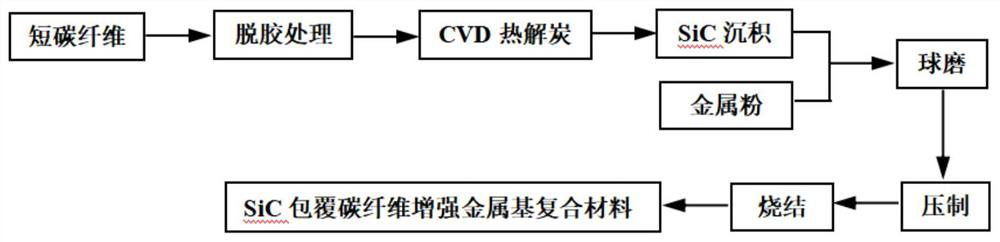

Preparation method for SiC coated carbon fiber reinforced metal based composite material

A composite material and fiber-reinforced technology, which is used in the preparation of SiC-coated carbon fiber-reinforced metal matrix composites, can solve various problems such as unsatisfactory performance and poor compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

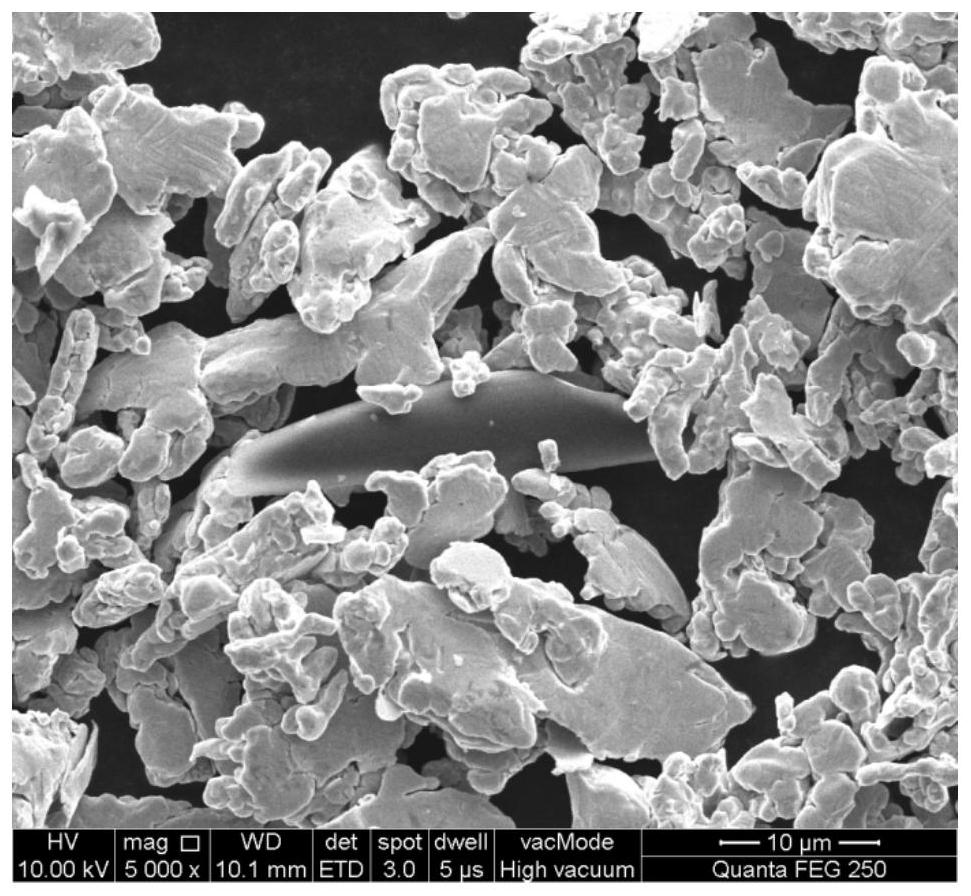

Embodiment 1

[0089] In this example, commercially available short carbon fibers are used as objects, and the short carbon fibers have a diameter of 7 μm and a length of 1 mm. Under vacuum conditions, heat preservation at 700°C for 60min for degumming treatment; then under protective atmosphere, heat the degummed short carbon fiber bundles to 950°C for chemical vapor deposition for 6h, the carbon source gas is propylene, the dilution gas is hydrogen, the carbon source gas and The volume ratio of the dilution gas is 1:2 to obtain short carbon fibers deposited by pyrolytic carbon; finally, under a protective atmosphere, the short carbon fiber bundles deposited by pyrolytic carbon are heated to 1000°C for chemical vapor deposition for 4 hours, and the source of silicon carbide is trichloro Methylsilane, the carrier gas is hydrogen, the diluent gas is hydrogen, the volume ratio of the carrier gas and the diluent gas is 1:0.5, and short carbon fibers coated with pyrolytic carbon-silicon carbide a...

