Patents

Literature

61results about How to "Small back pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling temporary flush type supersonic velocity wind tunnel with ejector function

ActiveCN103135624ASmall back pressureReduce the total pressure of the stable sectionAerodynamic testingFluid pressure control using electric meansEngineeringMechanics

The invention provides a method for controlling a temporary flush type supersonic velocity wind tunnel with an ejector function. The method includes that when the wind tunnel is started, firstly, the total pressure of a gas collection chamber of an ejector is adjusted to be working total pressure, then the total pressure of a stable section is adjusted to be a running total pressure value of a wind tunnel test, and then the ejector is closed for carrying out the wind tunnel test; and after specified testing items are finished, the total pressure value of the stable section maintains the same, the ejector is started to adjust the total pressure of the gas collection chamber to be a working total pressure value in a closed-loop mode, then gas flow is cut off, after the total pressure of the stable section is reduced to a preset cutoff total pressure value, the ejector is closed, and then a whole air-blowing testing process is finished. Through the method for controlling the temporary flush type supersonic velocity wind tunnel with the ejector function, the impact load in a start-up process of the wind tunnel and the impact load in a cutoff process of the wind tunnel can be reduced effectively, safety of models, a balance and a wind tunnel system can be guaranteed, requirements of the balance on strength and rigidity in a designing process of the balance can be effectively reduced, sensitivity of the balance can be improved, and the accuracy of the measurement of the balance and the quality of testing data can be improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

