Wear-resistant glaze material as well as preparation method and application thereof

A technology of glazed surface and ball abrasive, which is applied in the field of materials, can solve the problems of soft glazed surface and affecting the wear resistance of glazed surface, and achieve the effect of improving structural strength, ensuring uniformity, and having both wear resistance and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

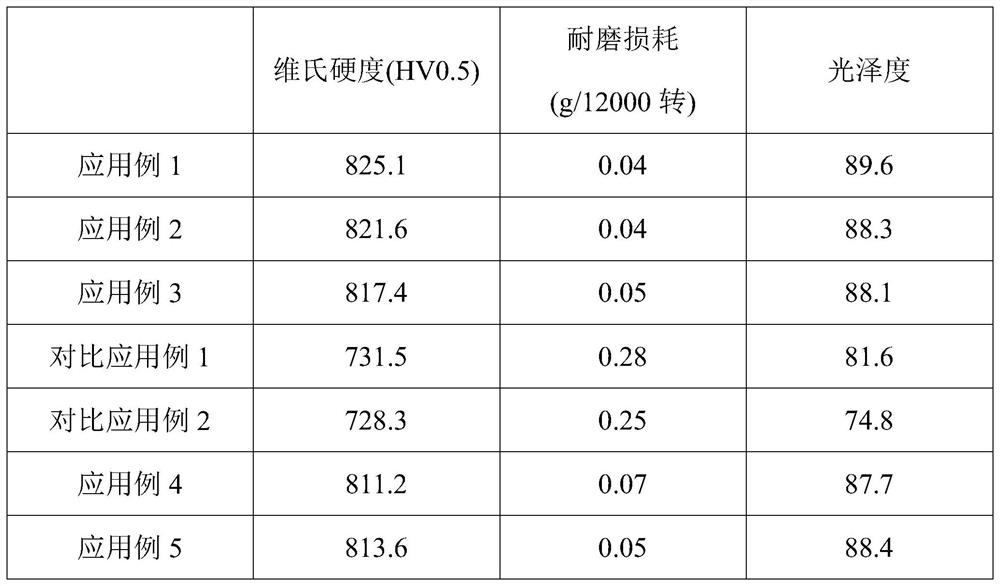

Examples

Embodiment 1

[0085] This embodiment provides a method of preparing a wear resistant glazed material, the preparation method comprising the steps of:

[0086] (1) According to the substrate measuring ball mill, calcined kaolin, dolomite, calcined talc powder, corundum and fluorite, to obtain a mixture, and the mixture is divided into the first mixture and the second mixture; the ball milling speed It is 1100R / min, the time is 15 min;

[0087] (2) Mix the first mixture obtained from 50% by weight from 50% by weight of boron sand, 50 wt% binder, 50 wt% of the chrose glass fibers, and then performing the first ball abrasive; The second mixture obtained from the sheet (1) was mixed with the remaining amount boron sand, trimophosphate, and chrose glass fibers were mixed according to the substrate, and then the second ball abrasive was obtained; the first ball milling speed was 1000R. / min, the time is 12 min; the second ball mill is 1400r / min, and the time is 16 min;

[0088] (3) Mix the first ...

Embodiment 2

[0096] This embodiment provides a method of preparing a wear resistant glazed material, the preparation method comprising the steps of:

[0097] (1) According to the substrate measuring ball mill, calcined kaolin, dolomite, calcined talc powder, corundum and fluorite, to obtain a mixture, and the mixture is divided into the first mixture and the second mixture; the ball milling speed It is 1000R / min, the time is 18 min;

[0098] (2) Mix the first mixture obtained from 50% by weight from 50% by weight of boron sand, 50 wt% binder, 50 wt% of the chrose glass fibers, and then performing the first ball abrasive; The second mixture obtained from the sheet (1) was mixed with the remaining amount boron sand, trimophosphate, and chopped glass fibers were mixed according to the substand, and then the second ball abrasive was obtained; the first ball milling speed was 800R. / min, the time is 15 min; the second ball mill is 1200r / min, and the time is 20 min;

[0099] (3) Mix the first b...

Embodiment 3

[0102] This embodiment provides a method of preparing a wear resistant glazed material, the preparation method comprising the steps of:

[0103] (1) According to the substrate measuring ball mill, calcined kaolin, dolomite, calcined talc powder, corundum and fluorite, to obtain a mixture, and the mixture is divided into the first mixture and the second mixture; the ball milling speed 1200R / min, time is 12 minutes;

[0104] (2) Mix the first mixture obtained from 50% by weight from 50% by weight of boron sand, 50 wt% binder, 50 wt% of the chrose glass fibers, and then performing the first ball abrasive; The second mixture obtained from the step (1) was mixed with the remaining amount boron sand, trimophosphate, and the chip glass fibers were mixed, and then the second ball abrasive was obtained; the first ball mill was 1200R. / min, the time is 8 minutes; the second ball mill is 1500r / min, and the time is 12 min;

[0105] (3) Mix the first ball abrasive obtained from step (2) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com