Method for preparing skin-care non-woven fabric through microemulsion atomization spraying process and application

A non-woven fabric and microemulsion technology, applied in the field of hygiene products, can solve the problems of not providing technical inspiration, and achieve the effect of preventing skin redness, swelling and tingling, retaining softness and comfort, and delaying skin aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The extraction method of embodiment 1 plant essence

[0054] The essence is composed of the following active ingredient extracts in parts by weight: 0.01-0.3 parts of aloe extract, 0.01-0.3 part of peppermint extract, 0.01-0.2 part of Caulis Spatholobus extract, and 0.01-0.2 part of Salvia miltiorrhiza extract;

[0055] First, crush the aloe vera and pass it through a 30-mesh sieve. According to the solid-liquid ratio (g:mL) of 1:18, ultrasonically extract with ethanol with a volume fraction of 90% for 85 minutes, and concentrate the extract to form an extract with a relative density of 1.1 to 1.3, namely Obtained, wherein, the frequency of ultrasonic extraction is 40kHz, and the power is 500W;

[0056] Secondly, boil Spatholobus Spatholobus and Salvia Spatholobus in water respectively, extract, filter and deslag to obtain the corresponding filtrate, boil Spatholobus Spatholobus and Salvia Spatholobus in water and leave for re-extraction; combine the extract with the fi...

Embodiment 2

[0059] The pretreatment of embodiment 2 camellia fiber

[0060] The camellia fiber pretreatment process in this embodiment includes: fiber impurity sorting, opening, carding; in the opening step, the amount of oil added is 0.5%.

