Preparation method of high-concentration malt wort

A high-concentration, wort technology, applied in the field of beer brewing, can solve problems such as no research reports, and achieve the effects of reducing production costs, pure color and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

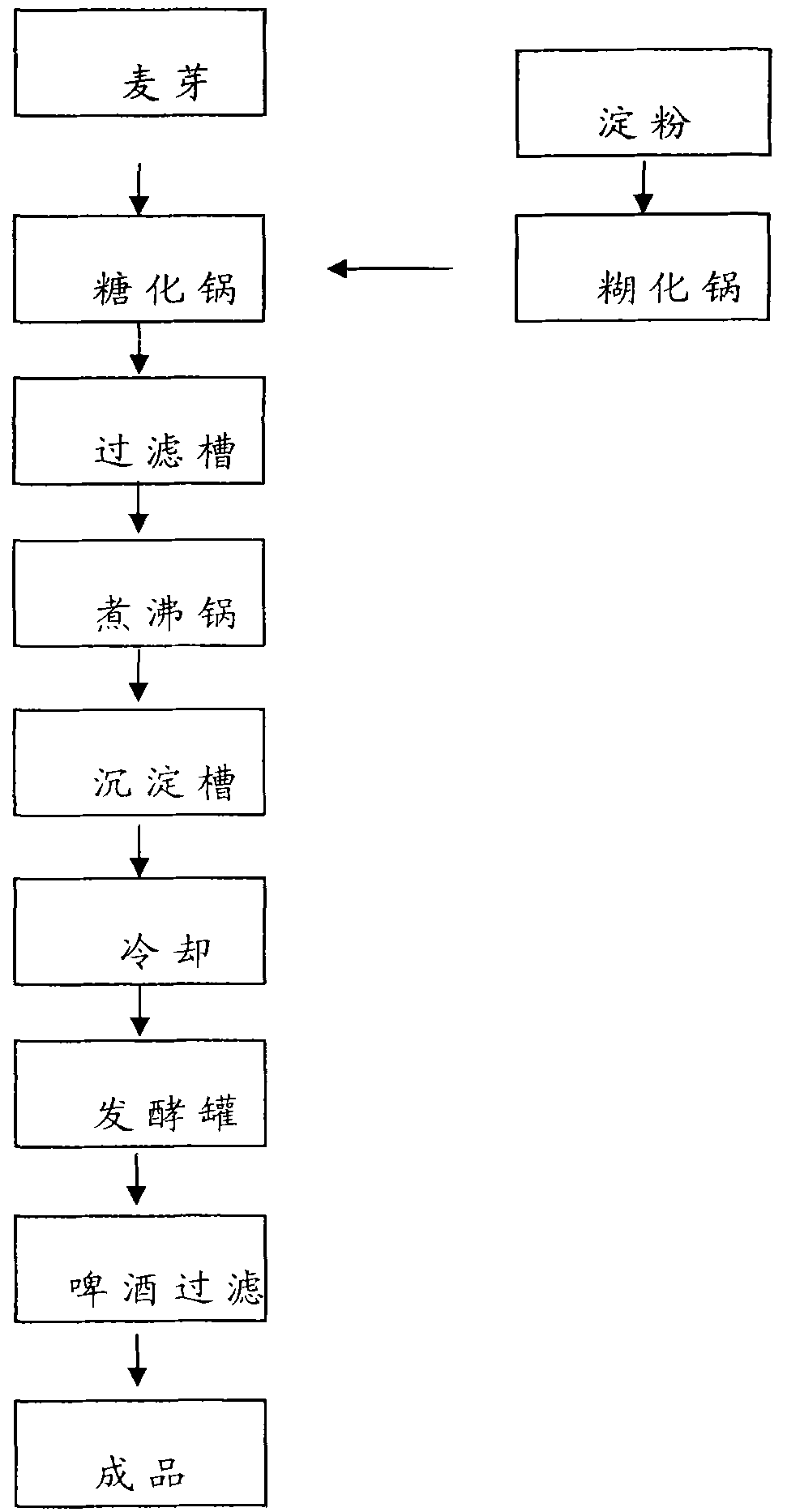

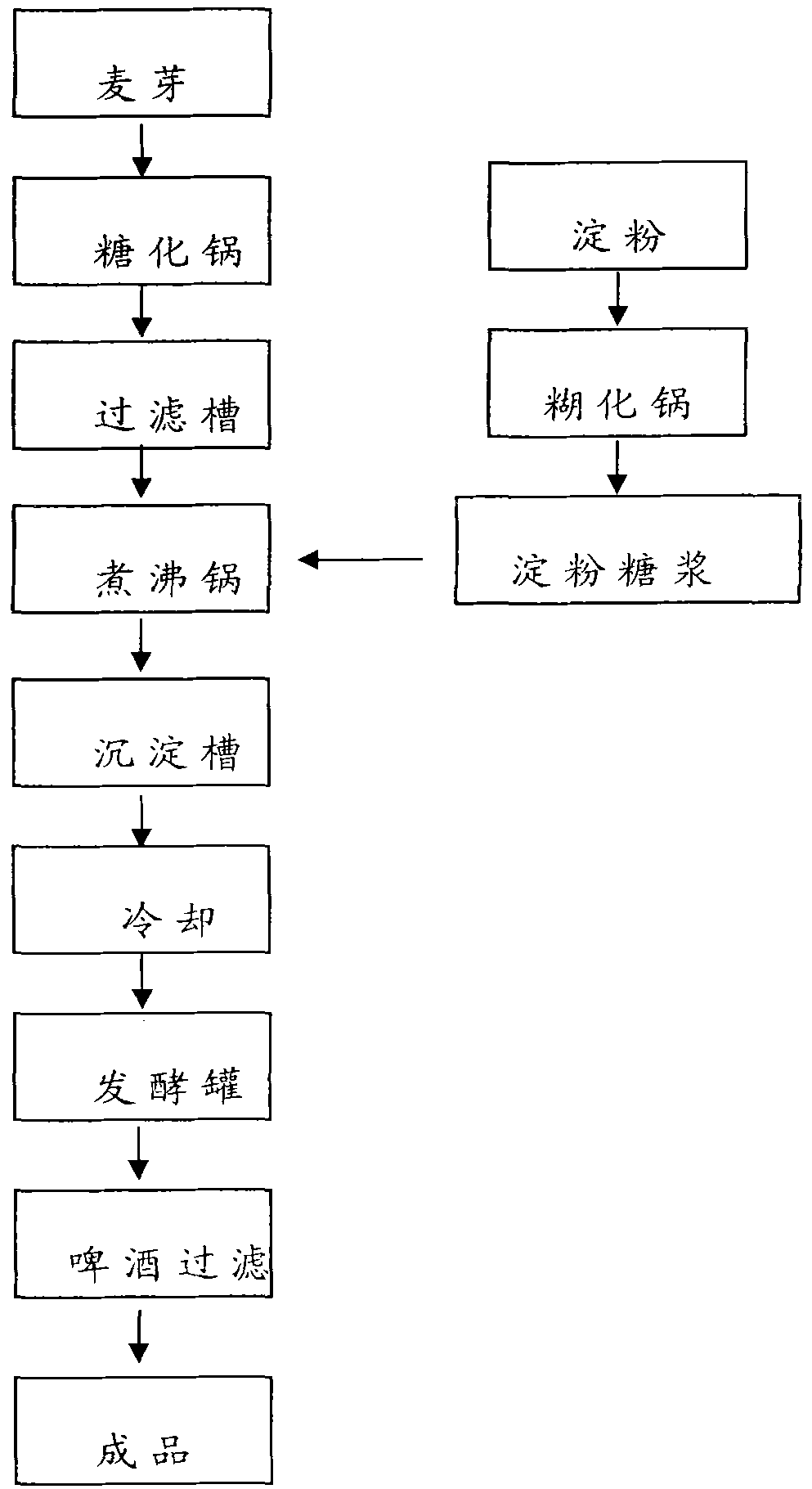

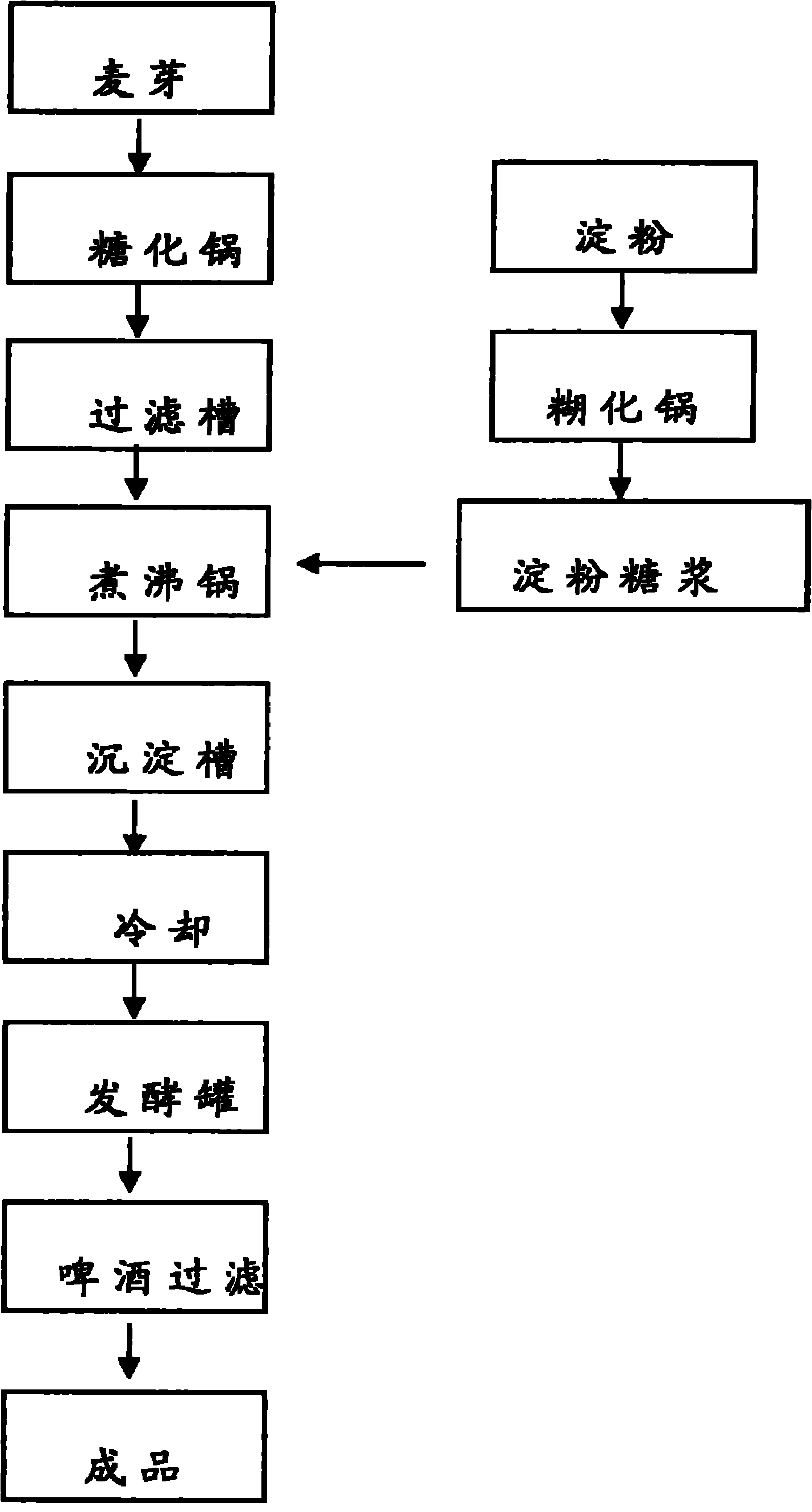

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of syrup for beer:

[0026] 1) Sizing: 6000kg of cornstarch and 50°C brewing water are used for pulping at the ratio of starch:water weight ratio of 1:2.5, and calcium sulfate 0.15mg / g starch is added based on the amount of cornstarch to adjust pH value of starch slurry to 5.5;

[0027] 2) Primary liquefaction: Add high-temperature-resistant amylase to the prepared starch slurry for primary liquefaction, add high-temperature-resistant amylase 28u / g starch based on the amount of corn starch, and heat up to 70°C. 1.0°C / min, keep warm for 30min, and make a liquefied mash;

