Soft antibacterial non-woven fabric and preparing method thereof

A non-woven and soft technology, applied in the direction of fabric kneading/softening treatment, equipment configuration for processing textile materials, non-woven fabrics, etc. , poor softness of non-woven fabrics, etc., to achieve the effect of improving softness and feel, speed and effect, and improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a soft antibacterial nonwoven fabric, the preparation method is applicable to the aforementioned soft antibacterial nonwoven fabric, and the preparation method comprises the following steps:

[0043] A1: Cotton fibers and polypropylene staple fiber equipment are used to make non-woven fabrics; polypropylene staple fibers are divided and laid in the production process, and cotton fibers are sprayed on polypropylene fibers during the process of dividing and laid to obtain fiber webs , and then hot-rolling and finishing the fiber web to obtain a non-woven fabric;

[0044] A2: The non-woven fabric prepared in the step A1 is processed with a needle-punched device to obtain a needle-punched non-woven fabric;

[0045] A3: Process the spunlace nonwoven fabric obtained in step A2 with a finishing device to obtain a finished soft antibacterial nonwoven fabric;

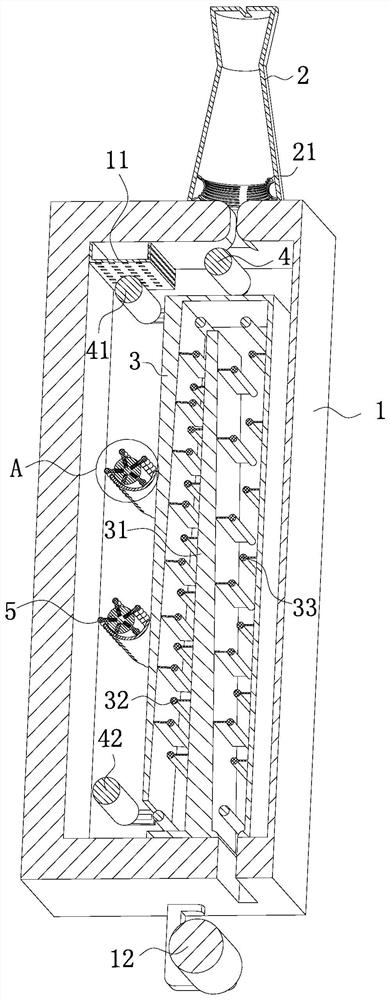

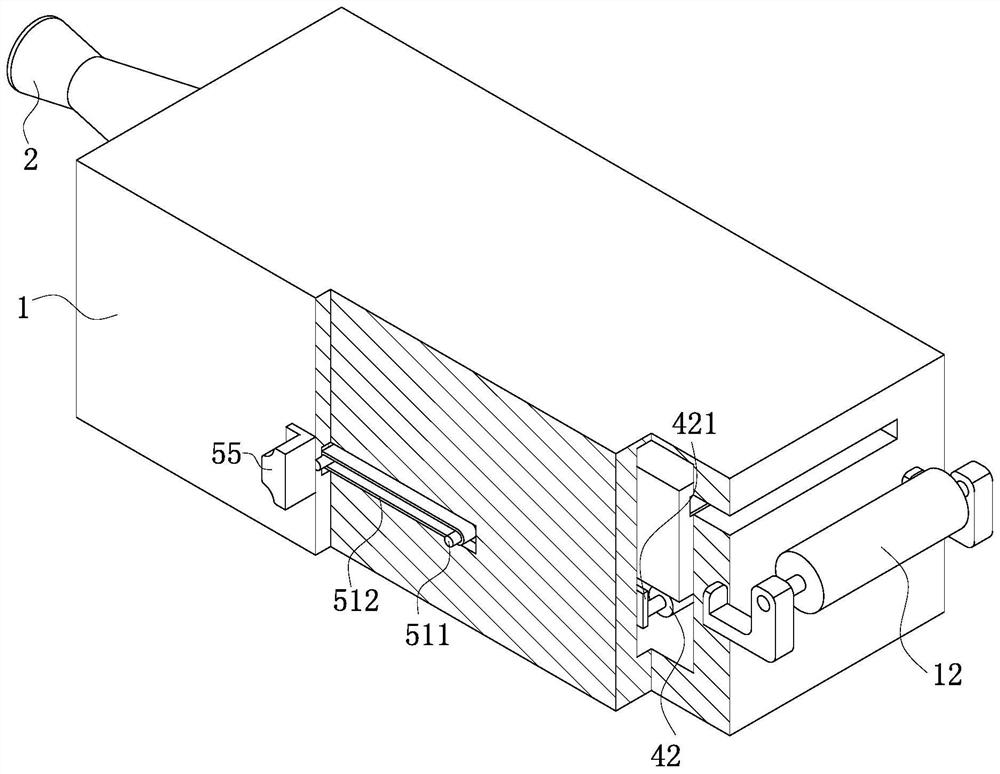

[0046] Wherein, the finishing device includes a body 1; a Venturi tube 2 is installed at one en...

