Integrated pulping device

A technology of system and feeding device, which is applied to mixers with rotating stirring devices, transportation and packaging, mixers, etc., can solve the problems of high slurry viscosity, affecting slurry pumping, high-speed dispersion, etc., to prevent agglomeration and Agglomeration, reduction of pulping time, and elimination of blisters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Some examples of the present invention are provided below to help further understanding of the present invention, but the protection scope of the present invention is not limited to these examples.

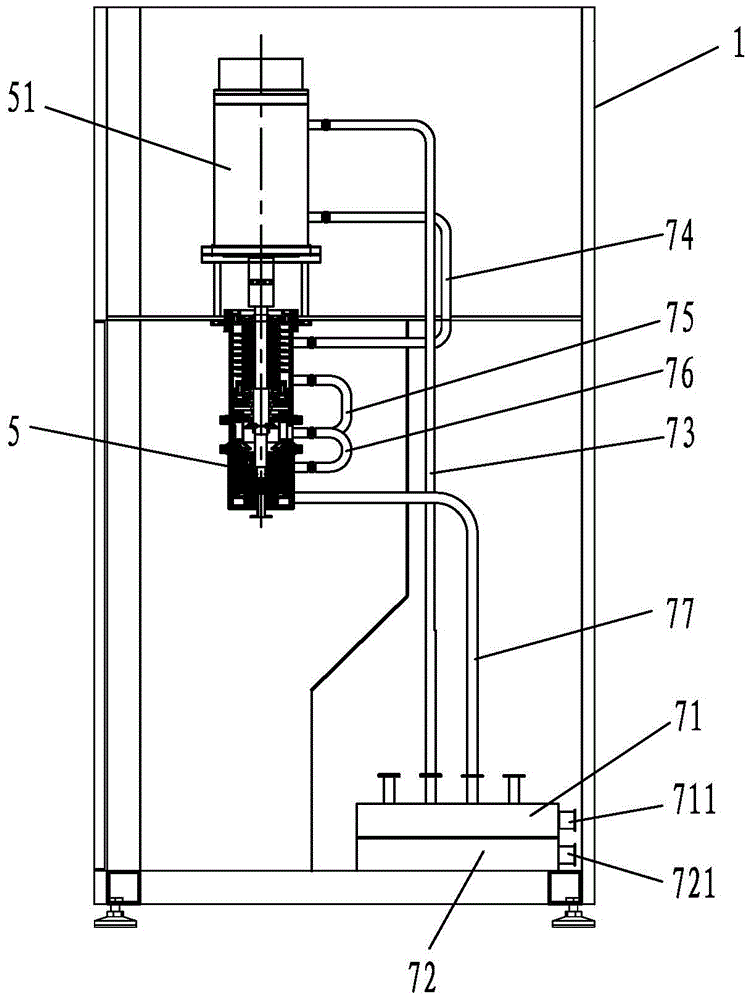

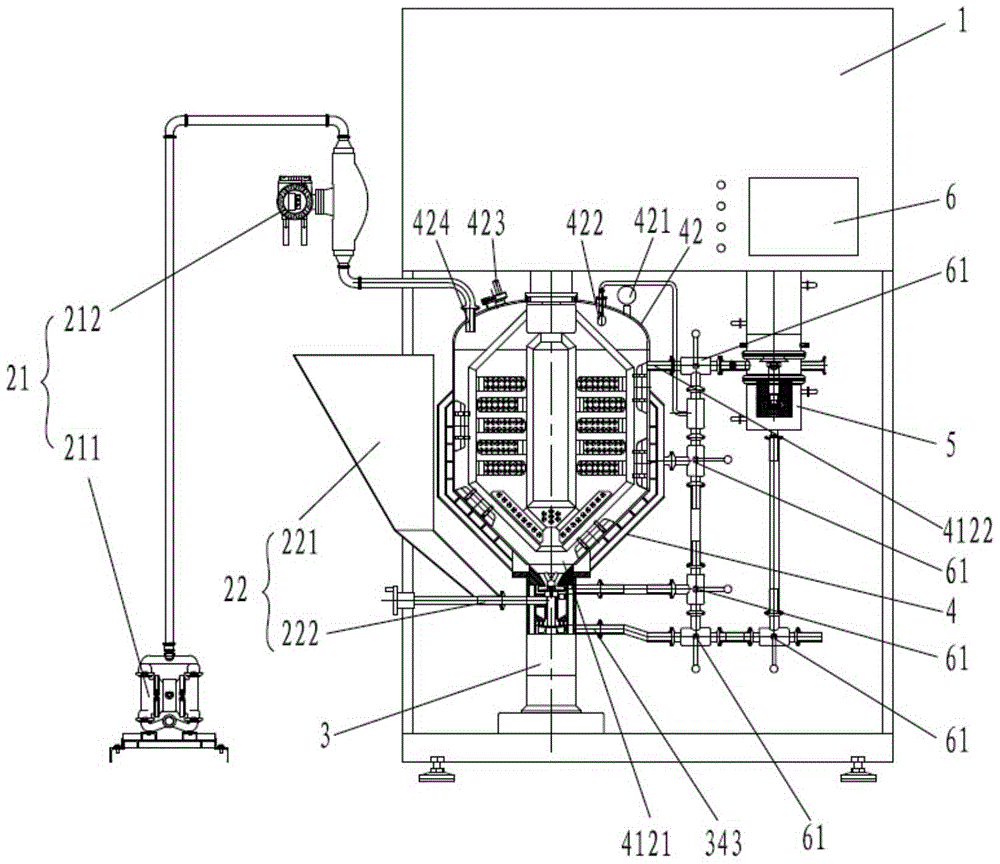

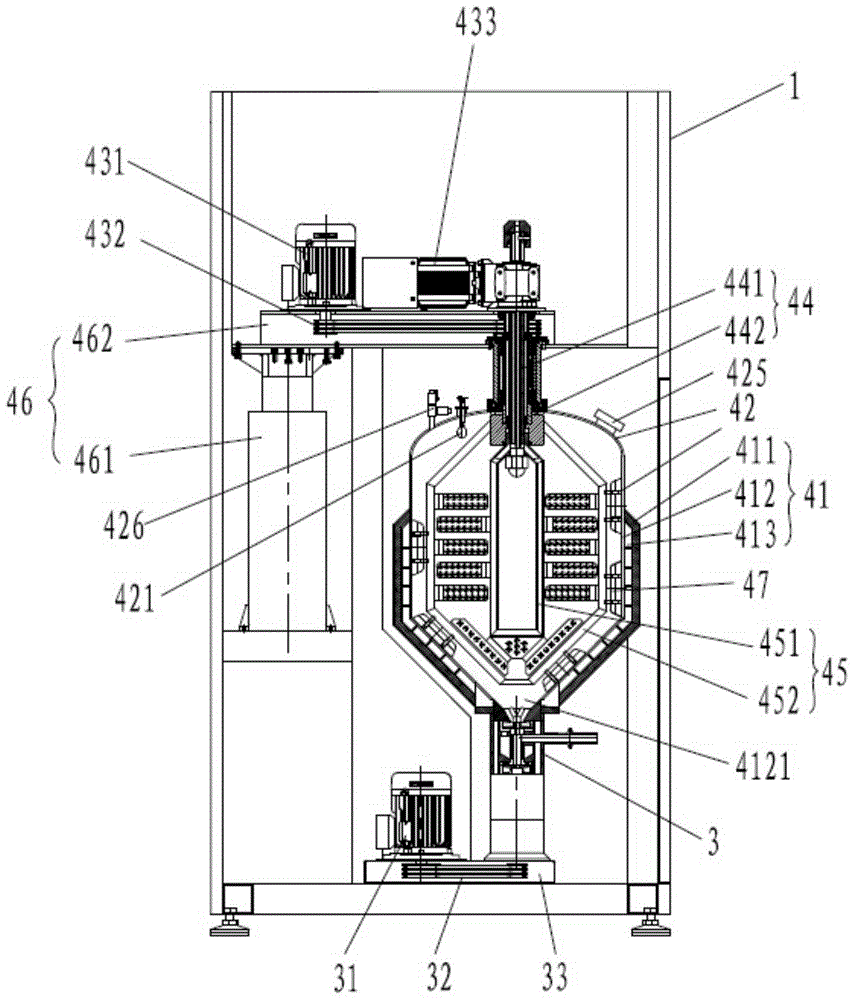

[0046] Such as figure 1 As shown, the present invention discloses an integrated pulping device, which includes an automatic feeding unit, a pre-dispersion unit 3, a stirring and mixing unit 4, a high-speed dispersion unit 5, a cooling unit 7, an electrical control unit 6, a CIP online cleaning unit and a cabinet 1, where:

[0047] The cabinet 1 carries the automatic feeding unit, the pre-dispersion unit 3 , the mixing unit 4 and the high-speed dispersion unit 5 .

[0048] The automatic feeding unit includes a solid feeding device 22 and a liquid feeding device 21. The solid feeding device 22 includes a powder feeding hopper 221 and a first valve 222. In this embodiment, the first valve 222 is a plunger valve, and the powder feeding hopper 221 passes through the The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com