Method for automatically adjusting temperature of coke ovenAutomatic coke oven temperature adjusting method

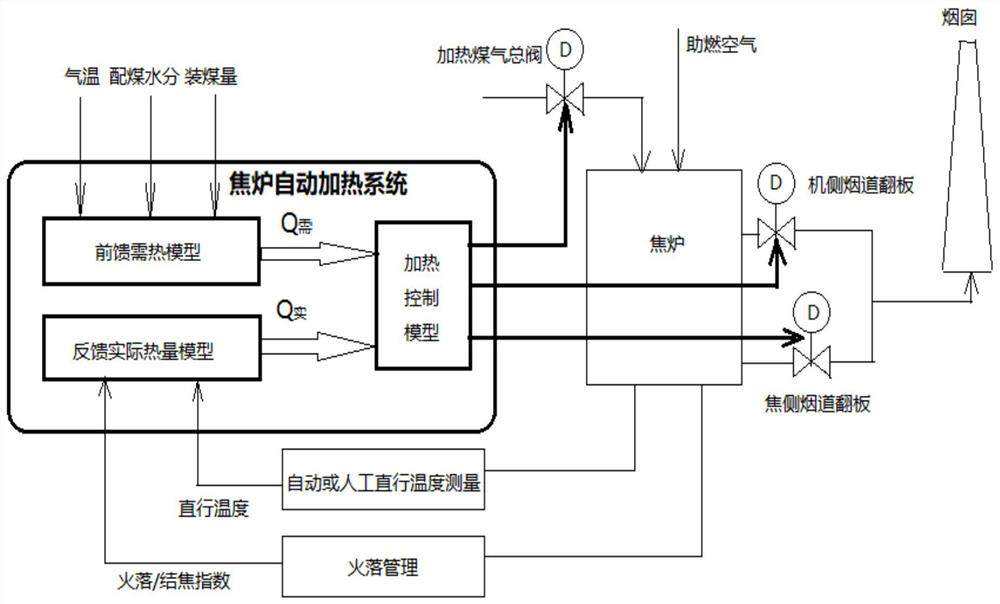

An automatic adjustment, coke oven technology, applied in coke oven, petroleum industry, design optimization/simulation, etc., can solve the problems of uncontrollable precision and low efficiency, and achieve the effect of avoiding coke overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