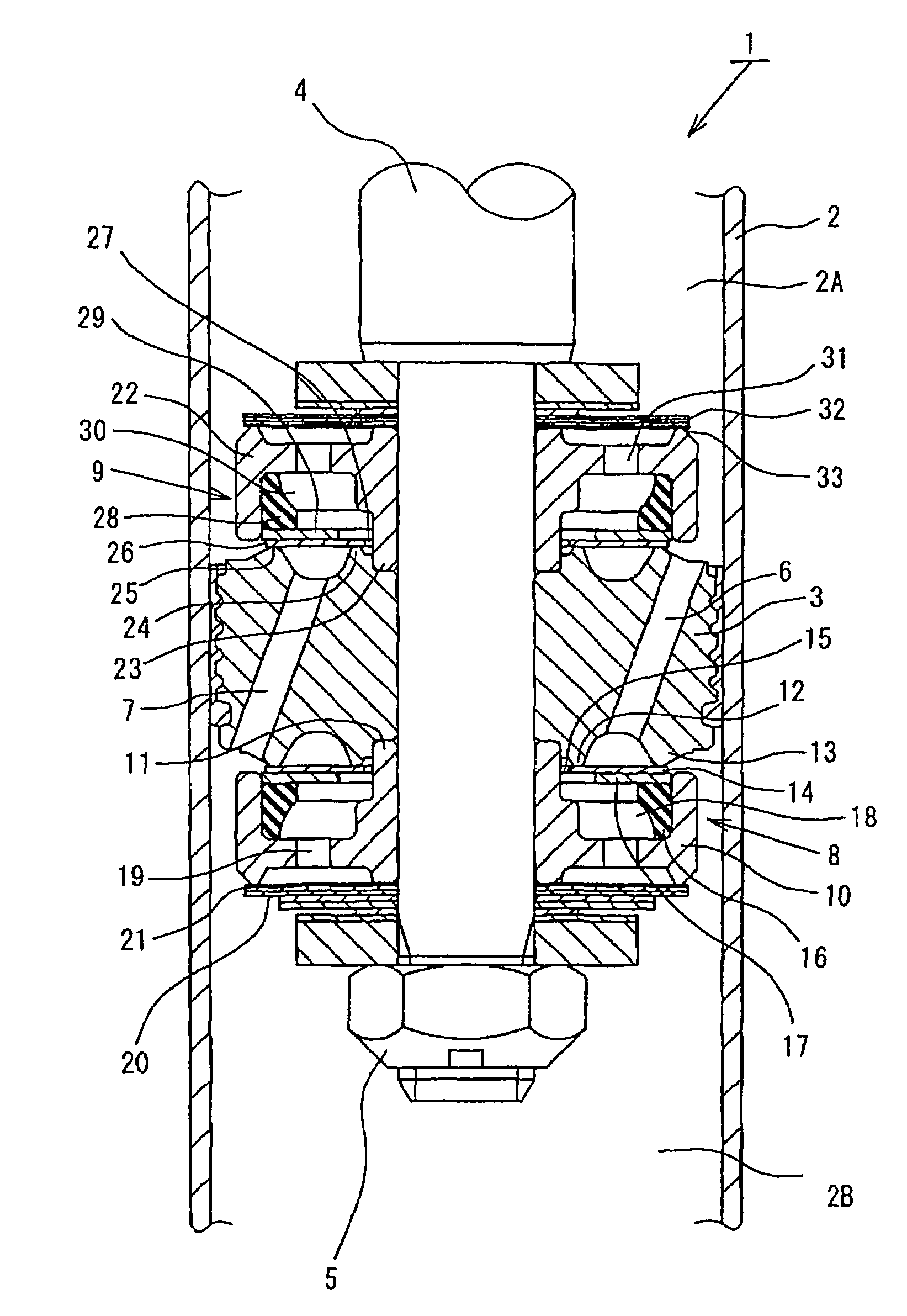

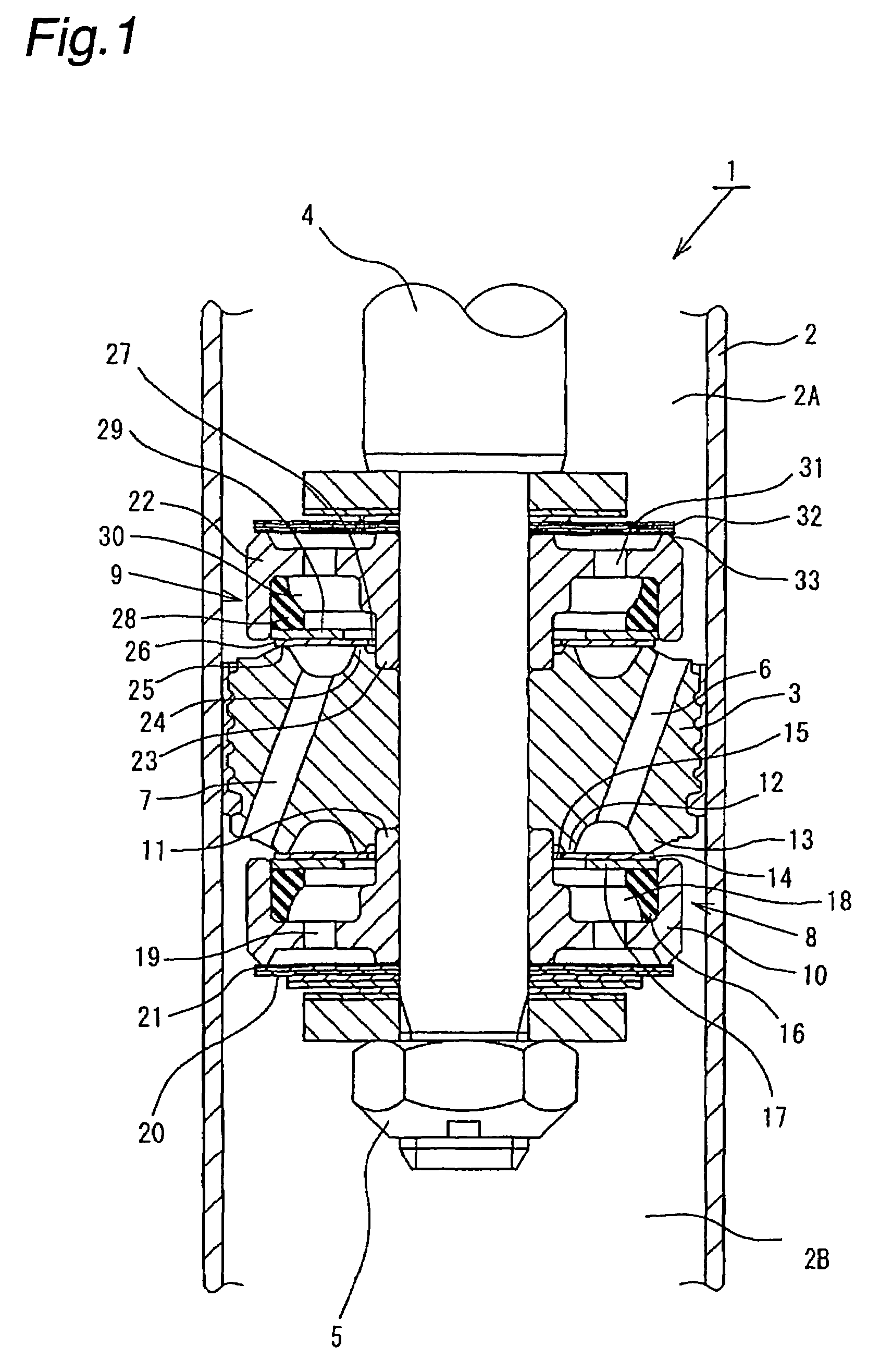

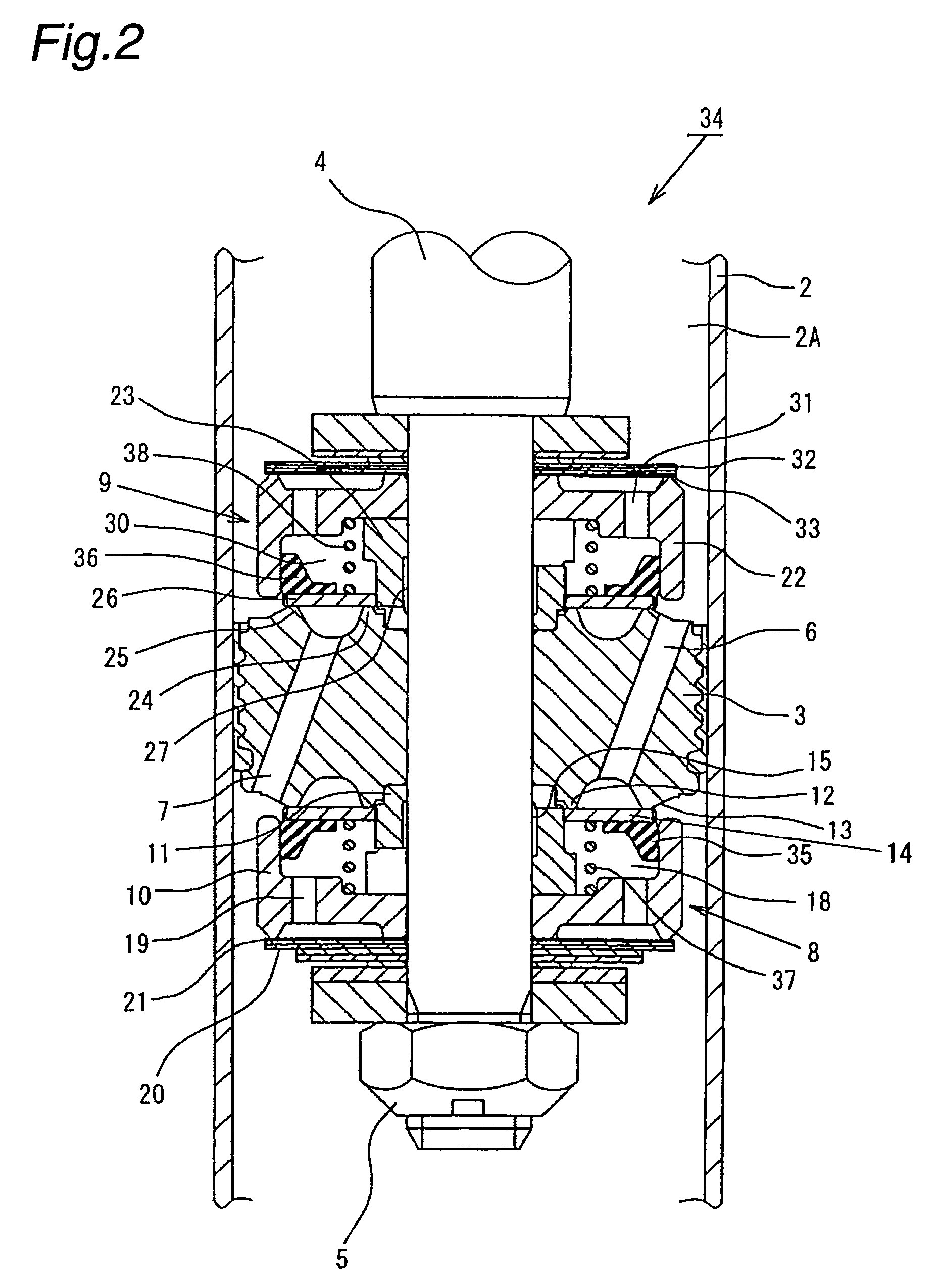

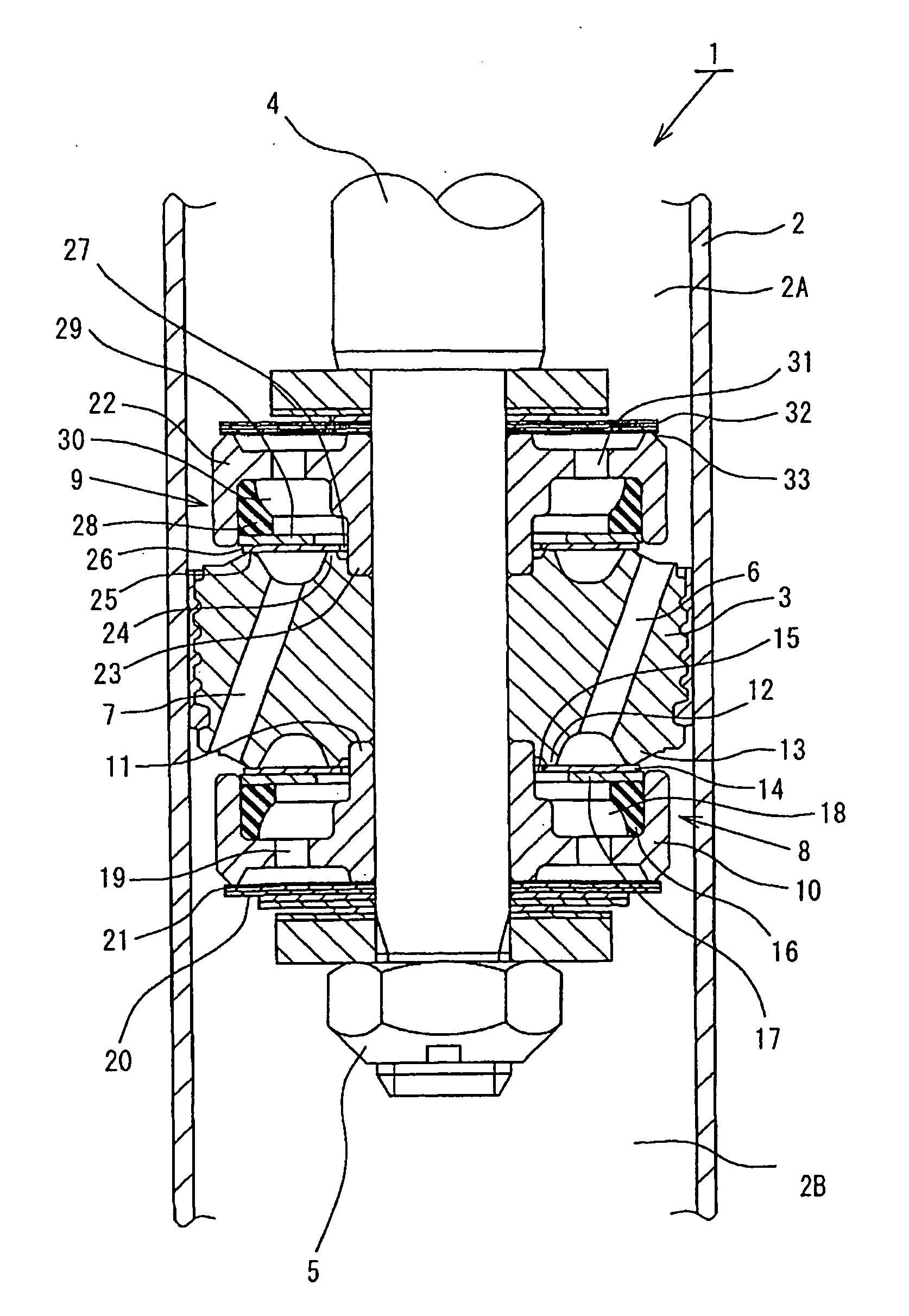

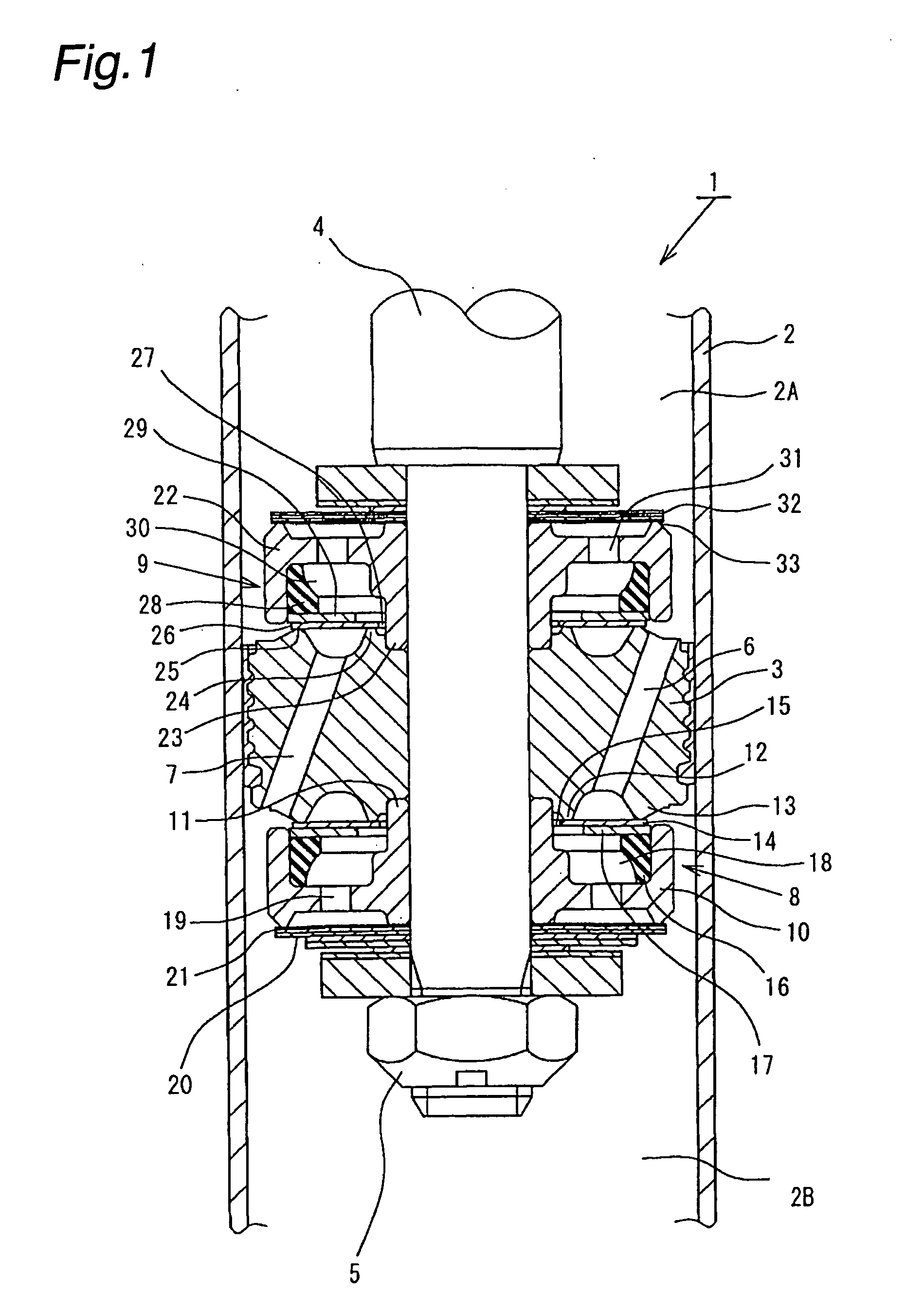

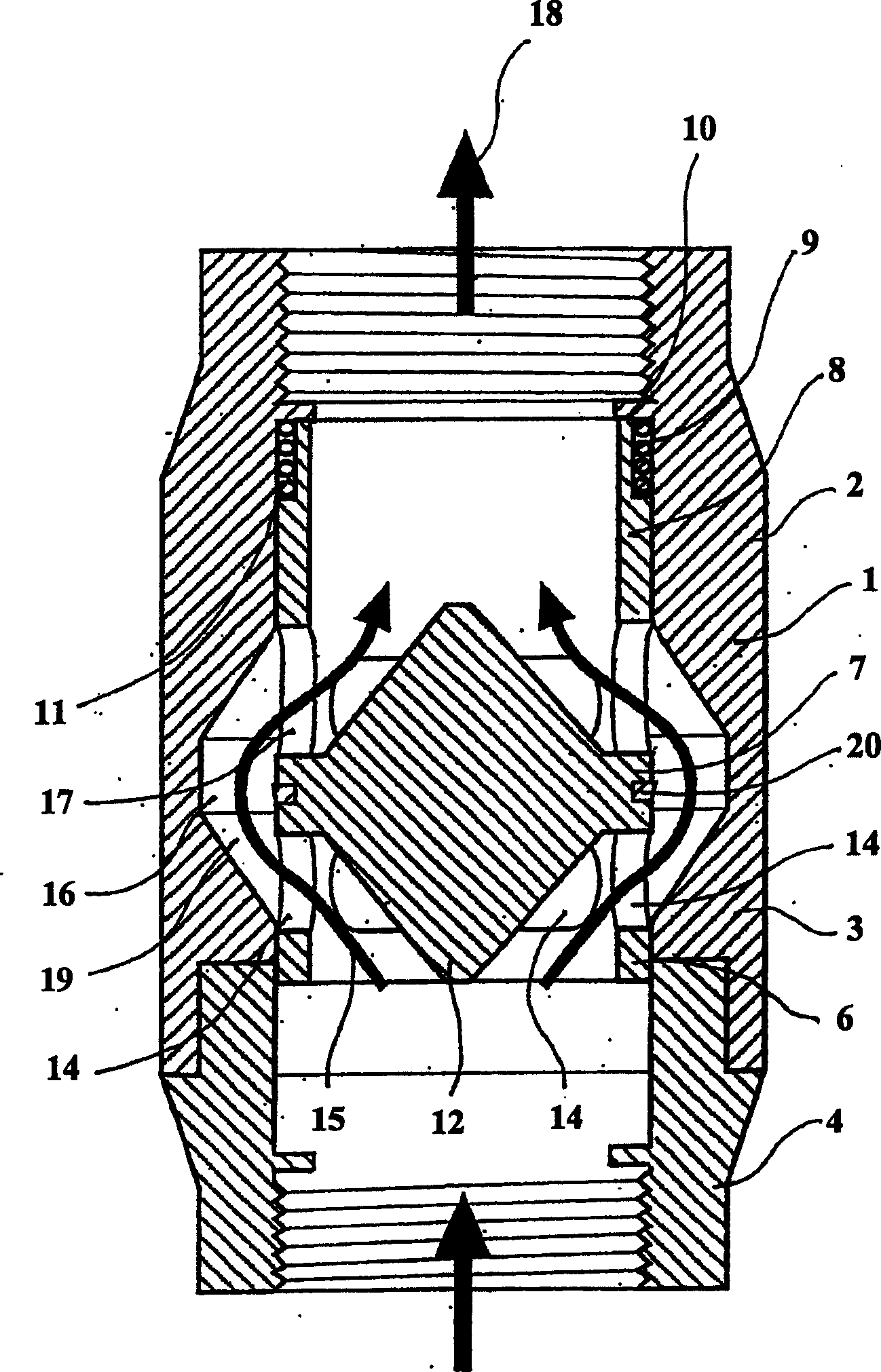

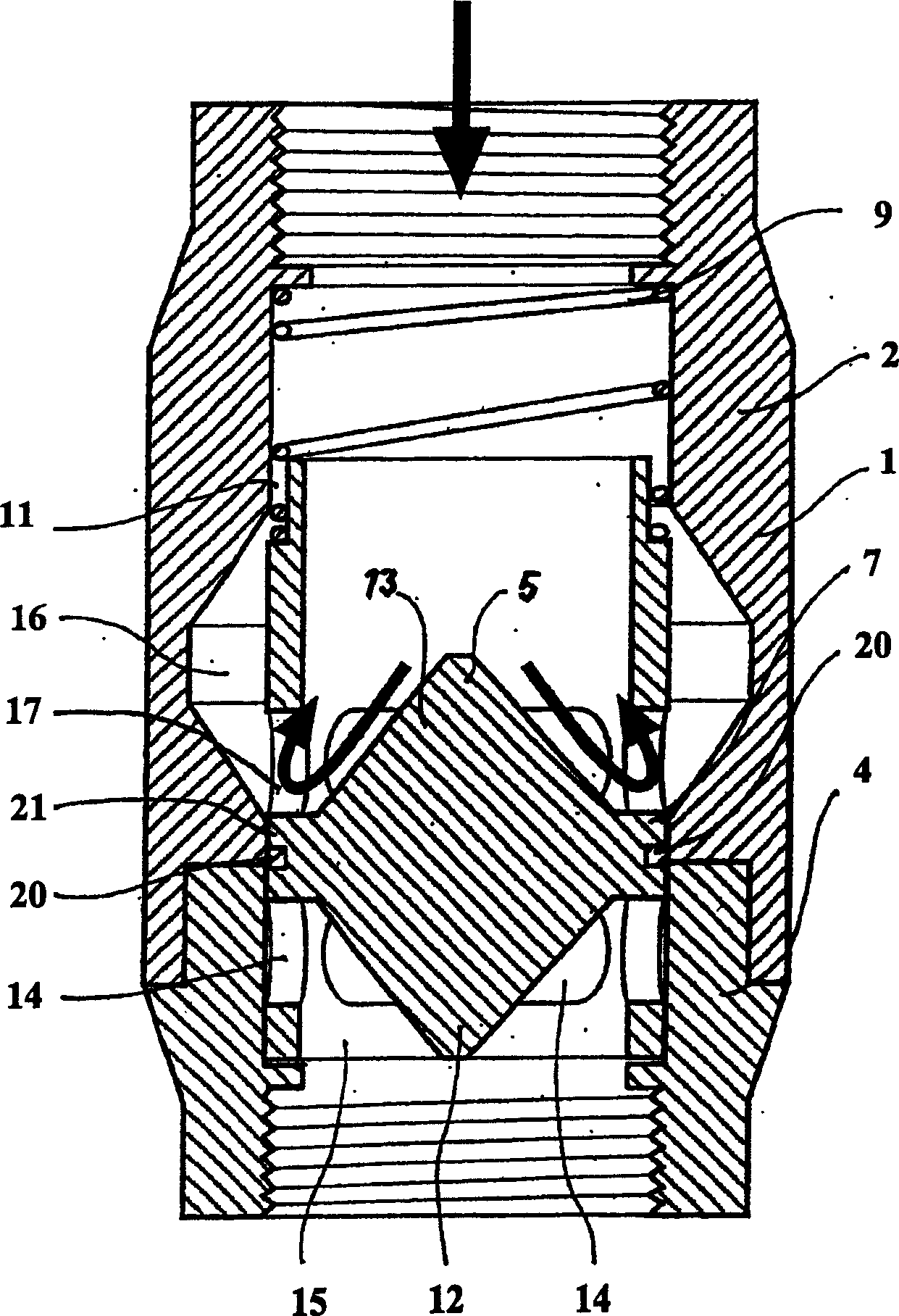

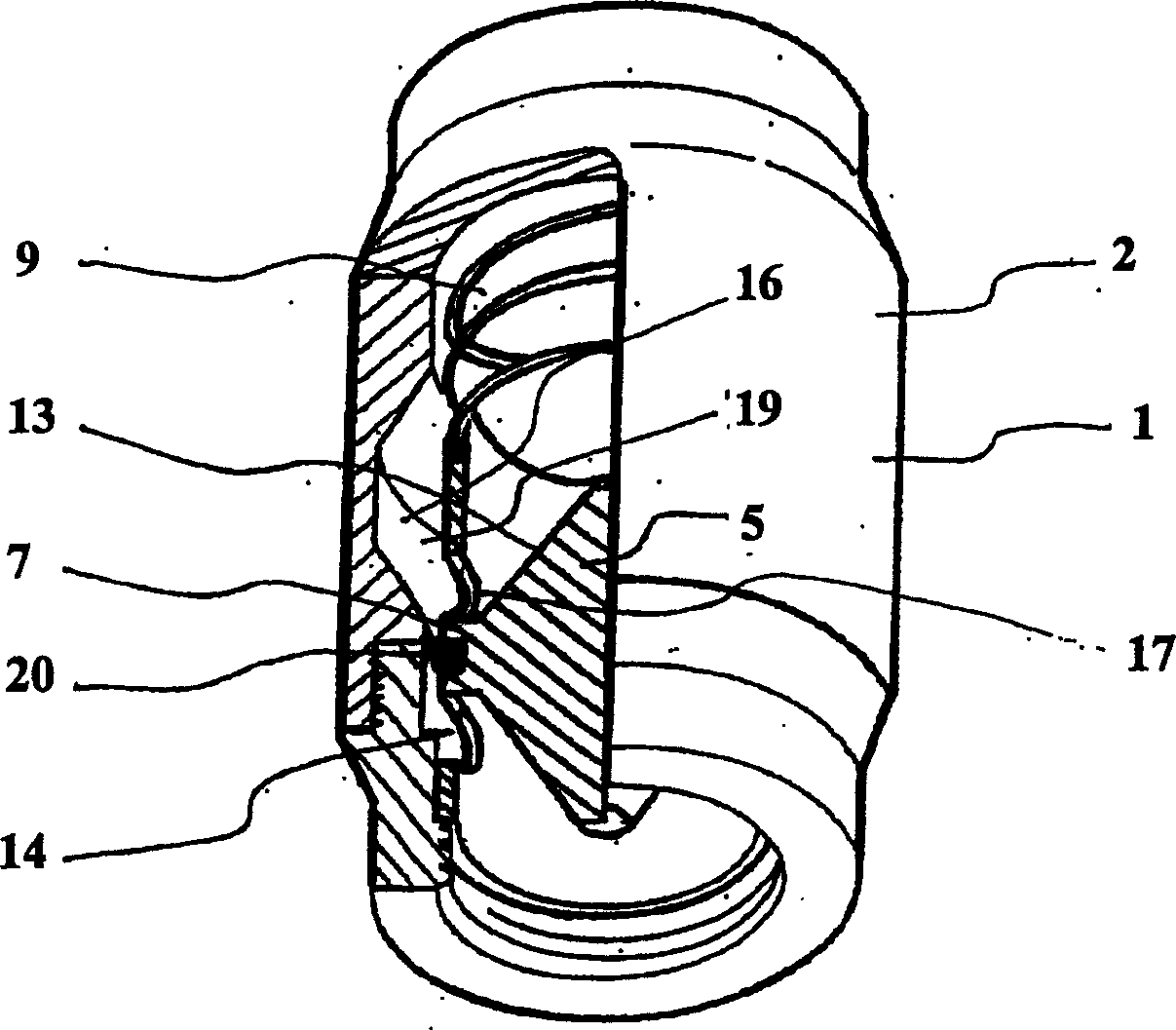

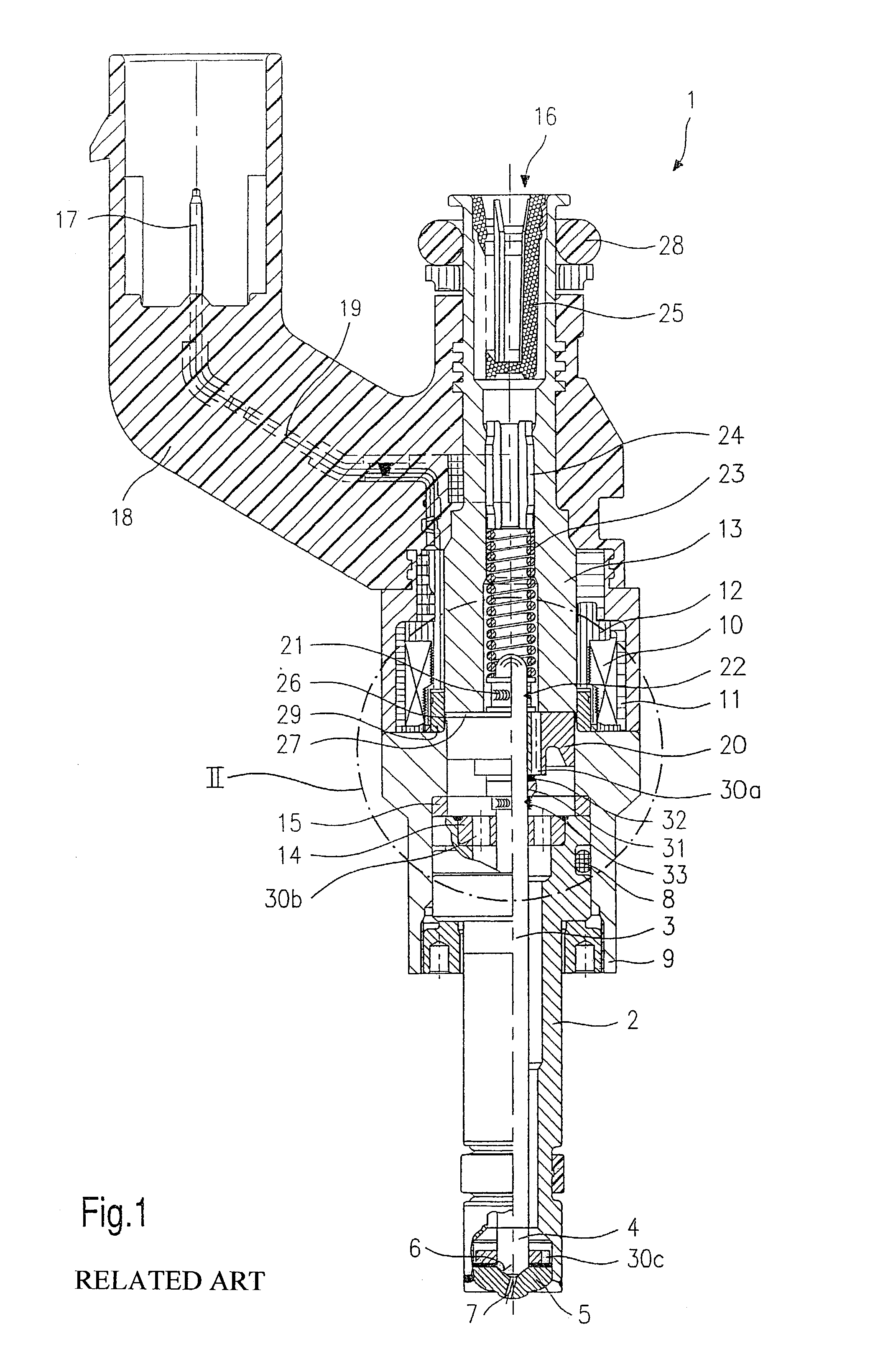

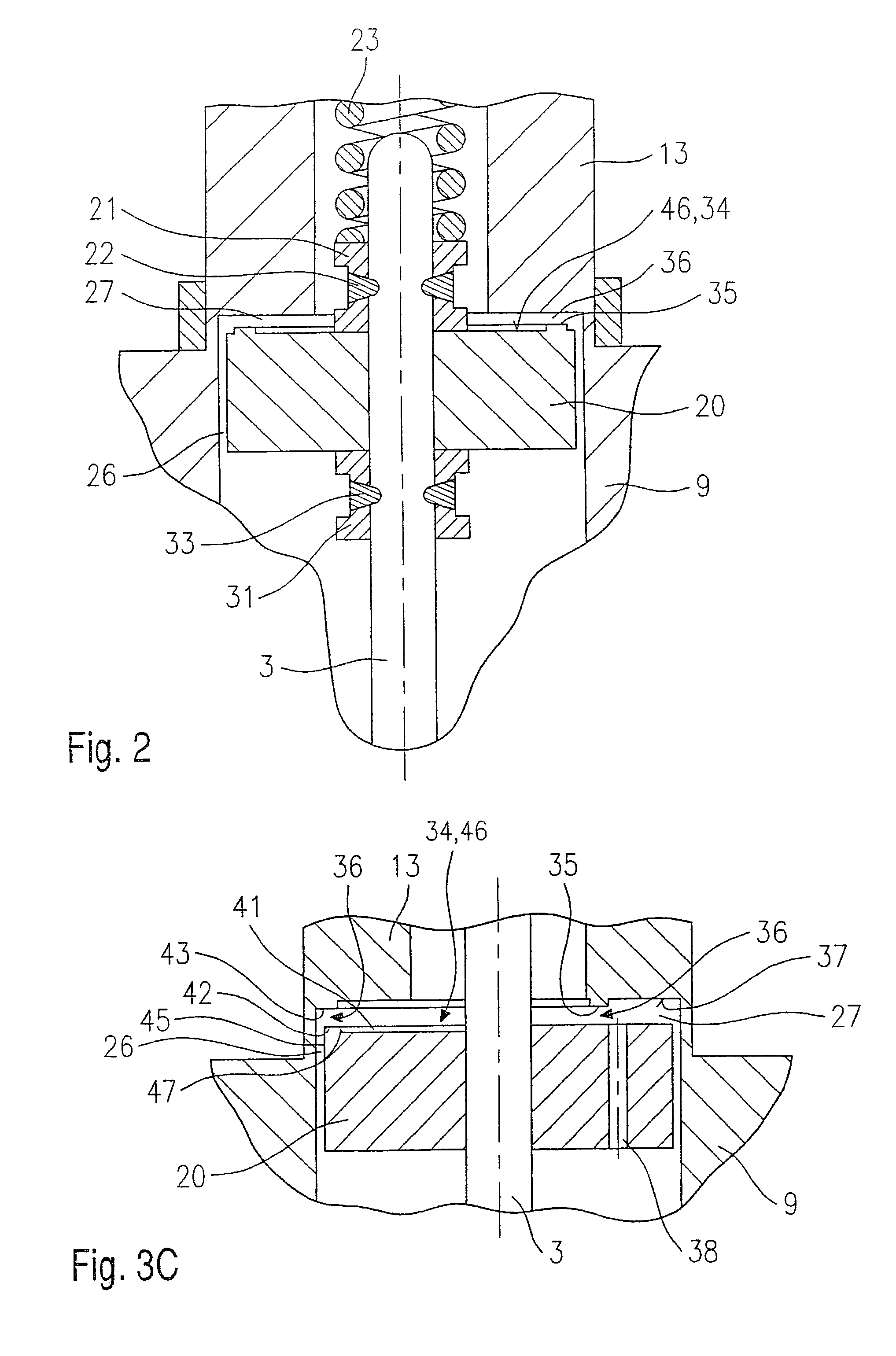

Hydraulic shock absorber

A hydraulic shock absorber in which the flow of hydraulic fluid induced in each of extension and compression hydraulic fluid passages, by sliding movement of a piston, is controlled by a main disk valve to generate damping force. The valve opening pressure of the main disk valve is adjusted by the pressure in a back-pressure chamber. In a low piston speed region, the main disk valve closes a back-pressure chamber inlet passage. Therefore, the pressure in the backpressure chamber will not rise, and sufficiently small damping force is obtained. When the main disk valve opens, the backpressure chamber inlet passage opens simultaneously. Consequently, the pressure in the backpressure chamber rises, and the damping force increases.

Owner:NISSAN MOTOR CO LTD +1

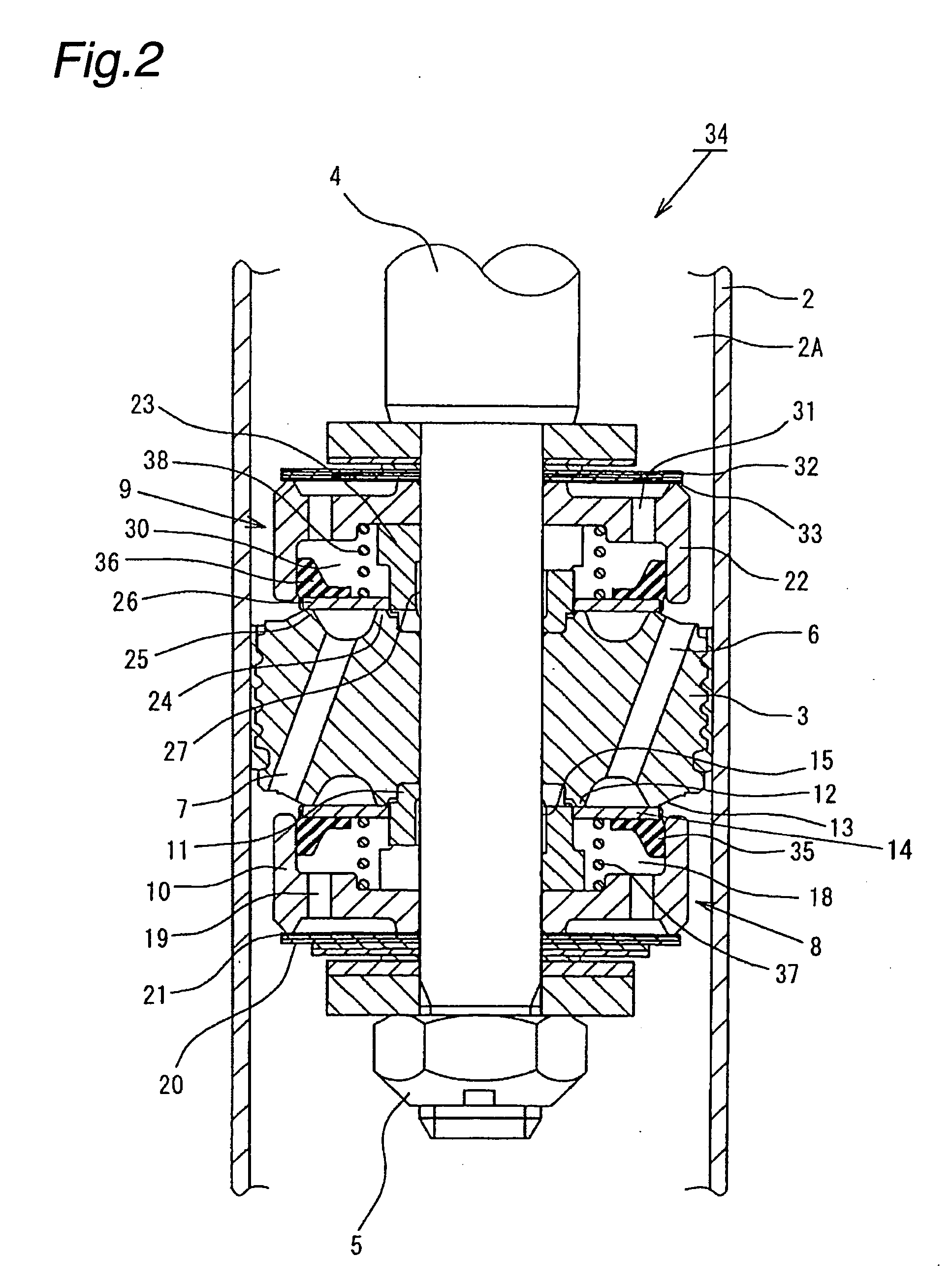

Hydraulic shock absorber

In the disclosed hydraulic shock absorber, the flow of hydraulic fluid induced in each of extension and compression hydraulic fluid passages by sliding movement of a piston is controlled by a main disk valve to generate damping force. The valve opening pressure of the main disk valve is adjusted by the pressure in a back-pressure chamber. In a low piston speed region, the main disk valve closes a back-pressure chamber inlet passage. Therefore, the pressure in the back-pressure chamber will not rise, and sufficiently small damping force is obtained. When the main disk valve opens, the back-pressure chamber inlet passage opens simultaneously. Consequently, the pressure in the back-pressure chamber rises, and the damping force increases.

