Coke oven burner double-flue supplemental heating method

A supplementary heating and coke oven technology, which is applied in the heating of coke ovens, coke ovens, and combustible gas heating coke ovens, etc., can solve problems such as low calorific value of lean coal gas, interference with thermal management order, and influence on coke quality. The effect of coke oven life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

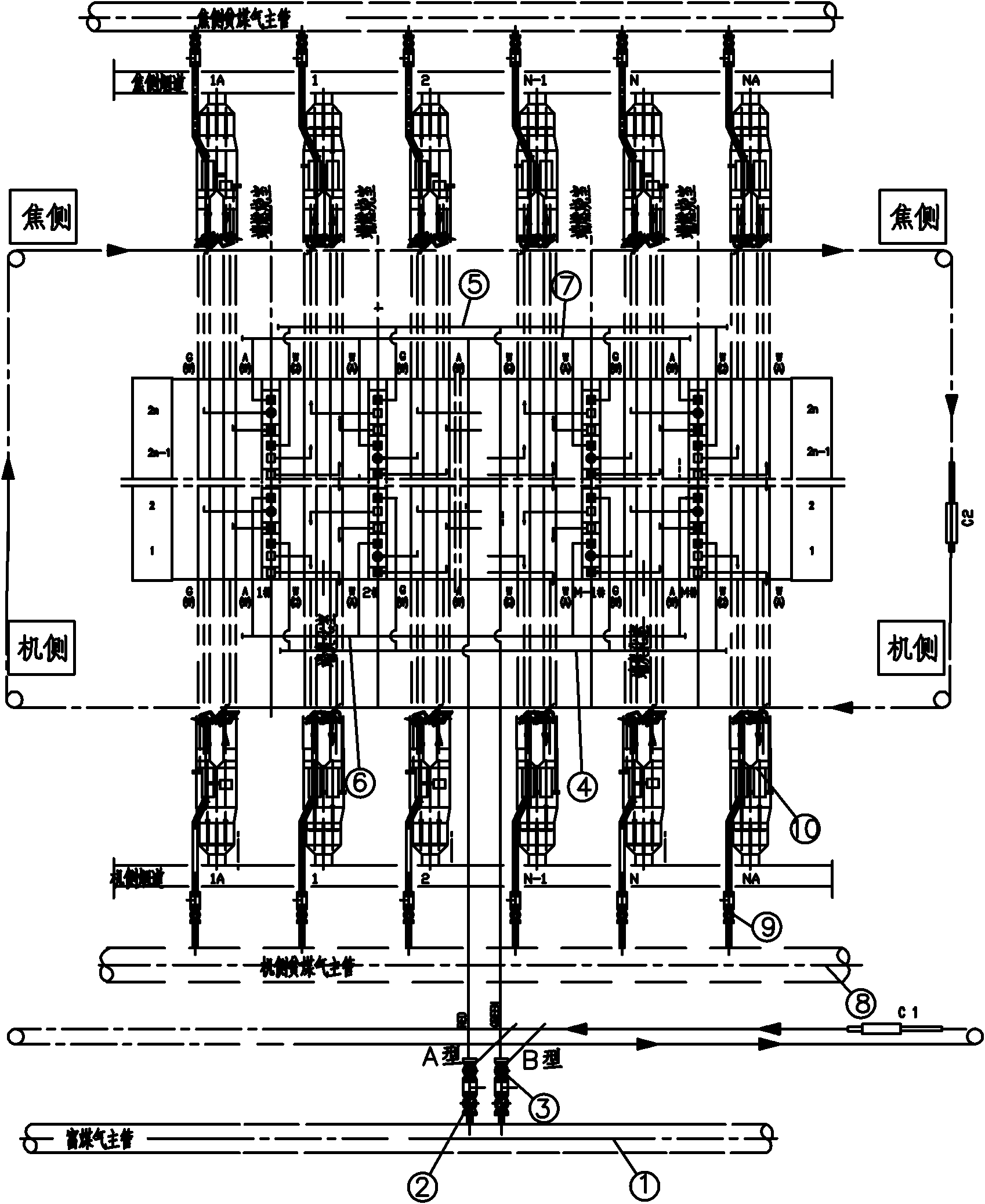

