Thermodynamic cycle system and method for ammonia water mixed working medium power cooling combined supply

A thermodynamic cycle system and mixed working medium technology, applied in the energy field, can solve the problems of large heat transfer temperature difference and large heat transfer temperature difference of rectification column reboiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

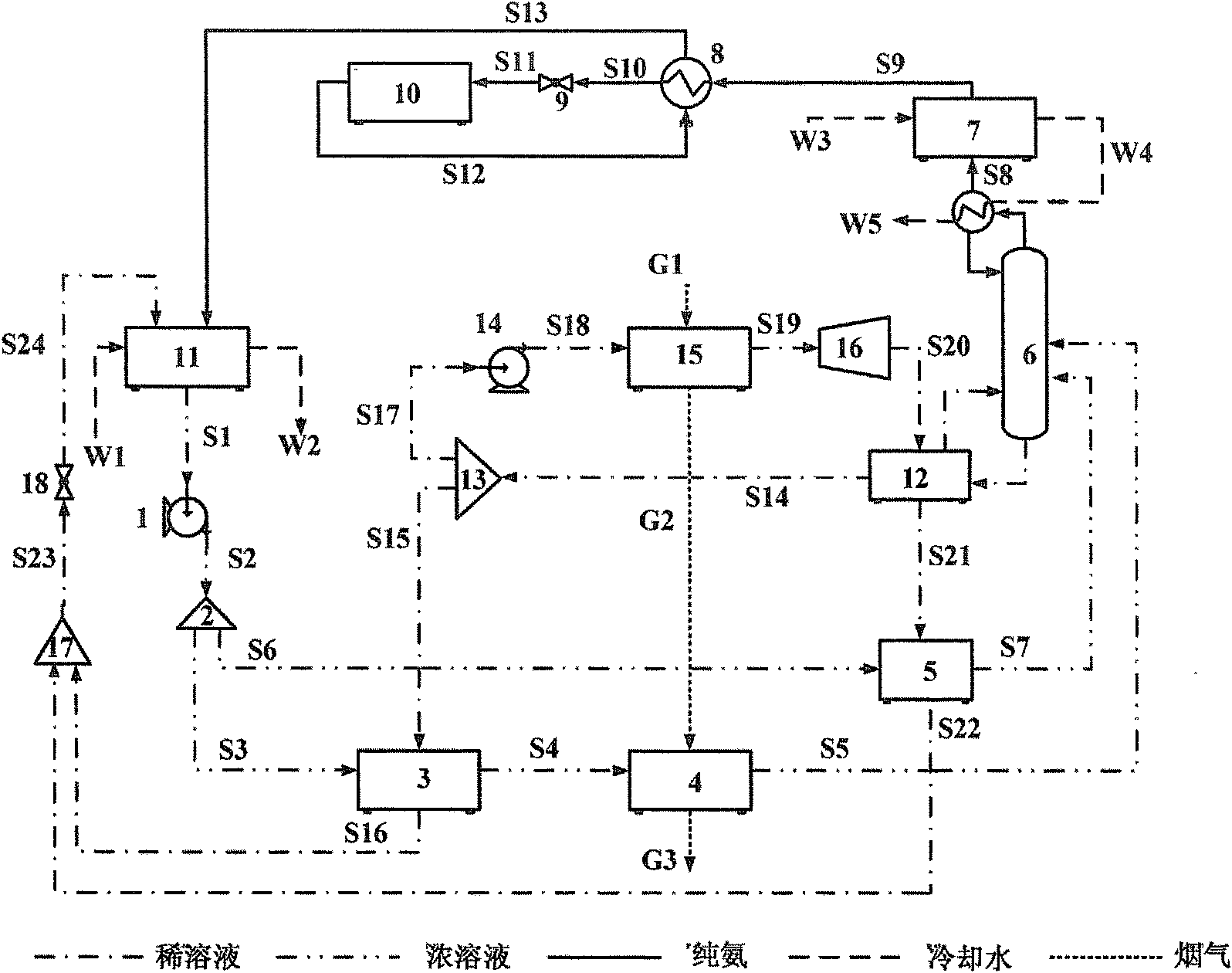

Embodiment 1

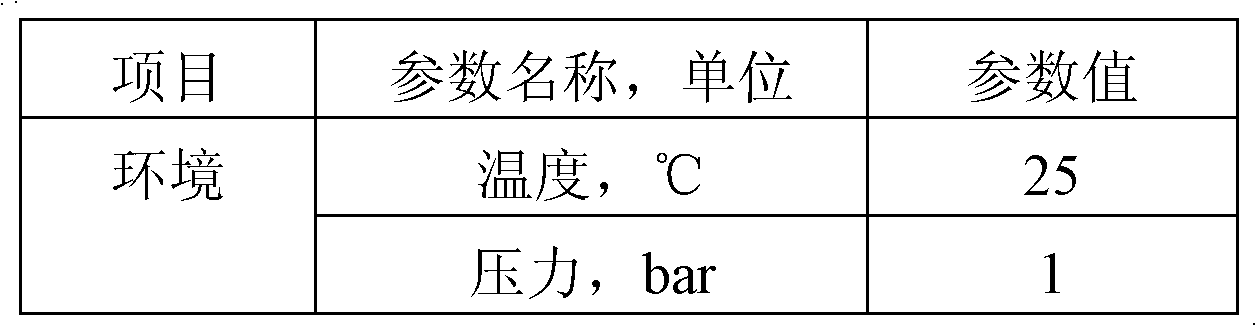

[0051] Table 1 (embodiment 1 and embodiment 2)

[0052] Assuming that the system is in steady state operation, see Table 2 to Table 5 for the calculation results of logistics simulation under equilibrium conditions and the comparison of thermal performance between the cogeneration system and the separate production system. Table 2 and Table 4 are the state parameters of the cycle balance working conditions of Embodiment 1 and Embodiment 2 respectively, and Table 3 and Table 5 are respectively the thermal performance comparisons of Embodiment 1 and Embodiment 2 with the corresponding production division systems.

