Novel detergent and preparation method thereof

A cleaning agent and a new type of technology, applied in the direction of detergent compositions, chemical instruments and methods, non-surface active detergent compositions, etc., can solve the problems of high energy and water resource consumption, waste of energy and water resources, single-use soap Long washing time and other problems, to avoid weight loss, reduce worker load, reduce the number of washing times and the effect of a single washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with embodiment:

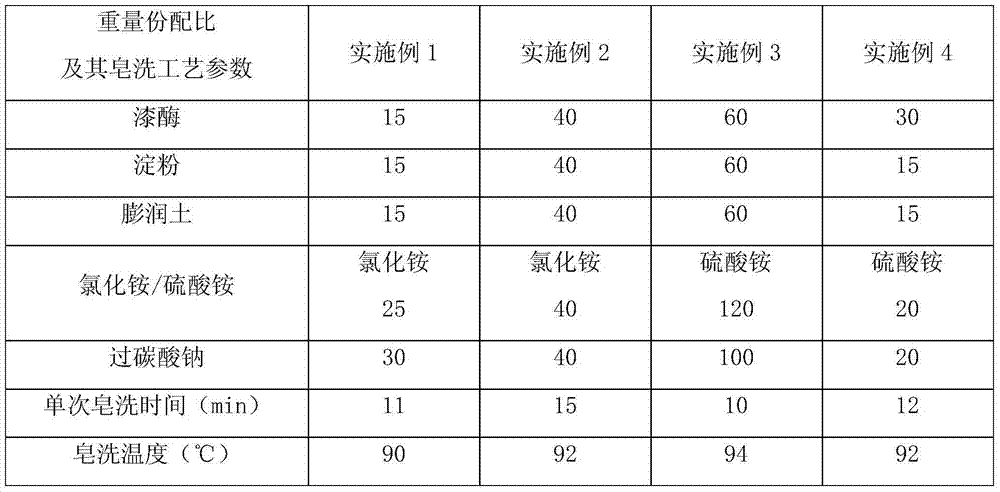

[0015] Add laccase, starch, bentonite, ammonium chloride or ammonium sulfate, sodium percarbonate or sodium perborate into the mixer in sequence according to the weight ratio in Table 1 and Table 2, and stir until uniformly mixed to obtain a new type of cleaning agent agent.

[0016] Table 1

[0017]

[0018] Table 2

[0019]

[0020] The novel detergents prepared in Examples 1 to 8 were respectively subjected to the cleaning process of the fabric cheese according to the dye concentration ratio shown in Table 3, wherein the liquor ratio (weight ratio of the fabric to the dye liquor) of the cheese was 1 :5 for dyeing. Wherein o.w.f is the weight percent of novel cleaning agent relative to fabric.

[0021] table 3

[0022]

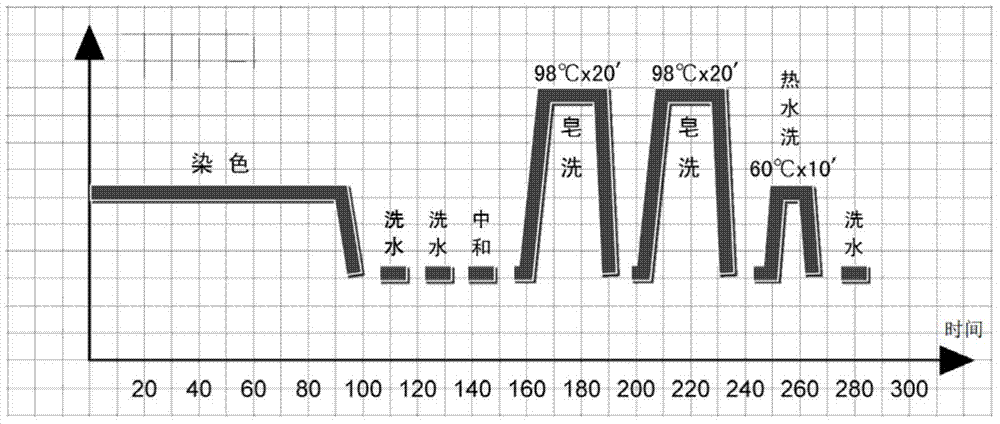

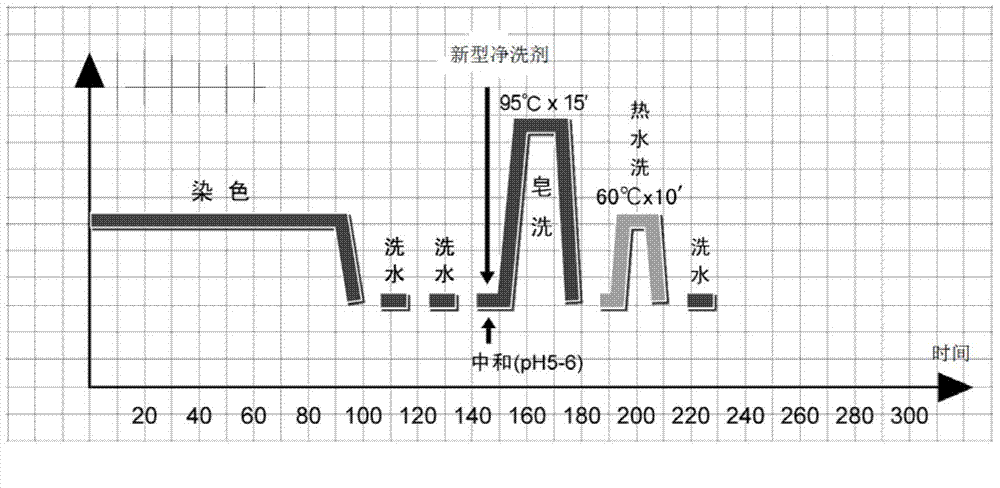

[0023] It can be seen that the higher the dye concentration, the more the amount of new detergent. Compared with the soaping process parameters of trad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com