Method for baking treatment on preserved fruits and baking room therefor

A processing method and drying room technology, applied in the fields of application, confectionery, confectionery industry, etc., can solve the problems of long baking time, poor product quality, long fruit feeding time, etc., and achieve short baking time and high efficiency , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The roasting treatment method of the preserved fruit adopts the following process steps.

[0026] 1. Send the material to be baked into a microwave drying oven with a microwave frequency of 2450 MHz. After microwaves, 55% of the moisture in the material will be removed, and the temperature of the material itself will reach 77°C;

[0027] 2. The material after microwave dehydration enters the drying room, and is baked in three different temperature zones of 75-80°C, 80-90°C and 70-80°C in sequence, and the total baking time is 9 hours; Get qualified preserved fruit;

[0028] 3. It is necessary to ensure that the temperature difference between the three areas of the drying room is 75-80°C, 80-90°C, and 70-80°C. The humidity in the drying room is greater than 50%, and the moisture can be discharged normally.

Embodiment 2

[0029] Embodiment 2: The roasting treatment method of the preserved fruit adopts the following process steps.

[0030] 1. Send the material to be baked into a microwave drying oven with a microwave frequency of 2400 MHz, and the material will remove 60% of the moisture through the microwave, and the temperature of the material itself will reach 79°C;

[0031] 2. The material after microwave dehydration enters the drying room, and is baked in three different temperature zones of 75-80°C, 80-90°C and 70-80°C in sequence, and the total baking time is 8 hours; Obtain qualified preserved fruit.

Embodiment 3

[0032] Embodiment 3: The roasting treatment method of the preserved fruit adopts the following process steps.

[0033] 1. Send the material to be baked into a microwave drying oven with a microwave frequency of 2500 MHz. The material will be dehydrated by 50% of the moisture through the microwave, and the temperature of the material itself will reach 75°C;

[0034] 2. The material after microwave dehydration enters the drying room, and is baked in three different temperature zones of 75-80°C, 80-90°C and 70-80°C in sequence, and the total baking time is 10 hours; Obtain qualified preserved fruit.

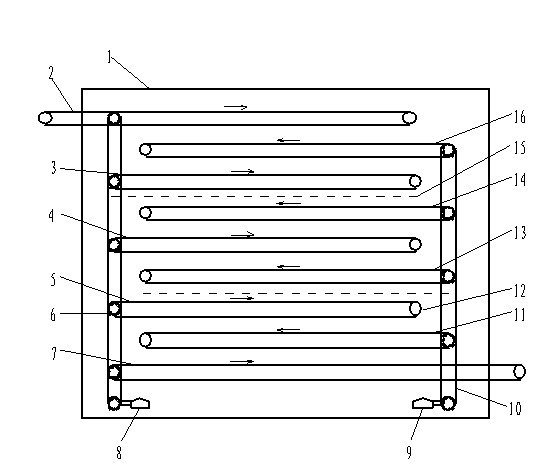

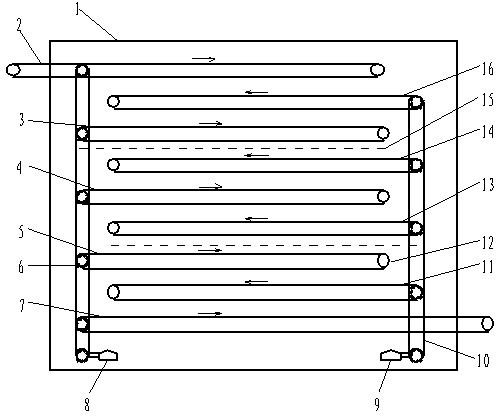

[0035] figure 1 As shown, the drying room includes a main body 1 of the drying room and an automatic moisture removal device. The main body of the drying room 1 has the same structure as the main body of a conventional drying room. A material inlet is opened on the upper part of the front end side of the main body of the drying room, and a material outlet is opened on the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com