Full-automatic beverage brewing machine

A fully automatic, beverage technology, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of high cost, complex structure, thick tea, etc., and achieve the effect of low cost, simple and reasonable structure, and increased practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

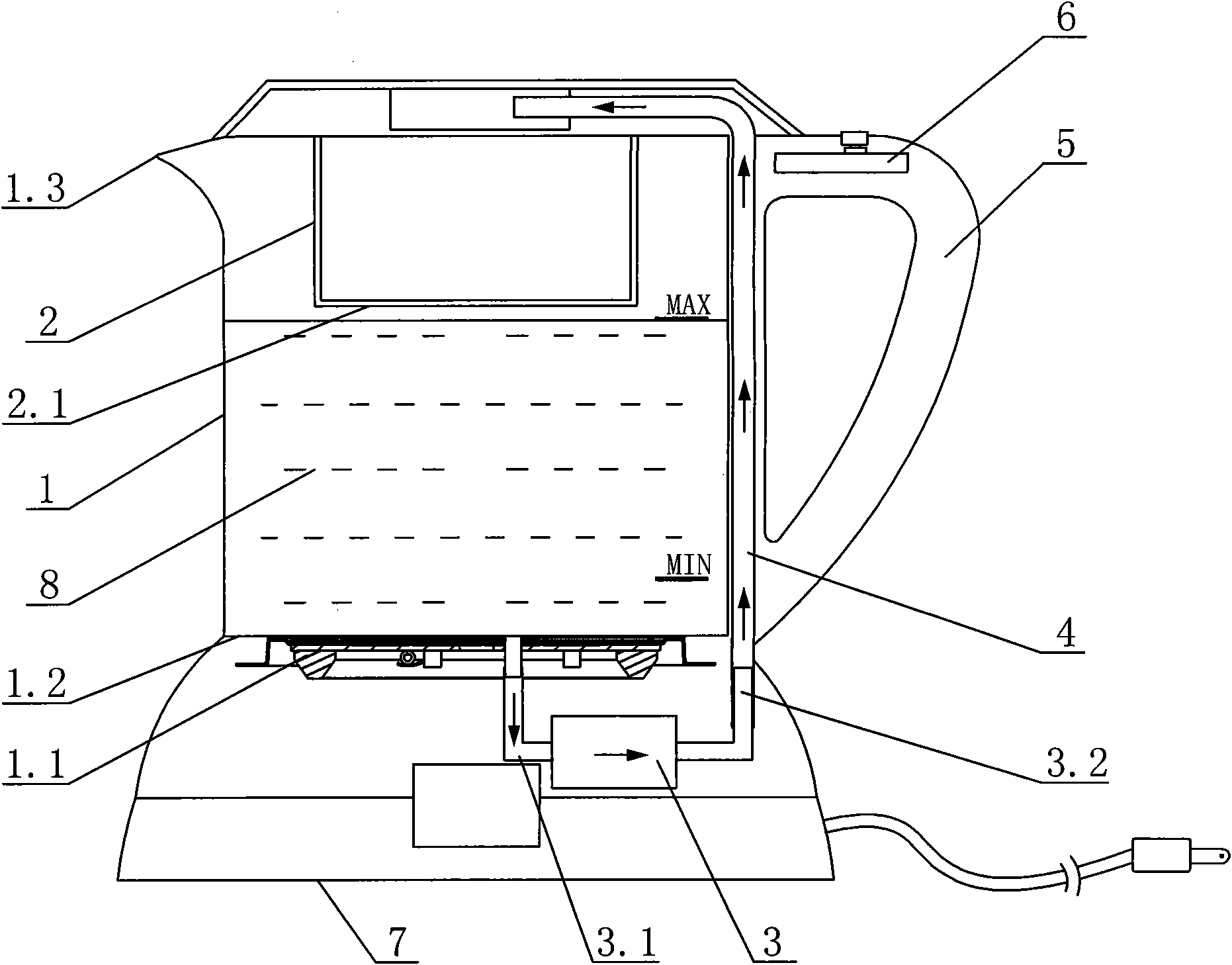

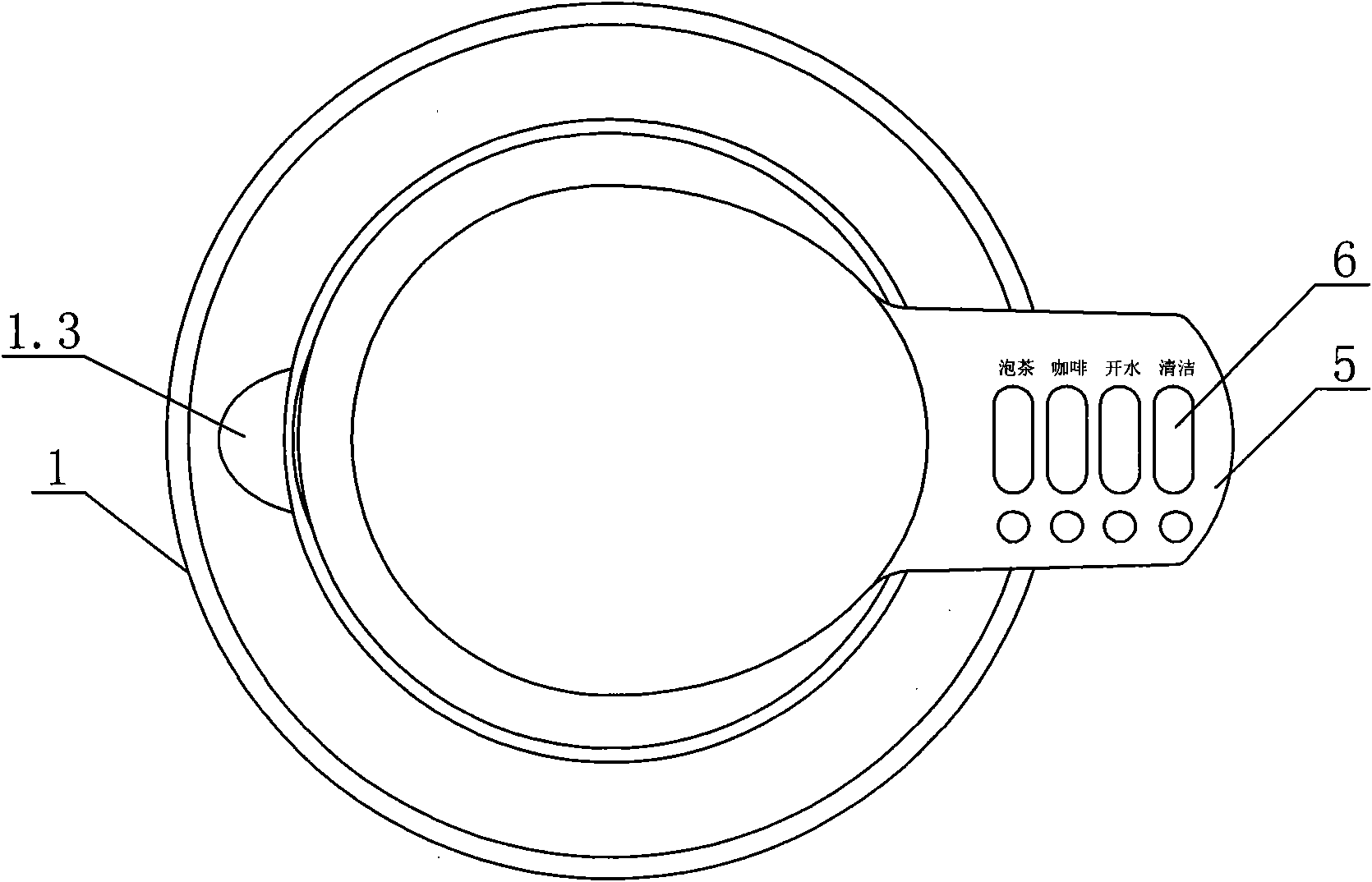

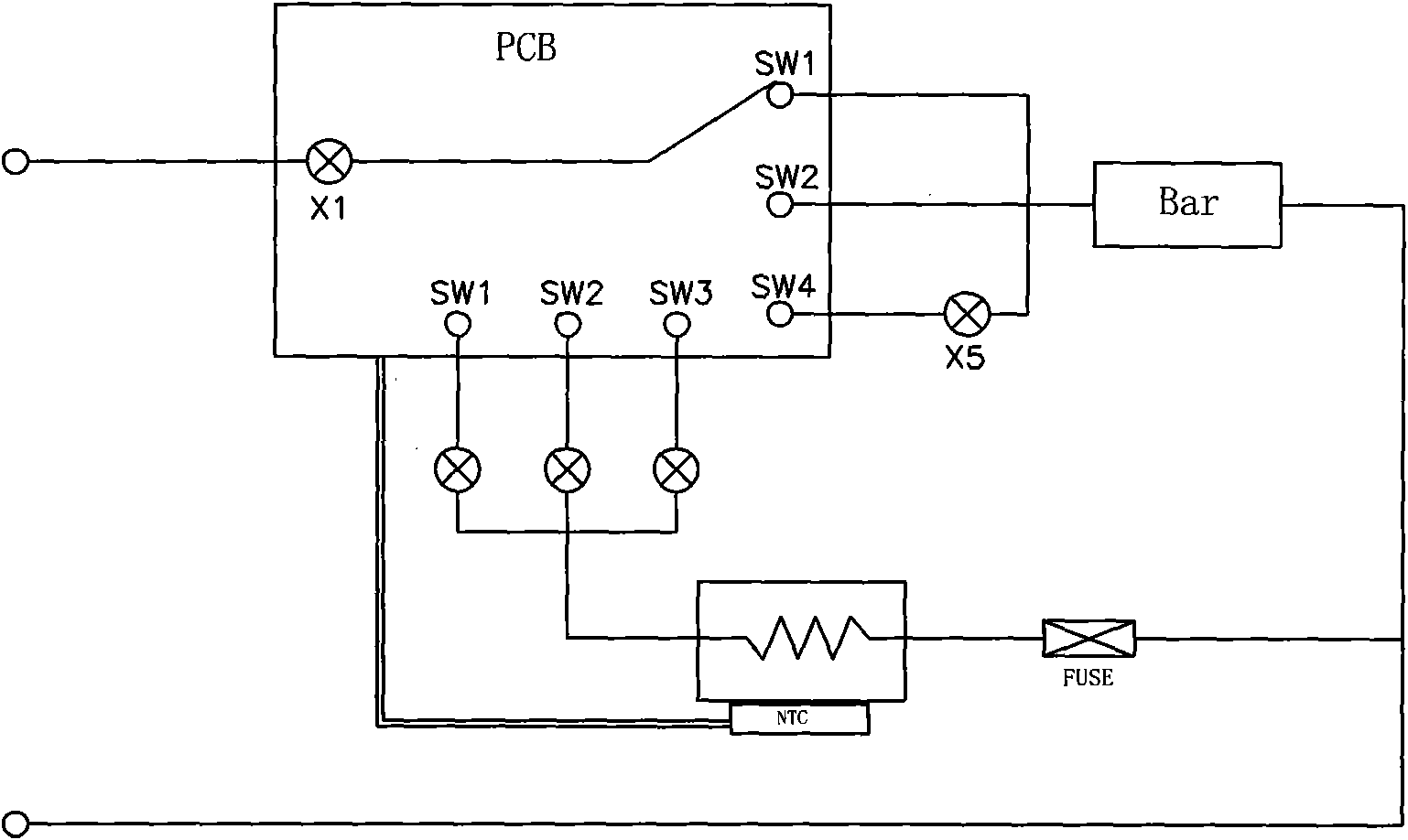

[0023] see Figure 1-Figure 3 , a fully automatic beverage brewing machine, including a pot body and its power supply base 7, the pot body is composed of a heating chamber 1 and a brewing chamber 2 movably connected with it. The heating chamber 1 is made of glass, and the outer wall of the heating chamber 1 is provided with a spout 1.3 and a handle 5, and the spout 1.3 and the