Gel coat resin, preparation method thereof and racer barrel seat using gel coat resin

A technology of gel coat resin and matrix resin, applied in the field of racing bucket chairs, can solve the problems of poor flame retardancy and long curing time of gel coat resin, and achieve the effects of reducing density, shortening curing time, and improving mechanical strength and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

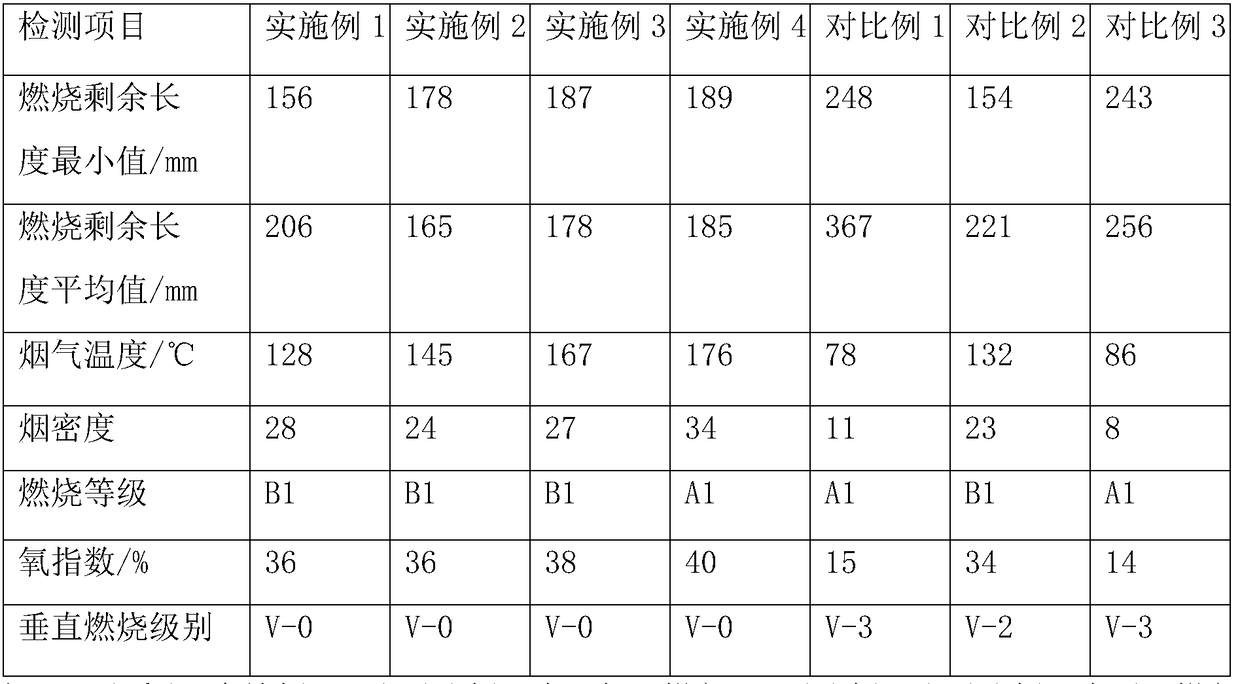

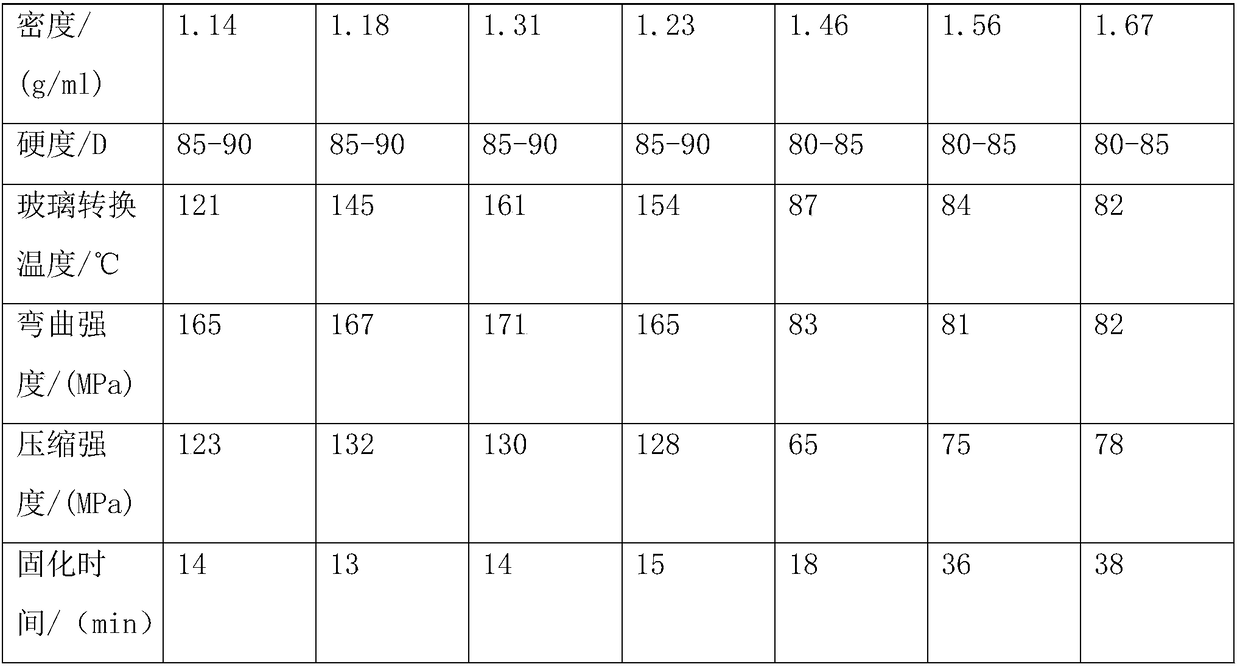

Examples

Embodiment 1

[0035]Embodiment 1: a kind of gel coat resin, the fineness of gel coat resin is 5 μm, comprises the matrix resin that parts by weight are 40 parts, 20 parts of flame retardants, 10 parts of curing agent, 12 parts of auxiliary agents, 21 parts of fillers and 0.5 parts of pigment;

[0036] The base resin is made up of the following parts by weight: 30 parts of tetrabromoic anhydride, 20 parts of propylene glycol, 5 parts of isophthalic anhydride, 10 parts of maleic anhydride, 8 parts of styrene and 5 parts of polymerization inhibitor;

[0037] The flame retardant is composed of the following substances by weight: 20 parts of ditellurium trioxide, 17 parts of zinc borate, 15 parts of attapulgite, 10 parts of triphenyl phosphate, 8 parts of magnesium hydroxide, 5 parts of aluminum hydroxide, 9 parts polysiloxane;

[0038] The curing agent is composed of the following parts by weight: 3 parts of methyl ethyl ketone peroxide with a mass fraction of 3.5%, 2 parts of cobalt isozincat...

Embodiment 2

[0045] Embodiment 2: a kind of gel coat resin, the fineness of gel coat resin is 10 μ m, comprises the matrix resin that is 55 parts by weight, 35 parts of flame retardants, 15 parts of curing agent, 15 parts of auxiliary agents, 27 parts of fillers and 1.5 parts of pigment;