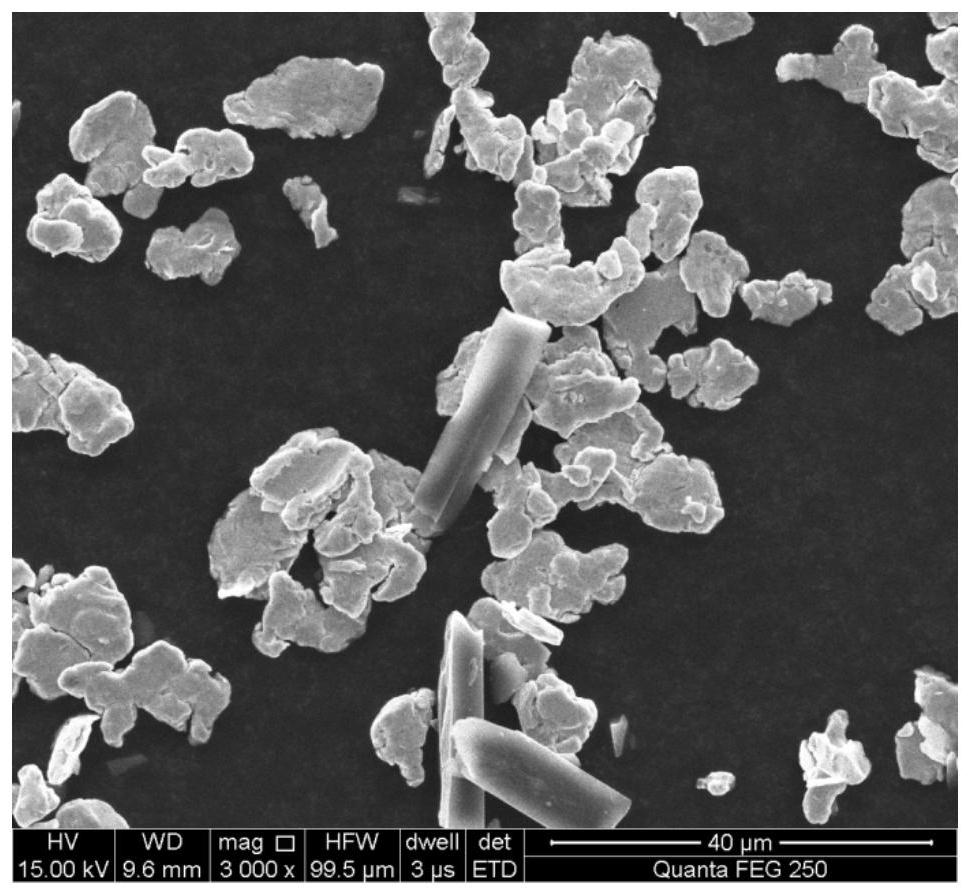

Embodiment 2

[0095]In this embodiment, commercially available short carbon fibers are used as objects, and the short carbon fibers have a diameter of 8 μm and a length of 2 mm. Under vacuum conditions, heat preservation at 750°C for 60min for degumming treatment; then under a protective atmosphere, heat the degummed short carbon fiber bundles to 950°C for chemical vapor deposition for 5h, the carbon source gas is propylene, the dilution gas is hydrogen, the carbon source gas and The volume ratio of the dilution gas is 1:2 to obtain short carbon fibers deposited by pyrolytic carbon; finally, under a protective atmosphere, the short carbon fiber bundles deposited by pyrolytic carbon are heated to 1050°C for chemical vapor deposition for 4 hours, and the source of silicon carbide is trichloro Methylsilane, the carrier gas is hydrogen, the diluent gas is hydrogen, the volume ratio of the carrier gas and the diluent gas is 1:0.5, and short carbon fibers coated with pyrolytic carbon-silicon carbi...

Embodiment 3

[0101] In this embodiment, commercially available short carbon fibers are used as objects, and the short carbon fibers have a diameter of 6 μm and a length of 2 mm. Under vacuum conditions, heat preservation at 720°C for 60min for degumming treatment; then under protective atmosphere, heat the degummed short carbon fiber bundles to 920°C for chemical vapor deposition for 6h, the carbon source gas is propylene, the diluting gas is hydrogen, the carbon source gas and The volume ratio of the dilution gas is 1:2 to obtain short carbon fibers deposited by pyrolytic carbon; finally, under a protective atmosphere, the short carbon fiber bundles deposited by pyrolytic carbon are heated to 1080°C for chemical vapor deposition for 4 hours, and the source of silicon carbide is trichloro Methylsilane, the carrier gas is hydrogen, the diluent gas is hydrogen, the volume ratio of the carrier gas and the diluent gas is 1:0.5, and short carbon fibers coated with pyrolytic carbon-silicon carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com