handle 5 are integrated with the heating chamber 1. The brewing chamber 2 is set on the upper part of the heating chamber 1. The brewing chamber 2 is sheathed in the heating chamber 1. There is a gap between the highest water level line of the heating chamber 1 and the brewing chamber 2. The purpose is to control the brewing The extraction concentration of the foam is suitable for people with different tastes. The bottom of the brewing chamber 2 is provided with a first filter screen 2.1, and the position of the brewing chamber 2 corresponding to the first filter screen is provided with a small hole com...

no. 2 example

[0028] see Figure 4 , the brewing chamber 2 includes an upper brewing chamber and a lower brewing chamber that communicate with each other, and a detachable second filter screen and a baffle plate 2.2 with a through hole are arranged between the lower brewing chamber and the upper brewing chamber , can play a double filtering effect, the opening position of the upper brewing chamber is provided with a sealing cover 2.3 and its sealing ring, and the sealing cover 2.3 is sealed and connected with the upper brewing chamber through the sealing ring to form a sealed cavity together.

[0029] The water circulation pipeline 4 is provided with a pressure balance assembly, the pressure balance assembly includes a return pipe, a regulating valve and a pressure relief valve 9, the pressure relief valve 9 is arranged on the water outlet pipe 3.2, and the return pipe communicates with the heating chamber 1 through the pressure relief valve 9, The flow regulating valve is arranged on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com