Open type intelligent monitoring comprehensive experiment platform in sugarcane sugar boiling process

An experimental platform and intelligent monitoring technology, applied in sucrose production, electrical program control, sugar production, etc., to achieve the effect of less material, flexible layout, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

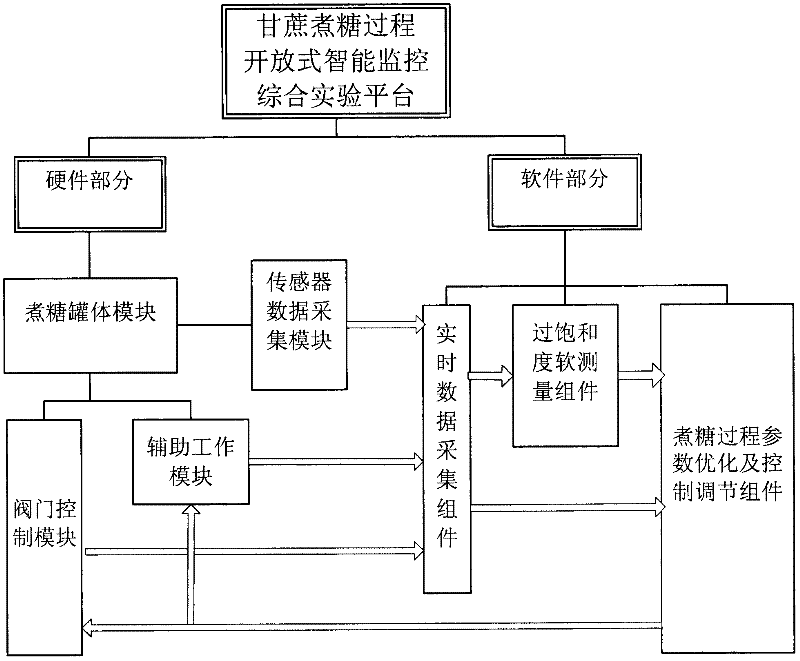

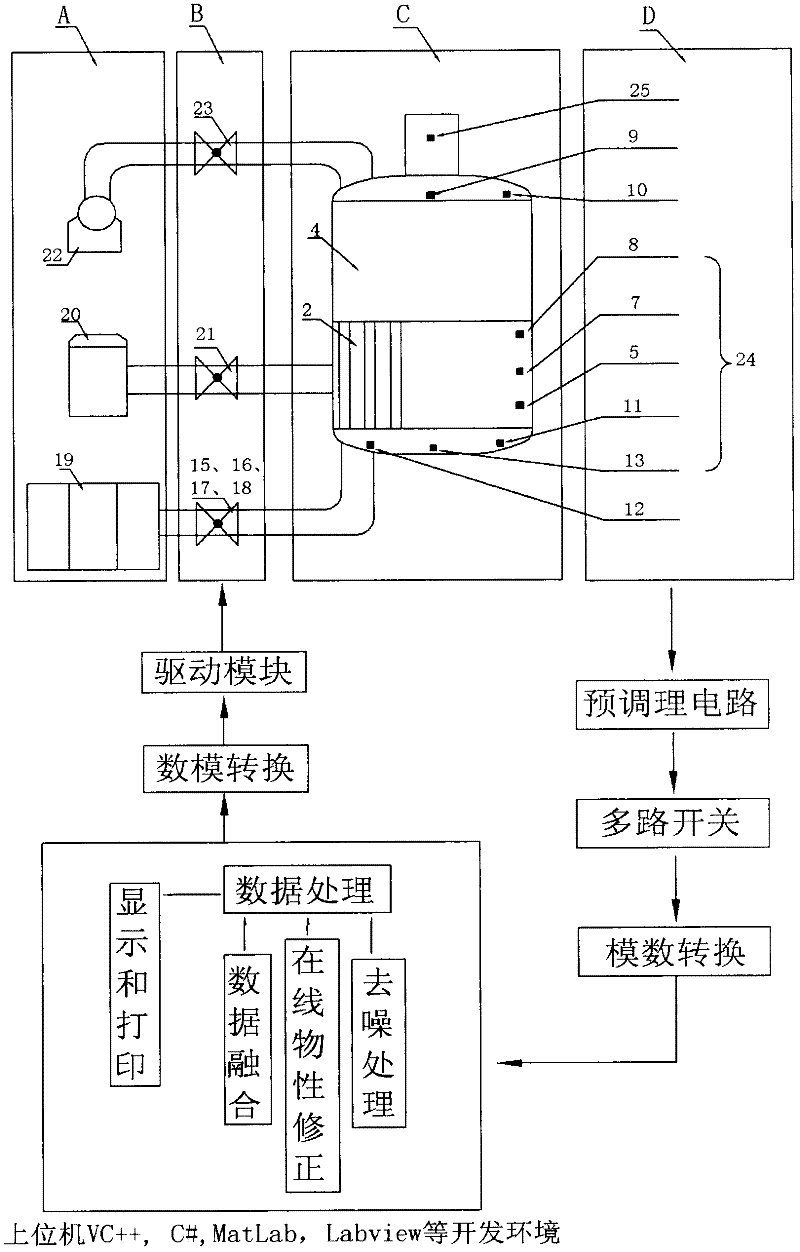

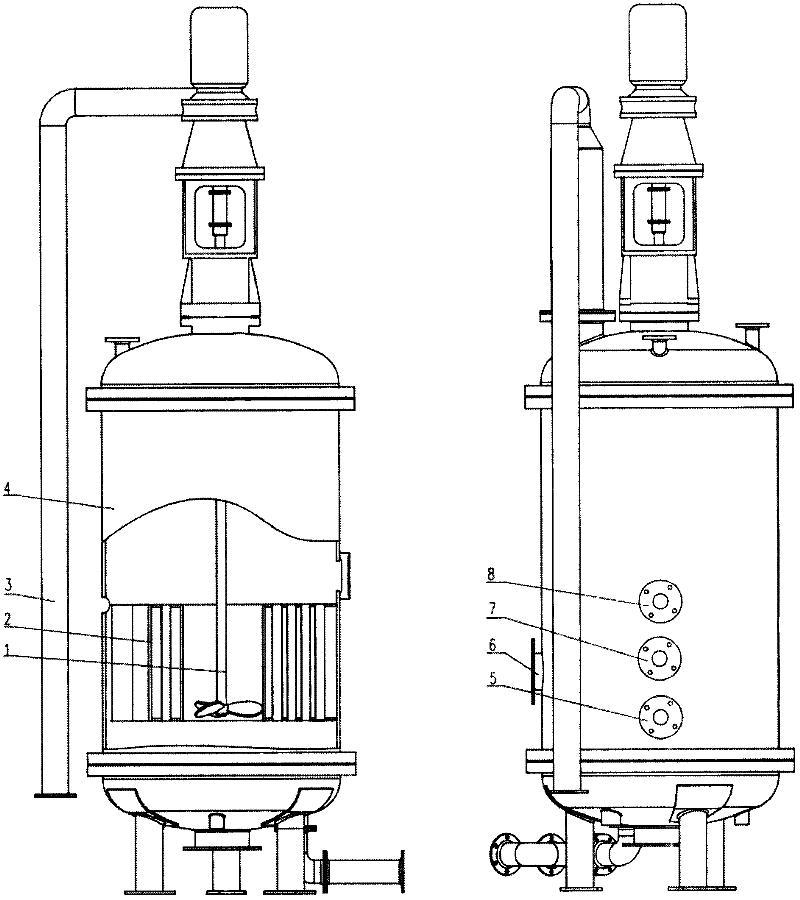

[0035] Such as figure 1 As shown, the comprehensive experimental platform for intelligent monitoring of the sugarcane boiling process of the present invention is composed of software and hardware. The hardware part includes the sugar cooking tank module, auxiliary working module, sensor data acquisition module and valve control module, and the software part includes real-time data acquisition components, supersaturation soft measurement components, dynamic parameter optimization and control adjustment components in the sugar cooking process, hardware and software Part of it is connected with CAN bus through Modbus bus. Most smart instruments use the Modbus serial communication protocol, while the CAN bus has high reliability, good flexibility and is easy to be controlled remotely through the network. Therefore, the temperature, density, conductivity, pressure, liquid level, motor speed and other data of the sensor data acquisition part can assist in the work. Part of the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com