Heating method for production of formed coke

A heating method and dome technology, which are applied in the field of coal coking, can solve the problems of small coke lumps and large coke content in the burner head, etc., and achieve the effects of reducing generation, ensuring product quality, and ensuring coke lumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

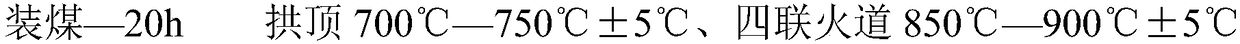

[0020] In the vault and the quadruple fire path, the temperature is raised step by step in different periods, and in the last 160h-195h, the vault is kept at 900°C ± 5°C, and the quadruple fire path is kept at 950°C ± 5°C.

[0021]

[0022] In this embodiment, the temperature of the quadruple flue remains constant, and the temperature of the vault rises slowly.

Embodiment 2

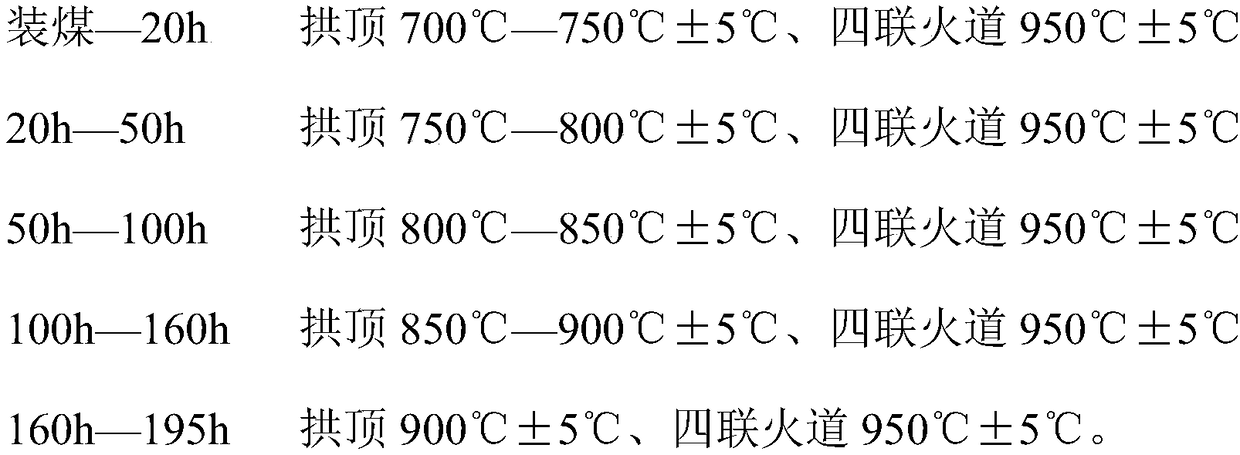

[0024] The heating method generally adopts step-by-step heating in the vault and quadruple fire channels, and keeps the vault at 900°C ± 5°C and the quadruple fire path at 950°C ± 5°C in the last 160h-195h.

[0025] Coal loading—20h vault 900℃±5℃, quadruple flue 850℃—900℃±5℃

[0026] 20h—50h vault 900℃±5℃, quadruple fire channel 850℃—900℃±5℃

[0027] 50h—100h vault 900°C±5°C, quadruple fire path 900°C—950°C±5°C

[0028] 100h—160h vault 900°C±5°C, quadruple fire path 900°C—950°C±5°C

[0029] 160h—195h Vault 900℃±5℃, quadruple fire channel 950℃±5℃.

[0030] In this embodiment, the temperature of the vault remains constant, and the temperature of the quadruple fire channels rises slowly.

Embodiment 3

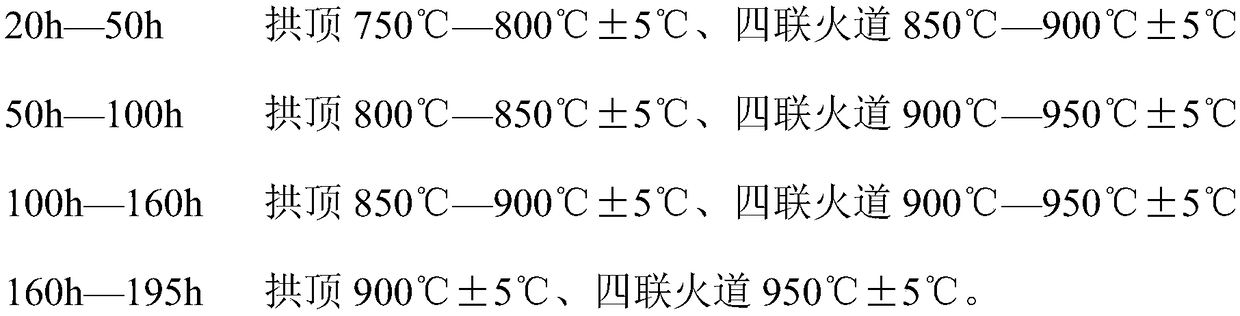

[0032] The heating method generally adopts step-by-step heating in the vault and quadruple fire channels, and keeps the vault at 900°C ± 5°C and the quadruple fire path at 950°C ± 5°C in the last 160h-195h.

[0033]

[0034]

[0035] In this example, starting from coal loading, the vault temperature rises with a gradient of 50°C at 0-20h, 20-50h, 50-100h, and 100-160h, from 700°C to 750°C±5°C to 850°C— 900°C±5°C, and keep at 900°C±5°C for 160h-195h. The temperature of the quadruple flue rises with a gradient of 50°C at 0-50h and 50-160h, from 850°C-900°C±5°C to 900°C-950°C±5°C, and keeps at 950°C from 160h-195h ±5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com