Cutting motif fabric and method of manufacture

A technology of patterned fabrics and weaves, which is applied in the direction of digging fabrics, textiles, papermaking, fabrics, etc., can solve the problems of simple weave structure of yarn-dyed fabrics, and achieve excellent ornamental effects, rich connotations, and soft touch effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

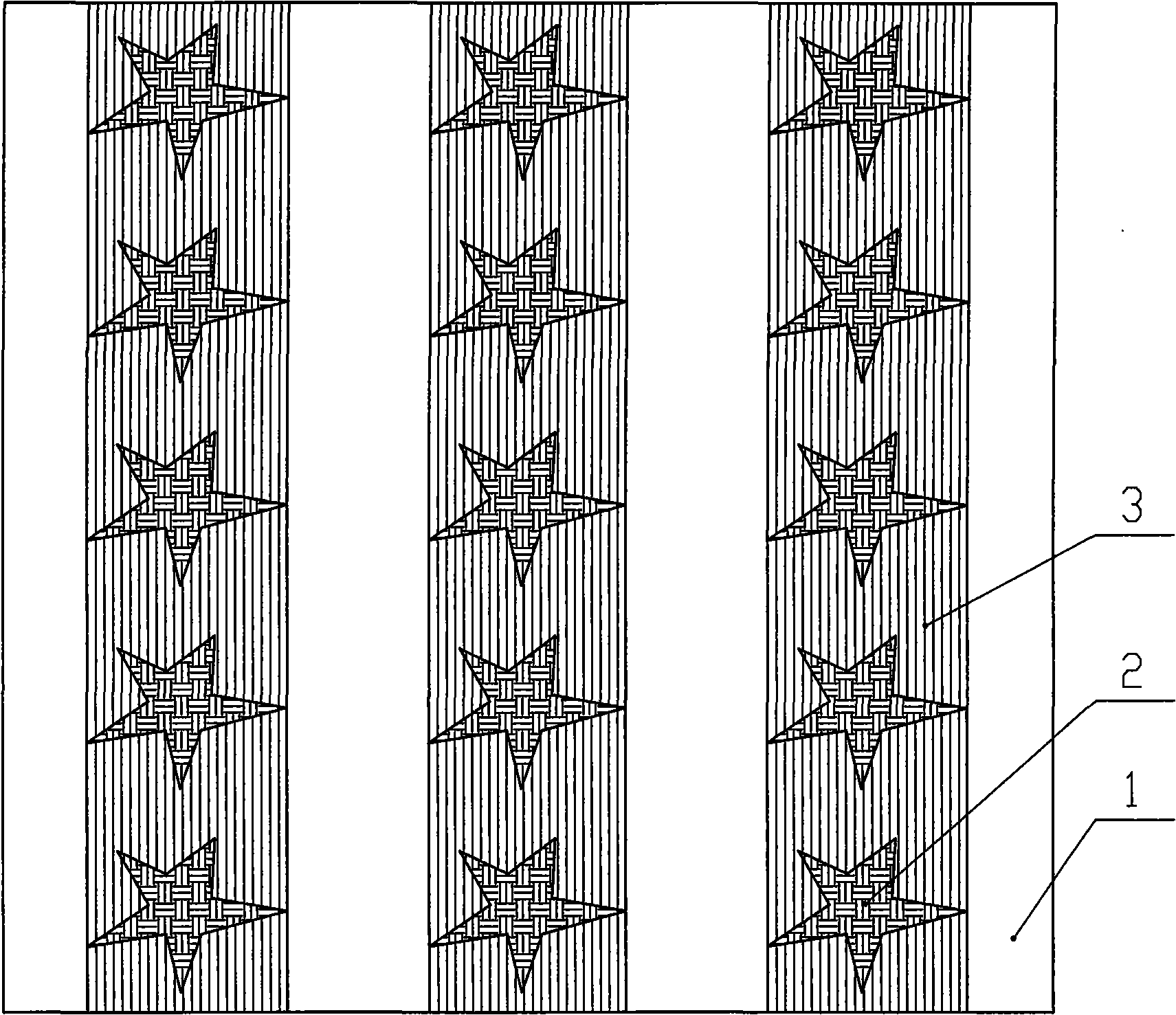

[0017] Such as figure 1 The shown first embodiment of the cut pattern cloth of the present invention has a plain weave base weave 1 and a local additional weave 2 interwoven on the surface of the plain weave base weave 1, the additional weave 2 is a jacquard weave, on the front of the fabric, in the There are floating yarns 3 between the two additional weaves adjacent to each other upwards; the warp yarn of the upper shaft is 40 / 2 cotton yarn, the warp yarn of the lower shaft is 40 cotton yarns, the additional color weft yarn and the background color weft yarn are both 40 cotton yarns, and the additional The color of the colored weft yarn and the background color weft yarn can be the same. At the additional weave 2, the warp yarn of the upper axis and the additional color weft yarn are interwoven, the warp yarn of the lower axis is interwoven with the background color weft yarn, and the plain weave base weave 1 is the warp yarn of the lower axis and the background color weft ya...

