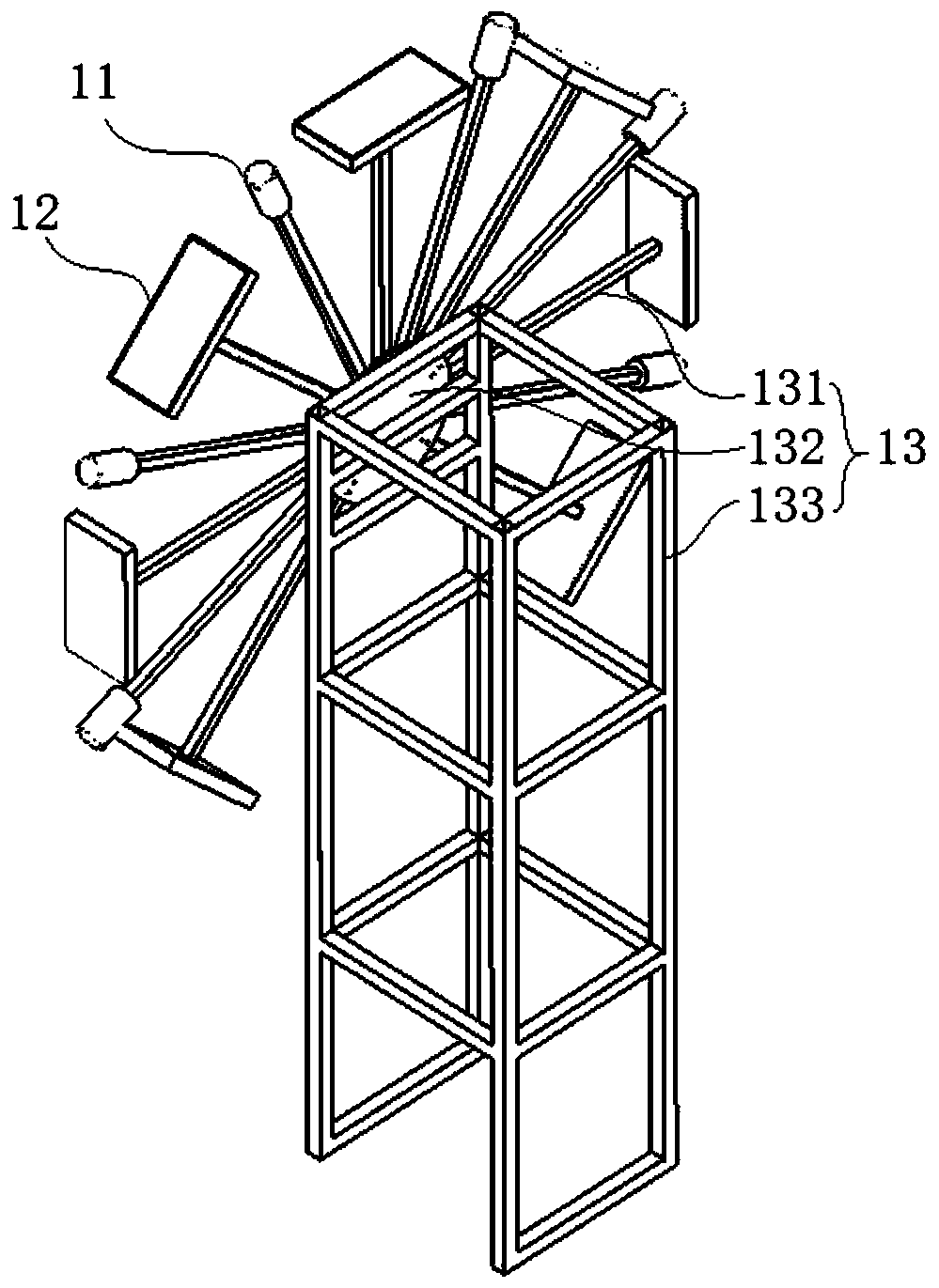

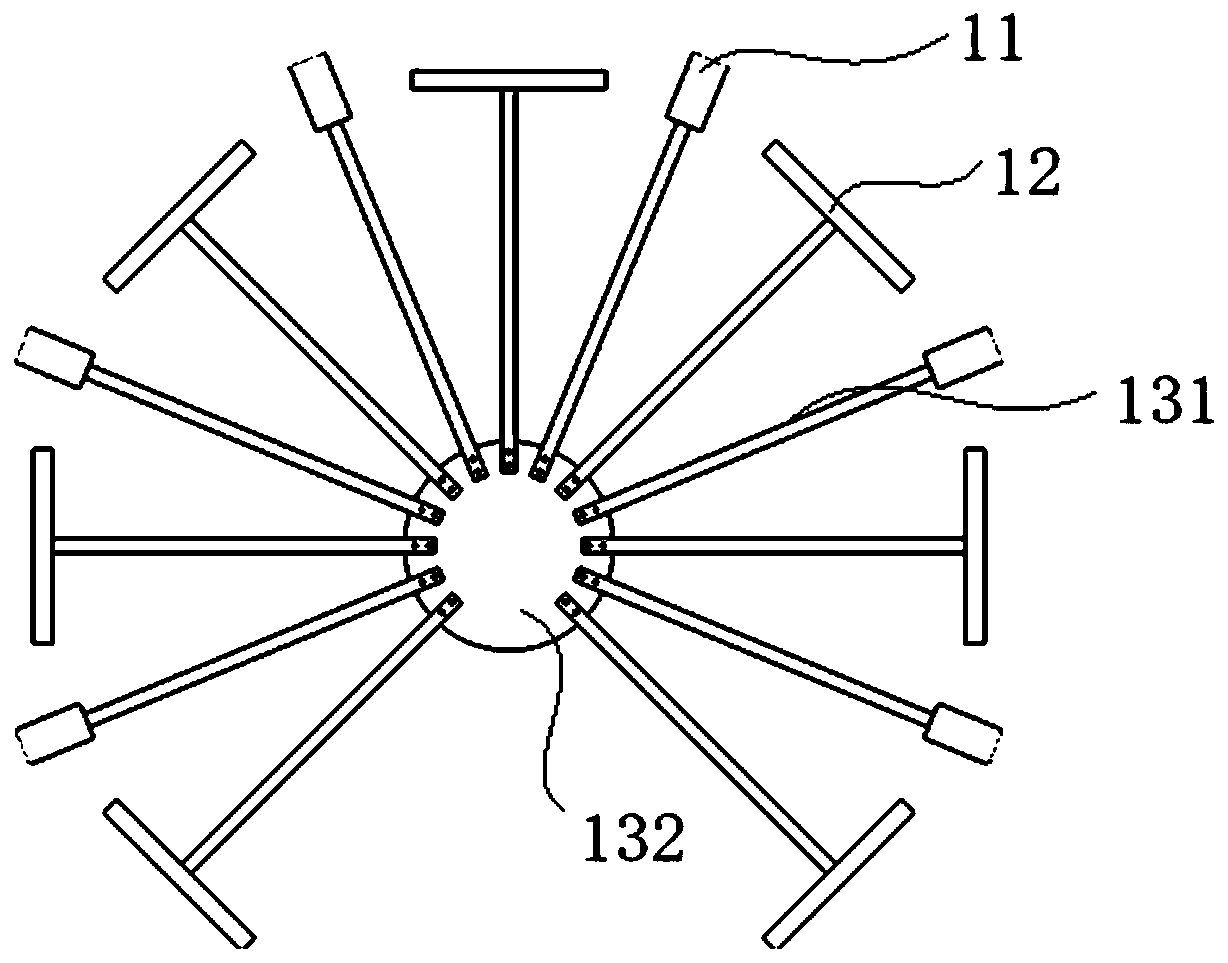

[0035] see figure 1 , the application provides a tunnel inspection image acquisition device, which is applied to the image acquisition of the inner lining of the tunnel, including: a plurality of CCD cameras 11, a plurality of auxiliary light sources 12 for CCD cameras 11 to shoot and expose, and a fixed bracket 13, The CCD camera 11 and the auxiliary light source 12 are fixed on the fixed bracket 13; wherein, the fixed positions of the multiple CCD cameras 11 are located on the same ring, and in the working state, the center of the ring is located at the center of the tunnel to ensure that the multiple CCD cameras 11 is consistent with the distance from the tunnel lining surface, and the overall shooting angle of multiple CCD cameras 11 covers the range of the tunnel lining surface.

[0036] Now specifically describe this embodiment in detail:

[0037] The image acquisition device for tunnel inspection in this embodiment can be installed on any platform, and connected and in...

