Transverse tube continuous cooking and steam explosion apparatus for biomass cellulosic ethanol

A technology of cellulose ethanol and steam explosion equipment, which is applied in the direction of digesters, fiber raw material processing, textiles and papermaking, etc., and can solve the problems that the continuous steaming system is not suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

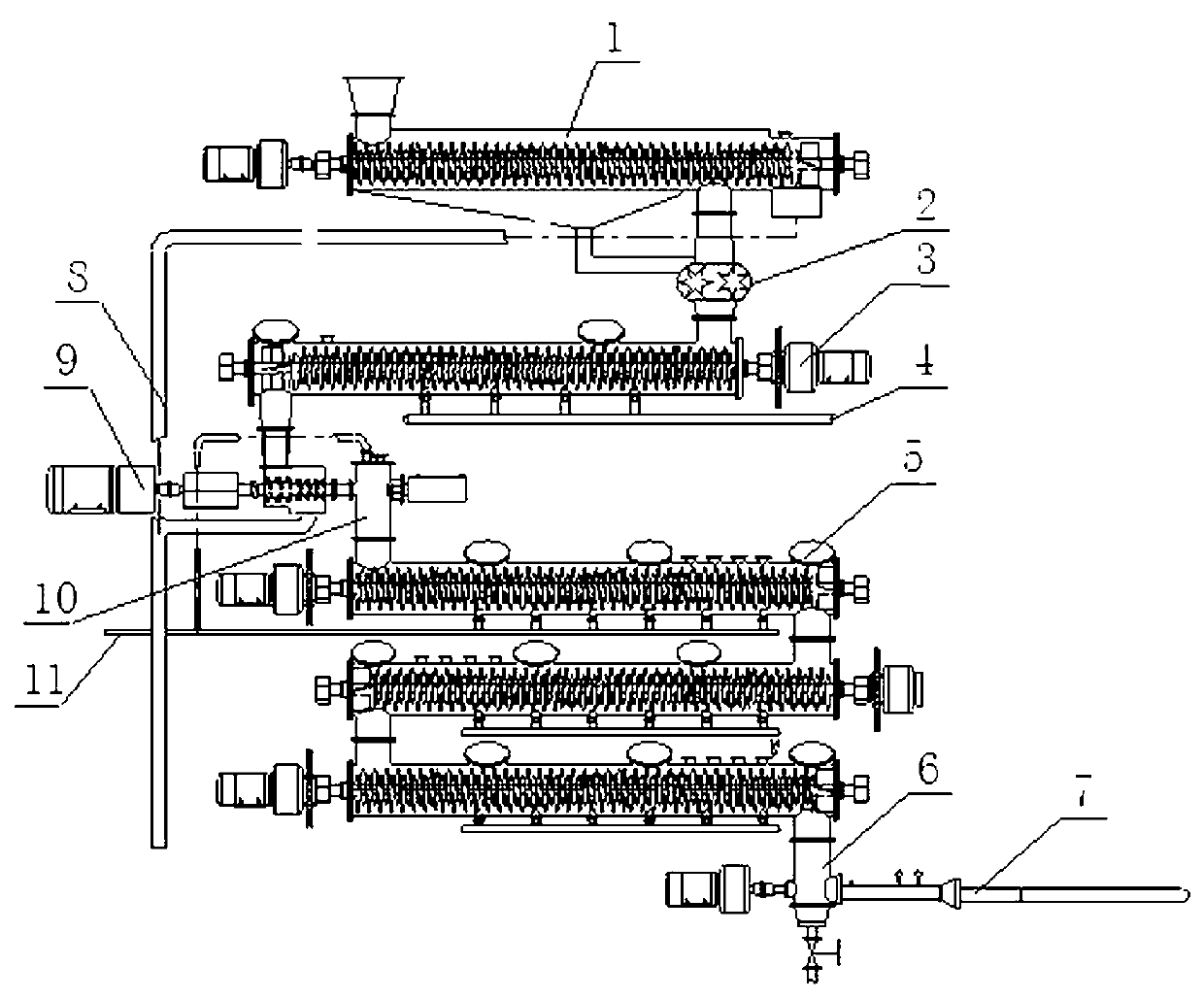

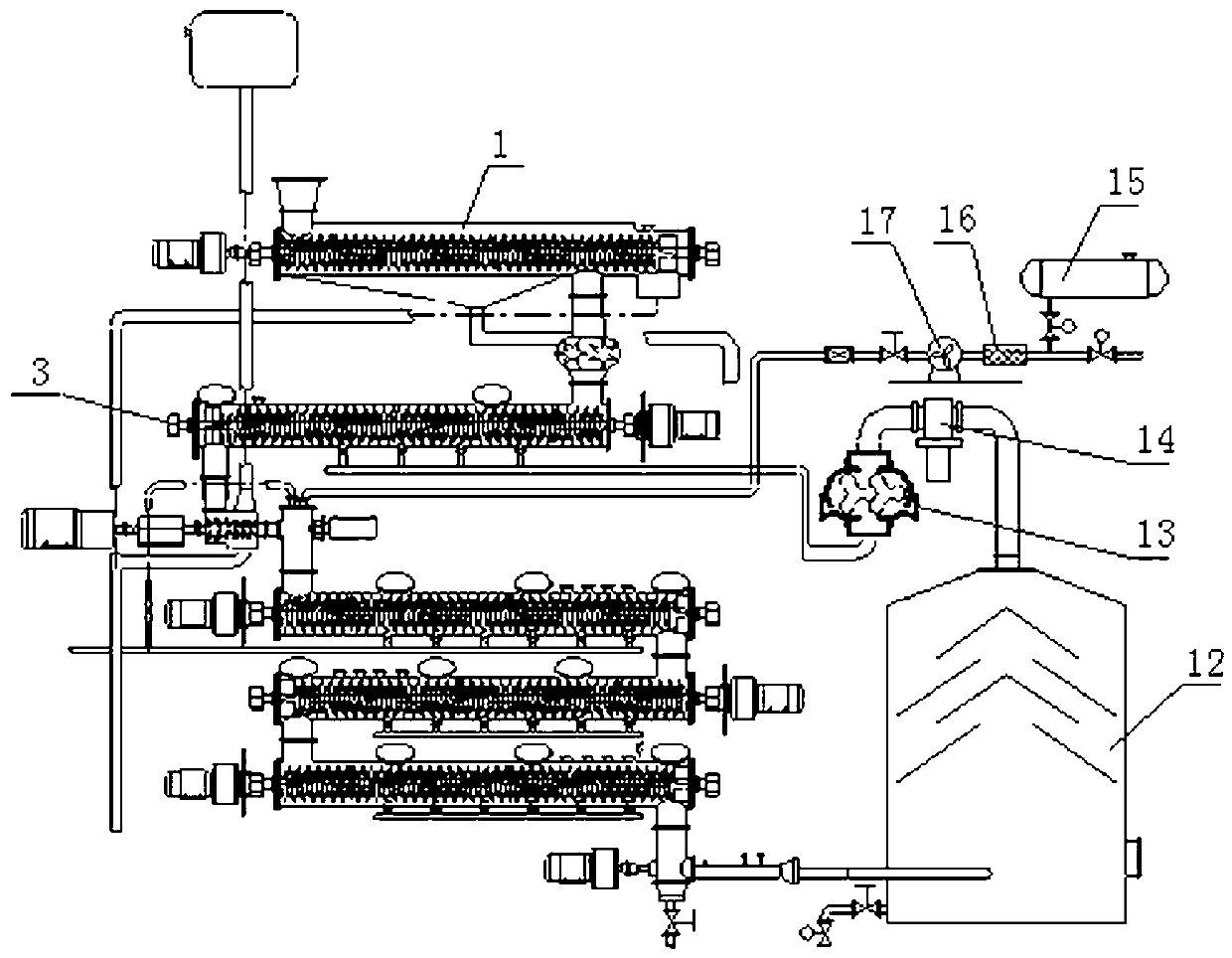

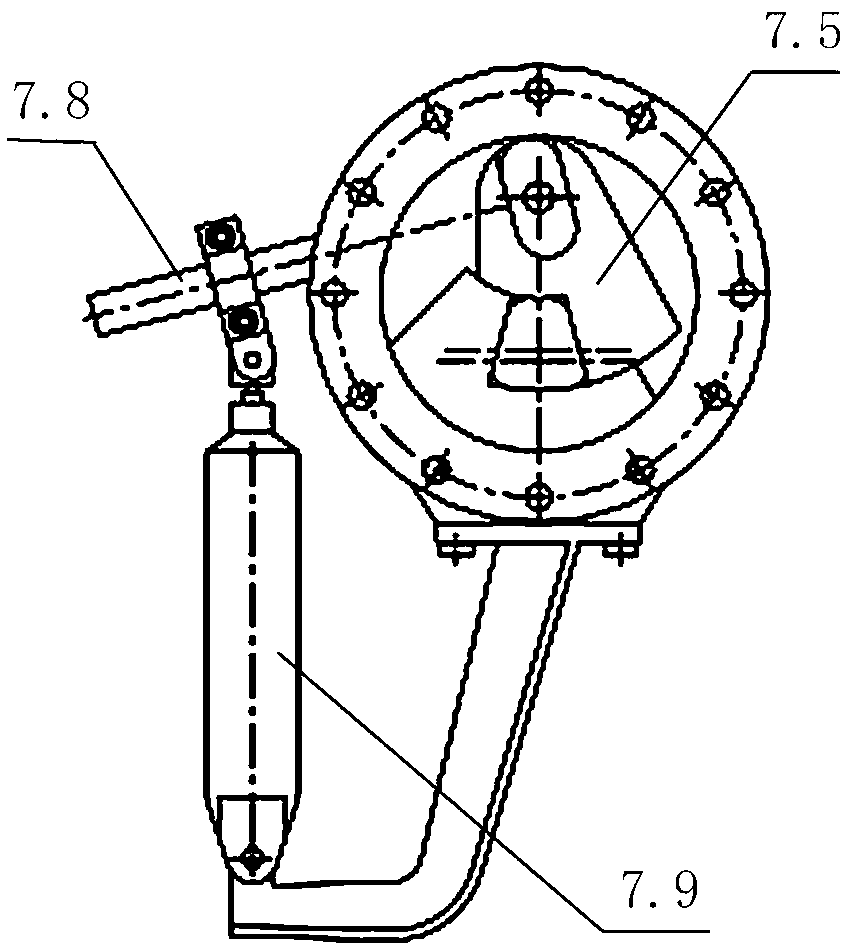

[0016] Such as figure 1 , 2 The biomass cellulose ethanol horizontal tube continuous cooking steam explosion equipment shown in . The cooking pipe 5 is connected, and the horizontal cooking pipe is composed of a steaming pipe, a central shaft and a spiral blade, and the steaming pipe is connected with a steam input pipeline 11, and the spiral blade is composed of a plurality of spiral blades with different pitches and different diameters, so that the pitch is between Unequal distances are formed within a certain range to ensure that the material filling between the pitches reaches the maximum value. On the edge of the smaller-diameter helical blade, there are setting teeth, and the two adjacent teeth are inclined to the two sides respectively, so as to ensure that the solid material is fluffy, separated and not agglomerated during the turning process. The outlet of the horizontal cooking pipe is connected with a horizontal feeder 6 , the helical blades of the feeding screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com