Owner:NISSAN MOTOR CO LTD +1

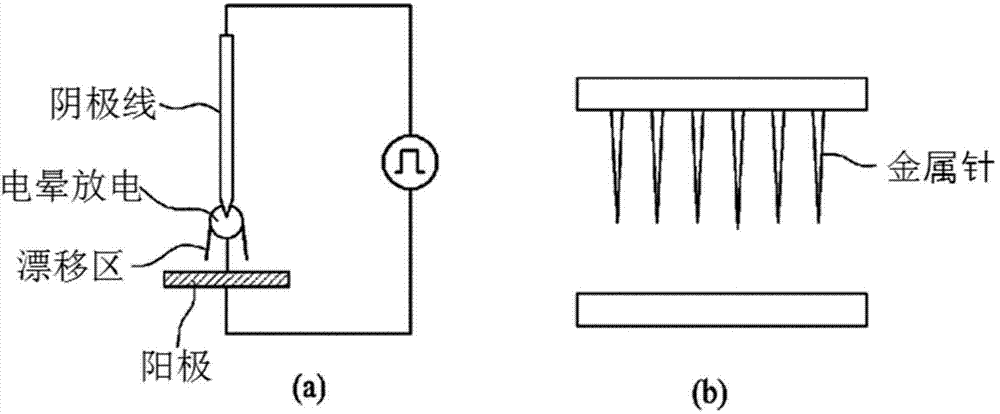

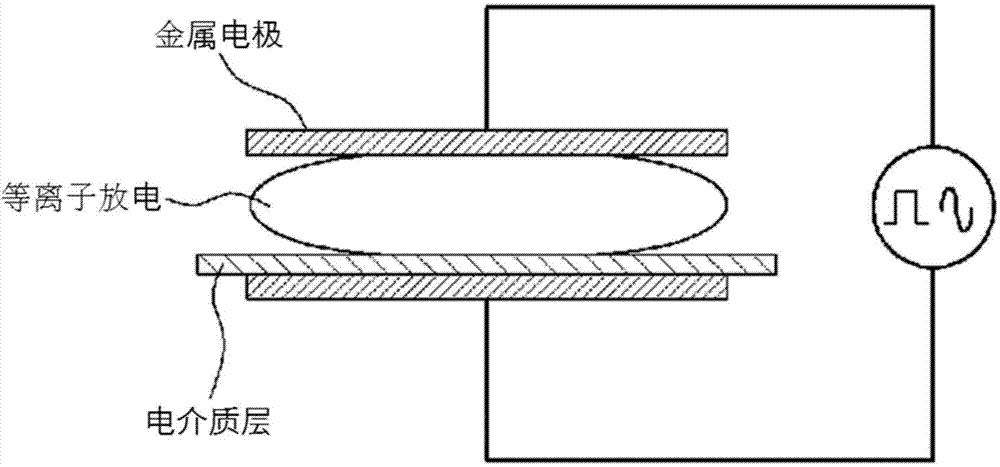

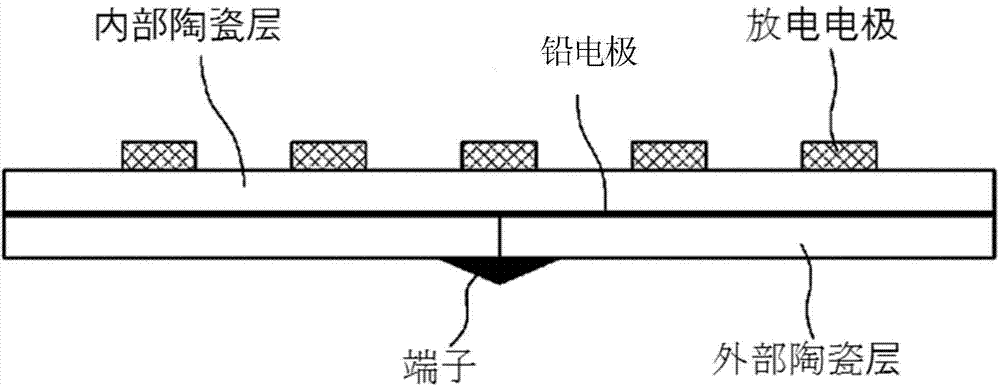

Dielectric barrier discharge-type electrode structure for generating plasma having conductive body protrusion on electrodes

ActiveCN104756334AReduce noiseExcellent plasma efficiencyDispersed particle separationDischarge tube main electrodesOptoelectronicsDielectric layer

Provided is a dielectric barrier discharge-type electrode structure for generating plasma. The electrode structure, according to the present invention, comprises: an upper conductive body electrode and a lower conductive body electrode; at least one conductive body electrode protrusion portion, which is formed on at least one surface of the upper conductive body electrode and / or the lower conductive body electrode; a dielectric layer which is formed on at least one of the inner surfaces of the upper conductive body electrode and the lower conductive body electrode that face each other, so as to have a substantially uniform thickness; and a specific gap (d) which is formed between the upper and lower conductive body electrodes and the dielectric layer, or between dielectric layers, due to the protruding effect of the conductive body electrode protrusion portion when the upper conductive body electrode and the lower conductive body electrodes come into close contact, wherein the plasma is generated by applying a pulse power or an alternating power to the upper conductive body electrode and the lower conductive body electrode.

Owner:SP TECHNOLOGY CO LTD

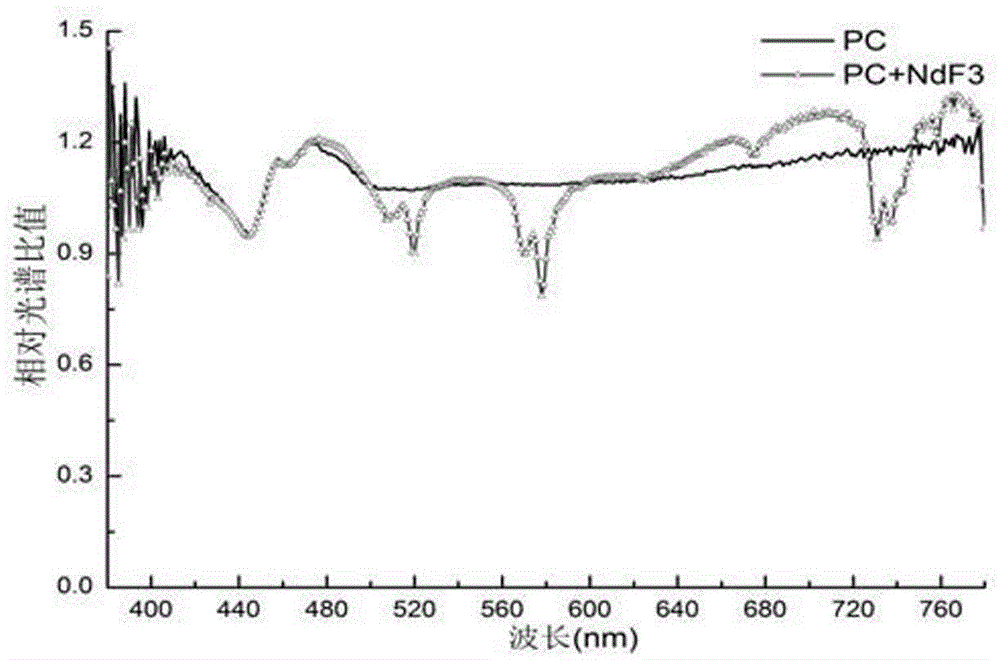

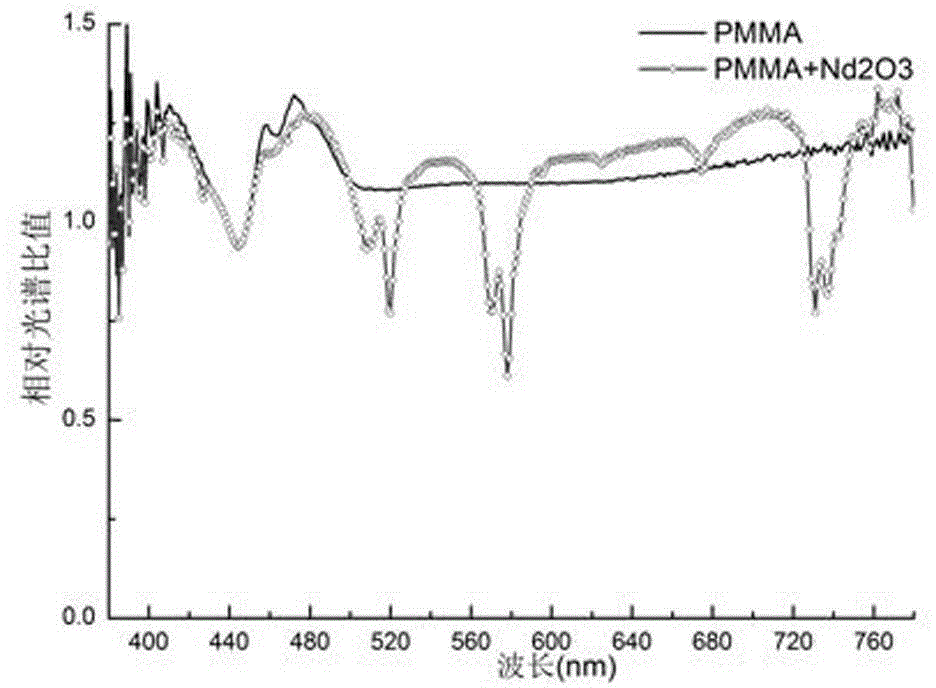

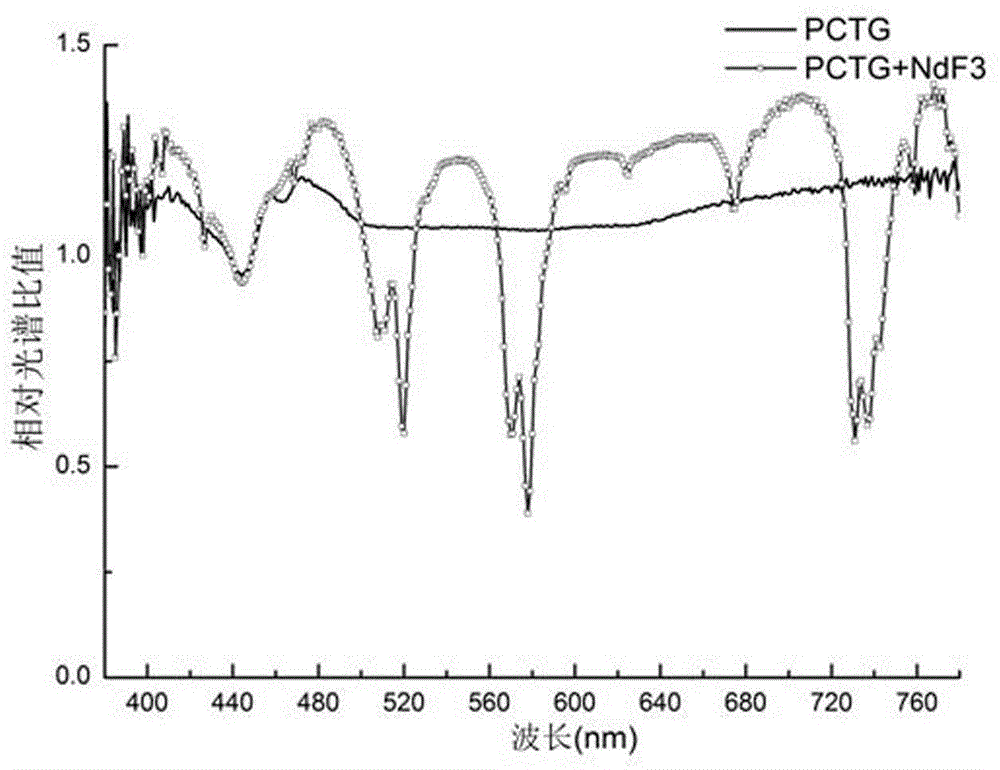

LED material for filtering yellow light and preparation method thereof

ActiveCN104650568AHigh light transmittanceExcellent optical properties such as hazePhysical chemistryOptical transmittance

The invention relates to the technical field of high-molecular materials and particularly relates to an LED material for filtering yellow light and a preparation method thereof. The LED material for filtering yellow light is prepared from the following raw materials in parts by mass: 60-100 parts of a base material, 1-13 parts of a yellow light filtration aid, 0.1-1.0 part of a light diffusing agent, 0.1-0.8 part of an antioxidant, 0.2-0.4 part of a dispersant DP310 and 2-26 parts of deionized water, wherein the yellow light filtration aid is one or more than one of neodymium fluoride, neodymium oxide, neodymium chloride and neodymium nitrate. The LED material for filtering yellow light, prepared by the method disclosed by the invention, is excellent in optical performances such as yellow light filtration property, light transmittance and haze and can be used for effectively filtering and eliminating yellow light generated by an LED lamp so as to relieve the fatigue of eyes and preventing the eyes from damages of yellow light. The preparation method of the LED material is simple in process, convenient to operate and control, stable in quality, high in yield, high in production efficiency and low in production cost.

Owner:DONGGUAN ZOYO ELECTRONICS TECH CO LTD

A check valve

A check valve comprising an outer body having an inner bore, and a reciprocating slide disposed within the inner bore for a closed position relative to the inner bore to prevent liquid flow through the valve and to allow liquid flow through the valve. Elastic means for moving between open positions of the valve and biasing the position of the reciprocating slide towards the closed position, characterized in that the reciprocating slide has a downstream portion, an upstream portion and an intermediate portion, each portion sliding fit in engagement with the bore and such that, when in the closed position, the intermediate portion sealingly engages the bore, and when in the open position, is configured to allow fluid to flow through a passage around the intermediate portion comprising at least The path through this external body.

Owner:HYDRO FLO HLDG

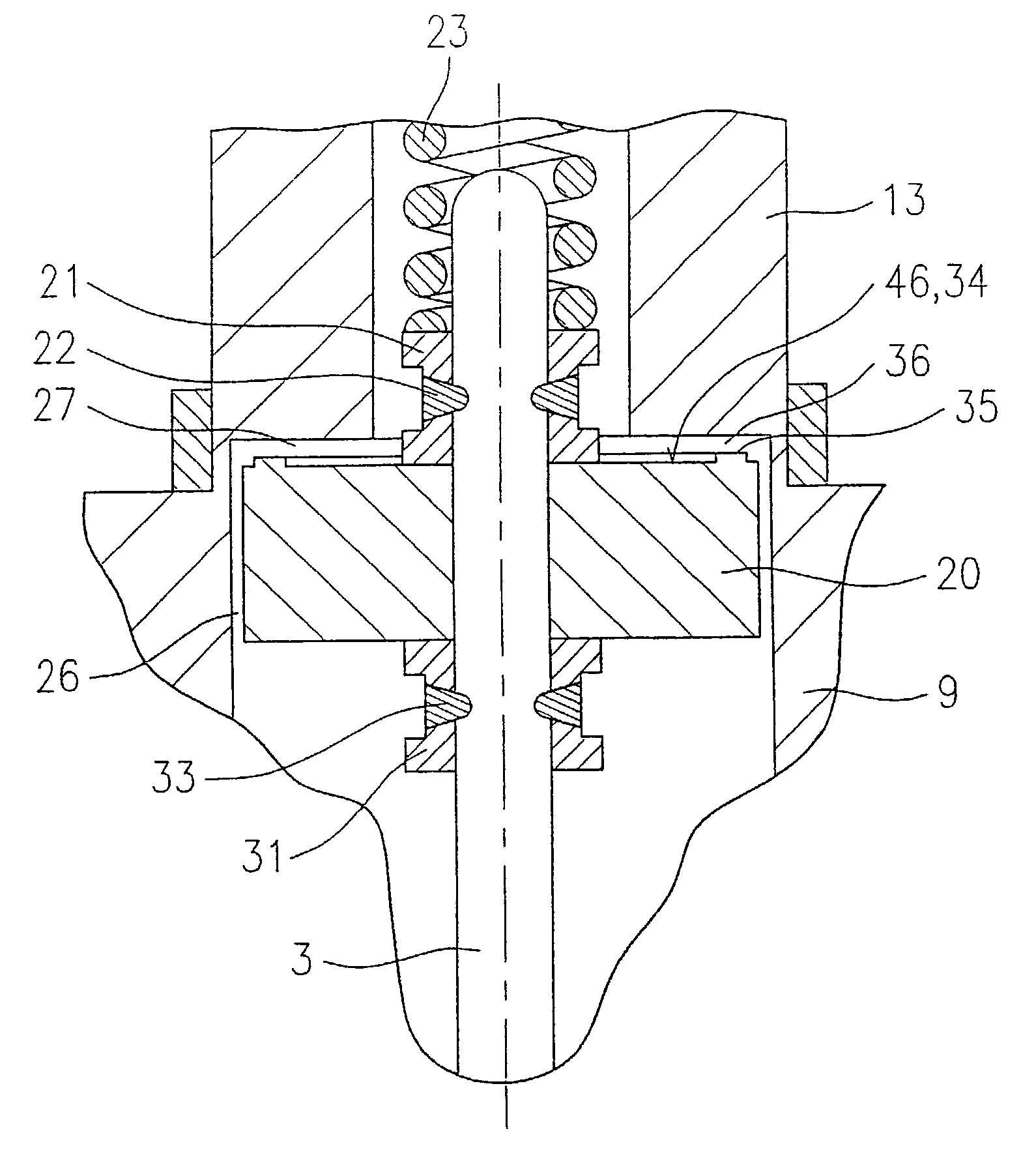

Fuel injector

InactiveUS7086614B2Shorten closing timeSmall back pressureSpray nozzlesMachines/enginesCombustionExternal combustion engine

A fuel injector is described for fuel injection systems in internal combustion engines that includes a magnet coil, an armature that is acted upon in a closing direction by a restoring spring, and a valve needle that is non-positively engaged with armature for actuating a valve closing body, which together with a valve seat surface forms a sealing seat, and armature with an inlet-side armature surface striking internal pole. A choke point is provided on inlet-side armature surface, and is formed by an annular, stepped prominence on inlet-side armature surface.