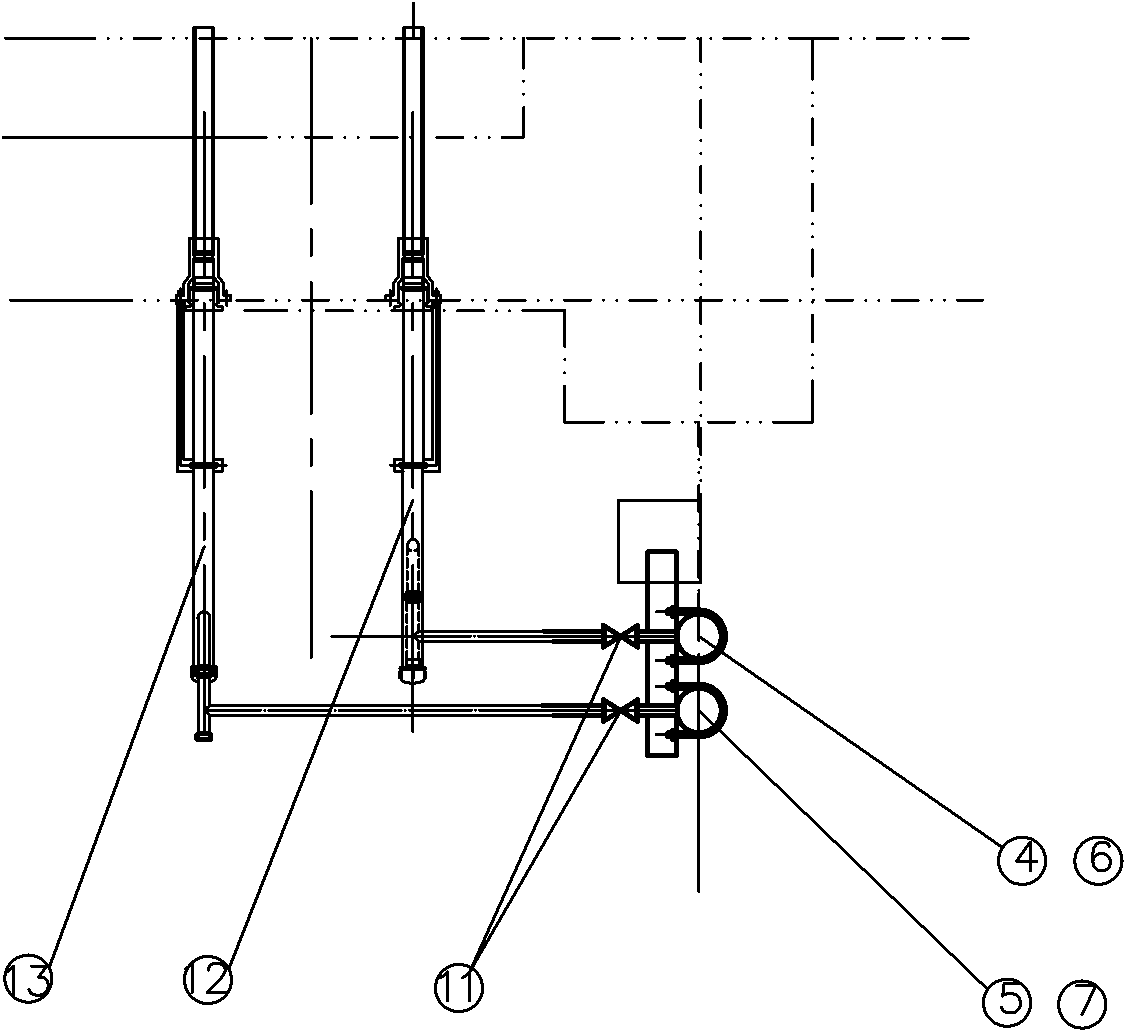

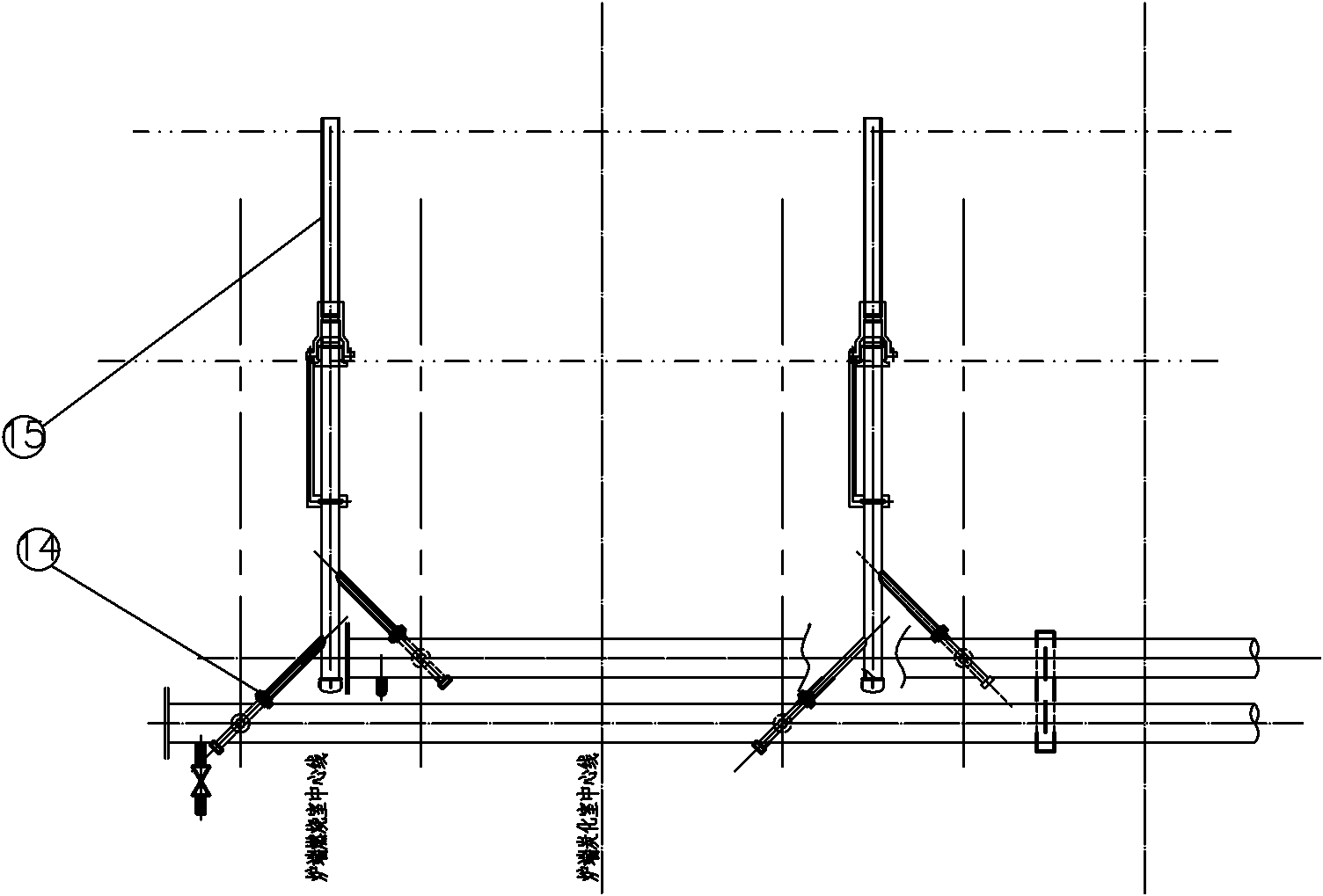

[0022] A method for supplementary heating with double fire passages at the burner head of a coke oven. In this method, two sets of vertical fire passages are used to heat the machine and the burner head on the coke side of the coke oven with lean gas, and the coke oven rich gas is sprayed down to carry out auxiliary supplementary combustion. The gas main pipe 1 is used as a coke oven gas-rich pipeline for supplementary heating, and the rich gas main pipe 1 leads to two gas distribution pipes 4 (or 6) on the coke oven machine and the coke side respectively, and the gas distribution pipe 5 (or 7) is respectively connected to the furnace head two The lower nozzle pipes 12 and 13 of the fire path are connected together. Copper ball valves 11 and stainless steel small orifice plates 14 are installed in front of each lower nozzle to adjust the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com