Rice noodle steaming equipment

A steaming and equipment technology, applied in the field of rice noodle steaming equipment, can solve the problems of poor taste, low efficiency, and uneven ripening, and achieve the effects of fast production efficiency, avoiding uneven ripening, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

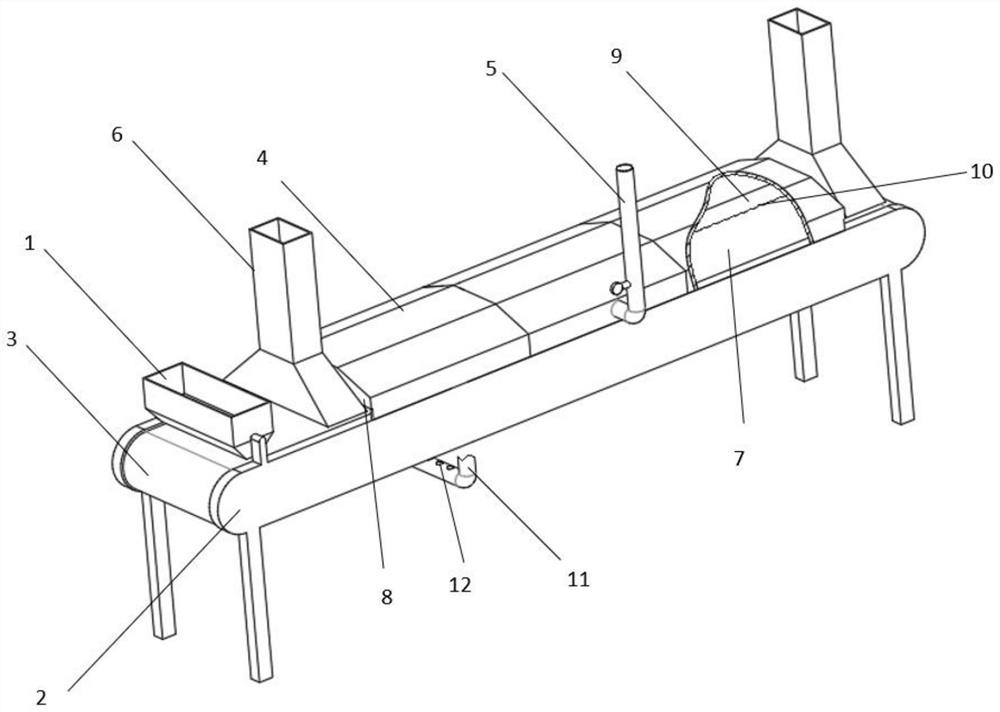

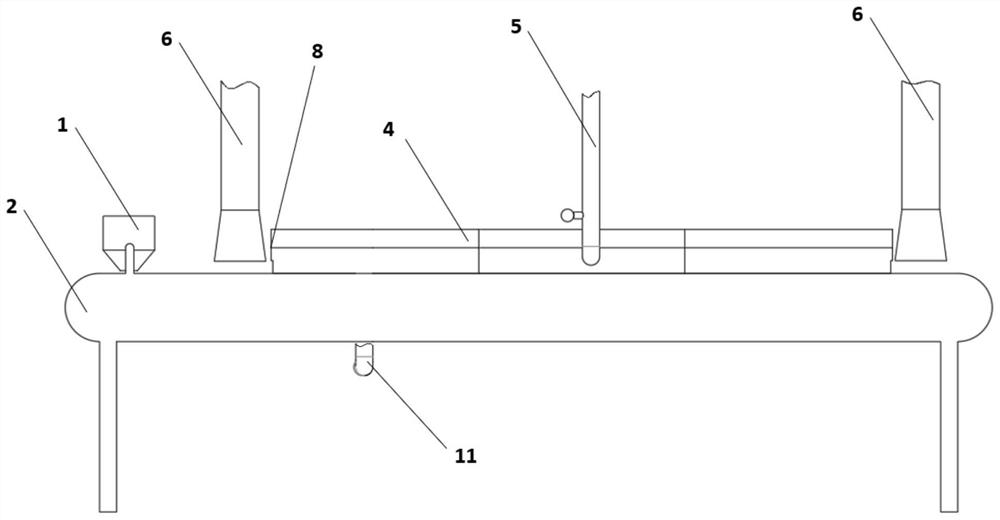

[0032] as attached Figure 1-2 As shown, the present embodiment exemplifies a kind of rice flour steaming equipment of the present invention, comprising a feed hopper 1, a conveyor belt support frame 2, a conveyor belt 3 arranged on the conveyor belt support frame 2, a steam cover 4, and a steam pipe 5 and two steam overflow pipes 6, the feeding hopper 1 is positioned on the conveyor belt support frame 2 at the starting end of the conveyor belt 3 through a bracket, and the large mouth of the feeding hopper 1 faces upwards to receive the rice milk sent in the previous process, and the feeding The small mouth of the bucket 1 faces the conveyor belt 3 and is 1 cm vertical to the conveyor belt 3. The rice slurry is sent out from the small mouth and spread on the conveyor belt 3; Shaped steam chamber 7, the two ends of the steam chamber 7 are provided with an end cover 8 sealing the upper part of the port, there is a gap between the bottom of the end cover 8 and the conveyor belt 3...