Owner:ROBERT BOSCH GMBH

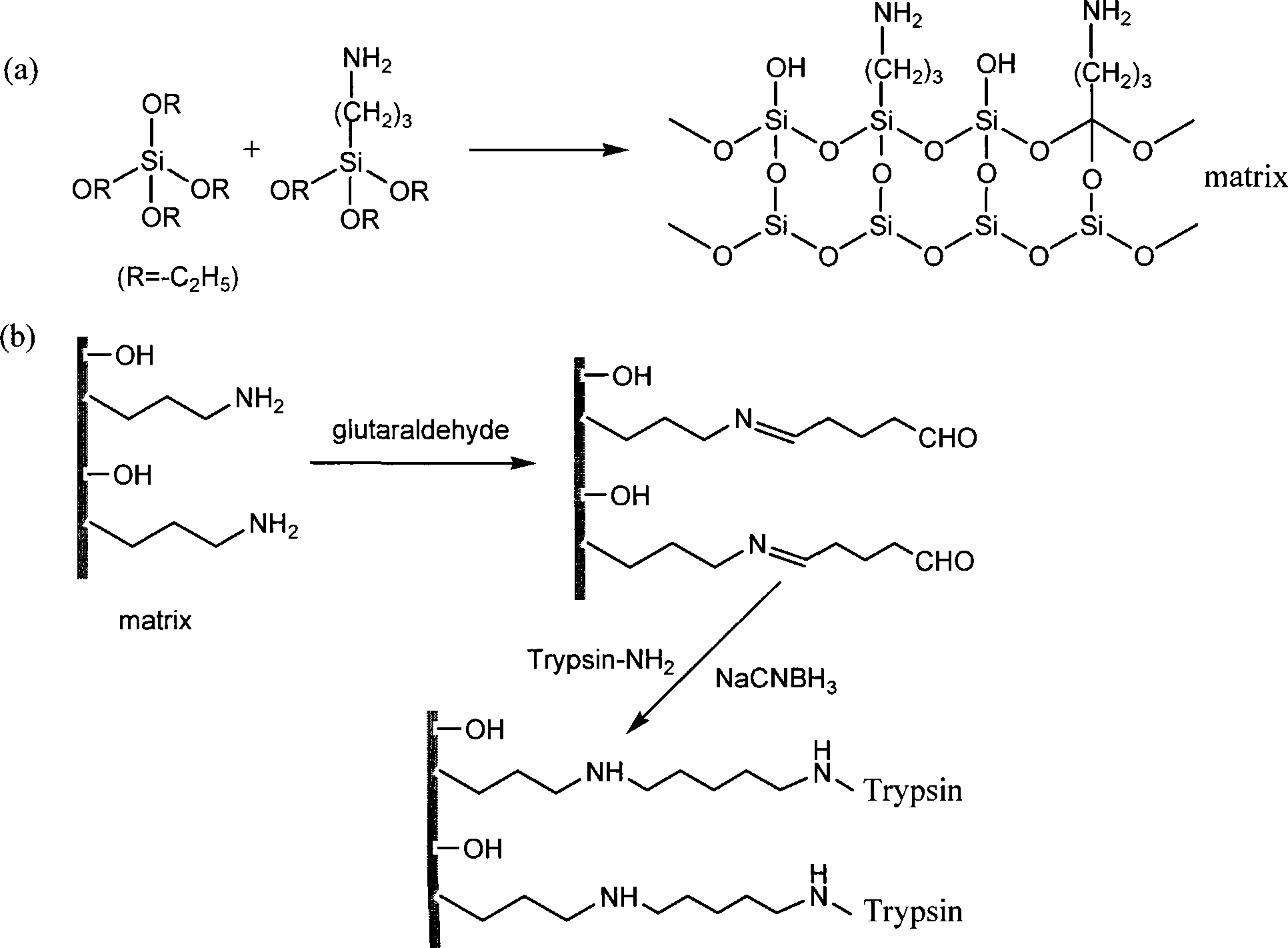

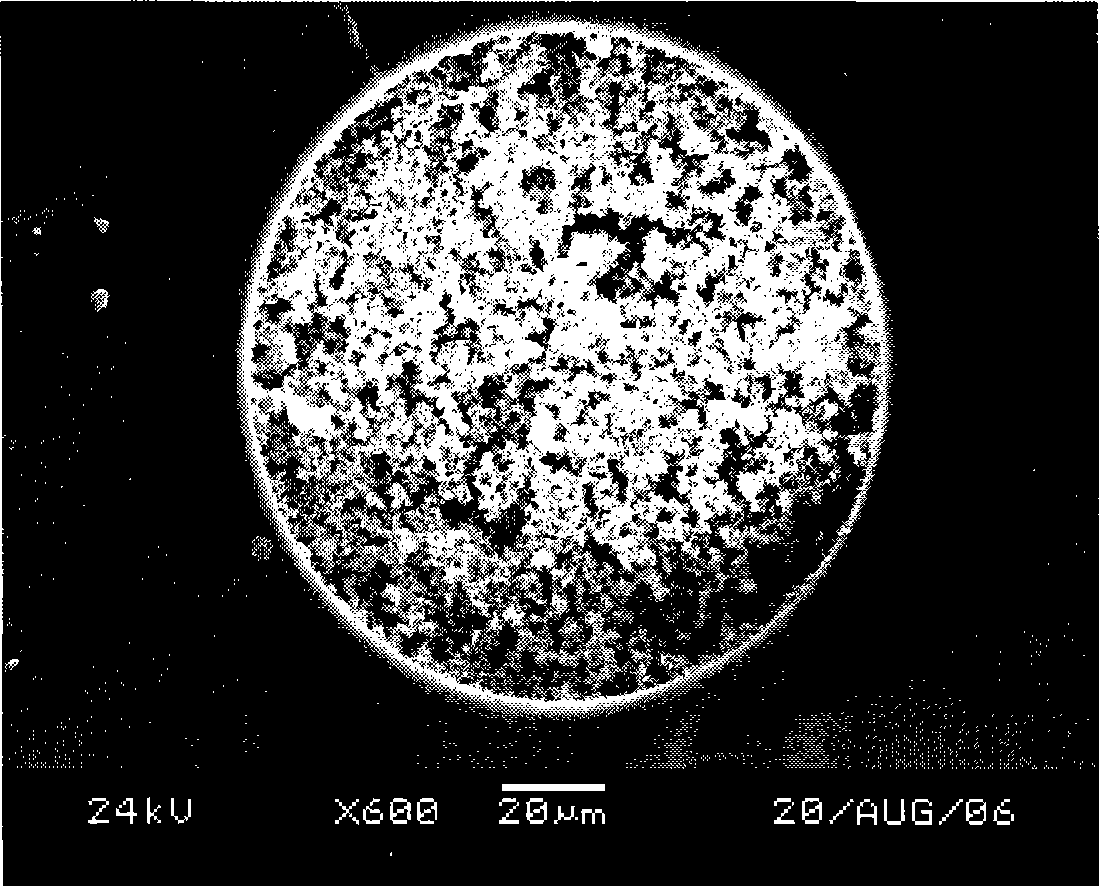

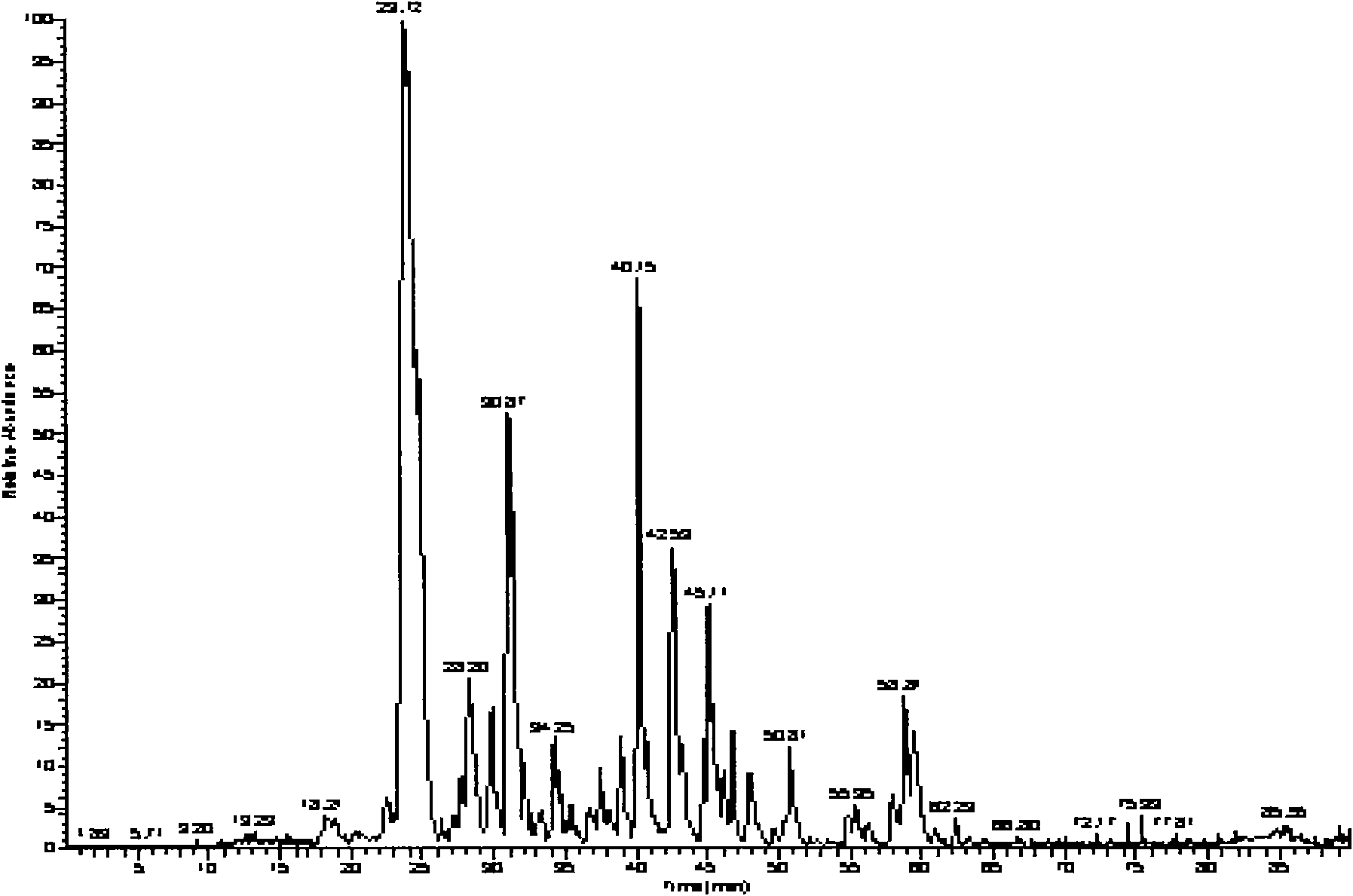

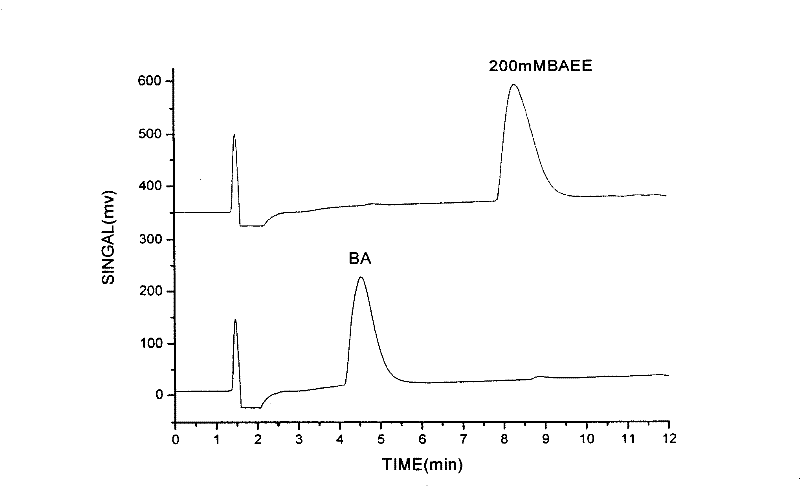

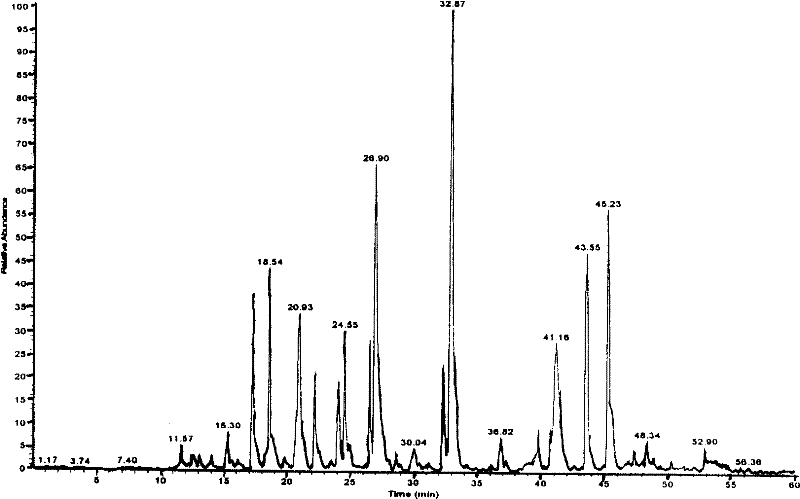

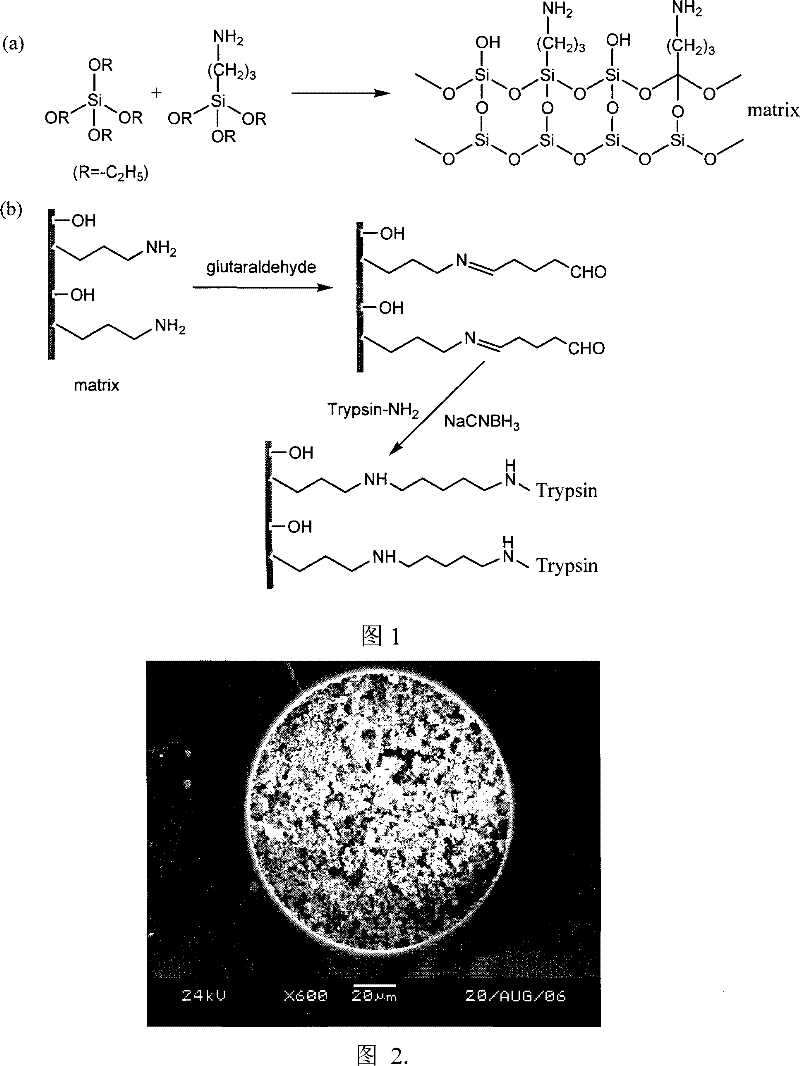

Preparation of porous integral material immobilized enzyme micro-reactor

ActiveCN101497879AAvoid self-degradationReduce consumptionOn/in organic carrierOn/in inorganic carrierSilanesFree solution

The invention relates to a zymohydrolysis method of protein samples, in particular to a porous organic-inorganic hybrid silica bulk material carrier which is prepared and obtained by using tetraethoxy silane and aminopropyl triethoxysilane as precursor molecules, using cetyltrimethylammonium trimethyl bromide ammonia as template molecules, using absolute ethyl alcohol as cosolvent through a sol-gel method and a template molecule self-assembly method. Hybrid silica bulk materials are activated by glutaric dialdehyde. After trypsinase is fixed, an organic-inorganic hybrid silica bulk material immobilized enzyme reactor is prepared. The invention has the advantages of simple and convenient preparation method, good permeability of the enzyme reactor, little counter pressure, high mechanical strength and high zymohydrolysis activity. Compared with free solution zymohydrolysis, the invention largely shortens reaction time, avoids the self-degradation of enzyme, can be repeatedly used, and also can be combined with an HPLC-MS / MS or CE-MS / MS system, thereby the on-line analysis of samples is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

