Granule material vibration cooling machine

A technology for granular materials and coolers, applied to direct contact heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve problems such as long-term storage, loss of manufacturers, hardening, etc., and facilitate inspection and maintenance , Improve the cooling effect and avoid the effect of material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

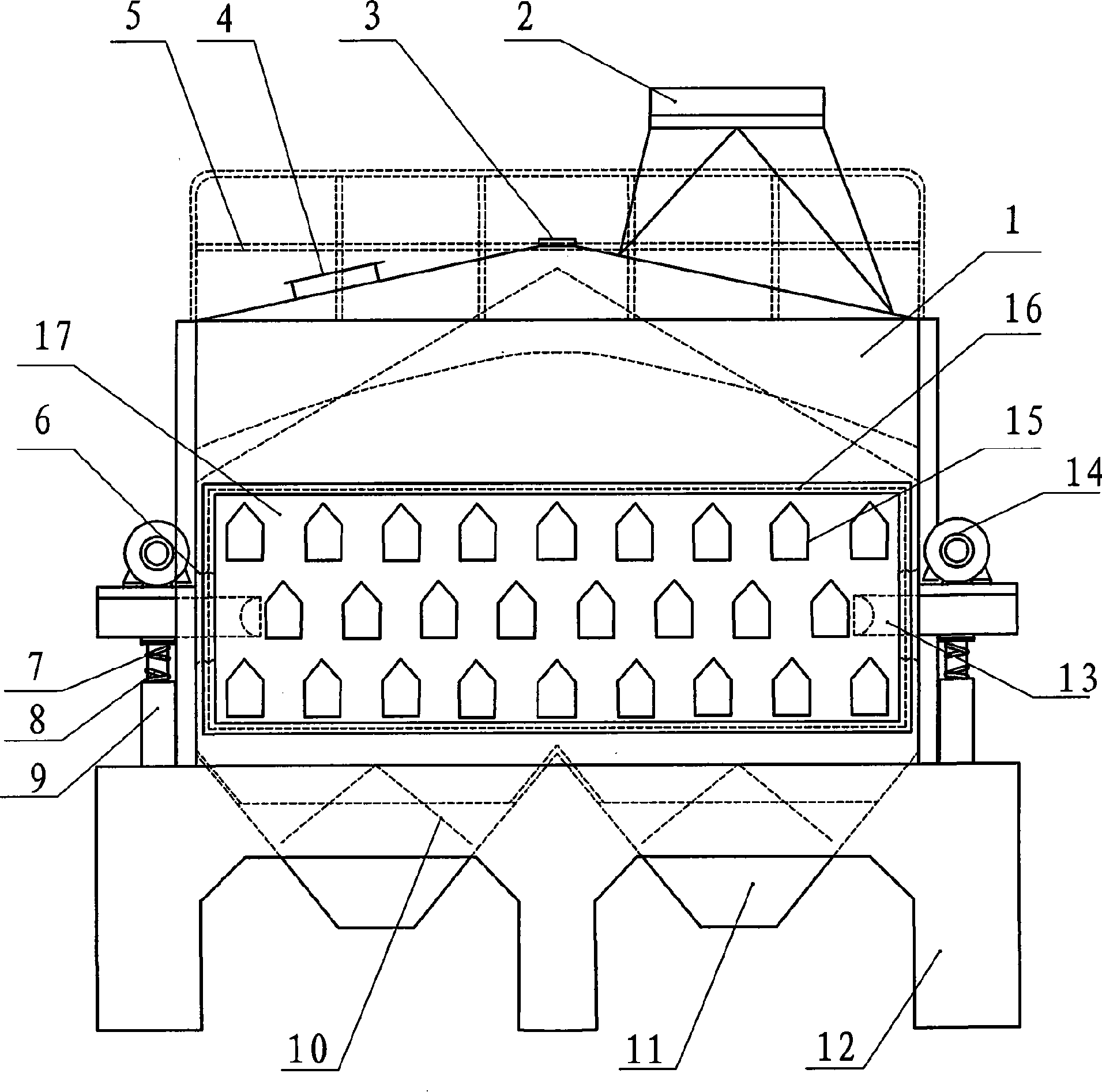

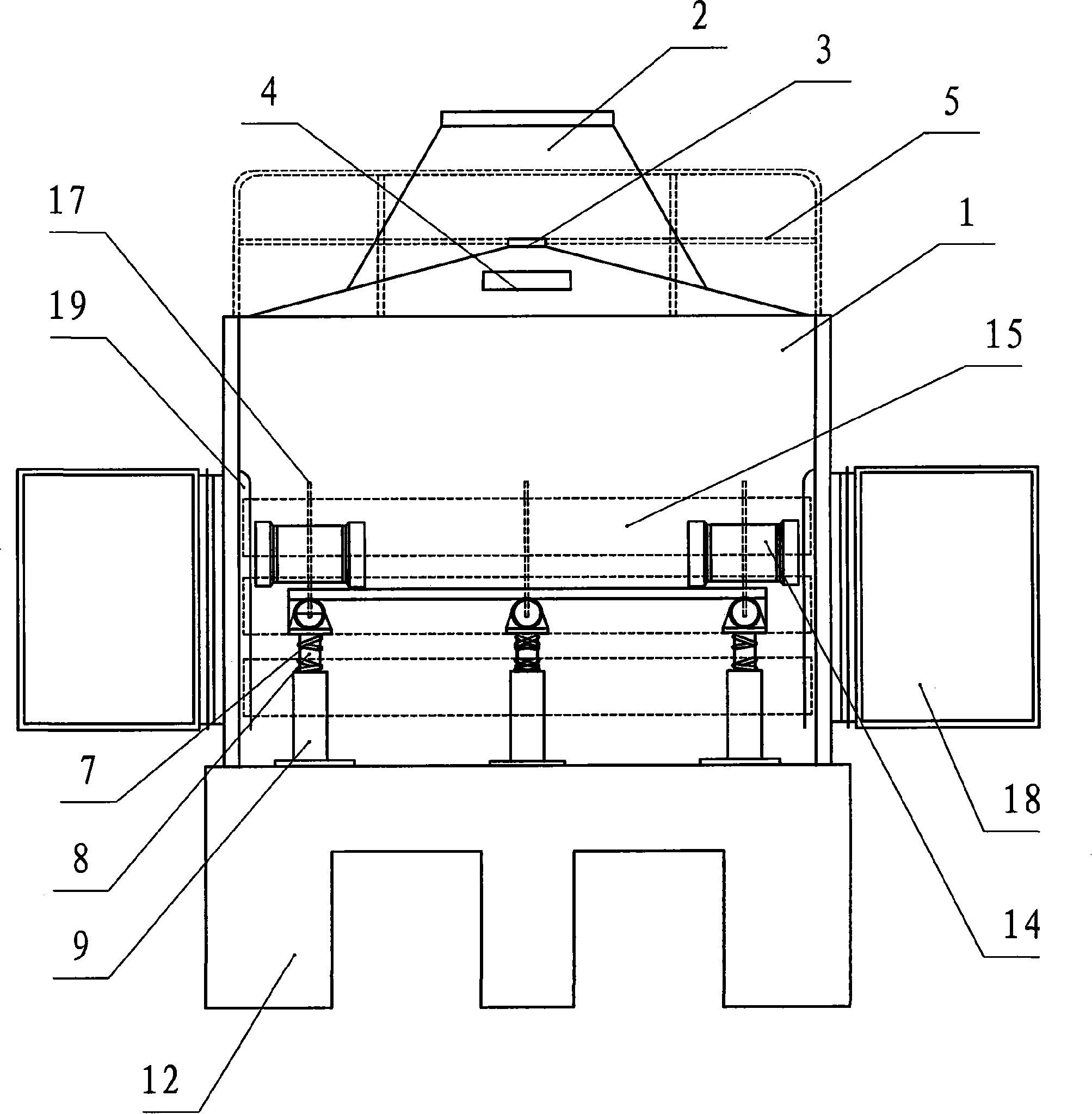

[0027] Embodiment one: see figure 1 , figure 2 , one A granular material vibrating cooler, including a ventilation mechanism, a material cooling chamber 1 and a vibrating mechanism are fixedly installed on a base 12, the upper part of the material cooling chamber 1 is provided with a material inlet 3 and an air outlet 2, and the lower part is provided with an outlet The feed port 11 is provided with an air inlet 16 on both corresponding side walls of the material cooling chamber 1, and the air inlet 16 is connected to the air inlet pipe 18; the ventilation mechanism is installed in the material cooling chamber 1 and includes a plate frame Skeleton 17, a certain number of air grooves 15; the air grooves 15 are opened downward, and the air grooves 15 are at least two layers, arranged in parallel and staggered, passing through and fixed on at least two of the above-mentioned plate frame skeletons 17; The two ends of the air groove 15 face the air inlet 16 and communicate with...