Embodiment 2

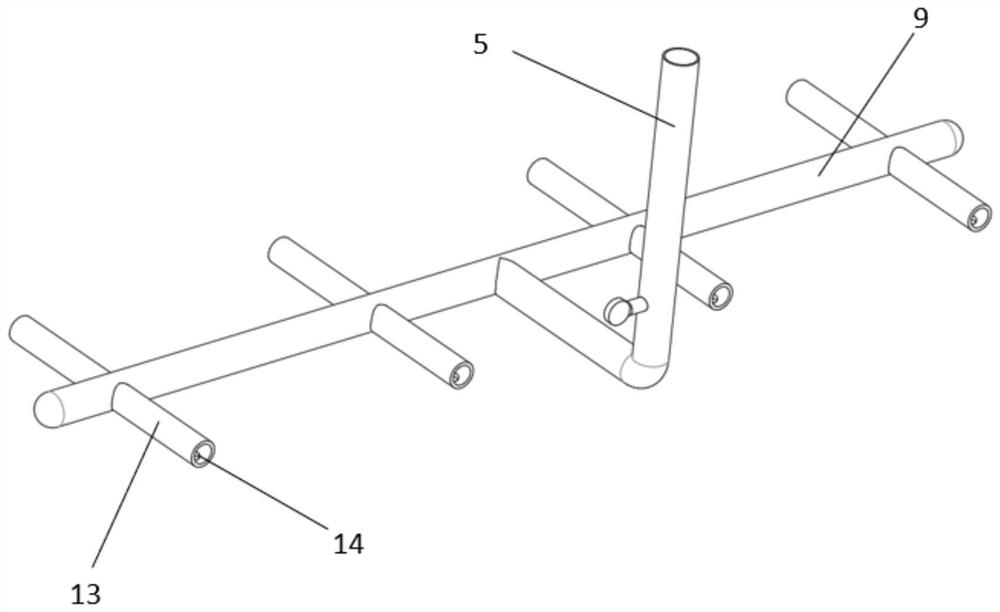

[0034] as attached image 3 As shown, a kind of rice noodle steaming equipment that the present embodiment exemplifies, compared with Embodiment 1, the heating pipe 9 is provided with several heating branch pipes 13 perpendicular to the heating pipe 9 and parallel to the conveyor belt 3, the heating branch pipes The lower part is provided with a number of branch pipe exhaust holes 14 facing the conveyor belt, and more exhaust holes are set in multiple positions, steam can be sprayed from multiple positions in the steam chamber for heating, and the rice milk is more evenly cooked and more efficient.

[0035] In the previous process, the rice milk is sent into the feeding hopper 1. The large opening on the top of the feeding hopper 1 can prevent the rice milk from overflowing, and the small opening below the feeding hopper 1 continuously pours the rice milk onto the conveyor belt 3 to form a covering on the conveyor belt. 3. The rice milk belt on the upper surface, the conveyer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com