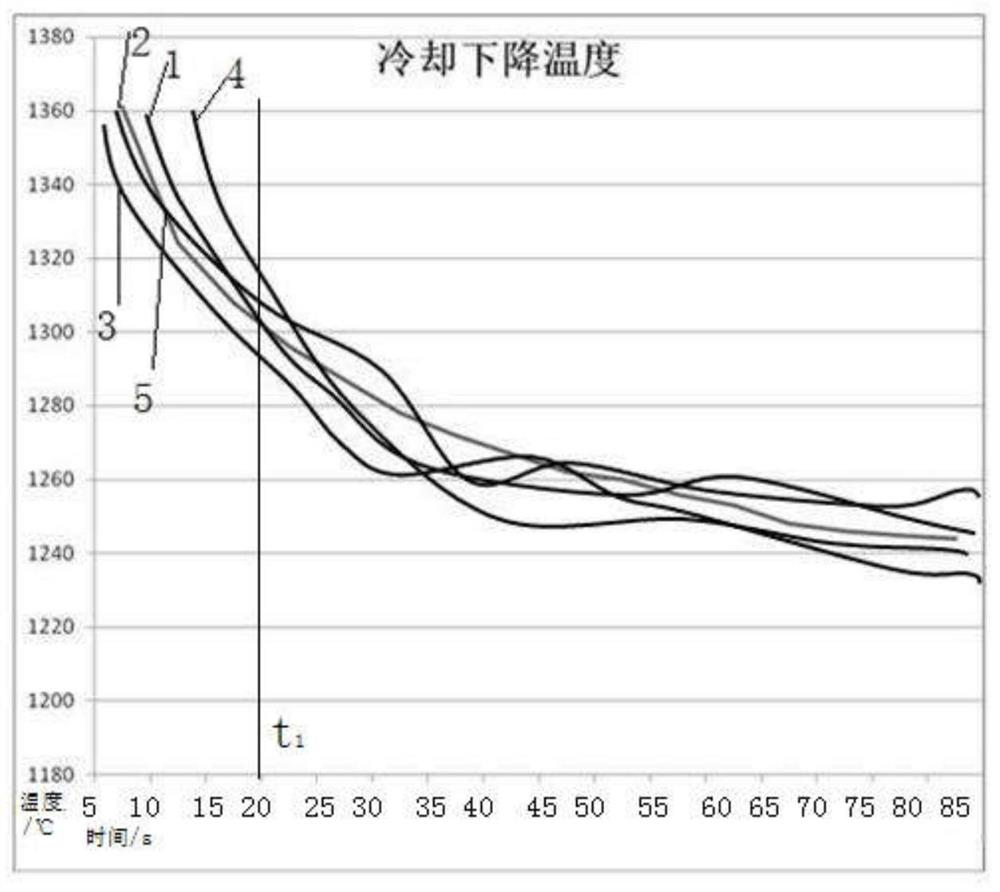

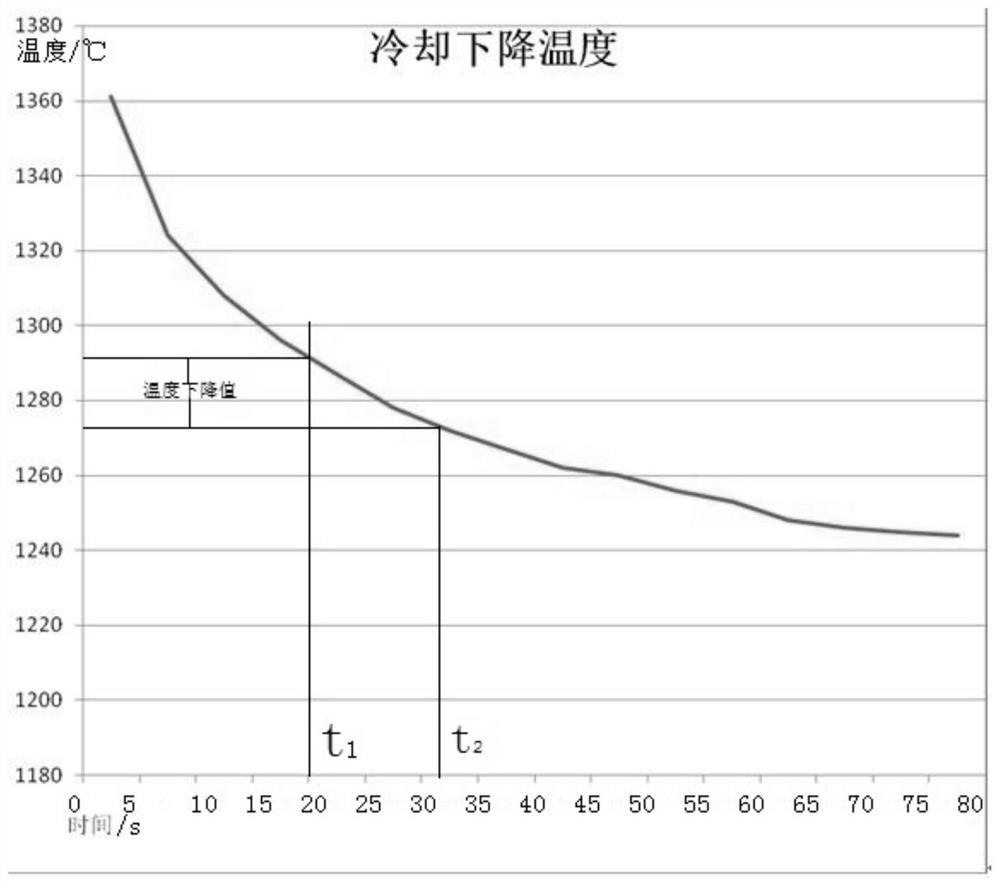

[0036] When the coke oven combustion chamber is taken as 60 holes, there are 61 combustion chambers, and the straight-line temperature of each combustion chamber is calculated as: Take time t 1 is a fixed value after coke oven exchange, preferably 20s, and the cooling drop temperature curves of all combustion chambers are obtained according to the above-mentioned modeling method,

[0037] Select N=1, that is, 5 fixed combustion chambers, 5 is the serial number, measure the temperature every 1 minute, and measure continuously for 27 minutes, take the average value of 6 sets of temperature data measured once as a temperature value, and draw a temperature The T-time t cooling curve is used as the standard cooling drop temperature curve T(t) for a period of time, and is drawn again according to the above method at an interval of 4-6 months to update the previous cooling drop temperature curve, where N is a positive integer.

[0038] In order to specifically illustrate the present ...

Embodiment 2

[0049] When the coke oven combustion chamber is taken as 60 holes, there are 61 combustion chambers, and the straight-line temperature of each combustion chamber is calculated as: Take time t 1 It is a fixed value after the coke oven is exchanged, preferably 20s. According to the above measurement method, the cooling drop temperature value curve of all combustion chambers is obtained. For all combustion chambers, the temperature is measured every 1 minute, and the temperature is measured continuously for 27 minutes, and the temperature value of each measurement is taken and time, draw a temperature T-time t cooling curve as the corresponding combustion chamber cooling drop temperature curve T in a period of time x (t), draw again according to the above method at an interval of 4-6 months, and update the previous cooling drop temperature curve, wherein N is a positive integer.

[0050] Calculate the straight-ahead temperature of the X-th combustion chamber, and the temperature-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com