Embodiment 2

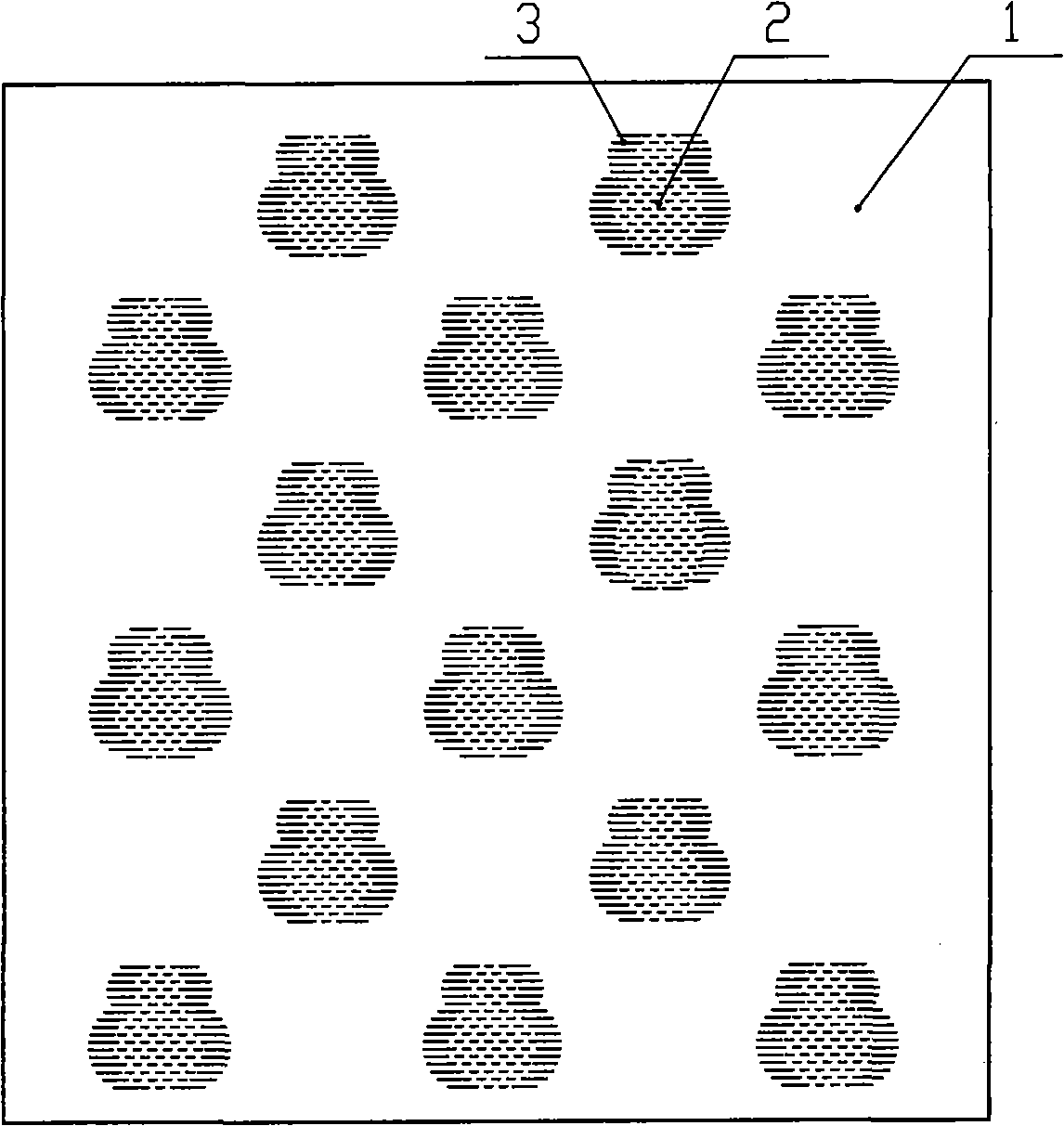

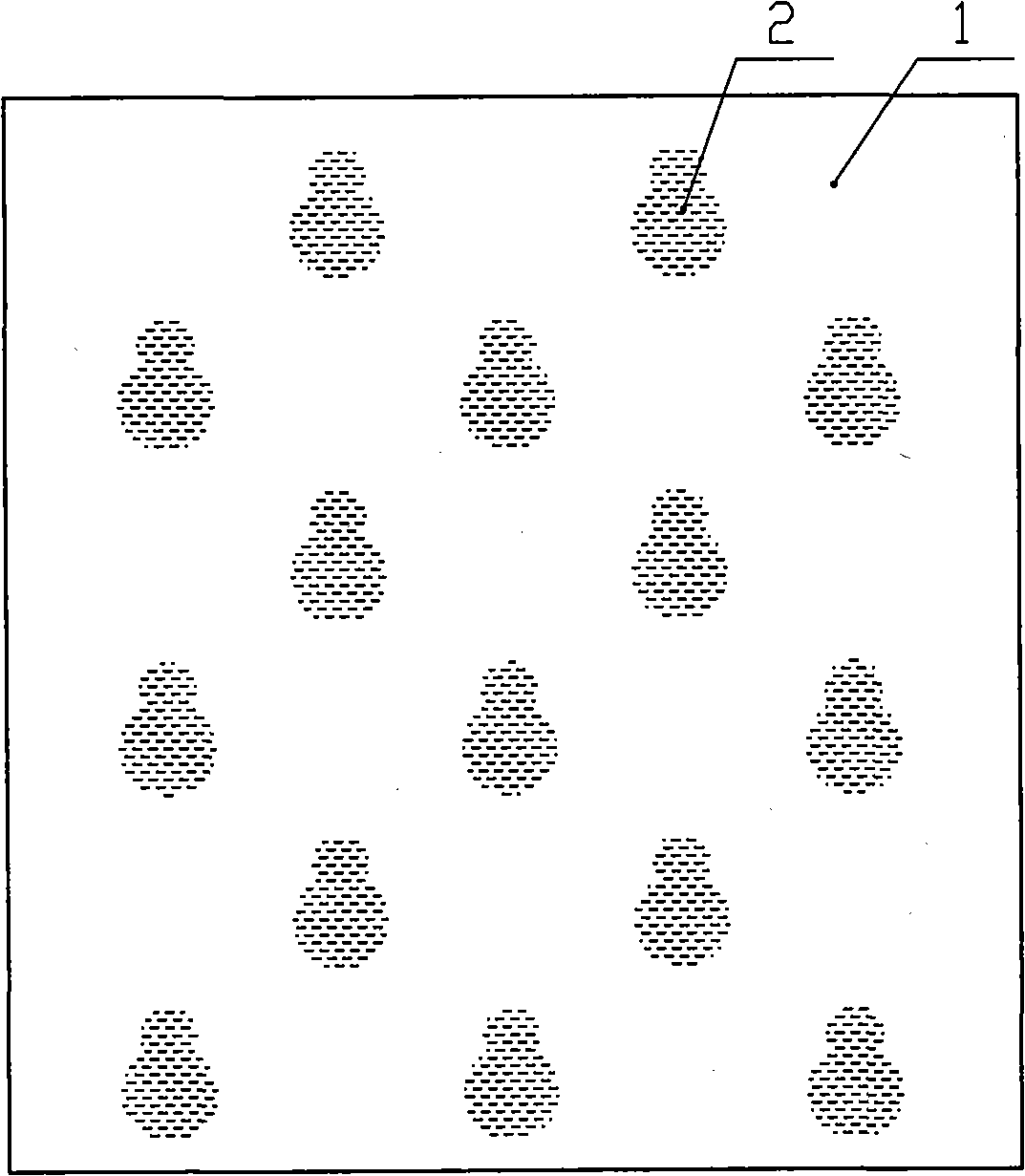

[0020] Such as figure 2 with image 3 The second embodiment of the cut pattern cloth of the present invention shown has a plain weave base weave 1 and a local additional weave 2 interwoven on the surface of the plain weave base weave 1, the additional weave 2 is a plain weave, and on the front side of the fabric, the additional weave There are short floating yarns 3 around 2, the warp yarn of the upper shaft and the warp yarn of the lower shaft are 40 cotton yarns, the background color weft yarn is 40 cotton yarns, and the additional color weft yarn is 40 / 2.

[0021] The manufacturing method of the cut flower cloth has a weaving process, the loom used in the weaving process is a rapier loom, the warp axis of the rapier loom is composed of an upper shaft and a lower shaft arranged in parallel, and the weft yarn is divided into ground color weft yarns And a variety of additional color weft yarns, according to the design requirements of the pattern, the warp yarns of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com