Production method of instant rice soup

A production method and technology of instant rice, applied in the direction of food drying, food science, etc., can solve the problems of unsatisfactory sensory and taste, unhealthy non-dairy pigment, poor brewing performance, etc., to avoid puffing, ideal bulkiness, Good brewing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

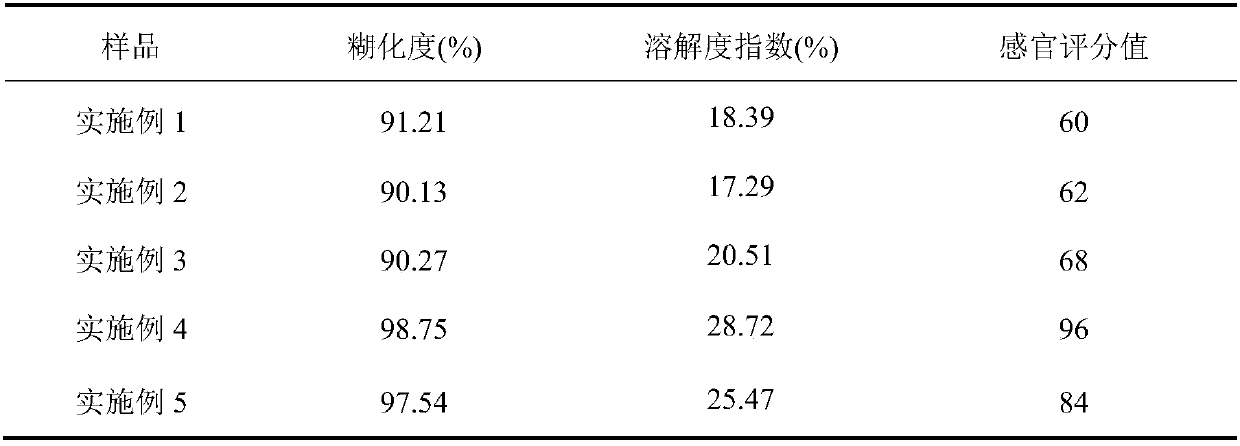

Embodiment 1

[0020] Weigh 7kg of rice, 1kg of oats, 1kg of corn, 0.5kg of millet and 0.5kg of barley, and spray 1.2kg of aqueous solution on the outer layer of raw materials evenly after atomization by atomization equipment; the spraying time is 10 minutes, and the liquid after atomization of aqueous solution The droplet average particle size is 10 μm. Superheated steam expansion treatment, the temperature is 175°C, the pressure is 2.6MPa, the treatment is 2min, and then the pressure is released to normal pressure within 0.8s. Grind the above raw materials through a 60-mesh sieve to obtain material A, then weigh 10g of Angel dry yeast and 3g of salt, dissolve them in 2kg of drinking water, add them evenly to material A, stir gently, and then place them in 40 Ferment at ℃ for 40 minutes; after fermentation, use ultrasonic wave for 3 minutes, ultrasonic frequency 32KHz, temperature 40 ℃. Then pour the material into the barrel of the twin-screw extruder at a constant speed for extrusion. The...

Embodiment 2

[0022] Weigh 7kg rice, 1kg oats, 1kg corn, 0.5kg millet and 0.5kg barley, and spray 1.2 kilograms of ethanol aqueous solution on the raw material outer layer evenly after atomizing by atomization equipment; wherein, the mass ratio of ethanol and water is 1: 10. The spraying time is 10 minutes, and the average particle size of the droplets after atomization of the ethanol aqueous solution is 10 μm. Grind the above raw materials through a 60-mesh sieve to obtain material A, then weigh 10g of Angel dry yeast and 3g of salt, dissolve them in 2kg of drinking water, add them evenly to material A, stir and mix them gently, and then place them in 40 Ferment at ℃ for 40 minutes; after fermentation, use ultrasonic wave for 3 minutes, ultrasonic frequency 32KHz, temperature 40 ℃. Then pour the material into the barrel of the twin-screw extruder at a constant speed for extrusion. The temperature setting is: 70°C in the first zone, 120°C in the second zone, and 85°C in the third zone. Unde...

Embodiment 3

[0024] Weigh 7kg of rice, 1kg of oats, 1kg of corn, 0.5kg of millet and 0.5kg of barley, and spray 1.2 kilograms of ethanol aqueous solution evenly on the outer layer of the raw material after atomizing by atomization equipment; wherein, the mass ratio of ethanol to water is 1: 10. The spraying time is 10 minutes, and the average particle size of the droplets after the ethanol aqueous solution is atomized is 10 μm. Superheated steam heating and puffing treatment, the temperature is 175°C, the pressure is 2.6MPa, the treatment is 2min, and then the pressure is released to normal pressure within 0.8s. Crush the above raw materials through a 60-mesh sieve to obtain material A, then weigh 3g of table salt, dissolve it in 2kg of drinking water, add it evenly to material A, stir gently, and then pour the material into the twin-screw extruder at a uniform speed Extrusion is carried out in the barrel of the machine, and the temperature is set to: 70°C in the first zone, 120°C in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com