Water boiling judgment control method for heater

A control method and heater technology, applied in the direction of heating devices, etc., can solve the problems of increasing product costs, different proportions of rice water addition, incompatibility with product structure diversity, and environmental temperature variability, etc., to achieve the effect of preventing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

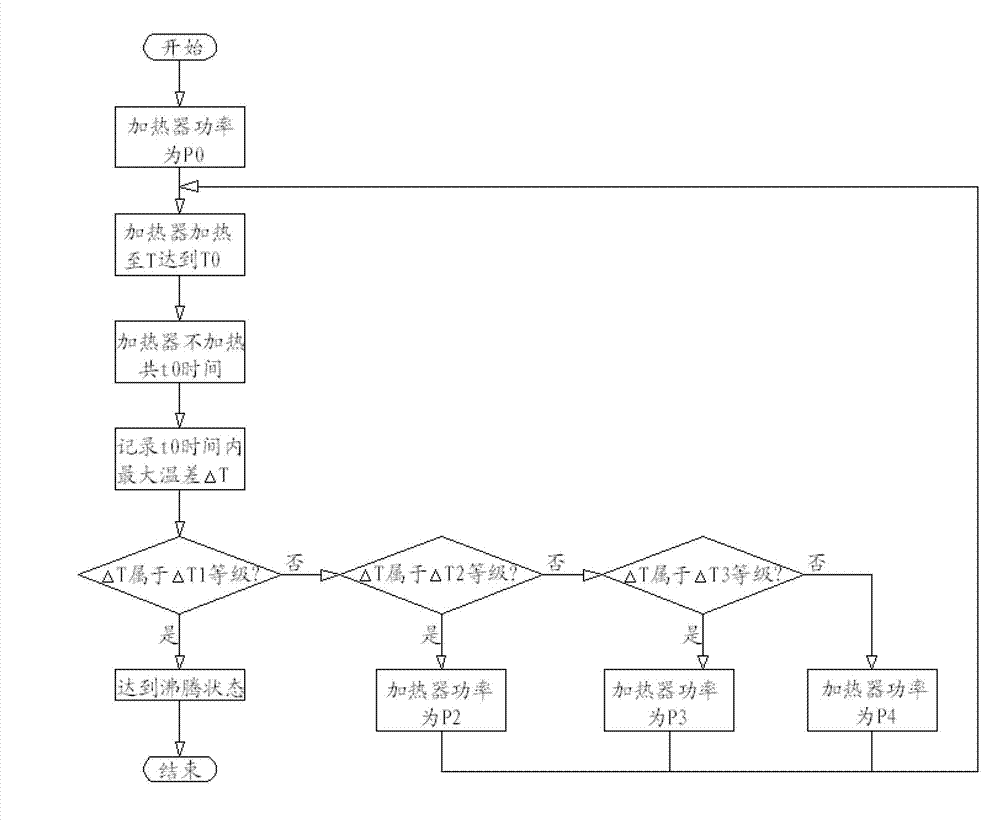

[0021] This embodiment discloses a control method for judging boiling by a heater, wherein the heater is provided with a bottom temperature sensor, and the method for controlling boiling judging by the heater includes the following steps:

[0022] S1, the heater is heated with the preset power adjustment ratio P0, and enters S2;

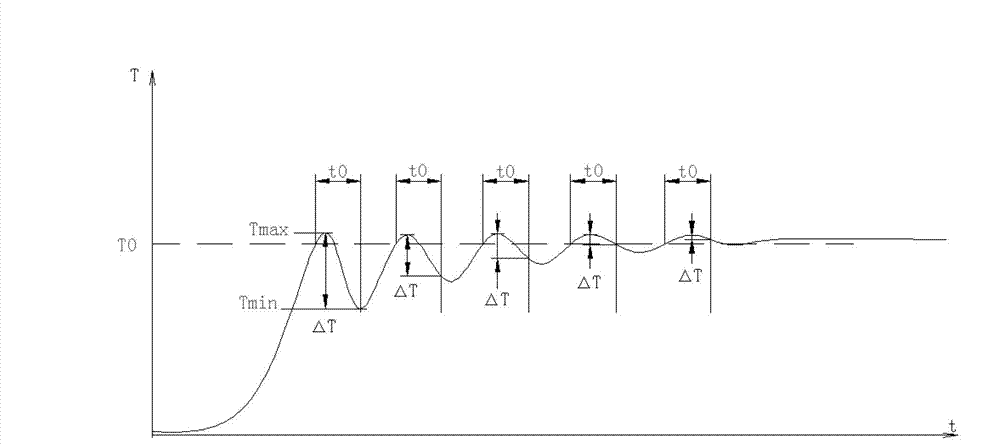

[0023] S2. When the temperature sensed by the bottom temperature sensor reaches the preset temperature T0, the heater stops heating and enters S3;

[0024] S3. When the time for the heater to stop heating reaches the preset time t0, record the highest temperature value Tmax and the lowest temperature value Tmin sensed by the bottom temperature sensor within the preset time t0, and calculate the difference between the two △T=Tmax -Tmin, enter S4;

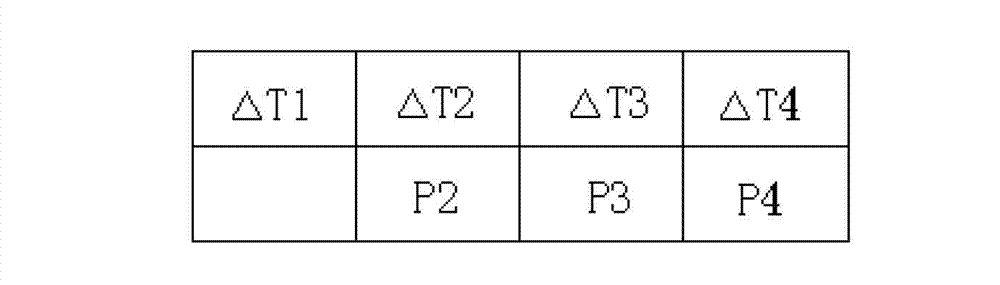

[0025] S4. The preset temperature difference level includes a boiling level ΔT1 and at least one non-boiling level ΔTn, and the difference ranges of each level are non-overlapping and continuous, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com