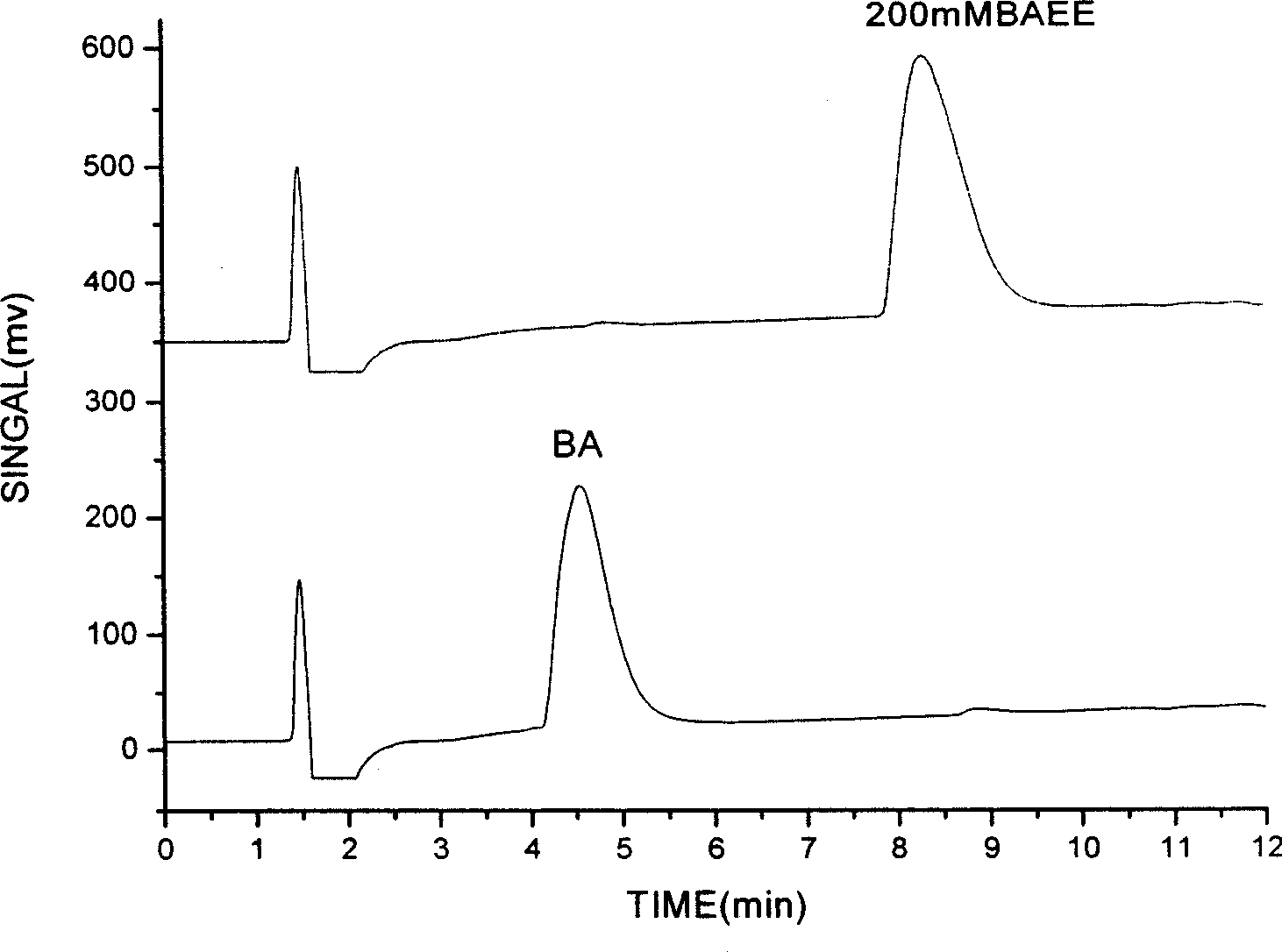

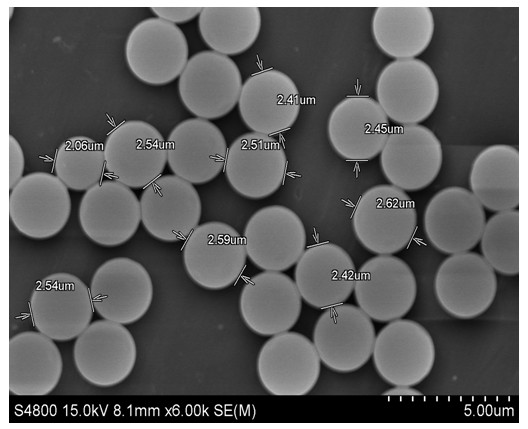

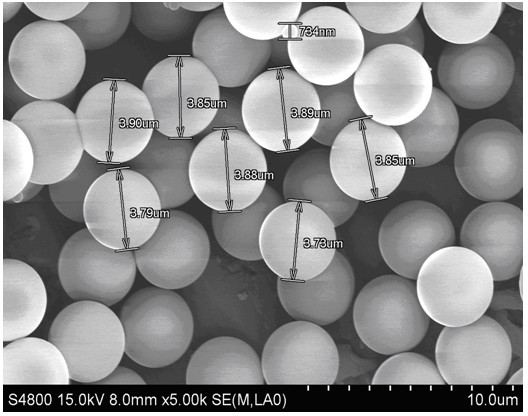

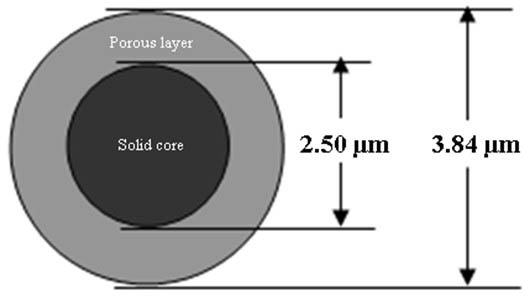

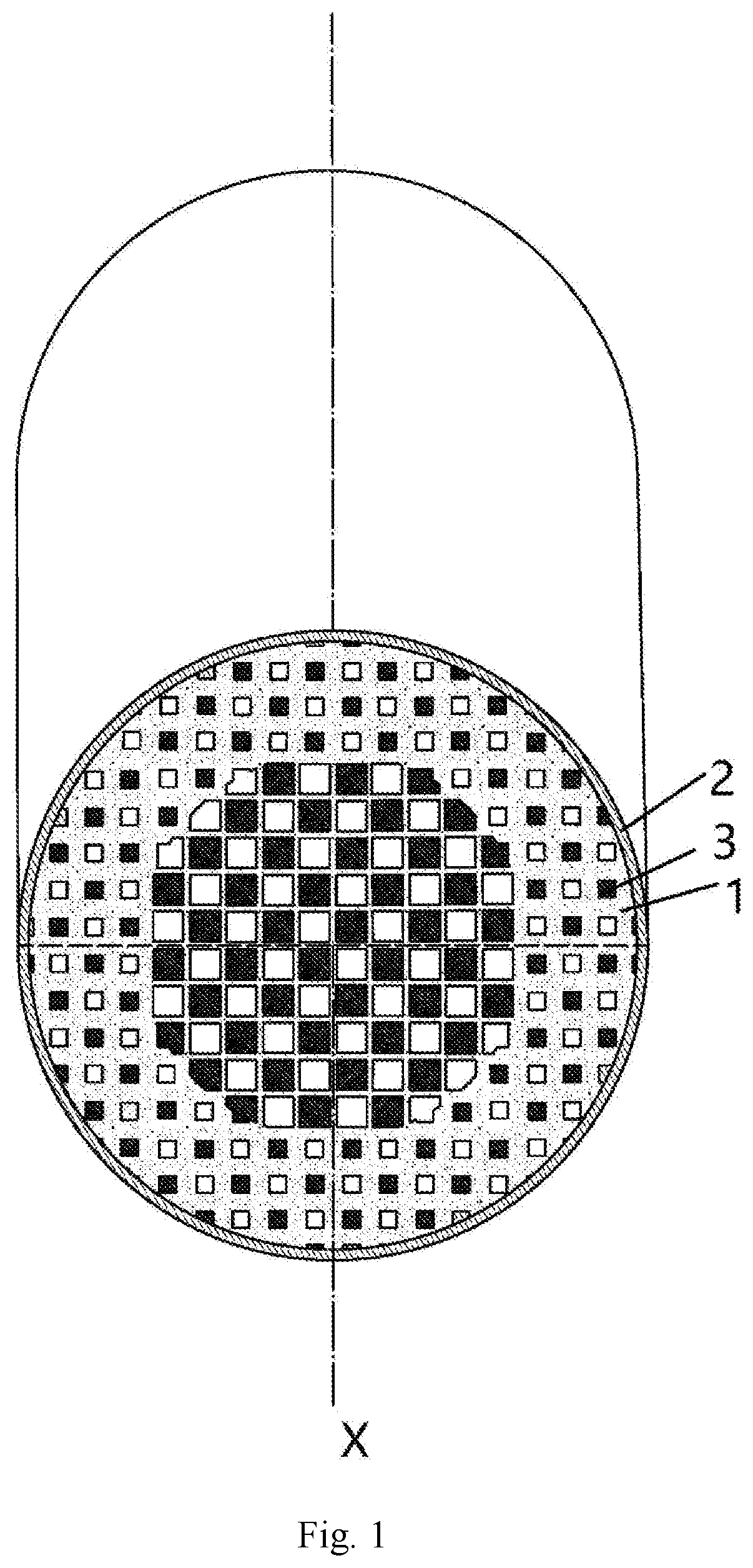

Synthesis method of core-shell type liquid chromatogram filler

InactiveCN102091606AModification thickness can be controlledMeet the needs of different separation modesOther chemical processesSynthesis methodsSilanes

The invention discloses a synthesis method of a core-shell type liquid chromatogram filler, which is characterized by comprising the following steps of: 1, mixing and stirring silane and an alcoholic mixture, and synthesizing non-porous spherical silicon gel to be used as a core part of the core-shell type filler; 2, carrying out calcination and acid treatment on the core part obtained from the step 1, and then coating a layer of cationic polymer electrolyte on the surface of the core part; and 3, modifying a layer of nano particles on the surface of a product obtained from the step 2 to obtain the core-shell type filler, wherein the alcoholic mixture comprises the following components in weight: 9.5-14.5 percent of alcohol, 60-80 percent of water and 6.5-13 percent of ammonia water. By adopting the preparation method disclosed by the invention, the core grain size of the obtained core-shell type filler and the modifying thickness of the nano particles can be controlled, and the surface functional groups can be freely selected, so that demands on different separation modes are met; and a filler detection column efficiency reaches 180,000 theoretical pedals / m which is over 2 times that of the conventional chromatograph filler.

Owner:苏州环球色谱有限责任公司

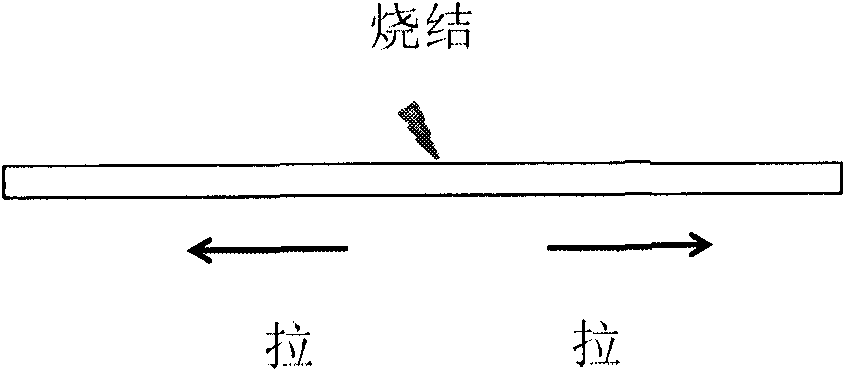

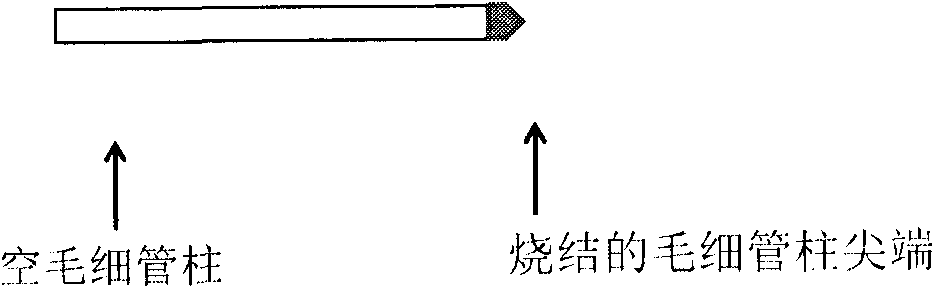

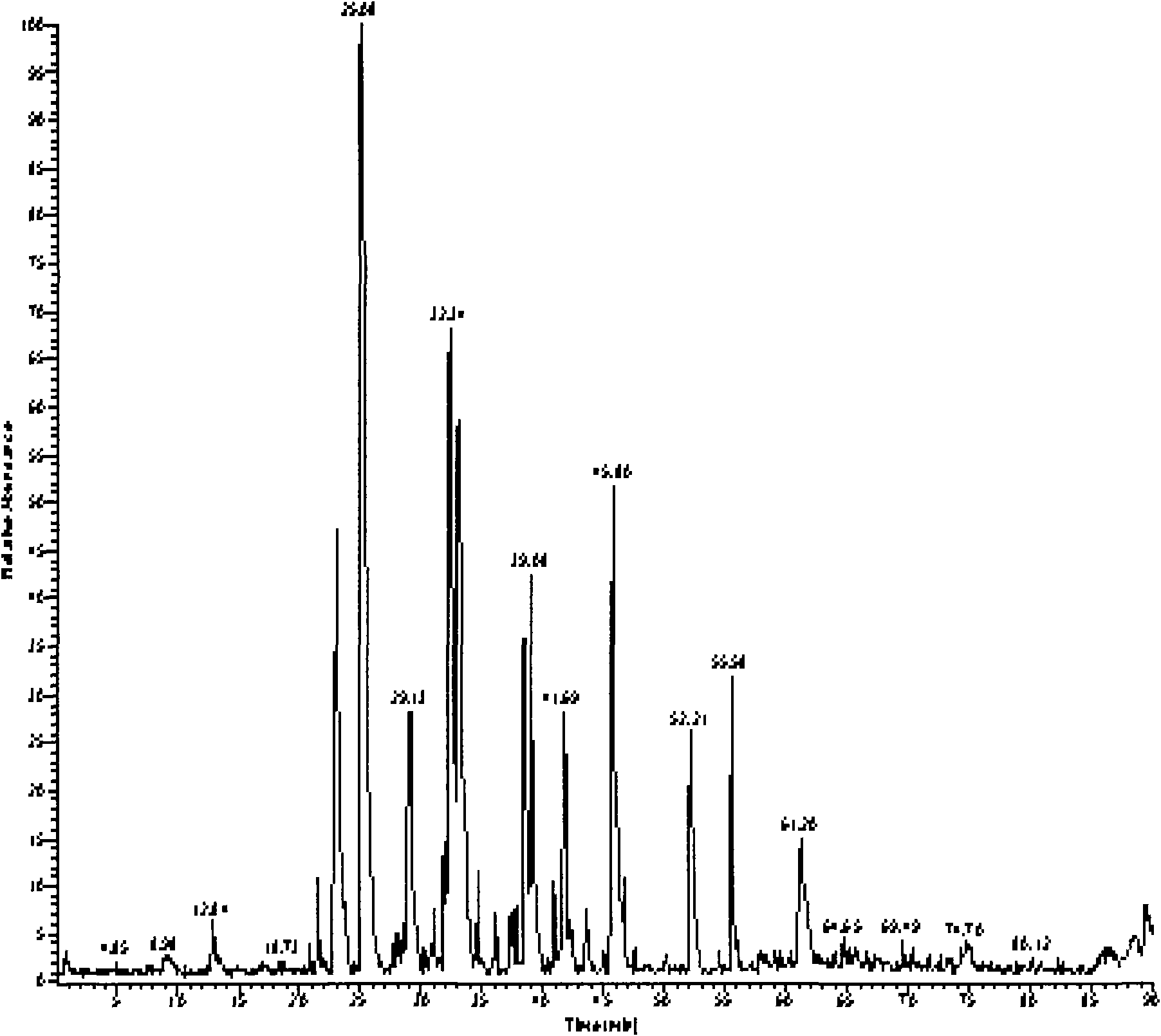

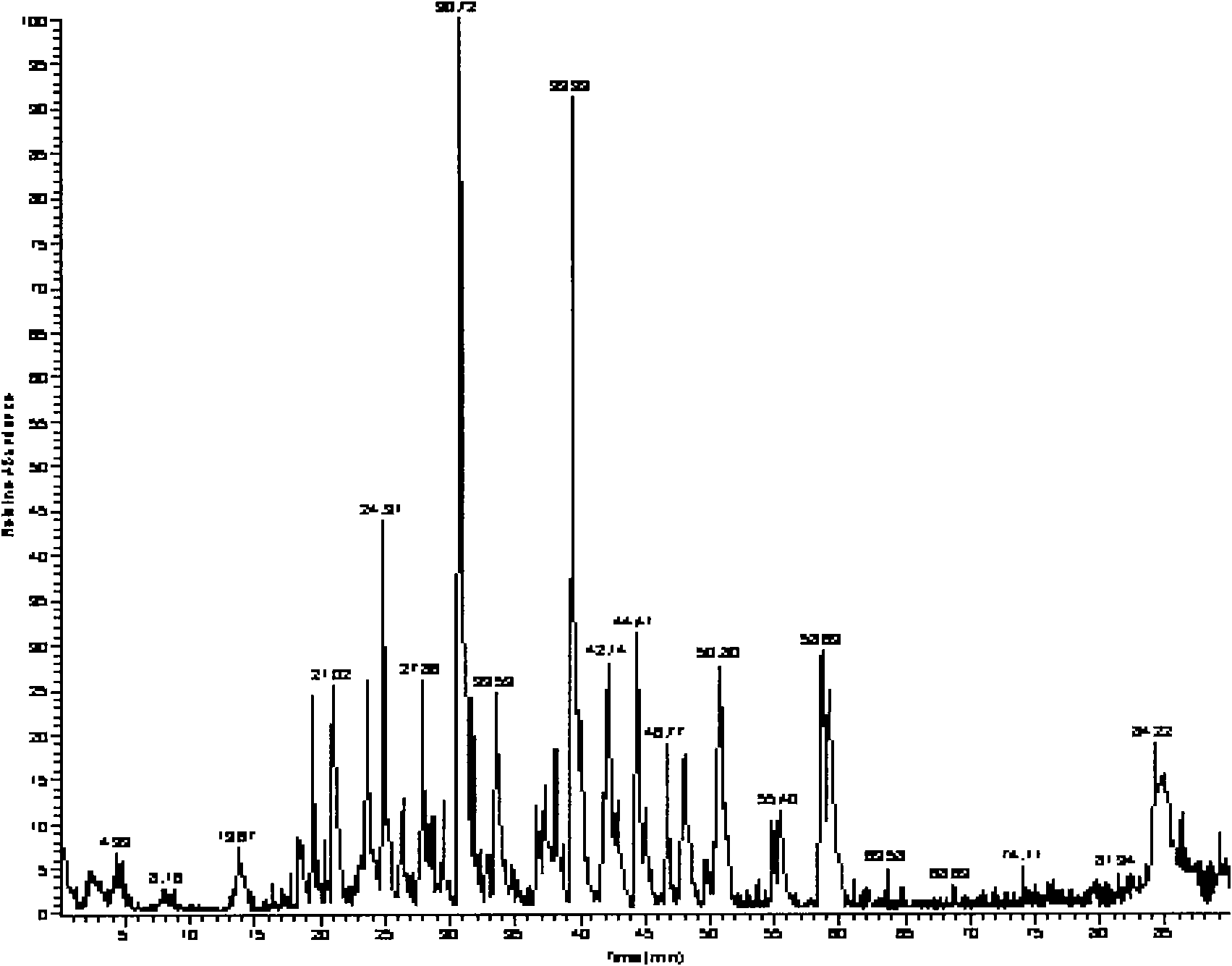

Nanospray capillary high pressure liquid chromatographic column and its preparation method

InactiveCN102243220AImprove resolution efficiencySmall back pressureGlass making apparatusComponent separationChemistryChromatography column

The invention belongs to the field of analytical chemistry. More specifically, the invention discloses a nanospray capillary high pressure liquid chromatographic column and its preparation method. The preparation method of the liquid chromatographic hollow column comprises three steps of: filling a polyimide-coated quartz capillary with a large-grained material which can be melted and solidified, removing the polyimide coating outside the capillary and drawing the capillary chromatographic column. The particle size of the meltable and solidifiable large-grained material in the chromatographic column is 10-15 microns, and a hollow gap can be formed after the large-grained material is heated and melted; in comparison with regular chromatographic columns, the chromatographic column provided by the invention has advantages of small back pressure on the tip as well as fast flow velocity and fast column-filling speed under the same pressure; when separating samples, the column has relatively small back pressure and high flow velocity. Therefore, a longer chromatographic column can be used on a regular liquid chromatogram under the same pressure so as to effectively raise the resolution and target protein identification efficiency of the chromatographic column.

Owner:徐平

Organic-inorganic hybrid monolithic material and application thereof in immobilized enzyme reactor

InactiveCN101845430AGood regeneration performanceImprove permeabilityImmobilised enzymesIminodiacetic acidAmmonium bromide

The invention relates to a monolithic material immobilized enzyme reactor, in particular to an organic-inorganic hybrid monolithic material and application thereof in the immobilized enzyme reactor. Methyl orthosilicate or tetraethyl orthosilicate, and 2-glycidoxypropyl trimethoxysilane are taken as precursor molecules; an iminodiacetic acid is taken as a metal ion chelating agent; cetyl trimethyl ammonium bromide serves as template molecules; octylamine is taken as a catalyst; monolithic material carriers are prepared by a sol-gel method, wherein the surface of the monolithic material carrier carries metal ion chelating groups; and then the reproducible monolithic material immobilized enzyme reactor can be prepared by sequentially and continuously making the monolithic material carriers pass through the solution of transition metal ions and enzyme solution. The prepared enzyme reactor has the advantages of relatively higher reproducibility, reusability, high activity, high permeability, low reaction pressure and high mechanical strength; and the preparation method is simple and convenient.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

