Pressurized molding process for plastic particles

A technology of plastic granules and molding process, which is applied in plastic recycling, metal processing, recycling technology, etc., can solve the problems of low efficiency and shadow molding productivity, and achieve the effect of simple principle, convenient operation and use, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

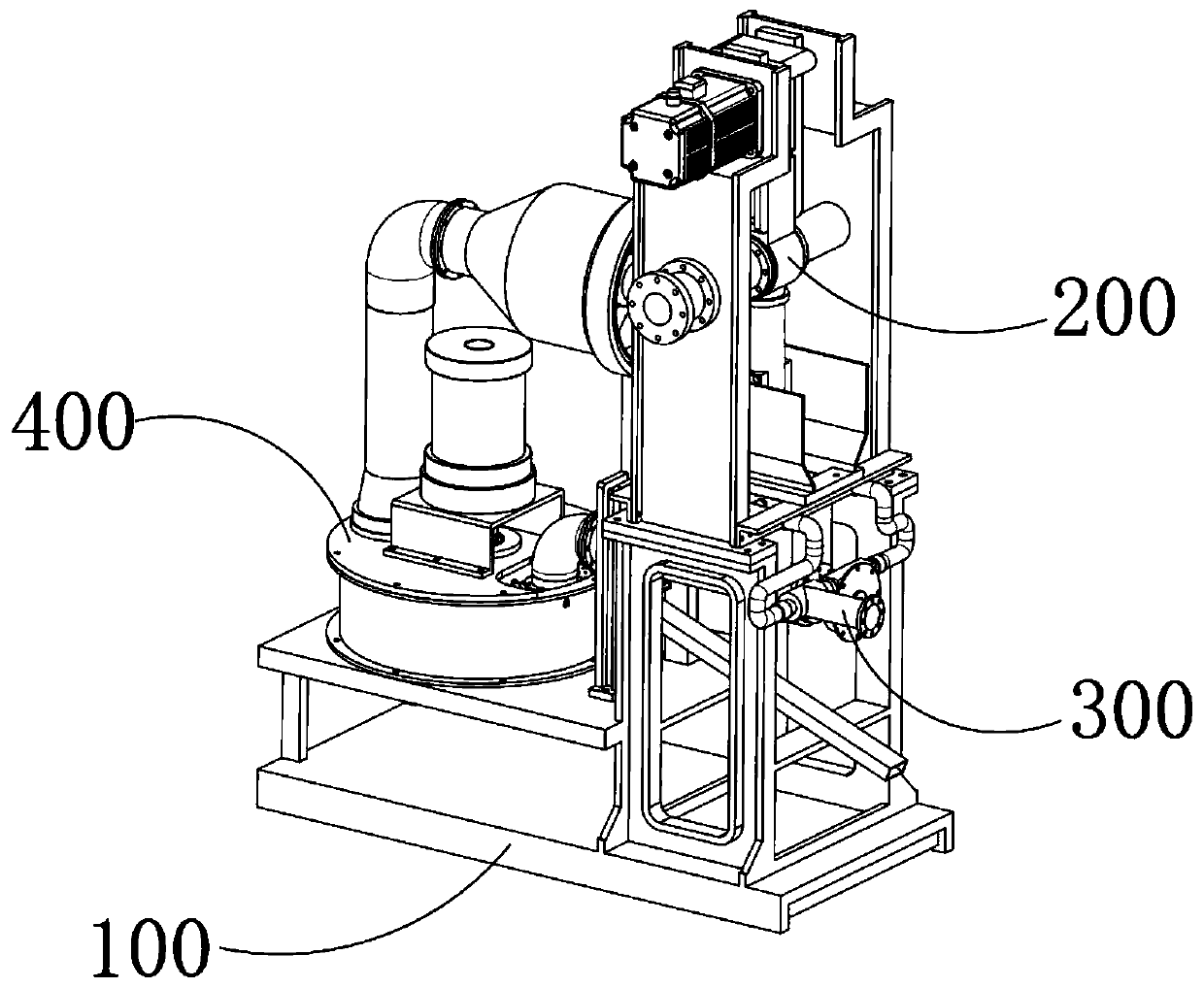

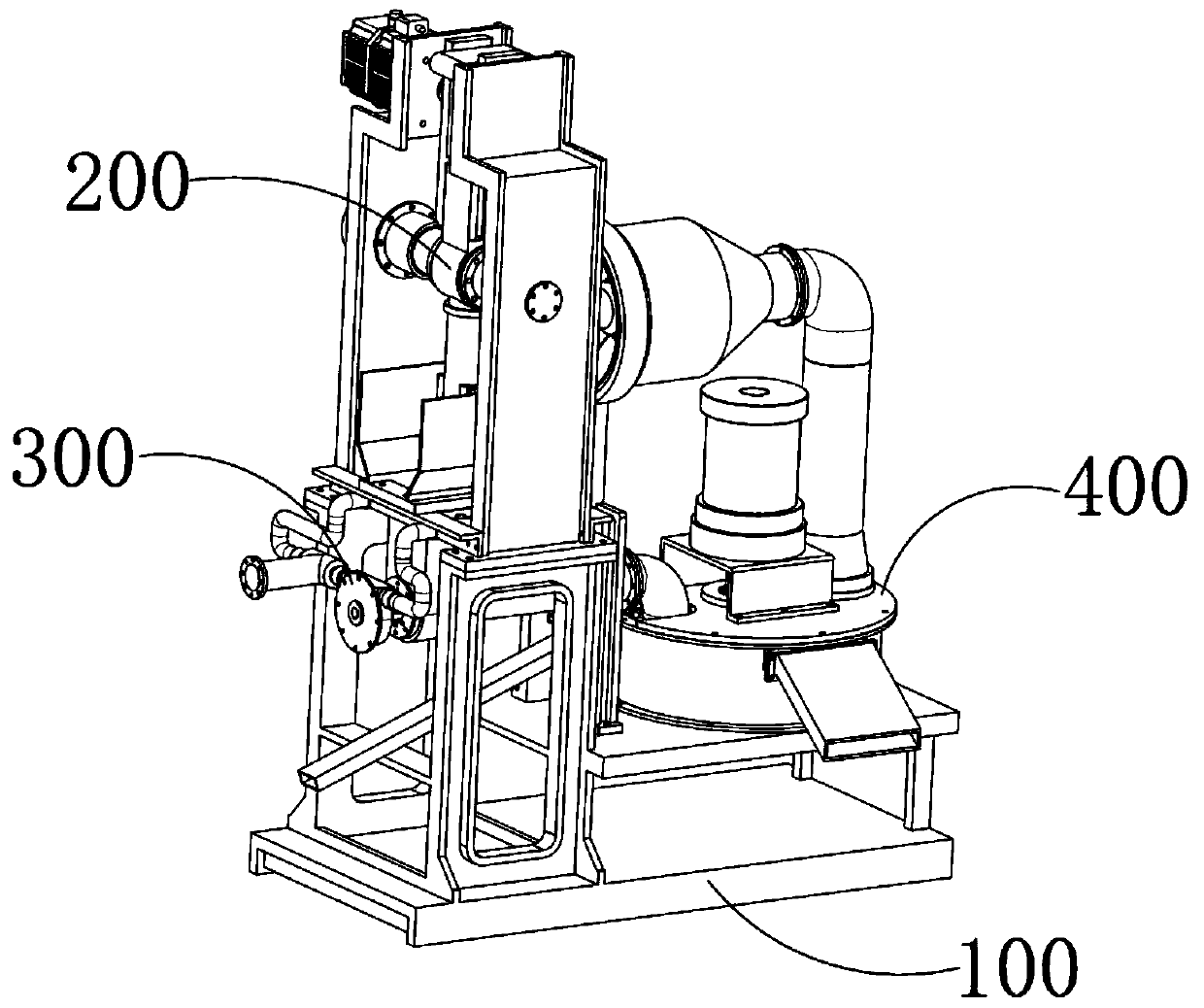

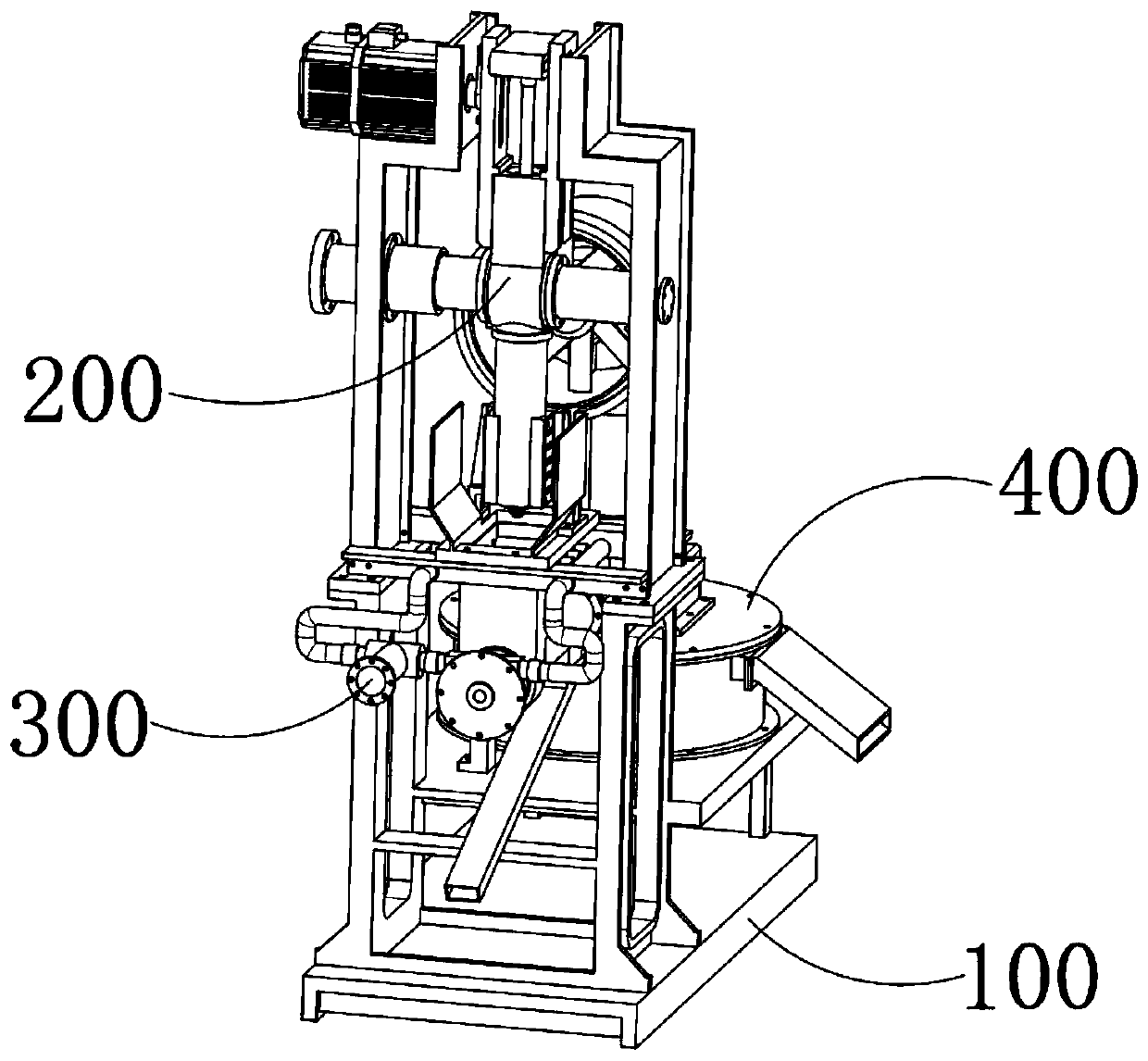

Image

Examples

Embodiment Construction

[0064] The pressurized molding process of plastic granules, the steps are:

[0065] (1) pressurization stage;

[0066] S1: Connect the butt joint pipe 217 in the booster mechanism 210 to the main body of the plastic pelletizer. The plastic pelletizer body heat-melts the waste plastics and extrudes them into the joint pipe 217. After being transported by the rotating shaft 216, it melts. The plastic flows into the booster cylinder 211. At this time, start the main motor 231 to rotate, the main motor 231 will drive the rocker 232 to rotate, the rocker 232 will cooperate with the flat slot 2 326 and drive the piston 212 along the booster The cylinder 211 slides back and forth, and when the piston 212 slides toward the pressurized cylinder 211, the molten plastic in the pressurized cylinder 211 is extruded toward the extrusion part B, and the pressure of the molten plastic increases and is extruded through the docking hole 219b;

[0067] The supercharging mechanism 210 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com