Large-leaf thick laver crisp chip and related production method

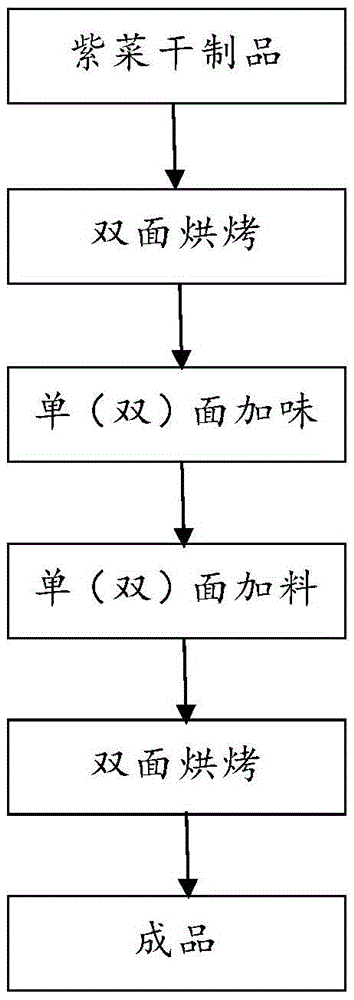

A production method and large-leaf technology, which are applied in food science and other directions, can solve the problems of destroying the structure of laver leaves, difficult to measure accurately, and difficult to attach accessories, and achieve the effects of being suitable for large-scale popularization and application, easy to bake, and convenient to eat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Select the unit area gram weight of 15.3mg / cm 2 1. 750 grams of dried seaweed sheets (Ruixue Ocean Foods (Zhangzhou) Co., Ltd., dried seaweed, 5.5 grams per piece) with the longest leaf body length of 3 cm preserved;

[0034] Carry out the first double-sided baking by electric oven then, and wherein baking temperature is 180 ℃, and baking time is 25 seconds / sheet; Thereby thick seaweed is carried out preliminary slaking, and water content reduces less than 10% weight (according to GB5009.3- 2010 National Food Safety Standard Determination of Moisture in Food);

[0035]Spray 110g of prepared edible seasoning (1.1g of edible vegetable oil (edible soybean oil), 49.5g of sugar, 27.5g of maltodextrin, 12.65g of starch, 2.75g of edible salt, 5.5g of soy sauce, 11g of spice (pepper)) Sprinkle on the upper surface of the laver sheet;

[0036] Sprinkle edible auxiliary material 140g evenly on the laver sheet, utilize the adhesive force of edible seasoning to absorb edible auxi...

Embodiment 2

[0039] Select the weight per unit area of 16mg / cm 2 1. 790 grams of dry laver sheets with the longest leaf body length of 5 cm (Ruixue Ocean Foods (Zhangzhou) Co., Ltd., dry altar laver, 6.5 grams per piece);

[0040] Carry out the first double-sided baking by electric oven then, and wherein baking temperature is 170 ℃, and baking time is 30 seconds / sheet; Thereby thick seaweed is carried out preliminary slaking, and water content reduces less than 10% weight (according to GB5009.3- 2010 National Food Safety Standard Determination of Moisture in Food);

[0041] Spray 110g of prepared food seasoning (1.1g of edible vegetable oil (edible peanut oil), 55g of sugar, 22g of maltodextrin, 5.5g of starch, 0.55g of edible salt, 16.5g of soy sauce, 9.35g of spices (scallions)) on the The upper and lower sides of the laver sheet;

[0042] Sprinkle 100g of edible auxiliary material (peanut) evenly on the top of the laver sheet, and use the adhesive force of the edible seasoning to ad...

Embodiment 3

[0045] Select the weight per unit area of 20mg / cm 2 1. 770 grams of sheets of dried laver (Ruixue Ocean Foods (Zhangzhou) Co., Ltd., dried laver, 7.2 grams per piece) with the longest leaf body length of 2 cm preserved;

[0046] Carry out the first double-sided baking by electric oven then, and wherein baking temperature is 175 ℃, and baking time is 30 seconds / sheet; Thereby thick seaweed is carried out preliminary slaking, and water content reduces less than 10% weight (according to GB5009.3- 2010 National Food Safety Standard Determination of Moisture in Food);

[0047] Spray 100g of prepared edible seasoning (2g of edible vegetable oil (edible corn oil), 55g of sugar, 15g of maltodextrin, 12g of starch, 1g of edible salt, 10g of soy sauce, 5g of spice (laurel)) evenly on the laver sheet. upper and lower sides;

[0048] Sprinkle 130g of edible auxiliary material (pine nuts) evenly on the top of the laver sheet, and use the adhesive force of the edible seasoning to adsorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com