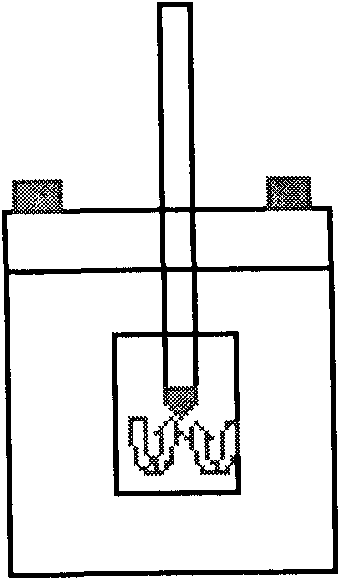

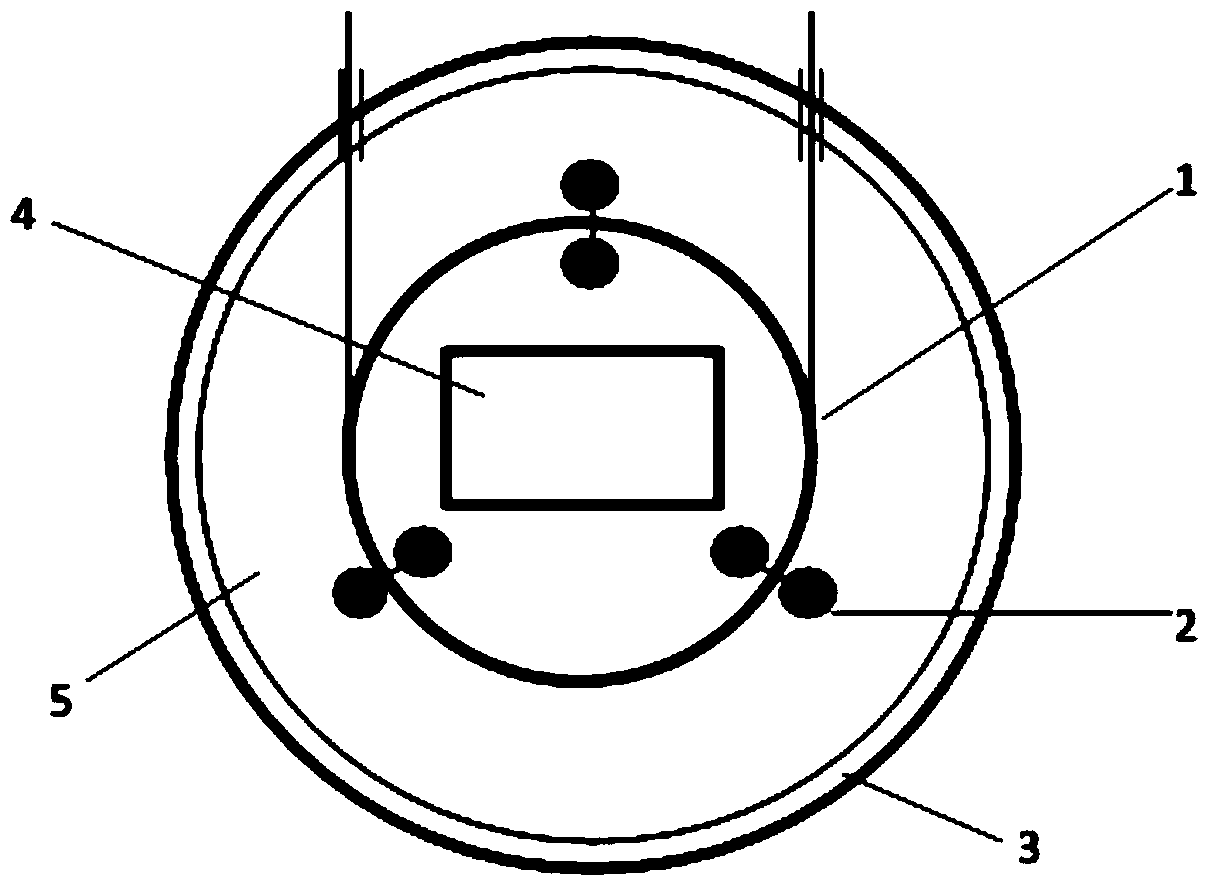

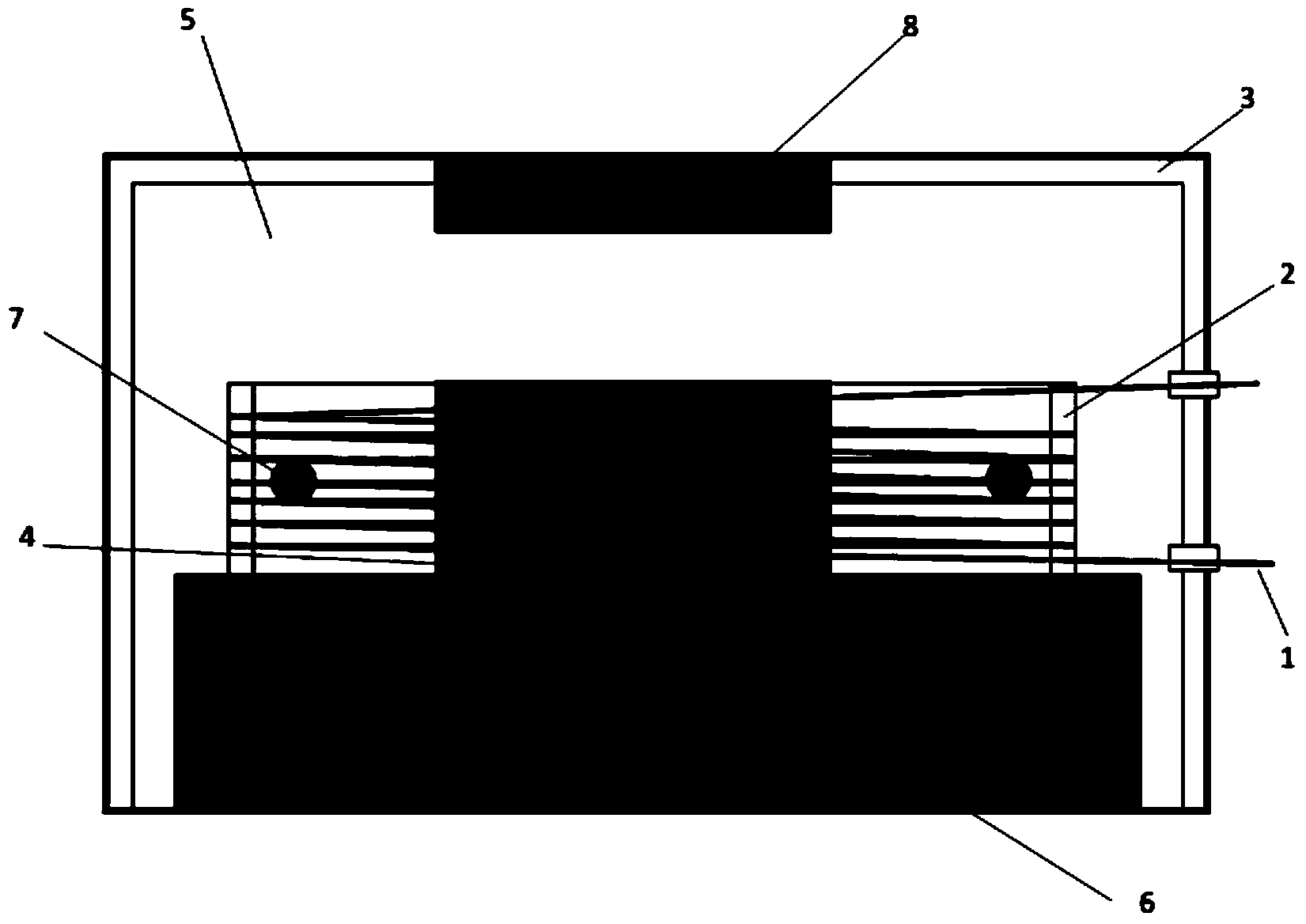

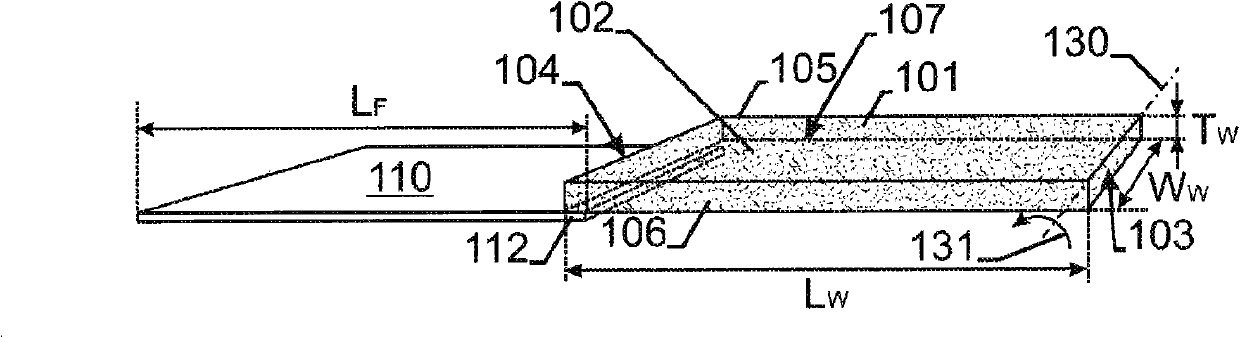

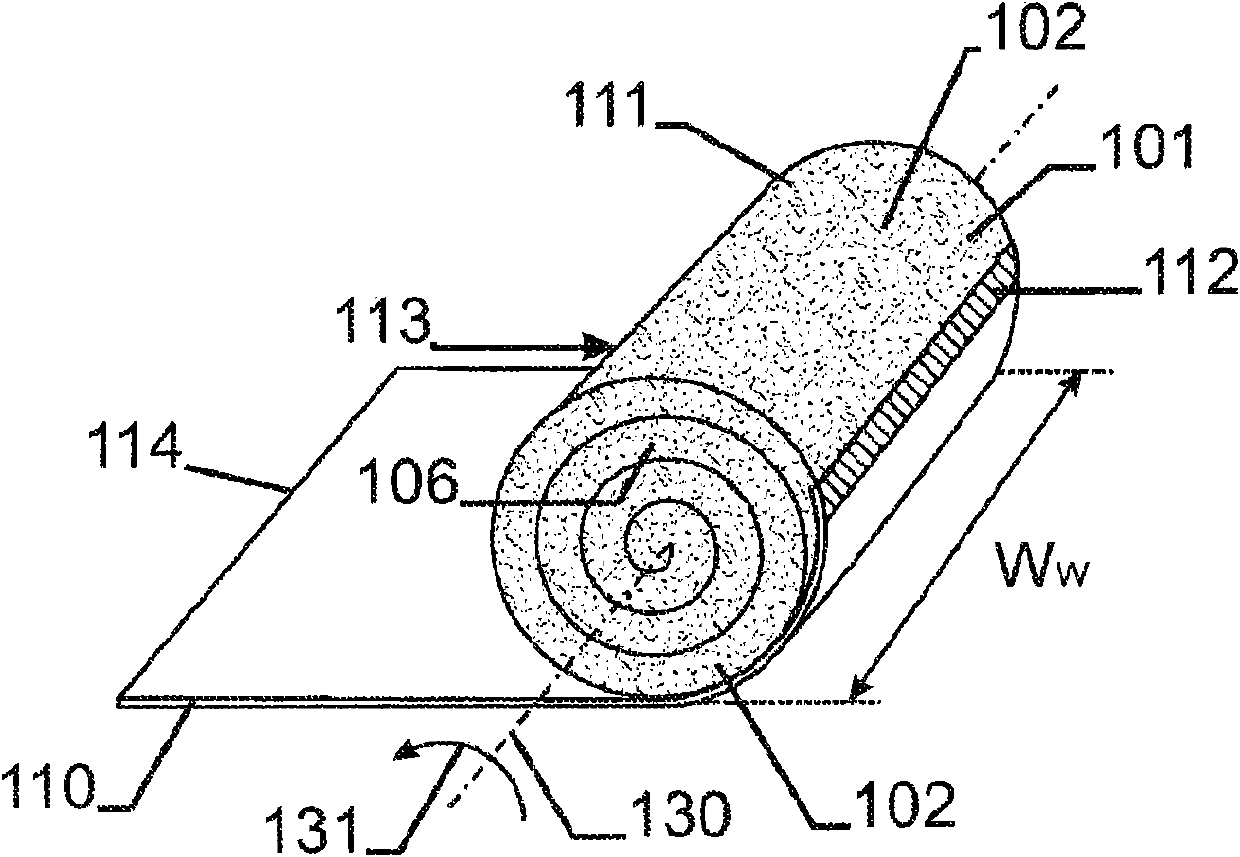

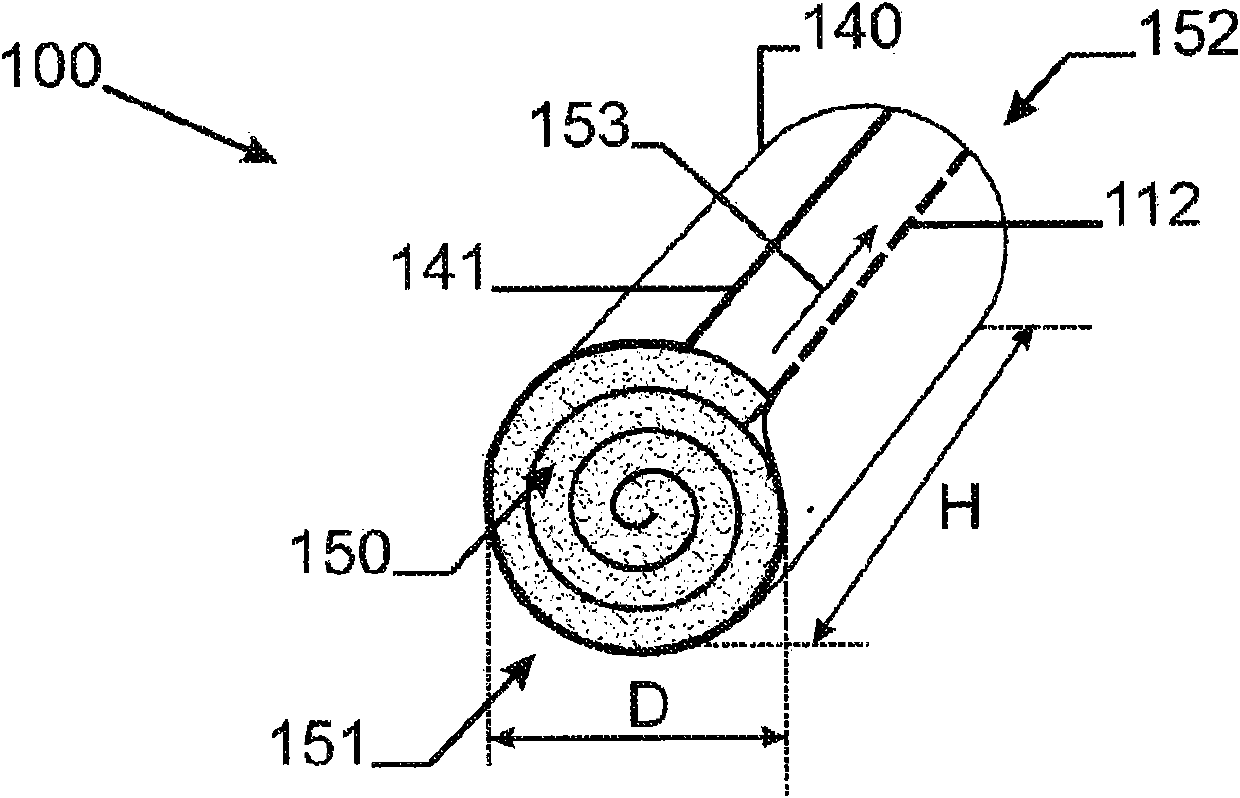

Super-long protein and polypeptide separation capillary liquid chromatography column system with automatic temperature control

The invention relates to a super-long protein and polypeptide separation capillary liquid chromatography column system with automatic temperature control. A support frame is fixed at the intermediate part of a shell; a filled capillary liquid chromatography column is wound on the support frame, and both ends of the filled capillary liquid chromatography column respectively protrude out of a small hole reserved in the edge of the shell; after a capillary is arranged, a heat-insulating material is filled between the capillary column and the shell; a control panel is fixed at the intermediate part of the shell and connected with a thermocouple which is arranged in the ring of the capillary column and close to the capillary column, and a temperature control module fixed in the ring of the capillary column and a semiconductor thermoelectric refrigerating fin as a part of the shell of the column system are connected. The super-long protein and polypeptide separation capillary liquid chromatography column system disclosed by the invention is easy to manufacture and low in price, the column temperature can be increased by combining the super-long capillary column and a temperature control system, and the viscocity of a mobile phase can be effectively reduced, the back pressure can be reduced, the mass transfer rate between two phases can be accelerated and the sample separation can be conveniently and efficiently realized.

