Vegetable distribution box

A side dish box and box body technology, which is applied in the field of cooking machines, can solve the problems of reducing the complexity of feeding manipulators, accurately controlling the order of ingredients in the pan, and adversely affecting the taste of dishes, etc., to achieve rapid connection and reduce complexity , to avoid the effect of wasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

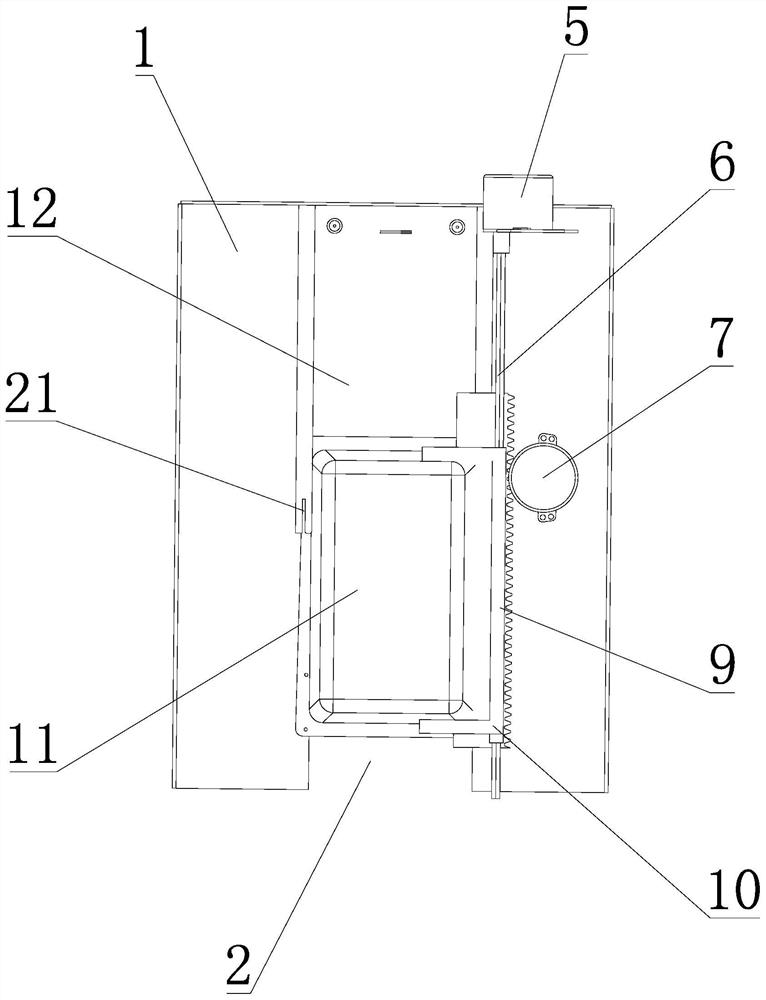

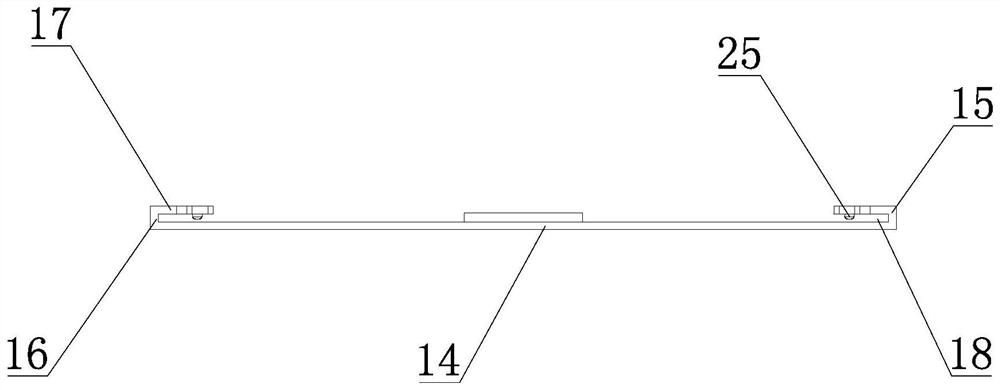

[0039] Such as figure 1 As shown, the blanking plate 1 is arranged obliquely. The blanking plate 1 is provided with a blanking port 2. The blanking port 2 is rectangular and arranged along the length direction of the blanking plate 1. The blanking plate 1 is an inverted U-shaped structure. The blanking port 2 is arranged in the middle of the blanking plate 1 along the width direction of the blanking plate 1 . The near upper end of blanking plate 1 upper end face is provided with mounting bar 3, and the number of mounting bar 3 is two and arranged at intervals, and the right side of mounting bar 3 is provided with the mounting plate 4 perpendicular to blanking plate 1, and the mounting plate The first motor 5 is fixed on the upper end surface, the output end of the first motor 5 is connected with the upper end of the guide rod 6, the guide rod 6 is parallel to the blanking plate 1 and arranged along the length direction of the blanking plate 1, the guide rod 6 is located in the...