[0028] 3) Saccharification: add 20°C brewing cold water to the mash that has been liquefied once, adjust the temperature of the mash to 65°C, and add two amylolytic enzyme preparations, low-calorie enzyme and pullulanase, for coordinated saccharification. For the calculation basis, add low-calorie enzyme 0.8ul / g starch, pullulanase 0.14PUN / g starch, control the saccharification pH value...

Embodiment 2

[0037] 1. Preparation of syrup for beer:

[0038] 1) Sizing: 5300kg of cornstarch and 50°C brewing water are mixed according to the ratio of starch:water weight ratio of 1:2.5, and calcium sulfate 0.25mg / g starch is added based on the amount of cornstarch to adjust pH value of starch slurry to 5.5;

[0039] 2) Primary liquefaction: Add high-temperature-resistant amylase to the prepared starch slurry for primary liquefaction, add high-temperature-resistant amylase 28u / g starch based on the amount of corn starch, and heat up to 70°C. 1.0°C / min, keep warm for 10 minutes, and make a liquefied mash;

[0040] 3) Saccharification: add 20°C brewing cold water to the mash that has been liquefied once, adjust the temperature of the mash to 60°C, and add two starch-decomposing enzyme preparations, low-calorie enzyme and pullulanase, to carry out coordinated saccharification. For the calculation basis, add low-calorie enzyme 0.7ul / g starch, pullulanase 0.14PUN / g starch, control the sacc...

Embodiment 3

[0049] 1. Preparation of syrup for beer:

[0050] 1) Sizing: 3780kg of cornstarch and 50°C brewing water are used for pulping at a ratio of starch:water weight ratio of 1:3, and calcium sulfate 0.15mg / g starch is added based on the amount of cornstarch to adjust pH value of starch slurry to 5.5;

[0051] 2) Primary liquefaction: Add high-temperature-resistant amylase to the prepared starch slurry for primary liquefaction, add high-temperature-resistant amylase 20u / g starch based on the amount of corn starch, and heat up to 70°C. 1.0°C / min, keep warm for 10 minutes, and make a liquefied mash;

[0052] 3) Saccharification: add cold brewing water below 20°C to the liquefied mash once, adjust the temperature of the mash to 65°C, add low-calorie enzyme and pullulanase two amylolytic enzyme preparations for cooperative saccharification, and use cornstarch The amount is the calculation basis, add low-calorie enzyme 0.4ul / g starch, pullulanase 0.07PUN / g starch, control the saccharif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com