Cushions including a coated elastomeric cushioning element and related methods

a cushioning element and elastomeric technology, applied in the direction of foam mattresses, chairs, upholstery, etc., can solve the problems of reducing the chance that the first wall, cushioning materials such as mattresses, are generally bulky objects that are difficult and costly to transport from a manufacturer to a retailer or a customer, and the chance of the first wall is generally small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working example

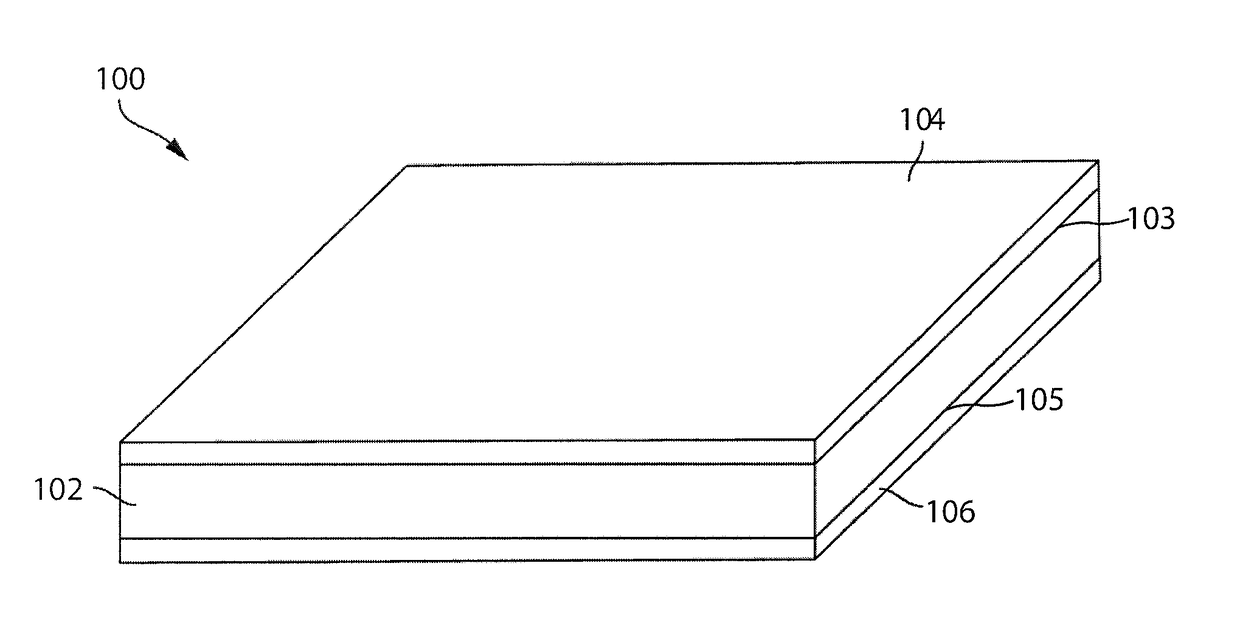

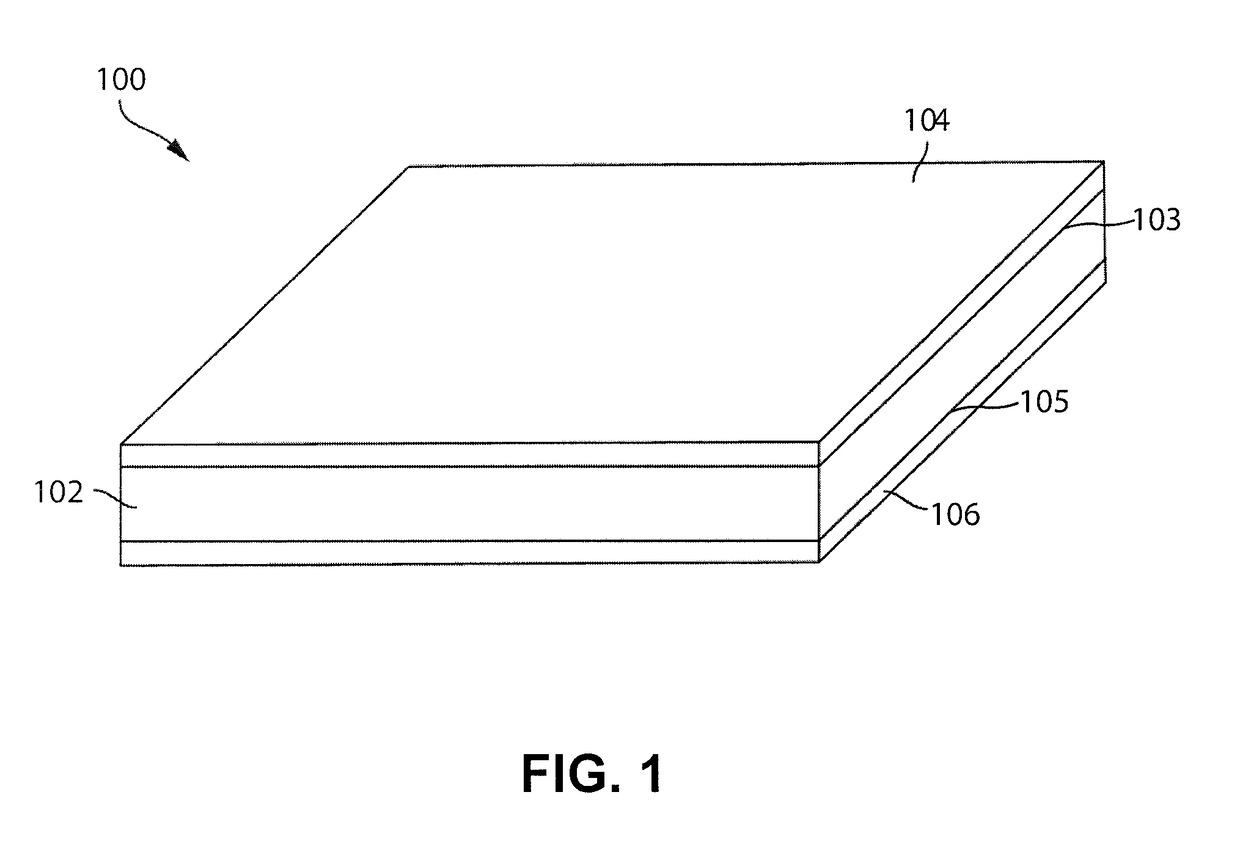

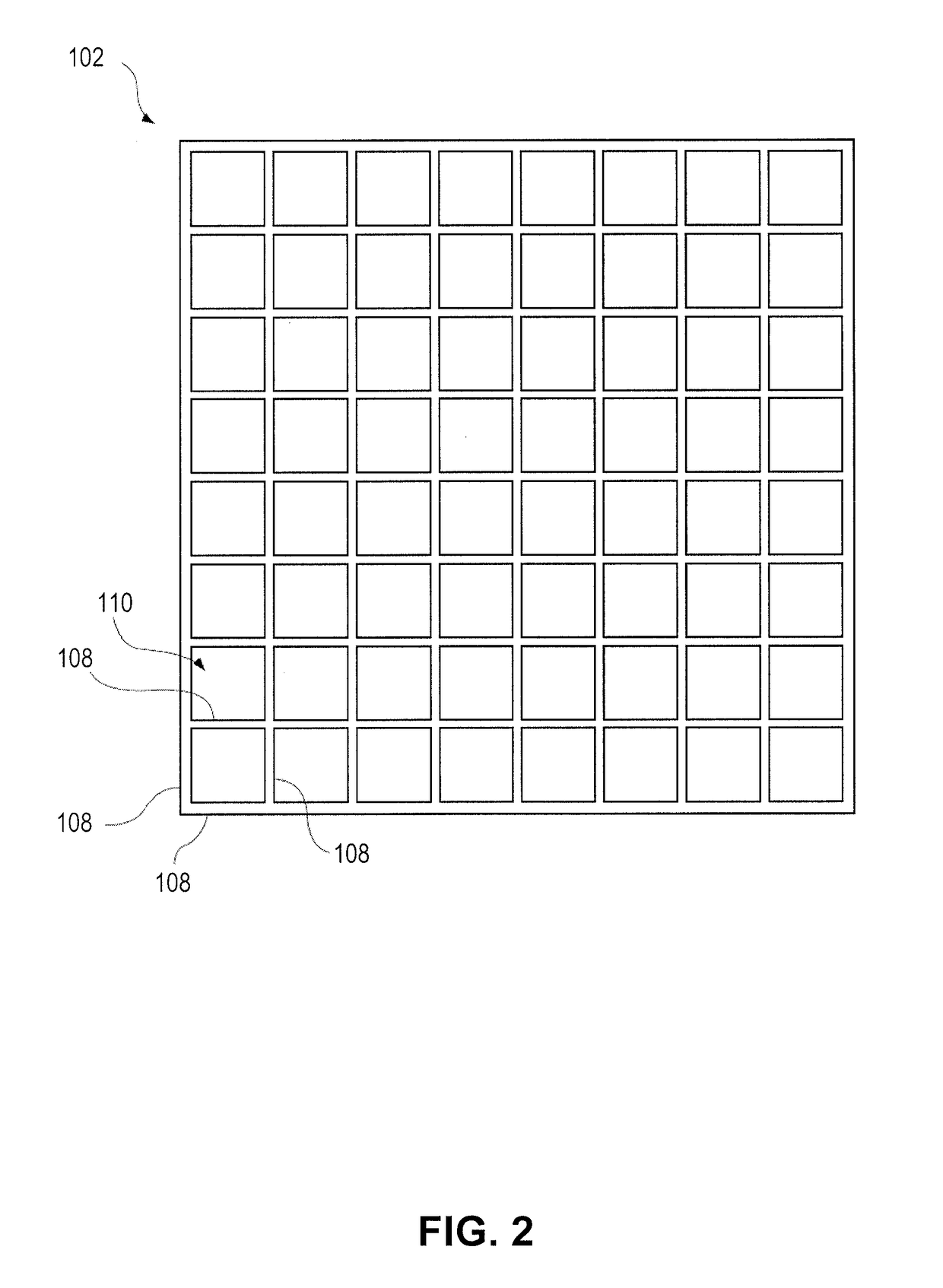

[0059]A mattress as illustrated in FIG. 1 was formed in accordance with a method as described herein. The mattress included an elastomeric cushioning element formed of an elastomeric mixture of plasticizer and polymer. The mixture included a plasticizer-to-polymer ratio of 4:1 by weight. The plasticizer comprised 70-weight oil, and the polymer comprised KRATON® E1830. The mixture also included pigment and antioxidants. The elastomeric mixture was subsequently provided with a filler. The filler comprised approximately 17% by volume hollow glass microspheres having a specific gravity of 0.4. The cushioning element formed of the elastomeric mixture and filler was coated with MICROTHENE® FA70900 powder comprising HDPE by disposing the cushioning element in a rotary tumbler having MICROTHENE® FA70900 powder disposed therein. To coat the cushioning element, a drum of the rotary tumbler was rotated for about 2 minutes. The cushioning element was removed from the rotary tumbler, and the exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com