Preparation method of low-temperature cured prefabricated meat product

A technology for low-temperature curing and meat products, which is applied in the direction of food science, etc. It can solve the problems of not promoting the rapid penetration of salt, unstable taste and quality, and slow penetration of salt, so as to facilitate cold chain transportation, reduce curing time, and be salty and light. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

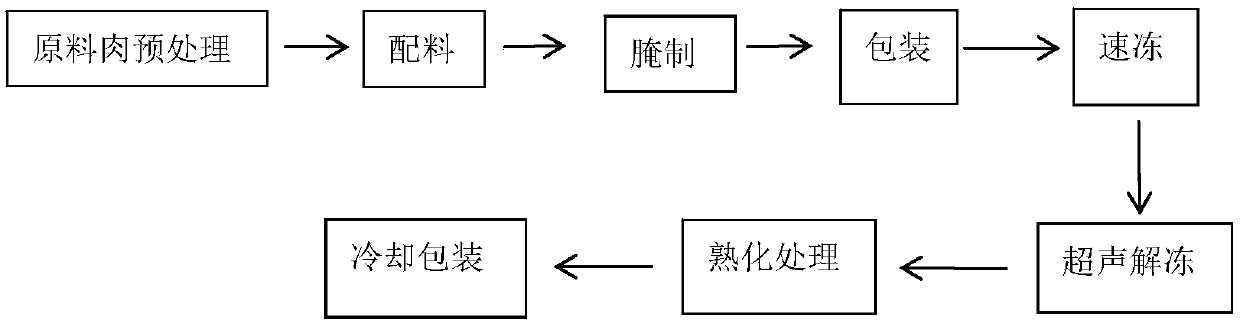

[0028] A kind of preparation method of low-temperature curing prefabricated meat product, see figure 1 , including the following steps:

[0029] (1) Take the raw meat (the ratio of fat to lean is 3:7), slice and rest. Get 1.6wt% salt (the addition of table salt is equivalent to 1.6wt% of raw meat, hereinafter all the same), 0.2wt% compound phosphate, 0.04wt% sodium nitrate, 0.009wt% sodium nitrite, 0.02wt% ascorbic acid, 1.2wt% spices (the ingredients of the spices are: 0.2wt% star anise, 0.2wt% white pepper, 0.3wt% Zanthoxylum bungeanum, 0.3wt% cumin, 0.2wt% cinnamon) were mixed evenly to obtain a mixture. Spread the above mixture evenly on the surface of meat products, and marinate at 15°C for 6 hours to obtain cured meat.

[0030] (2) Vacuum-pack the cured meat, put it into a freezer at -70°C for quick freezing for 24 hours to obtain frozen meat.

[0031] (3) The frozen meat was sonicated at an ultrasonic frequency of 50 kHz for 3 minutes with an ultrasonic machine, and ...

Embodiment 2

[0035] A method for preparing low-temperature cooked prefabricated meat products, comprising the following steps:

[0036] (1) Take the raw meat (the ratio of fat to lean is 3:7), slice and rest. Get 1.6wt% (the addition of salt is equivalent to 1.6wt% of raw meat, hereinafter all the same) salt, 0.2wt% compound phosphate, 0.04wt% sodium nitrate, 0.009wt% sodium nitrite, 0.02wt% ascorbic acid, 1.0wt% chili powder, 1.2wt% spices (the ingredients of spices are: 0.2wt% star anise, 0.2wt% white pepper, 0.3wt% Zanthoxylum bungeanum, 0.3wt% fennel, 0.2wt% cinnamon) were mixed evenly to obtain a mixture. Spread the above mixture evenly on the surface of meat products, and marinate at 15°C for 6 hours to obtain cured meat.

[0037] (2) Vacuum-pack the cured meat, put it into a freezer at -70°C for quick freezing for 24 hours to obtain frozen meat.

[0038] (3) The frozen meat was sonicated at an ultrasonic frequency of 50 kHz for 3 minutes with an ultrasonic machine, and then cooked...

Embodiment 3

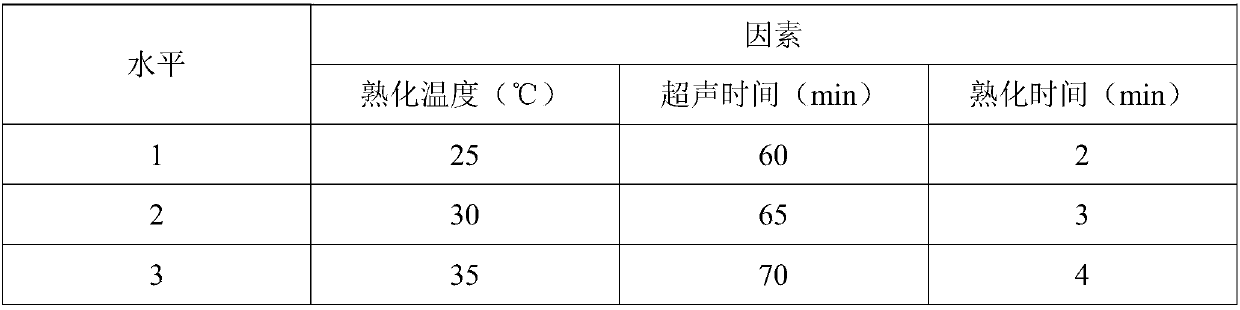

[0043] A method for preparing low-temperature cooked prefabricated meat products. According to the method of Example 1, experiments are carried out with the orthogonal design tables in Table 1 and Table 2, and the effects of curing temperature, ultrasonic time, and curing time on the quality of low-temperature cooked prefabricated meat products are investigated respectively. influences.

