Preparation method of stable slurry of lithium ion battery

A lithium-ion battery and preparation method technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of slow speed, inability to achieve dispersion effect, battery capacity reduction, and ineffectiveness, etc., and achieve the effect of shortening pulping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Nano-lithium iron phosphate (particle size range 1~100nm) is used as the positive electrode material, superfine carbon powder (SuperP) and carbon nanotubes (VGCF) are used as the conductive agent, polyvinylidene fluoride (PVDF) is used as the binder and dispersant , nitrogen methyl pyrrolidone (NMP) as solvent, lithium iron phosphate: ultrafine carbon powder: carbon nanotubes: polyvinylidene fluoride: nitrogen methyl pyrrolidone weight ratio = 94.5: 1.5: 1.5: 2.5: 100, according to the current It has the technology to prepare 300L lithium-ion battery positive electrode slurry.

[0013] The slurry preparation process is as follows:

[0014] (1) According to the conventional method, mix and stir the binder, dispersant and 50% solvent for 2 hours to make glue;

[0015] (2) Dry mix lithium iron phosphate and conductive agent for 0.5h, then mix and stir with another 50% solvent for 2h to make a wet material, then add glue to the wet material and mix for 0.5h to make a mixed...

Embodiment 2

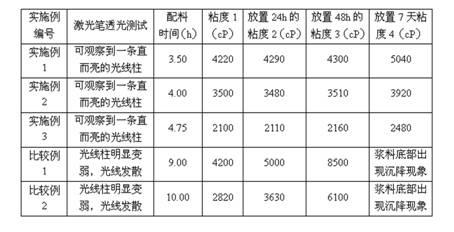

[0023] Slurry A was made completely according to the conditions of Example 1, and Slurry A was dispersed at a high-speed circulation for 4 times at a linear speed of 35m / s (that is, steps (3)-(5) in Example 1 were repeated 4 times, It takes about 15 minutes to disperse once, and the total time is about 1 hour), and then perform defoaming, filtering, and iron removal processes to obtain slurry B. Use a 500ml transparent glass cup to take slurry B, irradiate slurry B with a laser pointer, and observe through light transmission. A straight and bright beam of light can be observed in the solution, indicating that the dispersion is very uniform.

[0024] Test the viscosity of the slurry B taken to obtain a viscosity of 1, and then test and obtain a viscosity of 2 after being left open for 24 hours in an environment with a dew point of -50 degrees, and obtain a viscosity of 2 after testing for 48 hours, and obtain a viscosity of 4 after standing for 7 days. The obtained test results...

Embodiment 3

[0029] Ordinary natural graphite was used as the negative electrode material, superfine carbon powder (SuperP) and conductive graphite (SFG-6) were used as the conductive agent, sodium carboxymethylcellulose (CMC) was used as the binder and dispersant, and water (H 2 O) is a solvent, graphite: superfine carbon powder: conductive graphite: sodium carboxymethyl cellulose: the weight ratio of water is=96.3:1:1.5:1.2:110, and prepare 300L lithium ion battery negative electrode slurry. The slurry preparation process is as follows: CMC and 75% H 2 O mixed and stirred for 2h to make glue, dry mixed graphite and conductive agent for 0.5h, then added glue and another 25% H 2 O mixed and stirred for 2 hours to make a wet material; then according to the method of the present invention, the slurry A was circulated and dispersed at a high speed of 35m / s for 3 times (the time used for one dispersion is about 15min, and the total time is about 0.75h) , After the dispersion is completed, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com