[0053]

[0054]

[0055]

[0056] Table 2 (embodiment 1)

[0057]

[0058] Table 3 (embodiment 1)

[0059]

[0060]

[0061]

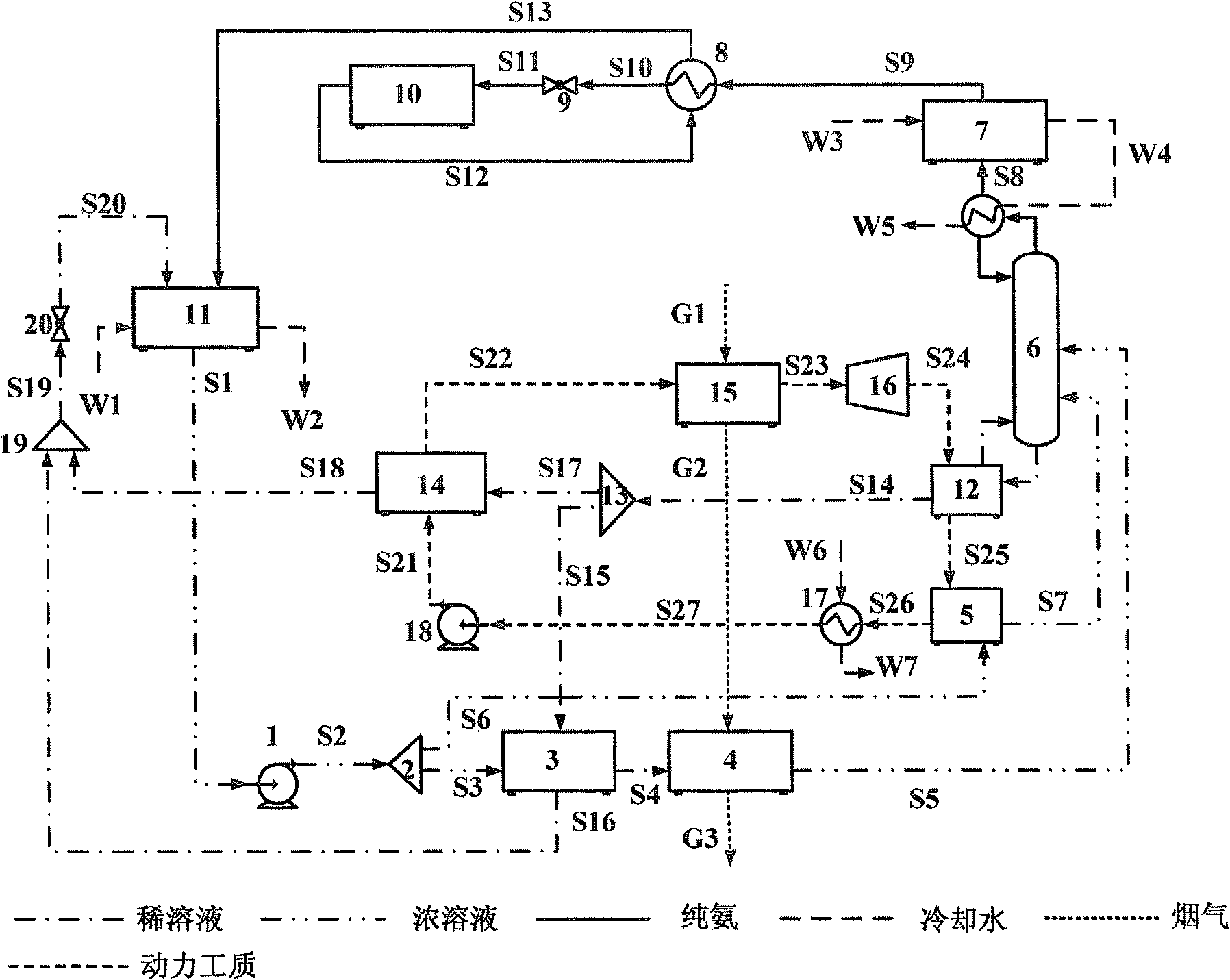

Embodiment 2

[0063]

[0064] Table 5 (embodiment 2)

[0065] As can be seen from Table 3, the system thermal efficiency and exergy efficiency of Embodiment 1 of the present invention are respectively 40.72% and 42.46%, which are respectively 46.2% and 46.82% higher than the production system thermal efficiency and exergy efficiency; Under the condition of energy saving, the energy saving rate of the system in embodiment 1 is 31.6%.

[0066] As can be seen from Table 5, the system thermal efficiency and exergy efficiency of embodiment 2 of the present invention are respectively 35.85% and 44.63%, which are respectively 36.2% and 36.7% higher than the production system thermal efficiency and exergy efficiency; Under the condition of energy saving, the energy saving rate of the system in embodiment 2 is 26.6%.

[0067] Compared with the reference system, the thermodynamic performance of the cogeneration system provided by the present invention is greatly improved, and the fundamental reas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com