Soymilk boiling method and soymilk making machine

A soymilk maker and cooking technology, which is applied to milk substitutes, beverage preparation devices, household appliances, etc., can solve the problem that the cooking efficiency is not very high, and achieve the effect of improving the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

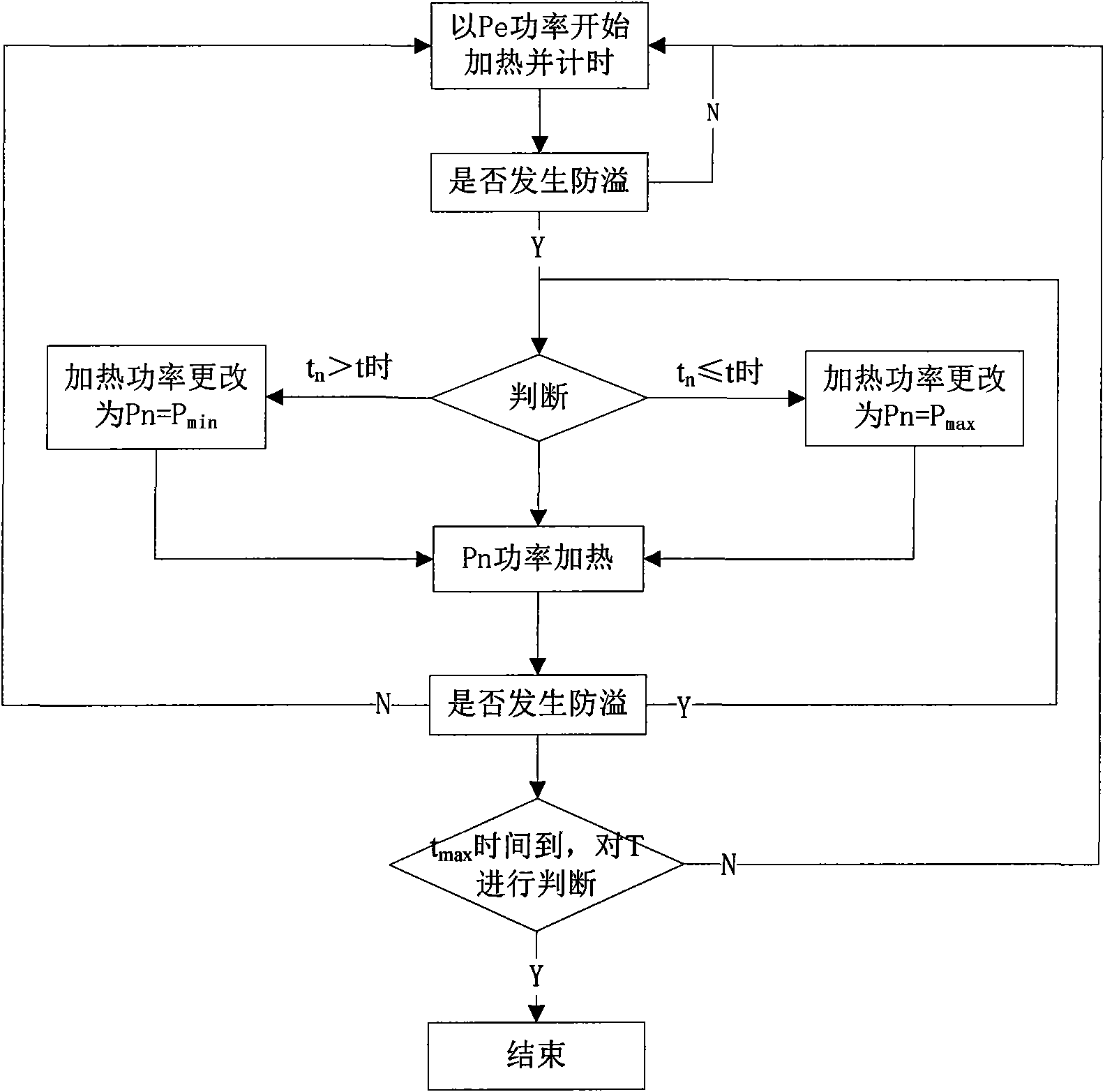

Embodiment 1

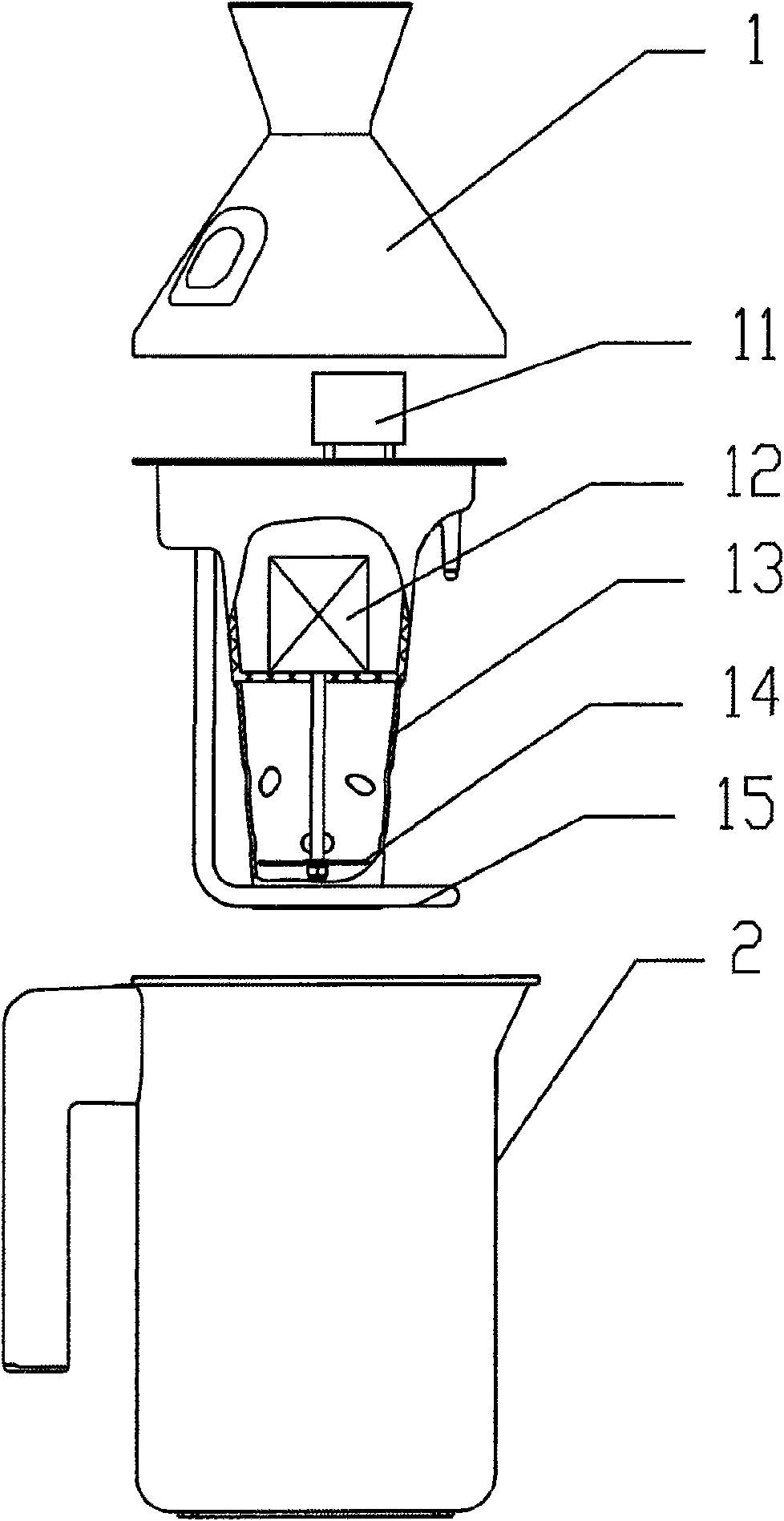

[0026] As the embodiment of the soya-bean milk machine that realizes the milk cooking method described in the present invention, as image 3 As shown, it includes a machine head 1, a cup body 2, a motor 12, a crushing device, a heating device and a circuit control board 11. The working procedure of the soybean milk machine includes the above-mentioned cooking method. In this embodiment, the crushing device includes a crushing cutter 14 and a deflector 13, and the heating device is a heating pipe 15. The soymilk machine adopting the method of cooking milk according to claim 1 has a simple structure and is easy to operate. The effect is good.

[0027] The soya-bean milk machine that realizes the milk cooking method of the present invention can also be realized by the following structure, as Figure 4 As shown, it includes a pulp making part 6, a pulp cooking part 5 and a circuit control system 3, and the working procedure of the soybean milk machine includes the pulp cooking me...