Owner:EAST CHINA UNIV OF SCI & TECH

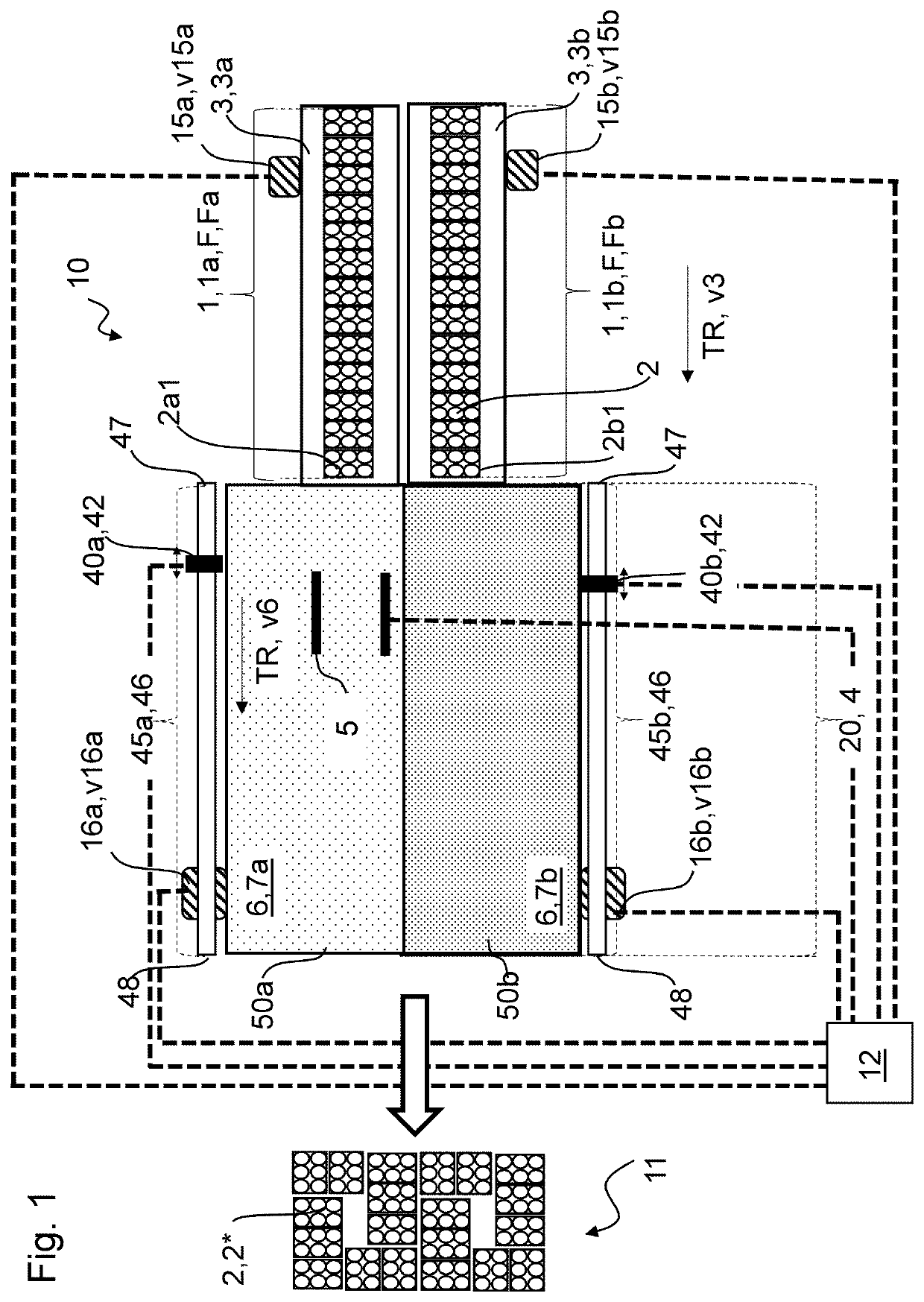

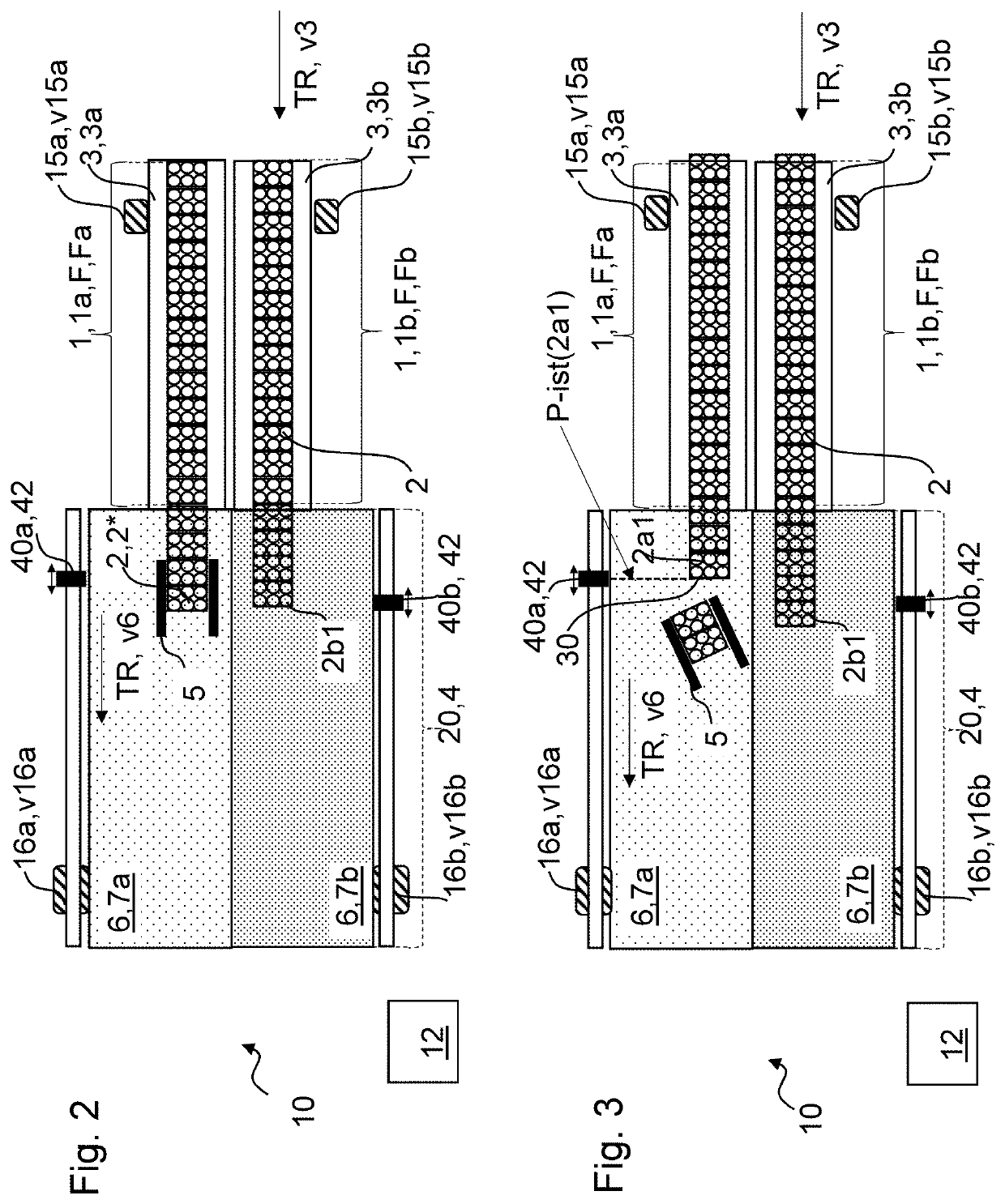

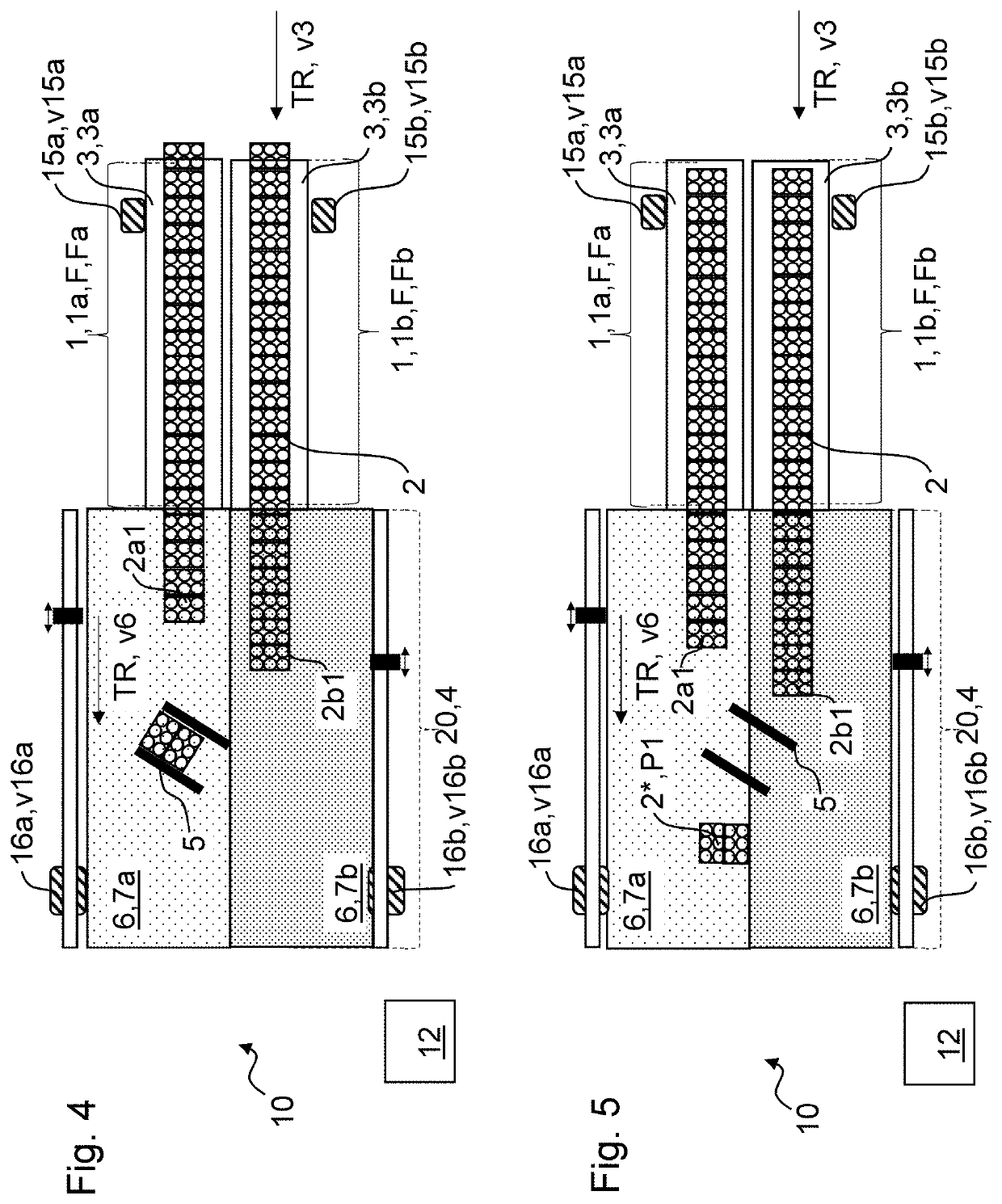

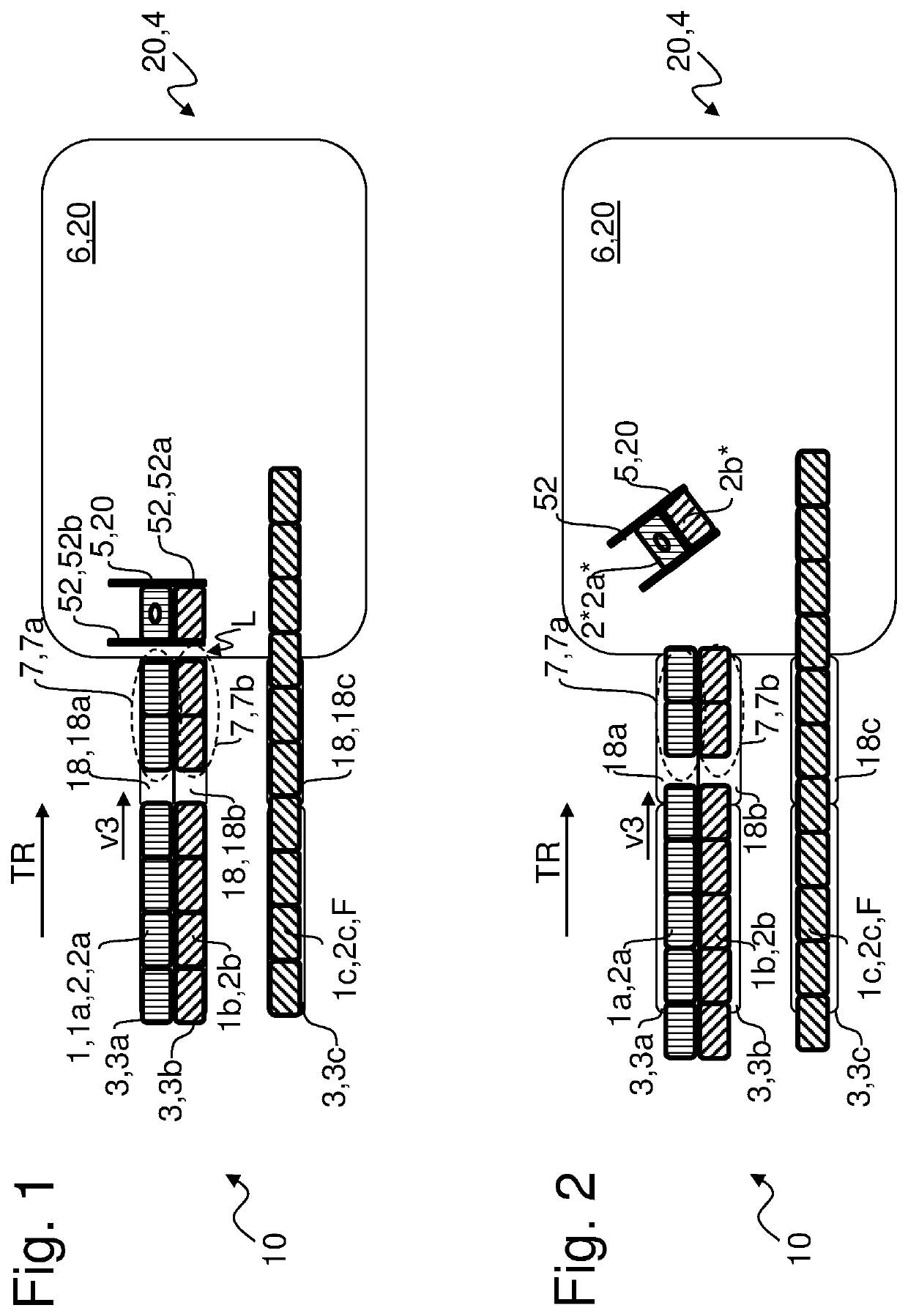

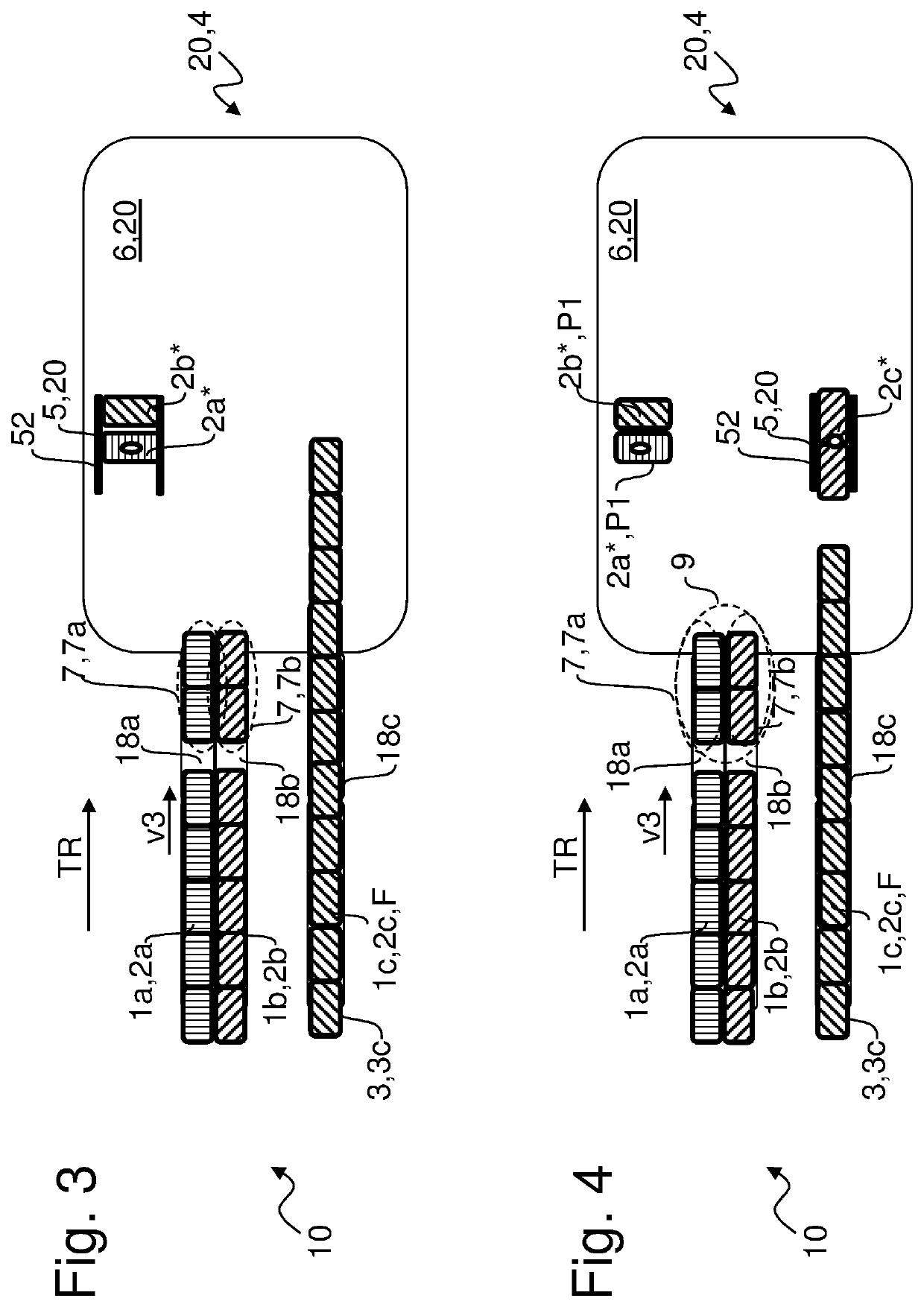

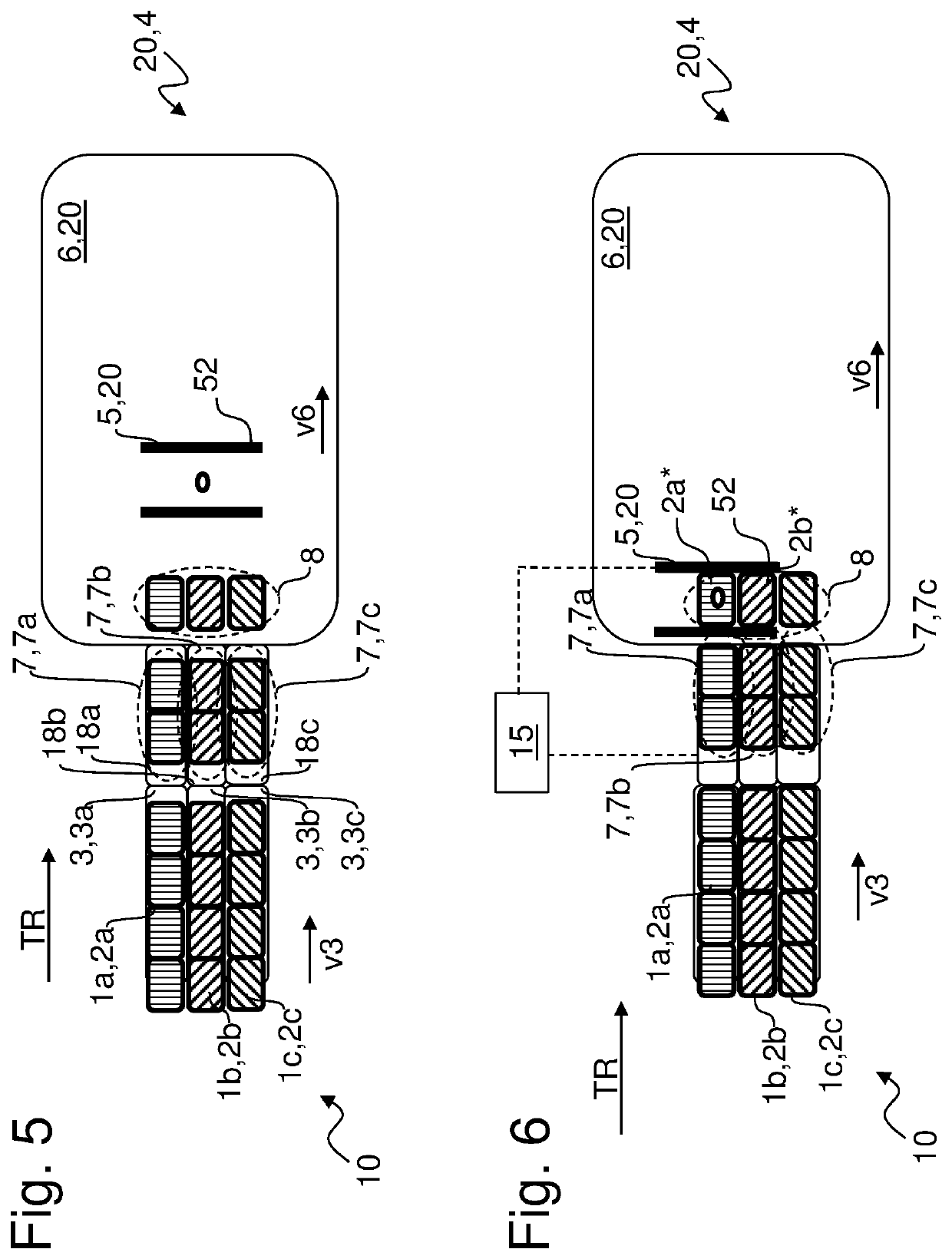

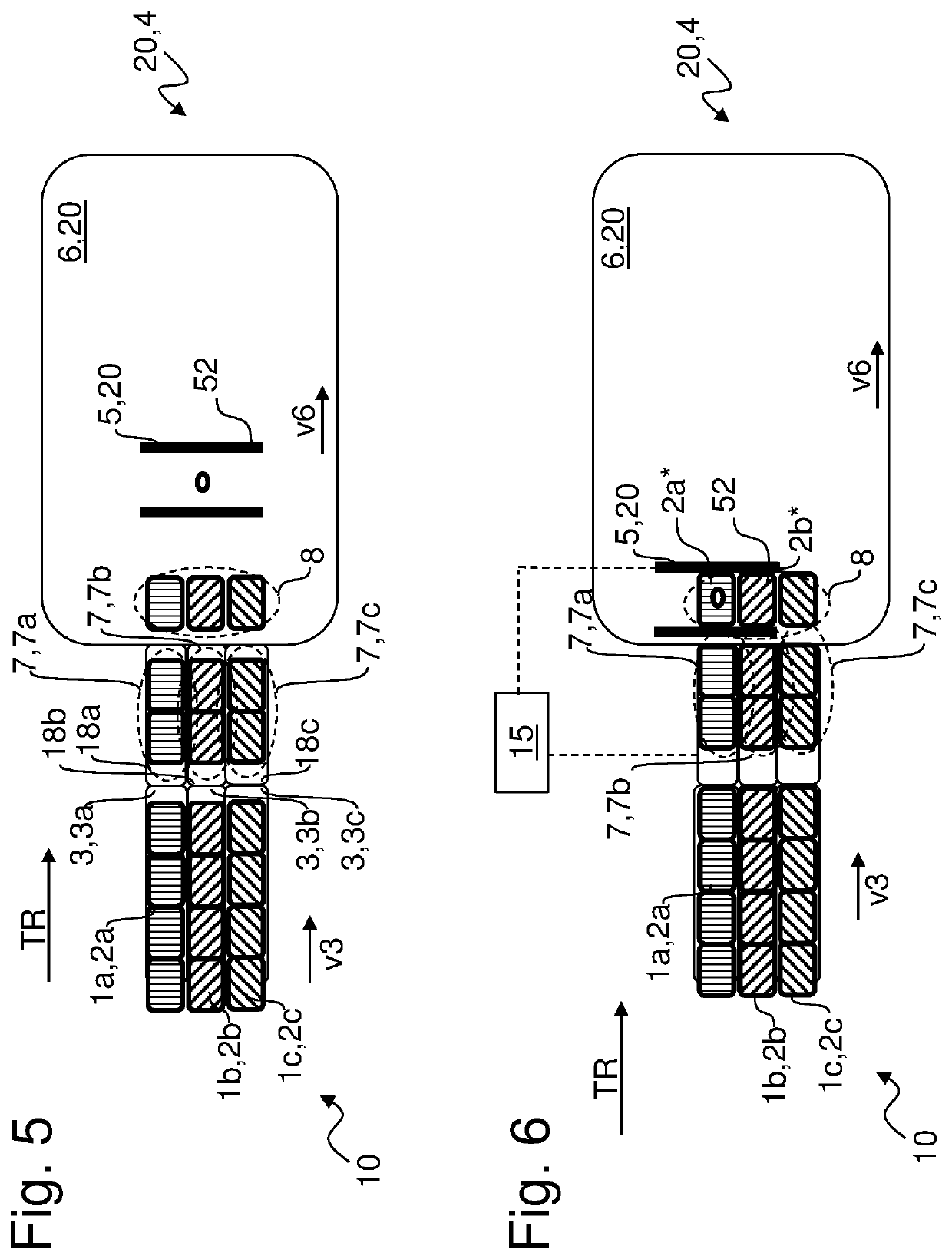

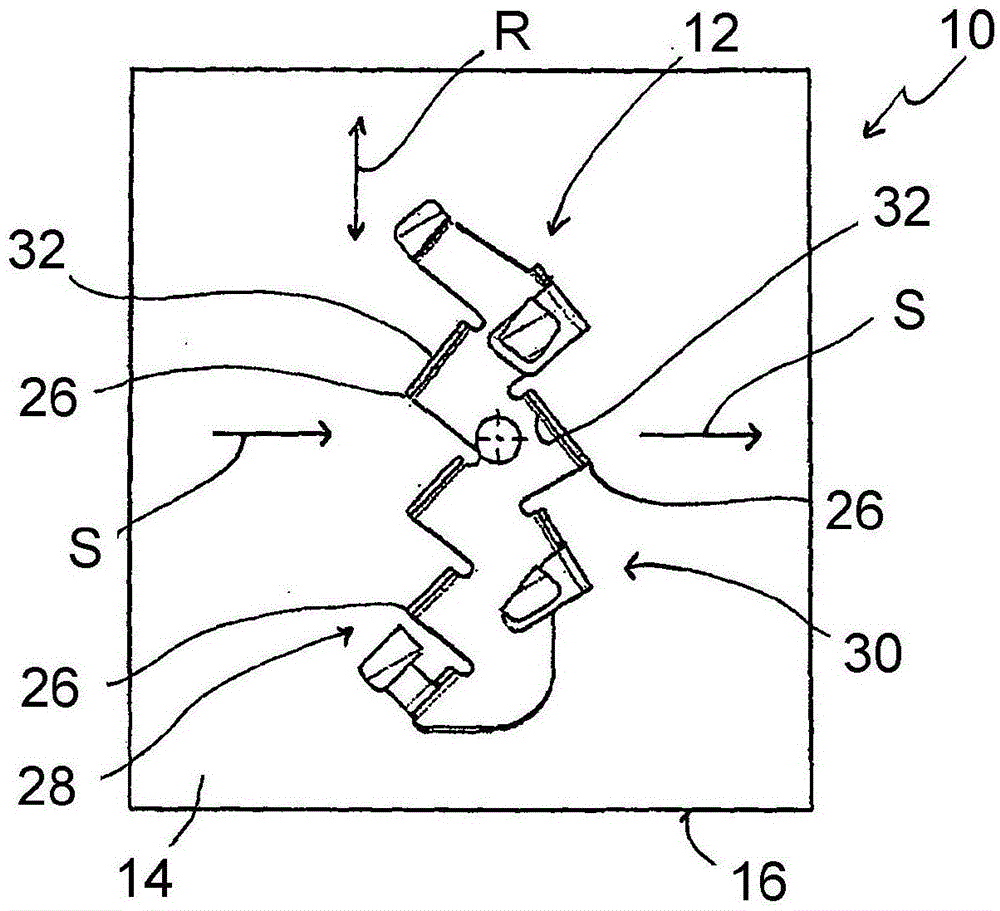

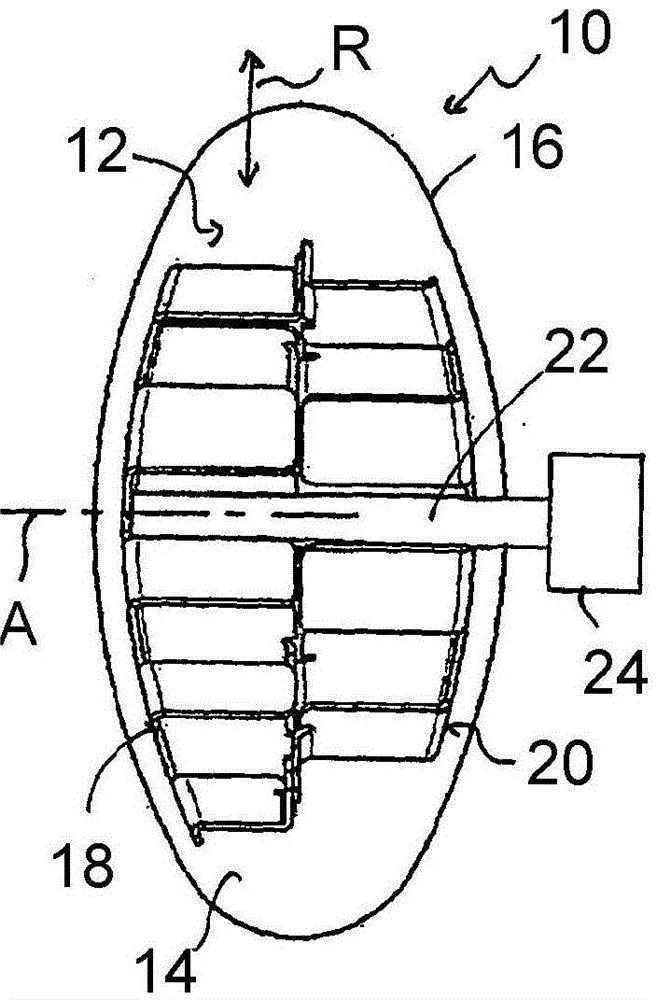

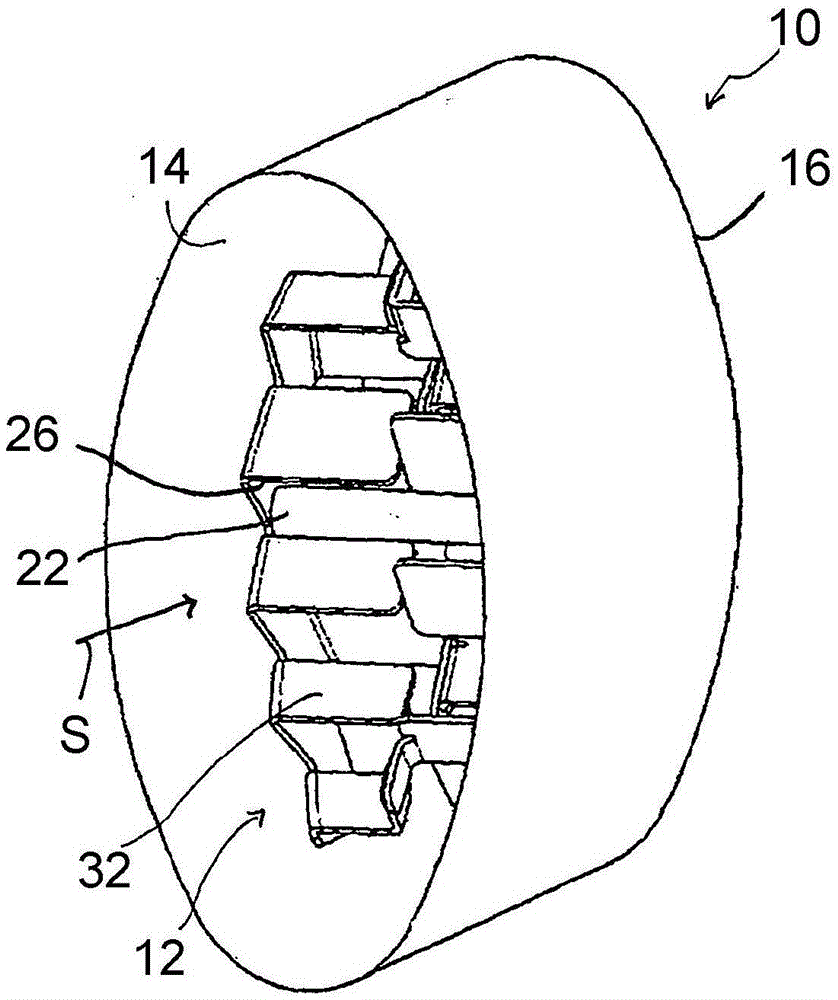

Apparatus and method for handling piece goods moved one after another

ActiveUS20200039756A1Adapt quicklyCorrection errorProgramme-controlled manipulatorConveyorsManipulatorIndustrial engineering

The invention relates to an apparatus and a method handling moved piece goods. The apparatus comprises a manipulator for the piece goods, at least one transport device transporting the moved piece goods to a seizing range of the at least one manipulator and at least one horizontal conveying device assigned to the seizing range and / or to a movement range of the at least one manipulator, via which horizontal conveying device the moved piece goods are transported in the seizing range of the at least one manipulator. Furthermore, the apparatus comprises at least one detection device for obtaining space coordinates and / or position data and / or contour data of piece goods to be seized by the manipulator, wherein the at least one horizontal conveying device and the at least one transport device are calibratable and / or controllable based on the space coordinates and / or position data and / or contour data.

Owner:KRONES AG

