Antibacterial thermal down quilt manufacturing method

A manufacturing method and a technology for a duvet, applied in the manufacturing field, can solve the problems of too many processes, cumbersome manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

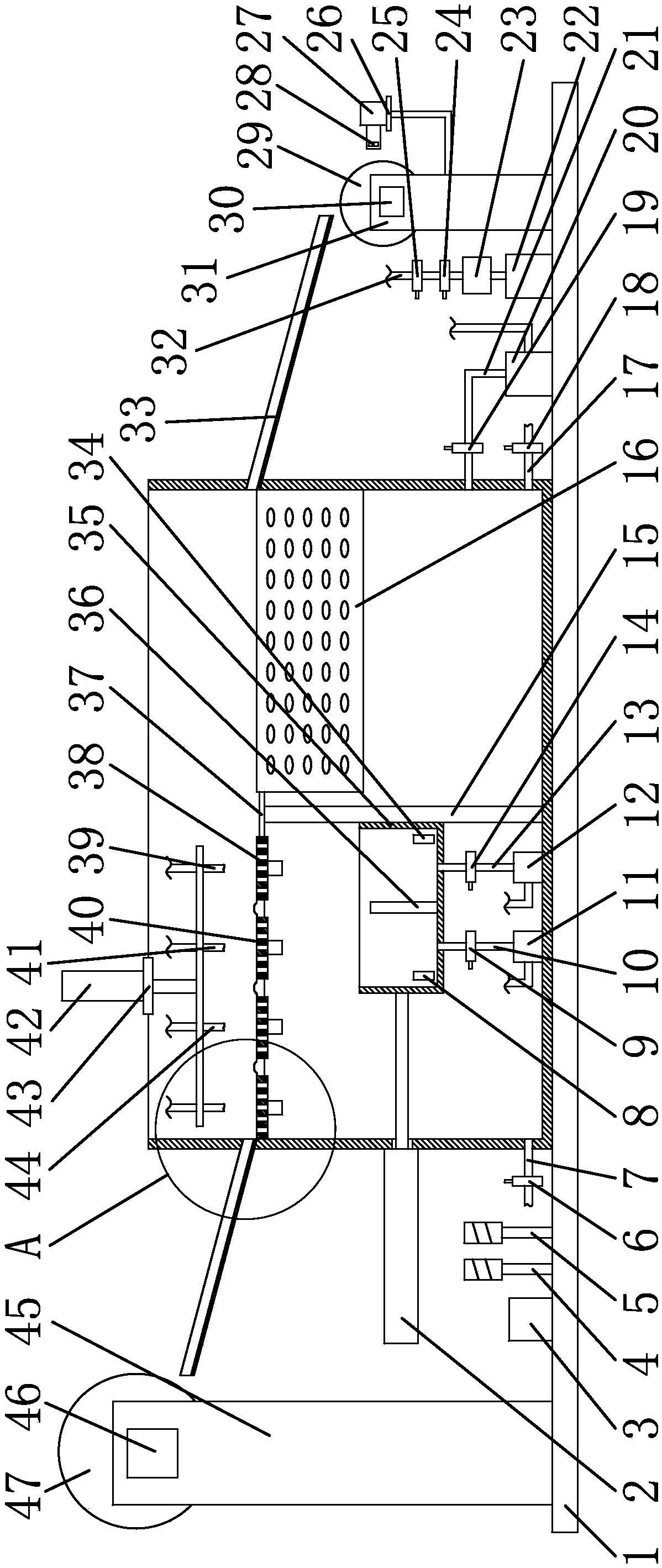

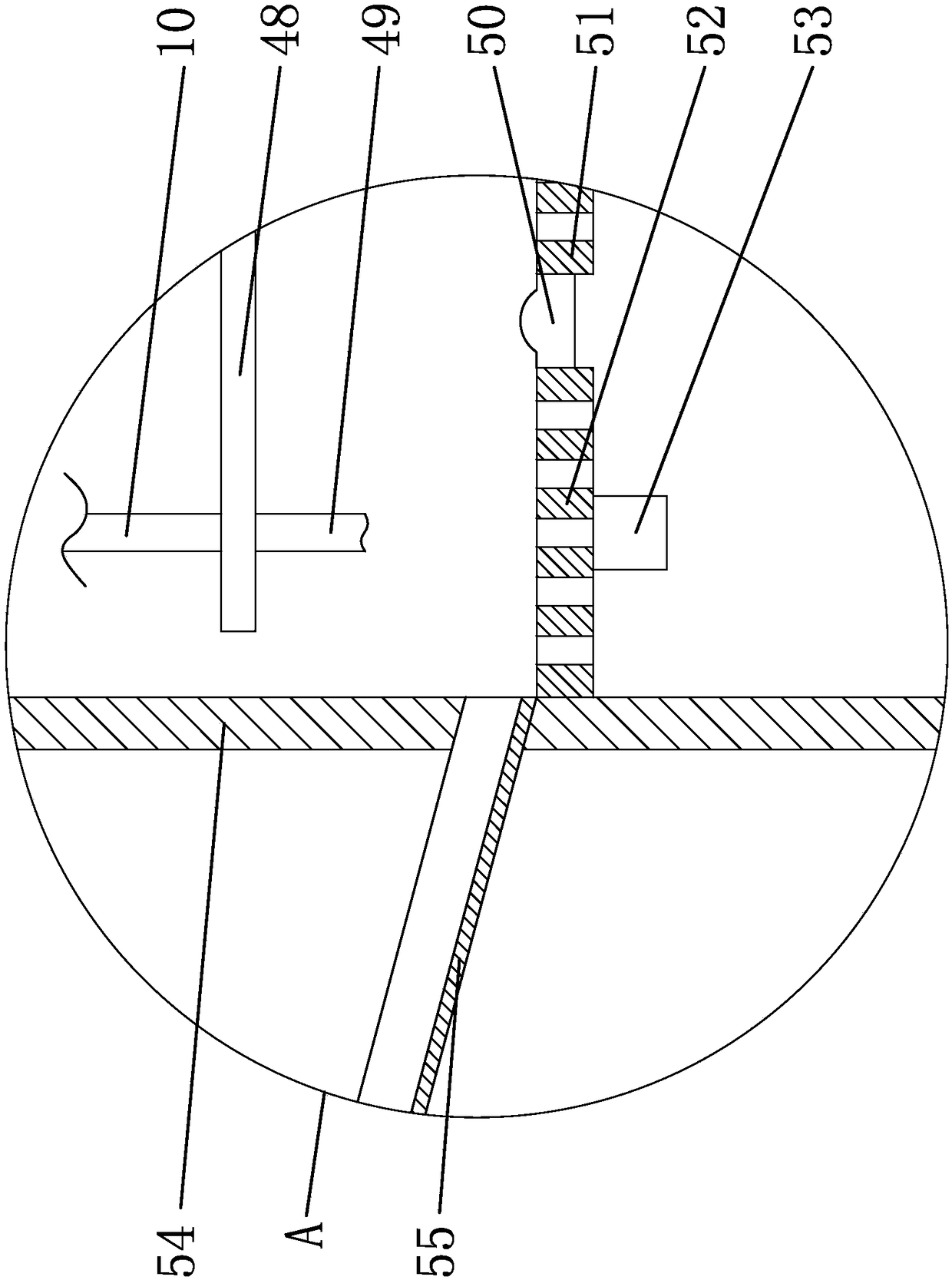

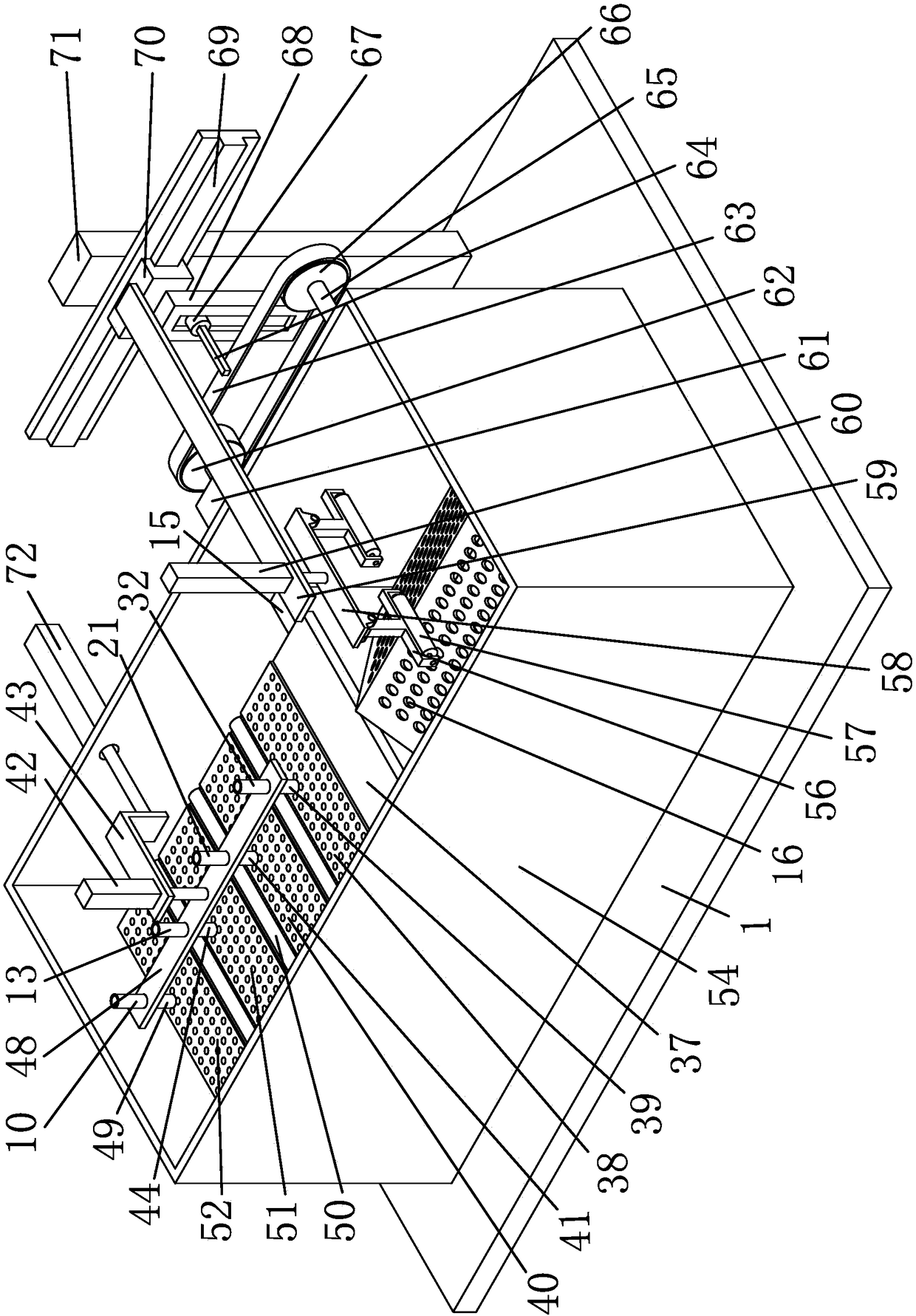

[0070] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0071] Such as Figure 1-Figure 5 Shown, the manufacture method of this antibacterial warm duvet, this manufacture method comprises the following steps:

[0072] S1, select the down filler for making the down quilt;

[0073] S2, pre-treating the down filler in S1;

[0074] S3, drying the down filler after the pretreatment in S2;

[0075] S4. Using an ultraviolet sterilizing device to sterilize the dried down filling in S3; in this embodiment, the ultraviolet sterilizing device is an existing product available on the market;

[0076] S5. Mix the heating fiber and antibacterial fiber into a mixed filling, and then immerse the mixed filling in the finishing solution, the dosage is 10-30g / L, the pH value is 6.5-7.5, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com