Novel cryogenic soaping agent and preparation method thereof

A low-temperature soap, a new type of technology, applied in detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems of environmental pollution, large dosage, high toxicity, etc., achieve high ecological safety, reduce dosage, The effect of bulkiness retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 15 parts by weight of laccase, 30 parts by weight of potassium persulfate, 20 parts by weight of soda ash, 15 parts by weight of polyvinylpyrrolidone with an average molecular weight of 50,000, 15 parts by weight of sodium polyacrylate with an average molecular weight of 3000, and 5 parts by weight of sodium polyacrylate with a viscosity of 200 centimeters The sodium carboxymethyl cellulose of poin is added into the mixer in sequence and stirred until it is evenly mixed to obtain a new type of low-temperature soaping agent.

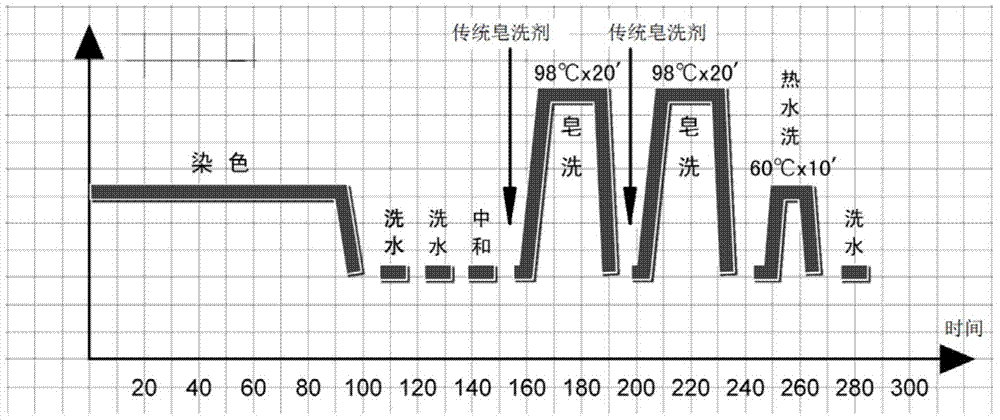

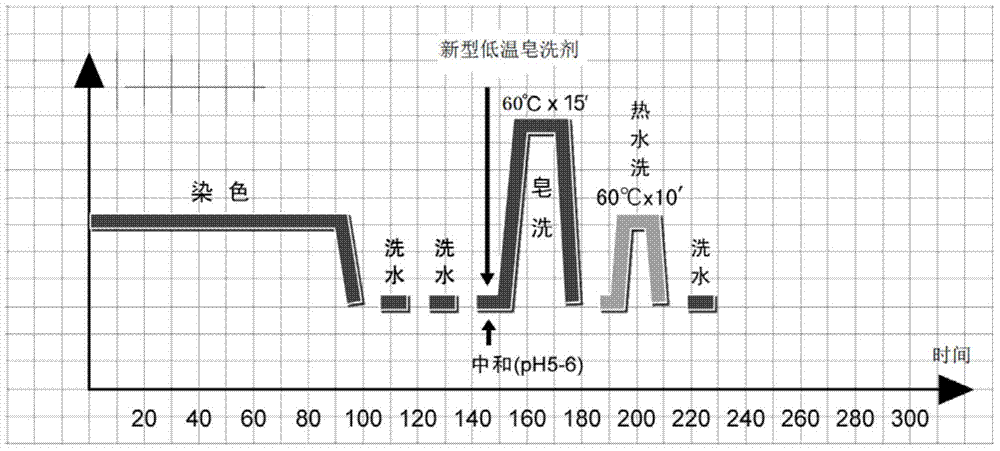

[0024] Use a new type of low-temperature soaping agent to soap the cheese. Compared with the traditional soaping process, the number of soaping times is reduced from two times to one time, the single soaping time is shortened from 20 minutes to 15 minutes, and the soaping temperature is also reduced from 98°C to 60°C, which reduces the cost of soaping process Energy and water consumption make the soaping process more energy-saving, and at the same ...

Embodiment 2

[0026] 25 parts by weight of laccase, 25 parts by weight of sodium persulfate, 15 parts by weight of soda ash, 15 parts by weight of polyvinylpyrrolidone with an average molecular weight of 400,000, 15 parts by weight of sodium polyacrylate with an average molecular weight of 5000 and 5 parts by weight of polyvinylpyrrolidone with a viscosity of 400 Sodium carboxymethyl cellulose is added into the mixer in sequence and stirred until it is evenly mixed to obtain a new type of low-temperature soaping agent.

[0027] Use a new type of low-temperature soaping agent to soap the cheese. Compared with the traditional soaping process, the number of soaping times is reduced from two times to one time, the single soaping time is shortened from 20 minutes to 12 minutes, and the soaping temperature is also reduced from 98°C to 70°C, which reduces the cost of soaping process Energy and water consumption make the soaping process more energy-saving, and at the same time reduce process time, ...

Embodiment 3

[0029] 20 parts by weight of laccase, 70 parts by weight of ammonium persulfate, 30 parts by weight of caustic soda, 30 parts by weight of polyvinylpyrrolidone with an average molecular weight of 1,000,000, 30 parts by weight of sodium polyacrylate with an average molecular weight of 8000 and 20 parts by weight of sodium polyacrylate with a viscosity of 2000 centimeters The sodium carboxymethyl cellulose of poin is added into the mixer in sequence and stirred until it is evenly mixed to obtain a new type of low-temperature soaping agent.

[0030] Use a new type of low-temperature soaping agent to soap the cheese. Compared with the traditional soaping process, the number of soaping times is reduced from two times to one time, the single soaping time is shortened from 20 minutes to 14 minutes, and the soaping temperature is also reduced from 98°C to 65°C, which reduces the cost of soaping process Energy and water consumption make the soaping process more energy-saving, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com