Embodiment 2

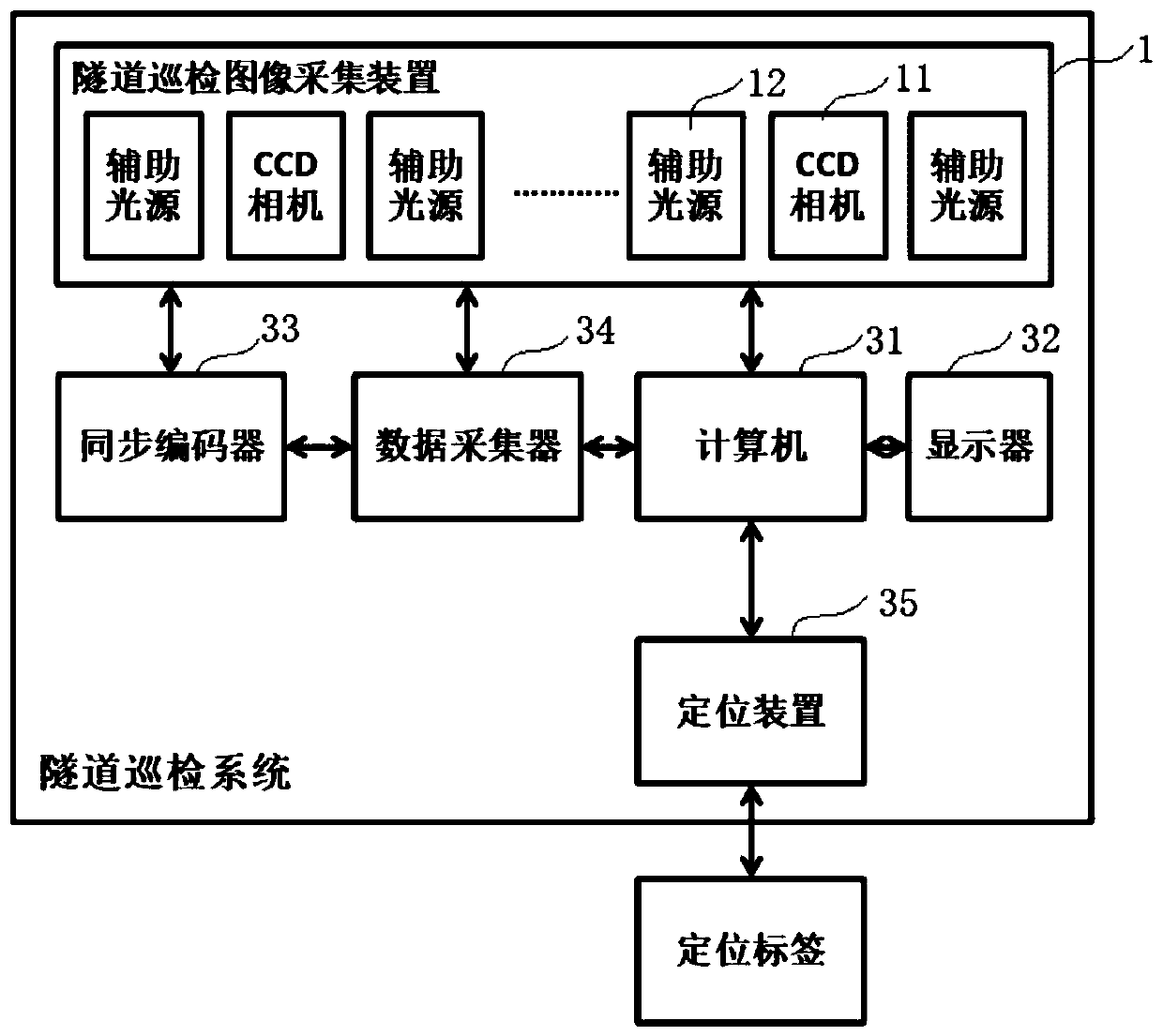

[0044] see image 3 , the present application provides a tunnel inspection system based on Embodiment 1, which includes a flaw detection mobile platform 2 for traveling on rails, and also includes a computer 31, a display 32, a synchronous encoder 33, A data collector 34, and the tunnel inspection image acquisition device 1 as in Embodiment 1;

[0045] Wherein, the fixed bracket 13 is arranged on the flaw detection mobile platform 2. Under the working condition, the center of the ring where the multiple CCD cameras 11 are located is located at the center of the tunnel, so as to ensure that the distances between the multiple CCD cameras 11 and the inner lining of the tunnel are consistent; The encoder 33 is electrically connected with the CCD camera 11 and the auxiliary light source 12 respectively, and is used to send a synchronous pulse signal every fixed distance to trigger synchronous work of multiple CCD cameras 11 and multiple auxiliary light sources 12 according to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com