Embodiment 2

[0047] The structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that, as Figure 7As shown, an identification code 26 is provided on the outer surface of the box body 11 . The identification code 26 records information such as the type of dishes, the composition of side dishes, and the frying time of different side dishes in the pot. 26 to identify and check whether the composition of the side dishes in the side dish box is consistent with the customer’s ordering requirements, so as to avoid the dish not meeting the customer’s needs due to the wrong call of the side dish box, so as to form a correction effect and improve the efficiency of automatic cooking at the same time Avoid wasting food. Further, after the loading manipulator moves the side dish box to the unloading plate 1, the identification module of the numerical control system identifies the identification code 26, and after the identification module reads the information of th...

Embodiment 3

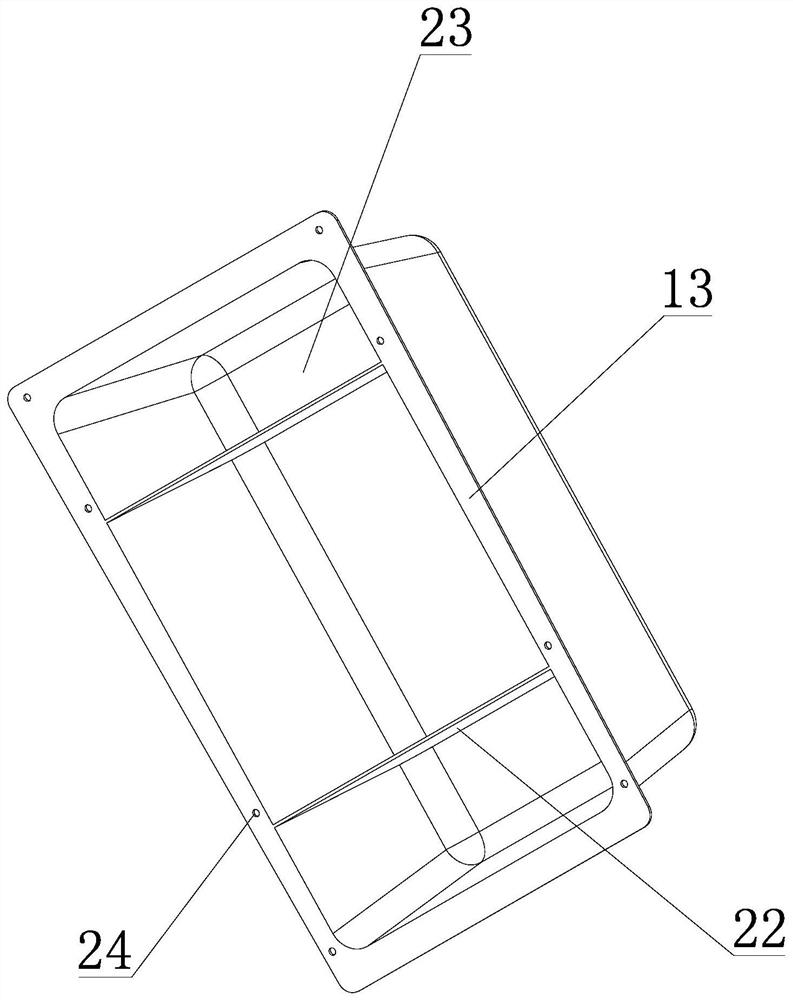

[0051] The structure of this embodiment is roughly the same as that of Embodiment 2, the difference is that, as Figure 8 As shown, the box body 11 is provided with three partitions 22, and the three partitions divide the box body 11 into 4 grids. The compartments are two compartments of different sizes. According to different recipes, put two kinds of main ingredients with different or the same weight. The fourth compartment is for later auxiliary materials, such as coriander, green onion, sesame, etc. After that, the auxiliary materials are placed. There is a logo on the outer surface of the box body 11 code 26, and the opening end of the box body 11 is provided with a position identification code 27. If there are two main ingredients, according to the read identification code 26 information, combined with the recipe to determine the order of the two main ingredients, whether to put them one after another or at the same time, the interval between the two main ingredients can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com