Soft and insulation high wet-absorption fabric and preparation method thereof

A manufacturing method and high moisture-absorbing technology, applied in the field of thermal fabrics, can solve the problems of hard fabrics, poor skin-friendly properties, soft skin-friendly properties, etc., and achieve the effects of reducing heat conduction, improving quick-drying ability, and improving water absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

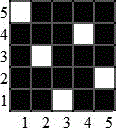

[0023] A soft, warm and high moisture-absorbing fabric, using 60S long-staple cotton yarn as warp yarn, 40S covering layer as long-staple cotton, core-spun yarn with 30D modified polyester filament as weft yarn, and 5 pieces of 3 flying warp satin Weaving, gray cloth warp density 173 / inch, weft density 115 / inch, gray cloth width 296cm, obtain gray cloth.

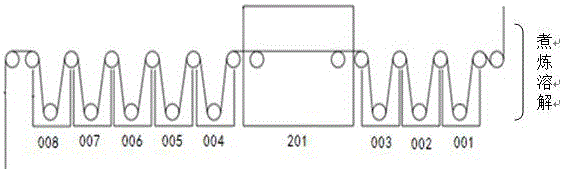

[0024] The gray cloth is singed first, and then the gray cloth is smelted on the open-width scouring machine to dissolve the yarn core of the core sand. During scouring, the fabric enters the open-width scouring machine at a speed of 40m / min, and after passing through the scouring machine The raw material goes through simmering and rolling tanks 001, 002 and 003 in turn. The concentration of caustic soda (36Be caustic soda) in the three padding tanks is controlled at 80g / l, the liquor ratio is controlled at 700:1, and the temperature is controlled at 50°C. After rolling the trough, the excess rolling rate of the fabric is co...

Embodiment 2

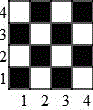

[0027] A soft, warm and high moisture-absorbing fabric, using 40S covering layer of long-staple cotton and core-spun yarn of 20D modified polyester filament as the warp yarn, 40S covering layer of combed fine-staple cotton, and yarn core of 20D The core-spun yarn of the modified polyester filament is used as a weft yarn, and is woven with a plain weave. The gray cloth has a warp density of 133 threads / inch, a weft density of 72 threads / inch, and a gray cloth width of 296 cm to obtain a gray cloth.

[0028] The gray cloth is singed first, and then the gray cloth is smelted on the open-width scouring machine to dissolve the yarn core. During scouring, the fabric enters the open-width scouring machine at a speed of 45m / min, and the fabric after passing through the scouring machine is sequentially smelted. For rolling tanks 001, 002 and 003, the concentration of caustic soda in the three padding tanks is controlled at 95g / l, the liquor ratio is controlled at 800:1, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com