[0046] The base resin is made up of the following parts by weight: 33.5 parts of tetrabromoic anhydride, 21 parts of propylene glycol, 7.5 parts of isophthalic anhydride, 11 parts of maleic anhydride, 10 parts of styrene and 6 parts of polymerization inhibitors;

[0047] The flame retardant is composed of the following substances by weight: 24 parts of ditellurium trioxide, 19.8 parts of zinc borate, 18 parts of attapulgite, 11 parts of triphenyl phosphate, 10 parts of magnesium hydroxide, 7 parts of aluminum hydroxide, 11 parts polysiloxane;

[0048] The curing agent is composed of the following parts by weight: 6 parts of methyl ethyl ketone peroxide with a mass fraction of 3%, 5 parts of cobalt isozi...

Embodiment 3

[0055] Embodiment 3: a kind of gel coat resin, the fineness of gel coat resin is 15 μ m, comprises the matrix resin that is 65 parts by weight, 45 parts of flame retardant, 25 parts of curing agent, 21 parts of auxiliary agent, 39 parts of filler and 2 parts paint;

[0056] The base resin is made up of the following parts by weight: 37.5 parts of tetrabromoic anhydride, 21.5 parts of propylene glycol, 8 parts of isophthalic anhydride, 13 parts of maleic anhydride, 12 parts of styrene and 7 polymerization inhibitors;

[0057] The flame retardant is composed of the following parts by weight: 32 parts of ditellurium trioxide, 25.3 parts of zinc borate, 24 parts of attapulgite, 13 parts of triphenyl phosphate, 14 parts of magnesium hydroxide, 11 parts of aluminum hydroxide, 13 parts polysiloxane;

[0058] The curing agent is composed of the following parts by weight: 12 parts of methyl ethyl ketone peroxide with a mass fraction of 2%, 11 parts of cobalt isozincate with a mass fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com