Embodiment 2

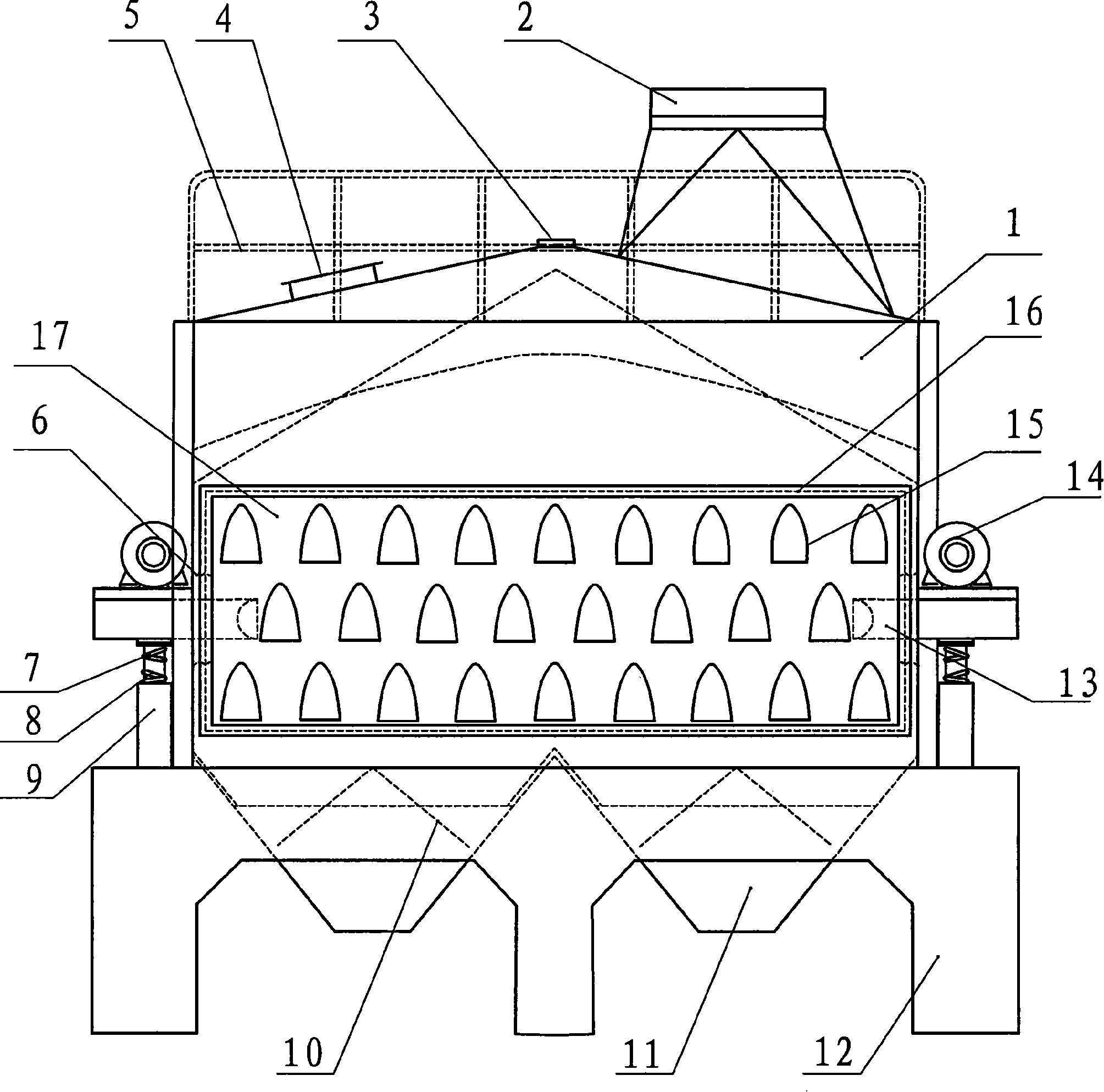

[0029] Embodiment two: see figure 2 , image 3 , Embodiment 2 is basically the same as Embodiment 1. The same symbols in the figure represent the same meanings, and the same parts will not be repeated. The difference is that the cross section of the air duct 15 described in Embodiment 2 is a hollow parabolic shape.

Embodiment 3

[0030] Embodiment three: see figure 2 , Figure 4 Embodiment 3 is basically the same as Embodiment 1. The same symbols in the figure represent the same meanings, and the similarities will not be repeated. The difference is that the cross-section of the ventilation groove 15 described in Embodiment 3 is a hollow elliptical arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com