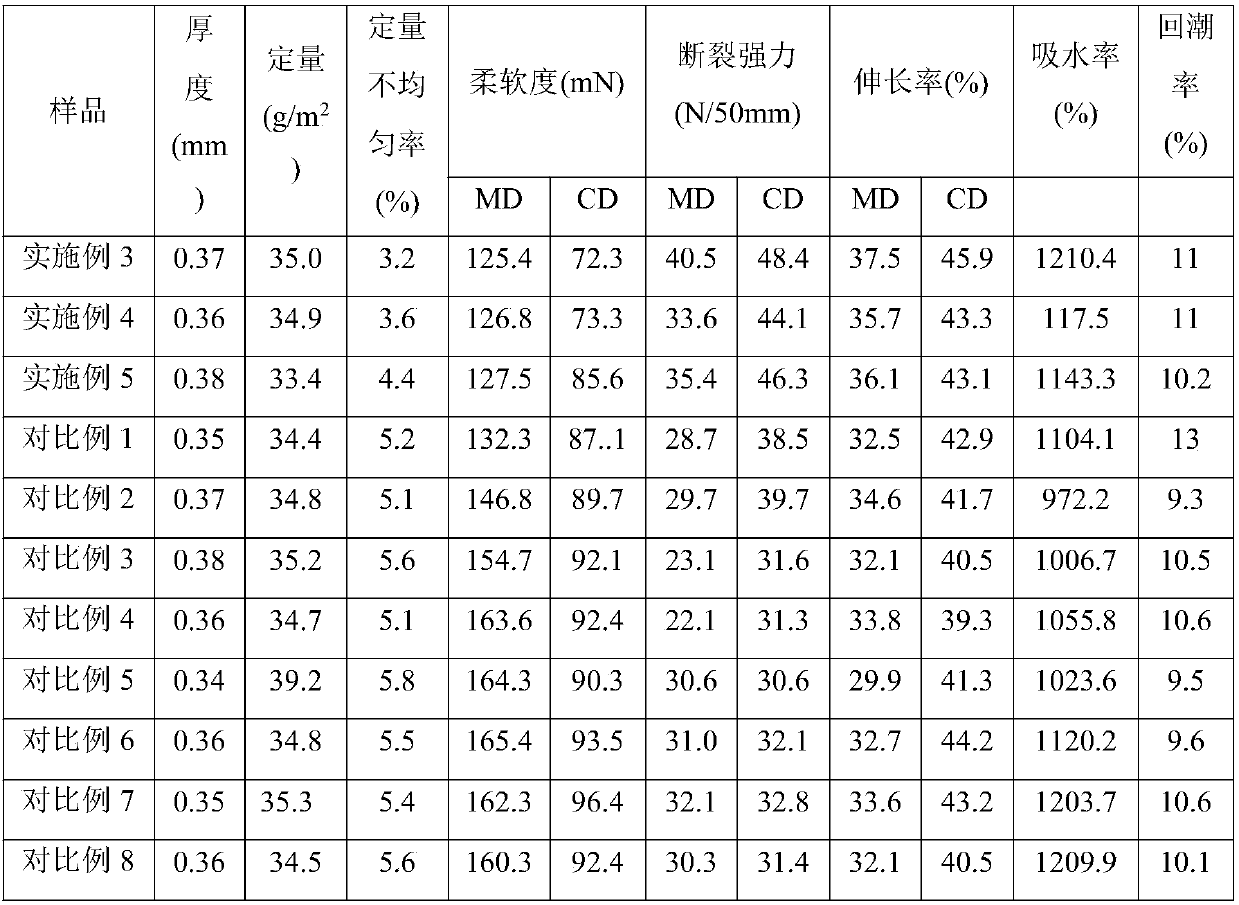

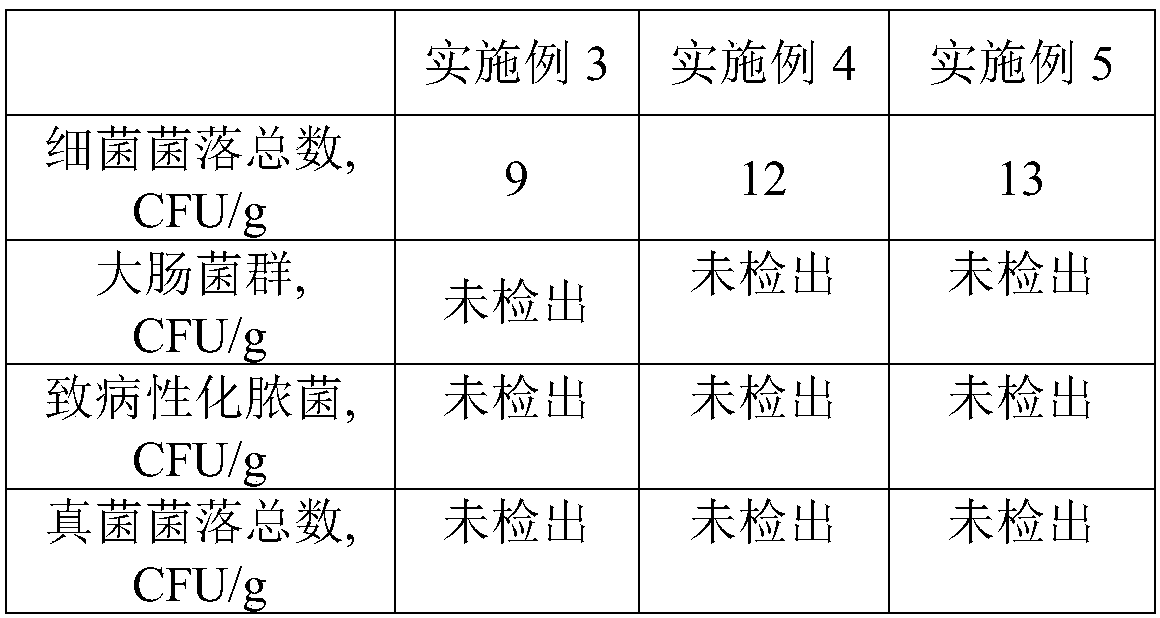

Embodiment 3

[0062] A non-woven fabric for skin care prepared by a microemulsion atomization spraying process, which contains camellia fiber and viscose fiber as raw materials, and is prepared by the following method:

[0063] S1. Camellia fiber and viscose fiber are carried out pretreatment respectively, and camellia fiber pretreatment is processed according to the method described in embodiment 1, and viscose fiber adopts Na 2 CO 3 solution for soaking; Na 2 CO 3 The solubility of the solution is 2g / L, and the soaking time is 100min.

[0064] S2. The camellia fiber after pretreatment and the viscose fiber are carried out according to the raw material ratio camellia fiber: the proportioning of viscose fiber 1:19 carries out box mixing;

[0065] S3. The mixed fiber is made into a fine sliver through the opening and cleaning, carding, and combing processes in sequence, and then broken into a fine mesh;

[0066] S4. The fine mesh undergoes hydrophilic treatment, opening, carding, laying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com