Straw bio-enzyme degradation aid and degradation pulping process

A straw biological and enzymatic degradation technology, which is applied in the fields of pulp bleaching, textile and papermaking, fiber raw material treatment, etc., can solve environmental problems such as pollution and black water discharge, and achieve the goals of reducing production costs, saving energy, reducing energy consumption and pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

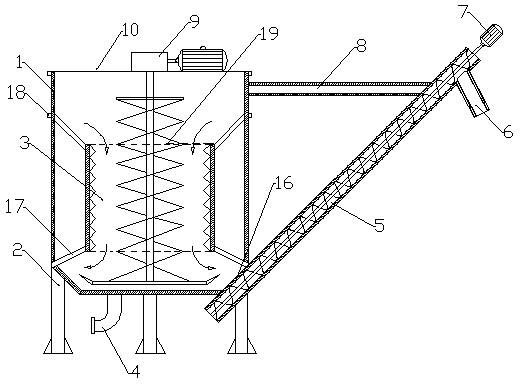

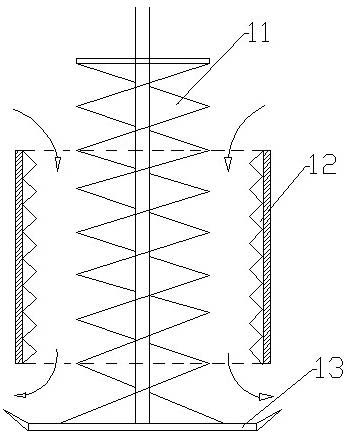

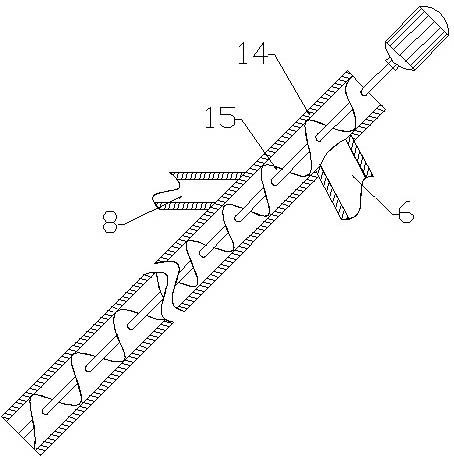

Method used

Image

Examples

Embodiment 1

[0031] A straw biological enzyme degradation aid, comprising the following components by weight:

[0032] Cellulase 8%, lipase 11%, α-1,4-glucose hydrolase 6%, catalase 10%, urea 20%, magnesium sulfate 16%, fatty alcohol polyoxyethylene ether 8%, alkyl Phenol polyoxyethylene ether OP-10 11%, the balance is calcium powder excipient;

[0033] The cellulase activity unit is 25000u / g, the lipase activity unit is 22000u / g, the α-1,4-glucohydrolase activity unit is 15000u / g, and the catalase activity unit is 20000u / g.

[0034] Wash and cut wheat straw straw with a water content of 7%, put it into a rapid pulper, add water and straw bio-enzyme degradation aid, the weight ratio of wheat straw: straw bio-enzyme degradation aid: water is 1:0.15: 5. Mix evenly, heat to 50°C in a fast pulping machine, rub and grind for 1.5 hours; add hydrogen peroxide accounting for 30% of the weight of wheat straw in four times for bleaching for 2 hours, hydrogen peroxide 2 o 2 The content is 27.5wt%,...

Embodiment 2

[0048] A straw bio-enzyme degradation aid is characterized in that it comprises the following components by weight:

[0049] Cellulase 8%, lipase 6%, α-1,4-glucose hydrolase 7%, catalase 4%, urea 10%, magnesium sulfate 12%, fatty alcohol polyoxyethylene ether 15%, alkyl Phenol polyoxyethylene ether OP-10 14%, the balance is an excipient mixed with calcium powder and sodium bicarbonate powder at a weight ratio of 1:1.

[0050] The cellulase activity unit is 25000u / g, the lipase activity unit is 22000u / g, the α-1,4-glucohydrolase activity unit is 15000u / g, and the catalase activity unit is 20000u / g.

[0051] A straw bio-enzyme degradation pulping process, the reed straw with a water content of 8% is washed and cut into sections, put into a rapid pulping machine, and water and straw bio-enzyme degradation aids are added, reed straw: straw bio-enzyme degradation aids : The weight ratio of water is 1:0.06:5, mixed evenly, heated to 60°C in a fast pulper, rubbed, and reacted for 1 ...

Embodiment 3

[0054] A straw biological enzyme degradation aid, comprising the following components by weight:

[0055] Cellulase 10%, lipase 11%, α-1,4-glucose hydrolase 10%, catalase 10%, urea 6%, magnesium sulfate 6%, fatty alcohol polyoxyethylene ether 11%, alkyl Phenol polyoxyethylene ether OP-10 15%, the balance is an excipient mixed with talc powder and sodium bicarbonate powder at a weight ratio of 1:1.

[0056] The cellulase activity unit is 25000u / g, the lipase activity unit is 22000u / g, the α-1,4-glucohydrolase activity unit is 15000u / g, and the catalase activity unit is 20000u / g.

[0057] A straw bio-enzymatic degradation pulping process. The bamboo fiber straw with a water content of 8% is washed and cut into sections, put into a rapid pulping machine, and water and straw bio-enzyme degradation additives are added. Reed straw: Straw bio-enzyme degradation Auxiliary: The weight ratio of water is 1:0.08:6, mix evenly, heat to 60°C in a fast pulper, rub and grind for 1.5 hours; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com