Silk drawing driving mechanism for silk liner in silk quilt

A technology of driving mechanism and silk quilt, applied in application, interior decoration, household appliances, etc., can solve the problems of uneven thickness of silk quilt inner tire, inability to guarantee simultaneous drawing consistency, low production efficiency, etc., and achieve low cost, Simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

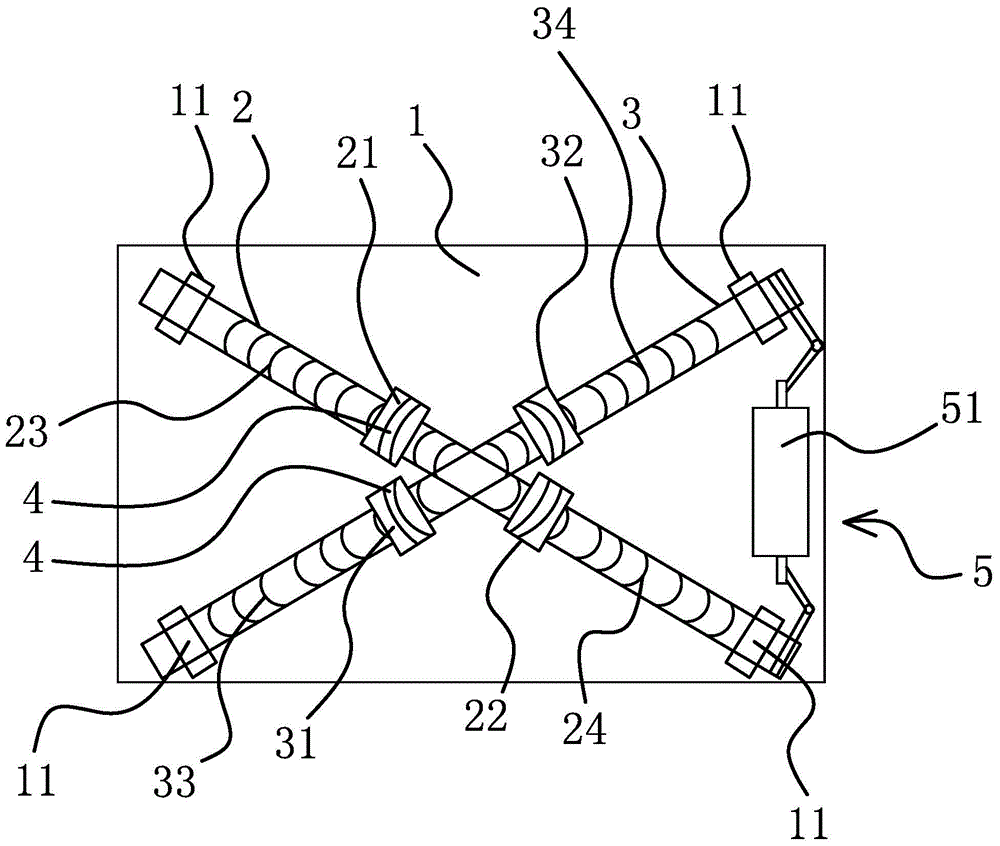

[0017] Such as figure 1 As shown, the wire drawing driving mechanism used for the silk quilt inner tire includes a frame body 1, and the frame body 1 is provided with a first driving rod 2 and a second driving rod 3 distributed in a horizontal direction through a mounting structure. The middle part of the rod 2 and the middle part of the second driving rod 3 are intersected with each other, and the first driving rod 2 is respectively provided with a first moving sleeve 21 and a second moving sleeve 22 located on both sides of the second driving rod 3, and the second The driving rod 3 is respectively provided with a third moving sleeve 31 and a fourth moving sleeve 32 located on both sides of the first driving rod 2, the first moving sleeve 21, the second moving sleeve 22, the third moving sleeve 31 A wire drawing block 4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com