Embodiment 2

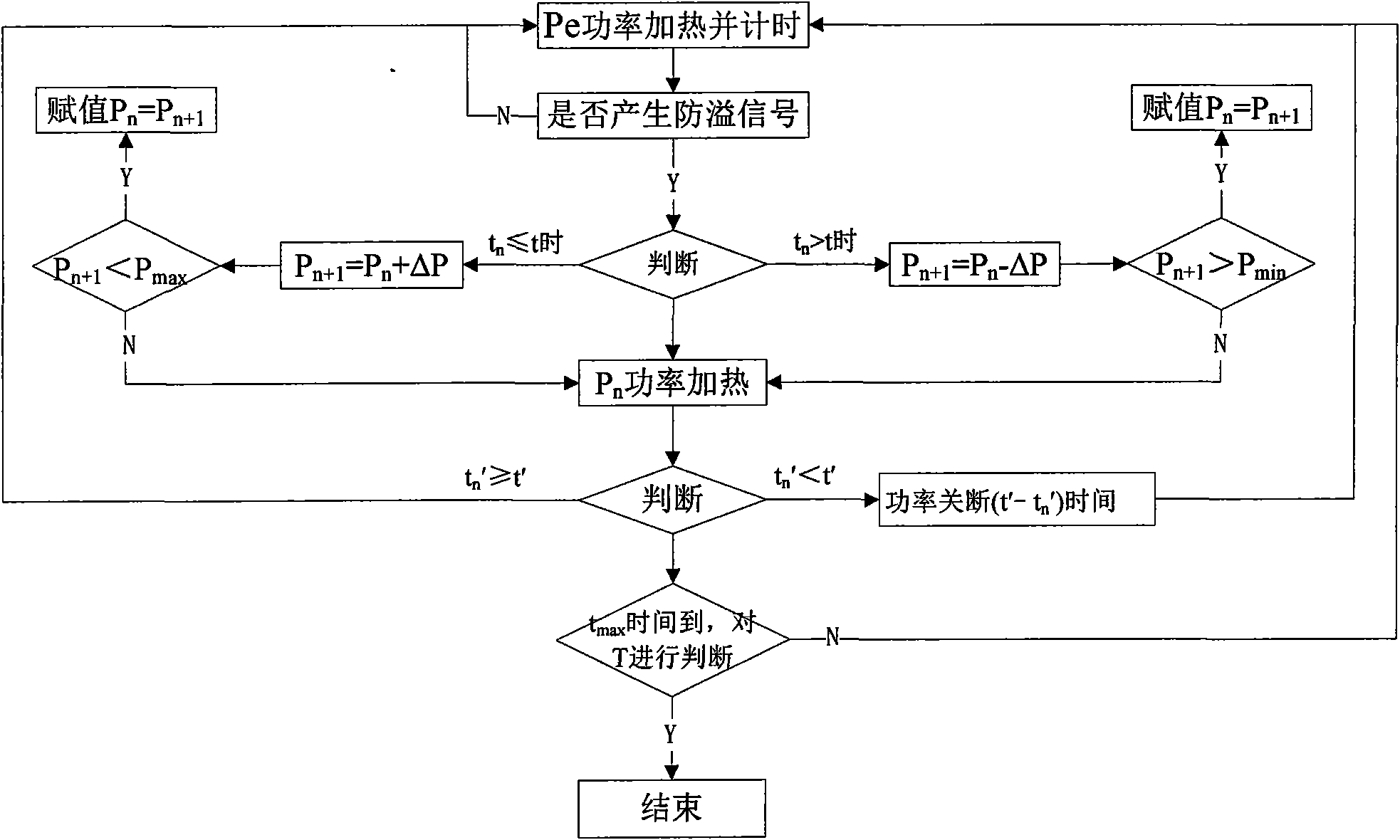

[0032] As the best embodiment of the pulp cooking method of the present invention, as figure 2 As shown, the difference from Embodiment 1 is that the pulp cooking method is provided with a heating power reference value P of the heating device 1 , P 1 n is based on P 1 based on changes.

[0033] In this embodiment, after the heating device heats the slurry with Pe power and touches the anti-overflow electrode, the P n The slurry is heated in a state of increasing or decreasing, the adjustment value of the heating power of the increasing or decreasing is ΔP, and ΔP is adjustable, and the size of ΔP can be adjusted according to the actual situation, so that the slurry is always at a high boil during the cooking process state, which is conducive to more fully cooking the milk and improving the taste of soy milk.

[0034] The specific changes are as follows: heat with Pe power and start timing, and detect the anti-overflow signal at the same time, if there is no anti-overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com