Embodiment approach

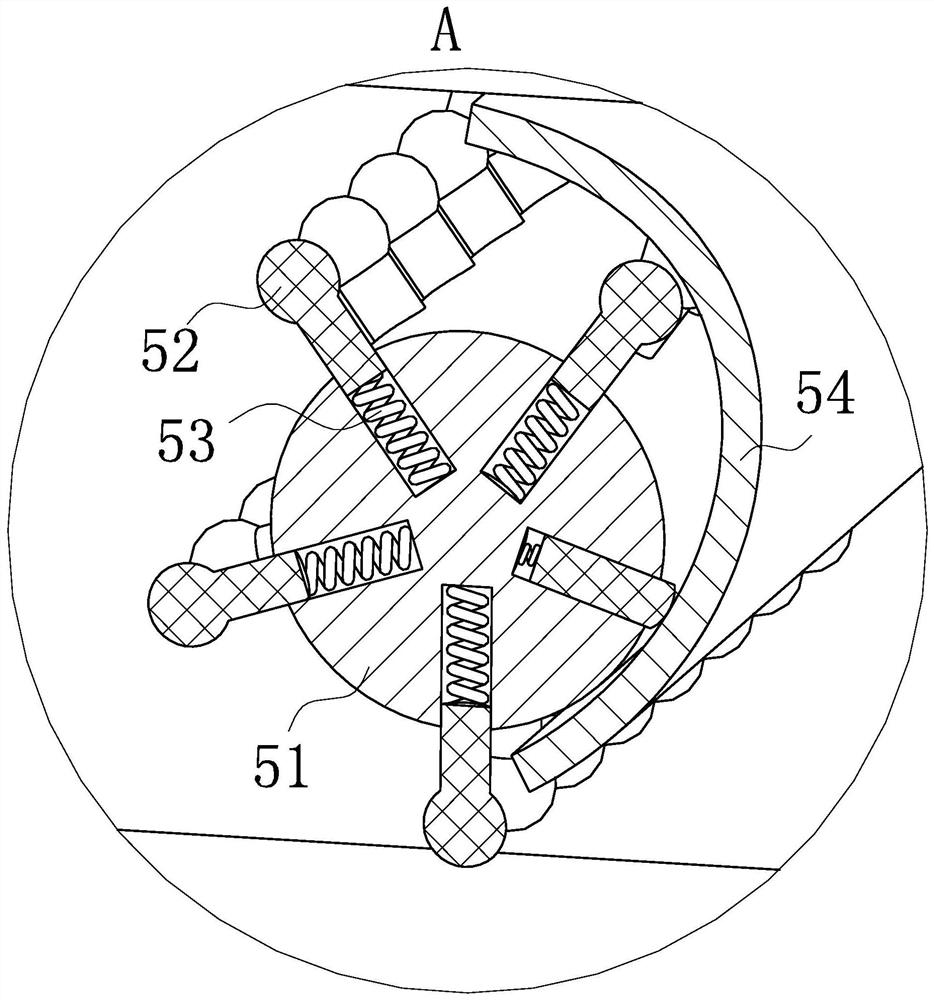

[0052] As an embodiment of the present invention, a cleaning rod 5 is installed in the body 1; there are two cleaning rods 5 at the same height; the cleaning rod 5 is located between the second guide roller 41 and the third guide roller 42 The cleaning rod 5 is located below the drying box 3; the cleaning rod 5 is positioned above the non-woven fabric passing through the cleaning liquid; the cleaning rod 5 includes a rod main body 51, a rotating shaft 511, an impact rod 52, a spring 53 and Limiting plate 54; the rod body 51 is installed on the body 1 through the rotating shaft 511; grooves are evenly opened on the rod body 51; the impact rod 52 is installed in the groove; the spring 53 is installed in the groove , and located below the impact rod 52; the limit plate 54 is installed on the inner wall of the body 1, and the distance between the top of the limit plate 54 and the rod main body 51 is greater than the distance between the bottom of the limit plate 54 and the rod main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com