Strong mesh cloth coating processing fabric

A technology of mesh cloth and composite fabrics, which is applied in the field of fabrics and textiles, can solve the problems of complex processing technology, poor tension and adhesion, etc., and achieve the effect of simple processing technology, enhanced tension and adhesion, and good drape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

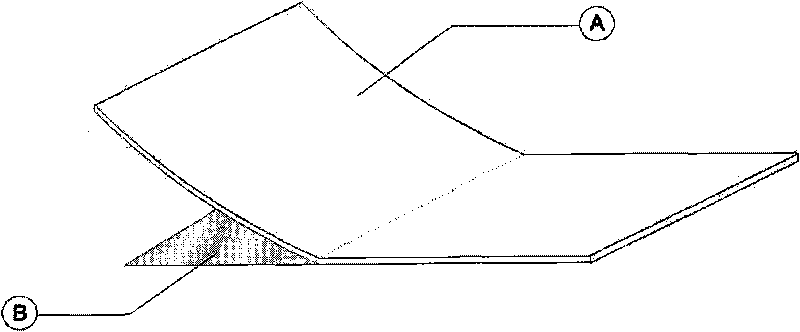

[0018] Embodiment 1: see attached figure 1 . Using 70% of composite fabrics and 30% of knitted mesh fabrics, each component is calculated by weight percentage of raw materials;

[0019] The knitted mesh fabric is used as a raw material for one layer, and the composite fabric is used as a raw material for another layer. The two layers of knitted mesh fabric and composite fabric are blended and refined to prepare a strong mesh cloth laminating processed fabric; the finished product is made at a temperature of 50 degrees Celsius The weight of the cloth is 220g / m.

Embodiment 2

[0020] Embodiment 2: see attached figure 1 . 60% of composite fabric and 40% of knitted mesh fabric are used, and the components are calculated by weight percentage of raw materials;

[0021] The knitted mesh fabric is used as a raw material for one layer, and the composite fabric is used as a raw material for another layer. By blending and refining the two layers of knitted mesh fabric and composite fabric, a strong mesh cloth laminating processed fabric is prepared; the finished product is produced at a temperature of 80 degrees Celsius The cloth weight is 210g / m.

Embodiment 3

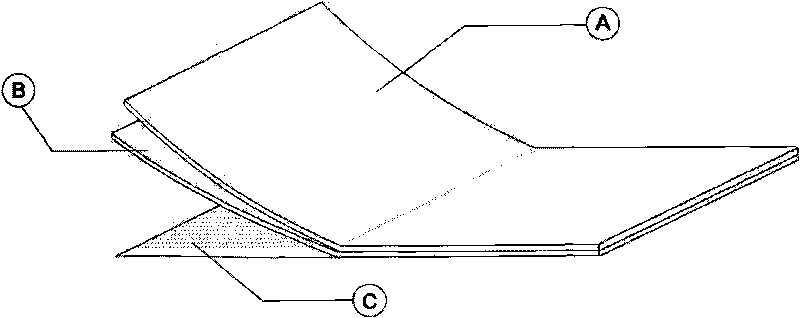

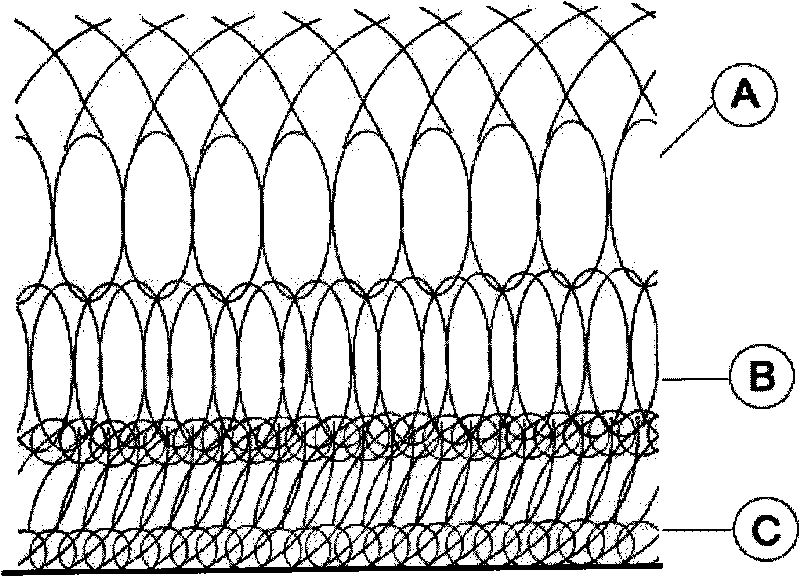

[0022] Embodiment 3: see attached figure 2 , attached image 3 , attached Figure 4 . Wool-polyester blended fabric with 21% wool, 10.5% fiber, 10.5% Tencel and 28% polyester, and 30% knitted mesh fabric are used to calculate the weight percentage of raw materials;

[0023] Knitted mesh fabric A is used as a raw material for one layer, wool and fiber B are used as raw materials for another layer, and tencel and polyester C are used as raw materials for the third layer. It is refined by blending knitted mesh cloth, wool, fiber tencel and polyester as raw materials. The strong mesh cloth is laminated with the processed fabric; the weight of the finished cloth is 250g / m;

[0024] The knitted mesh fabric A, the wool and fiber layer B, and the tencel and polyester layer C are stacked together, and then it is made into a single fabric by needle punching. Card clothing processing does not use adhesives. A special metal needle is used to penetrate the fabric back and forth. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com