Visual inspection and transient measurement system for micro-scale explosive boiling process

A measurement system, micro-scale technology, applied in the direction of measurement device, investigation stage/state change, material analysis through optical means, etc., can solve problems such as inability to give reasonable explanations and appropriate descriptions, limited understanding of microscopic mechanisms, etc. To achieve the effect of ensuring instantaneity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

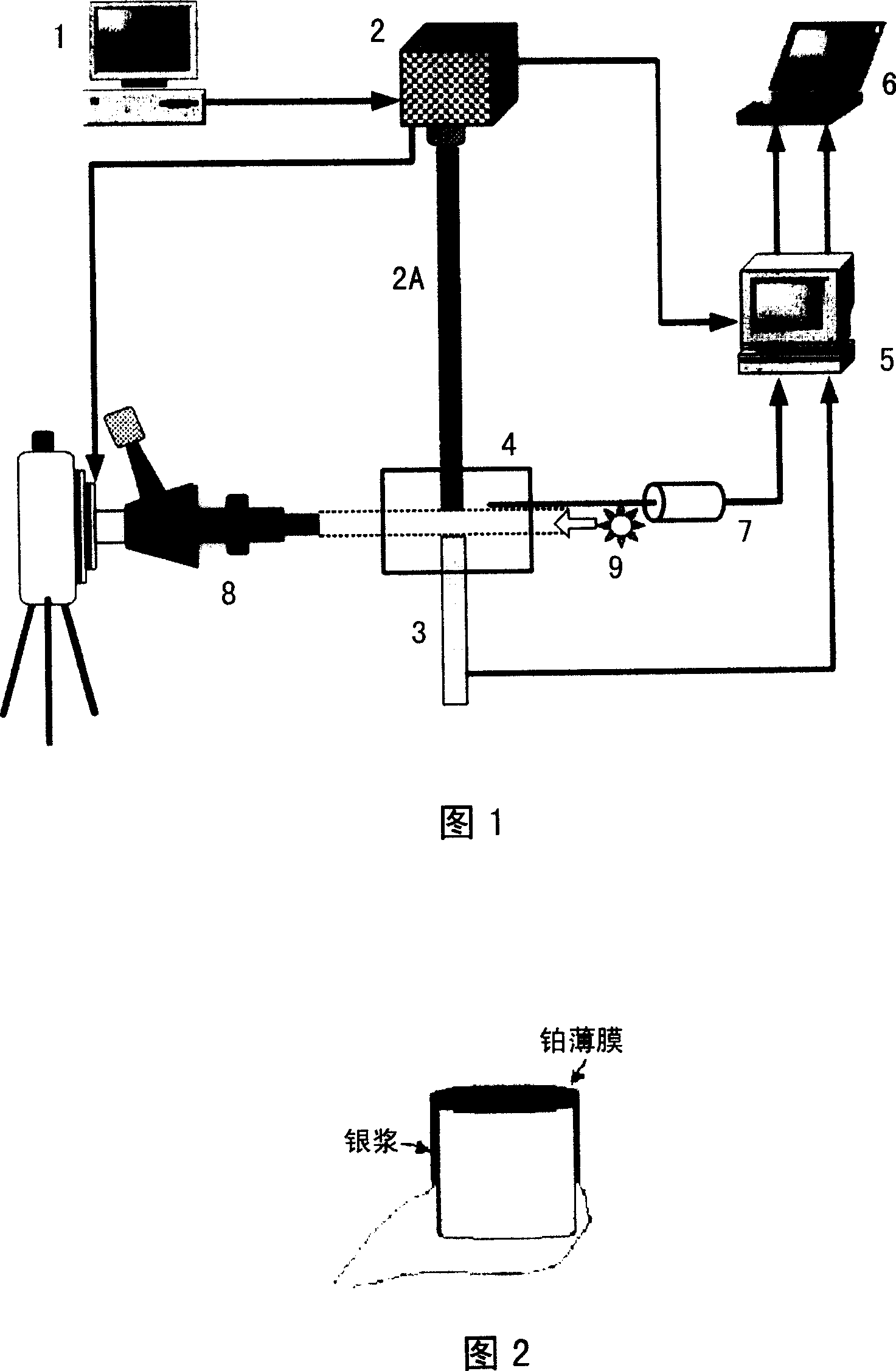

[0023] Please combine Figure 1 and Figure 2, the present invention is mainly composed of a pulsed laser heating system, a transient temperature measurement system, a transient pressure measurement system and a high-speed microscopic magnification photographic observation and analysis system.

[0024] In the pulse laser heating system, the laser controller 1 controls the output power of the pulse laser 2 to irradiate the laser beam 2A onto the surface of the platinum thin film test piece 3 .

[0025] The pulse laser 2 used in the present invention has a wavelength of 1.06 μm, an adjustable pulse width of 800 ns to 5 μs, an adjustable spot diameter of 0.2 to 10 mm, and a power density of 10-10000 MW / m 2 Adjustable, through the controller to control the switching power supply to adjust its output parameters.

[0026] Platinum thin film test piece 3 is formed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com