[0044] Table 1: Factor level table

[0045]

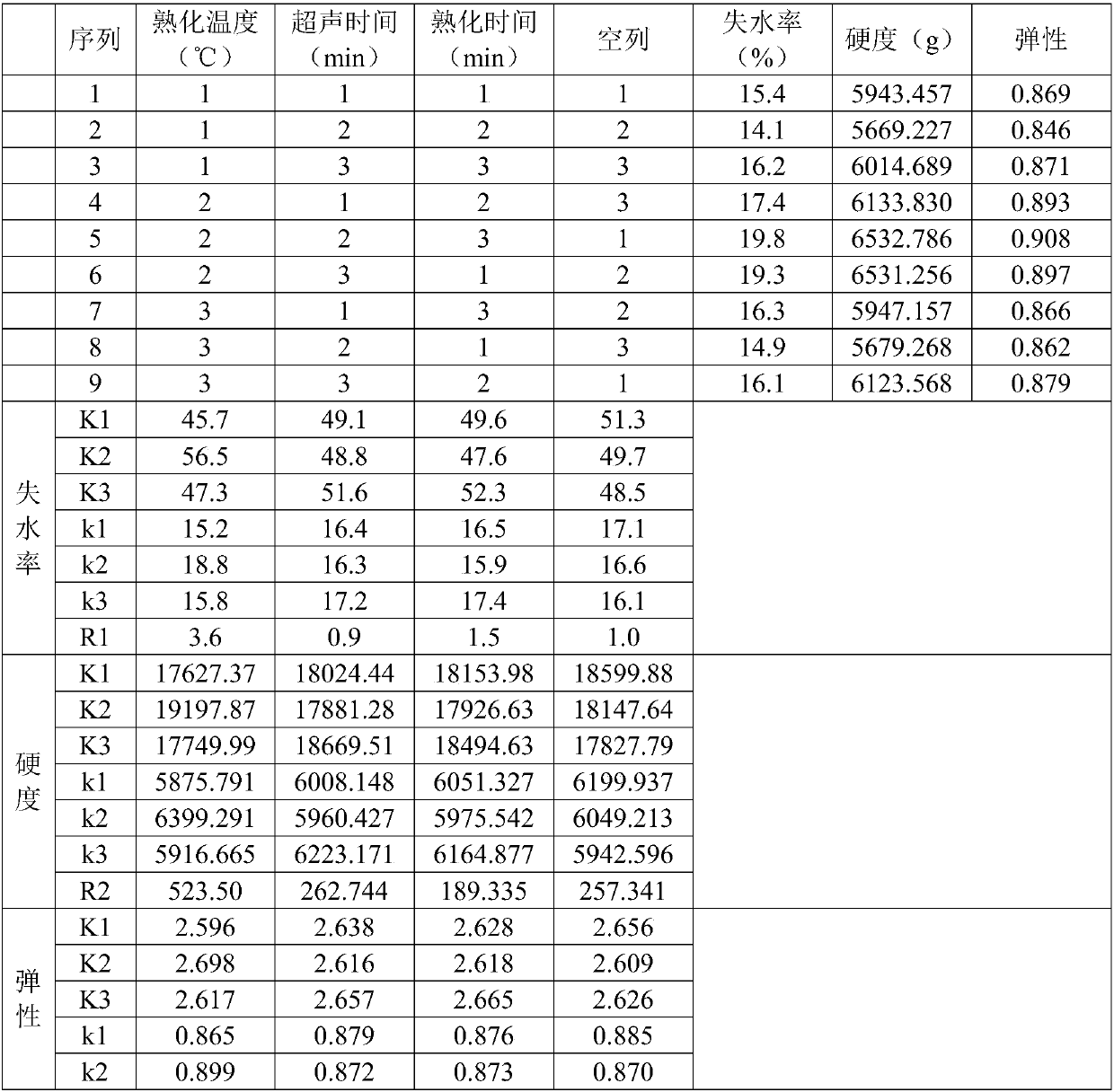

[0046] Table 2: Orthogonal Design Table

[0047]

[0048]

[0049] From the comparison of the R value of each factor in the orthogonal test design table of Table 1 and Table 2 with the R value of the empty column, it can be concluded that the empty column R>R (ultrasonic time), that is, the impact of ultrasonic time on the water loss rate is No effect. For the water loss rate, R 1 (curing temperature) > R 3 (curing time)>R 2 (Ultrasonic time), that is, the primary and secondary order affecting the water loss rate of pork tenderloin d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com