Preparation method of organic-inorganic hybrid monolithic column

InactiveCN110090634AEasy to makeSimple structureOther chemical processesSolid sorbent liquid separationPorosityMetal-organic framework

The invention relates to a preparation method of an organic-inorganic hybrid monolithic column, belonging to the technical field of detection. The organic-inorganic hybrid monolithic column is obtained by using methyl methacrylate and polyethylene glycol as organic materials and adding a copper metal organic gel. Due to a special structure, the polyethylene glycol has little effect on biological macromolecules such as proteins and the like, and is a recognized biocompatible material. As a novel pore-forming template, the metal organic gel is used to prepare a macroporous transparent organic polymer material which is in a gel state of a metal organic framework. The metal-organic framework is a porous material with a periodic network structure formed by an organic ligand and metal ions through a self-assembly process. The metal-organic framework is also known as coordination polymer. The metal-organic gel is simple to prepare, has the characteristics of good porosity, structural diversity, good chemical stability and thermal stability, and the metal in gel can effectively improve the rigidity of the monolithic column and enhance the mechanical properties of the monolithic column.

Owner:吴培建

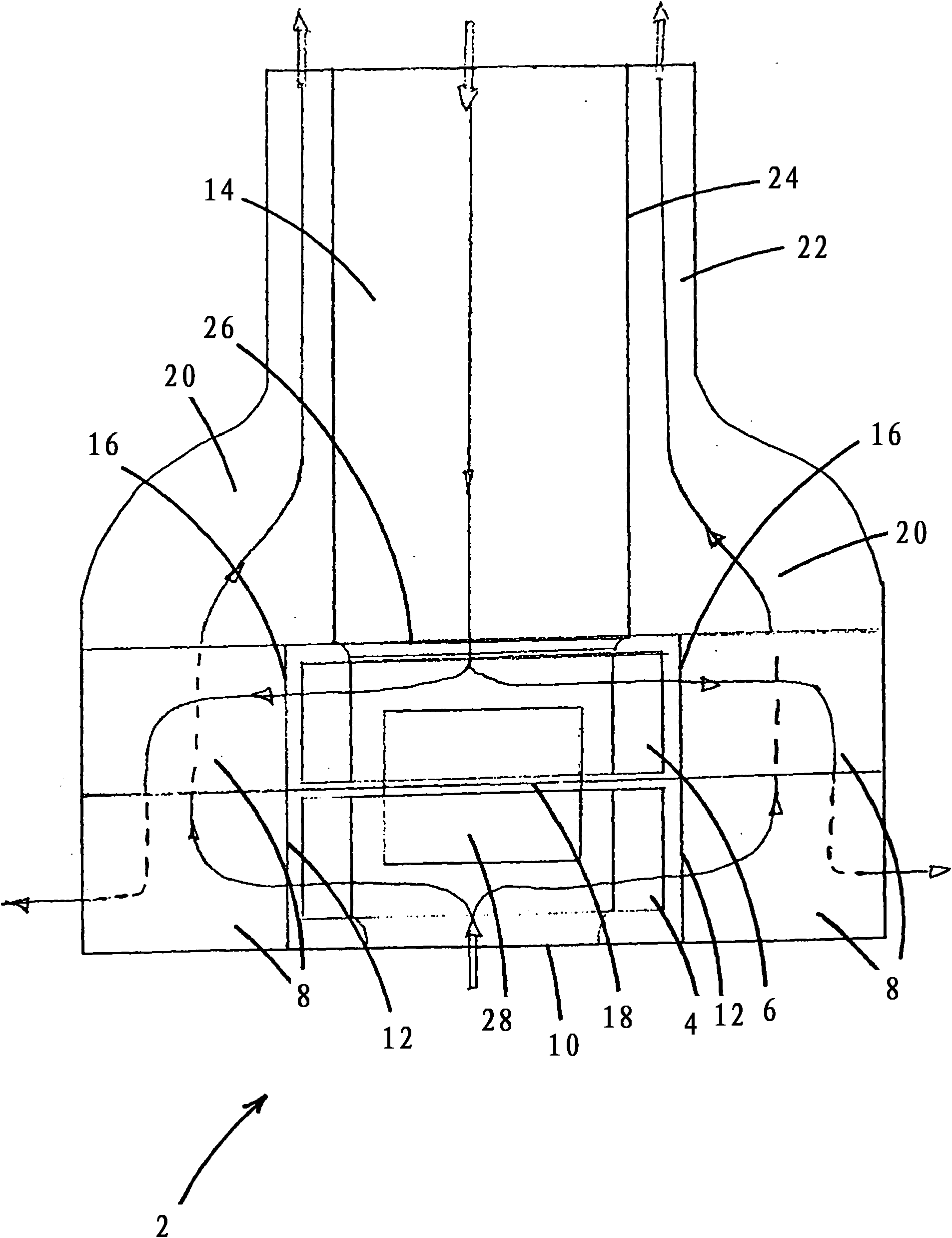

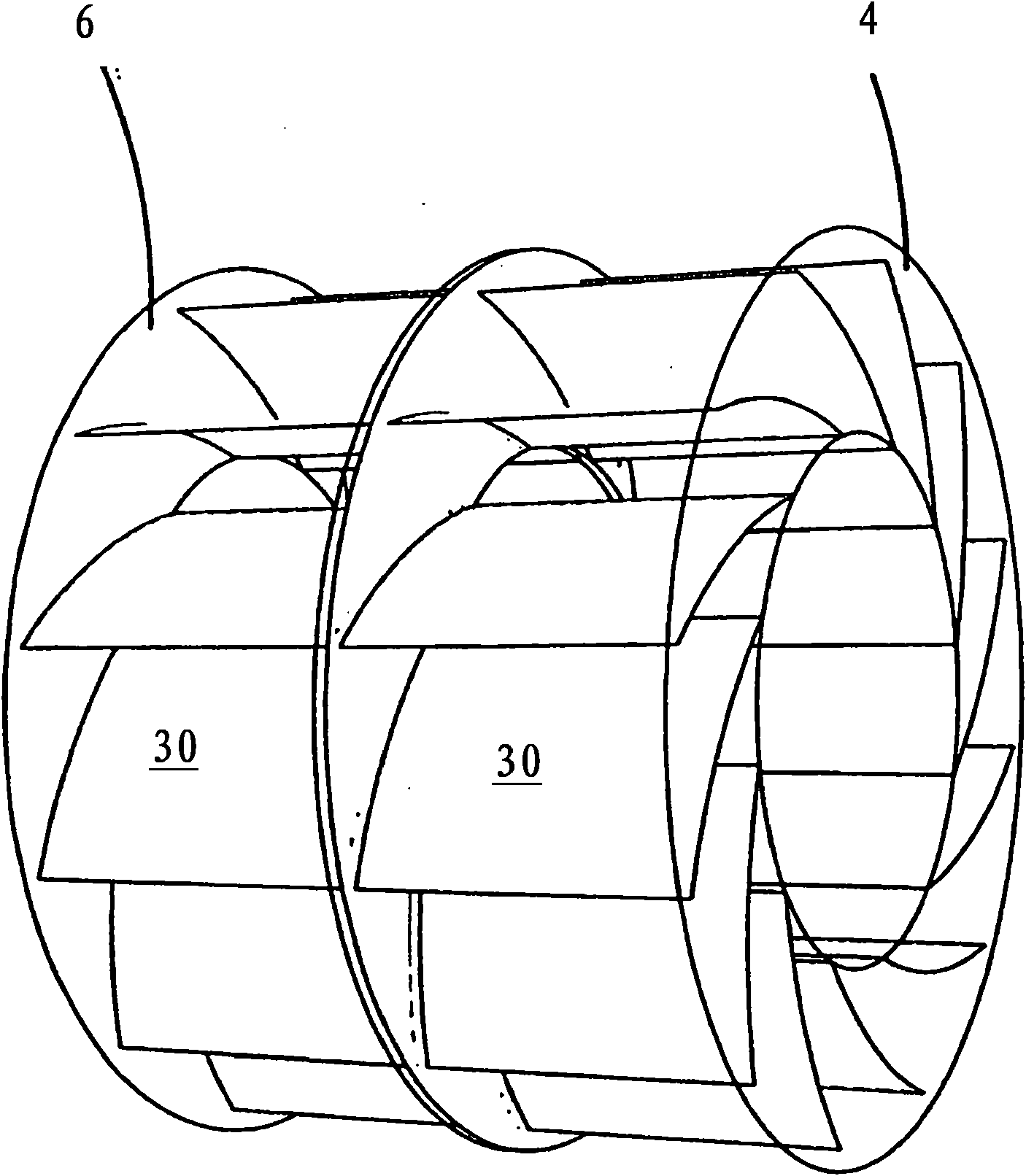

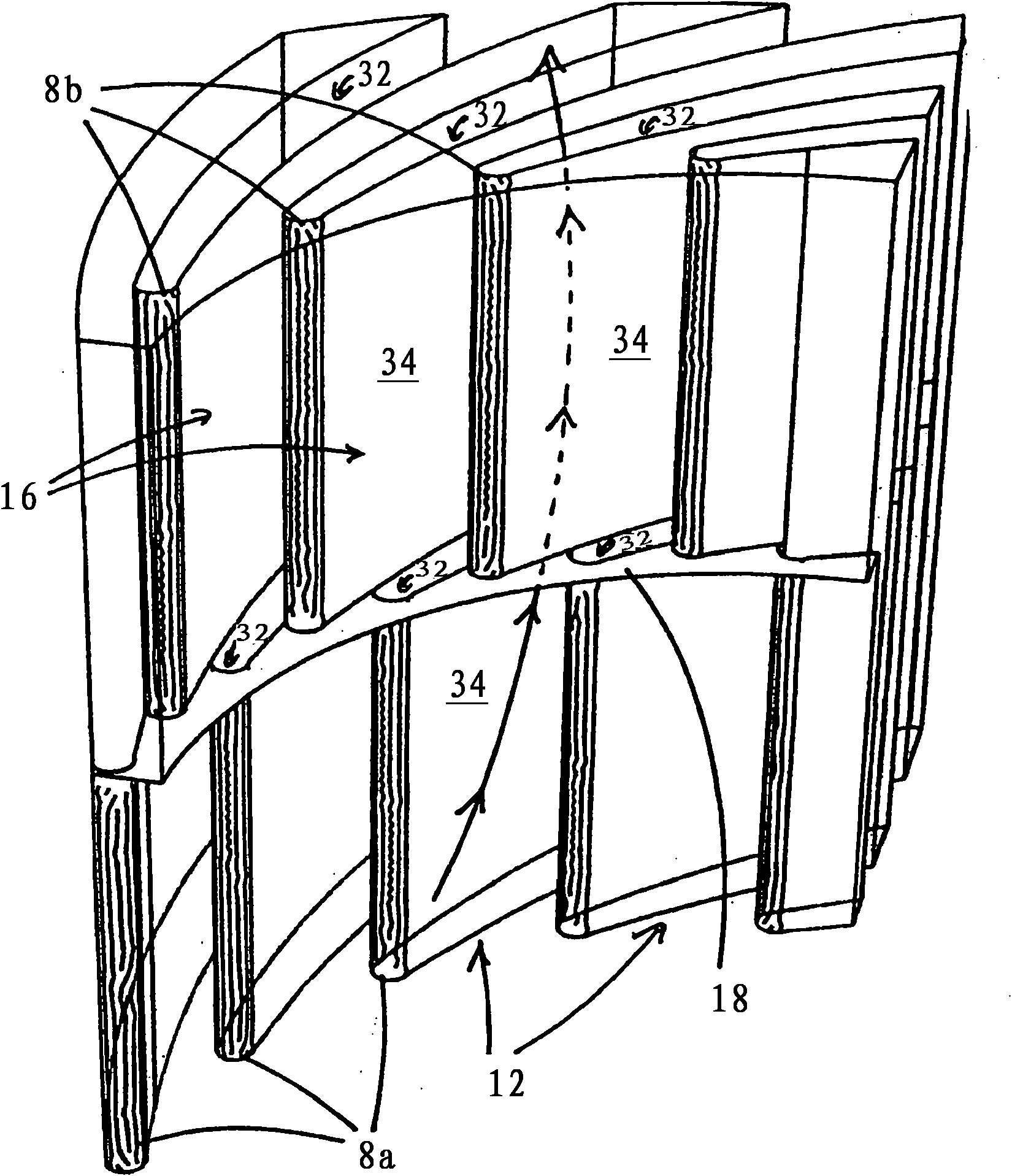

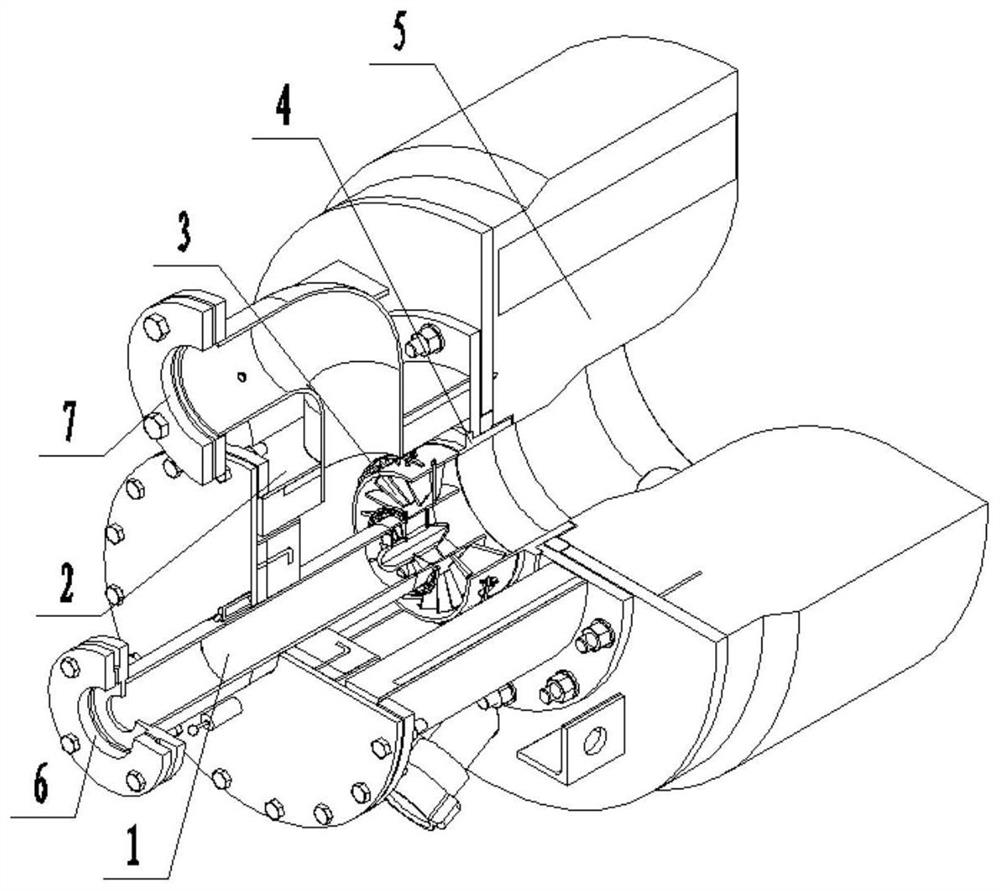

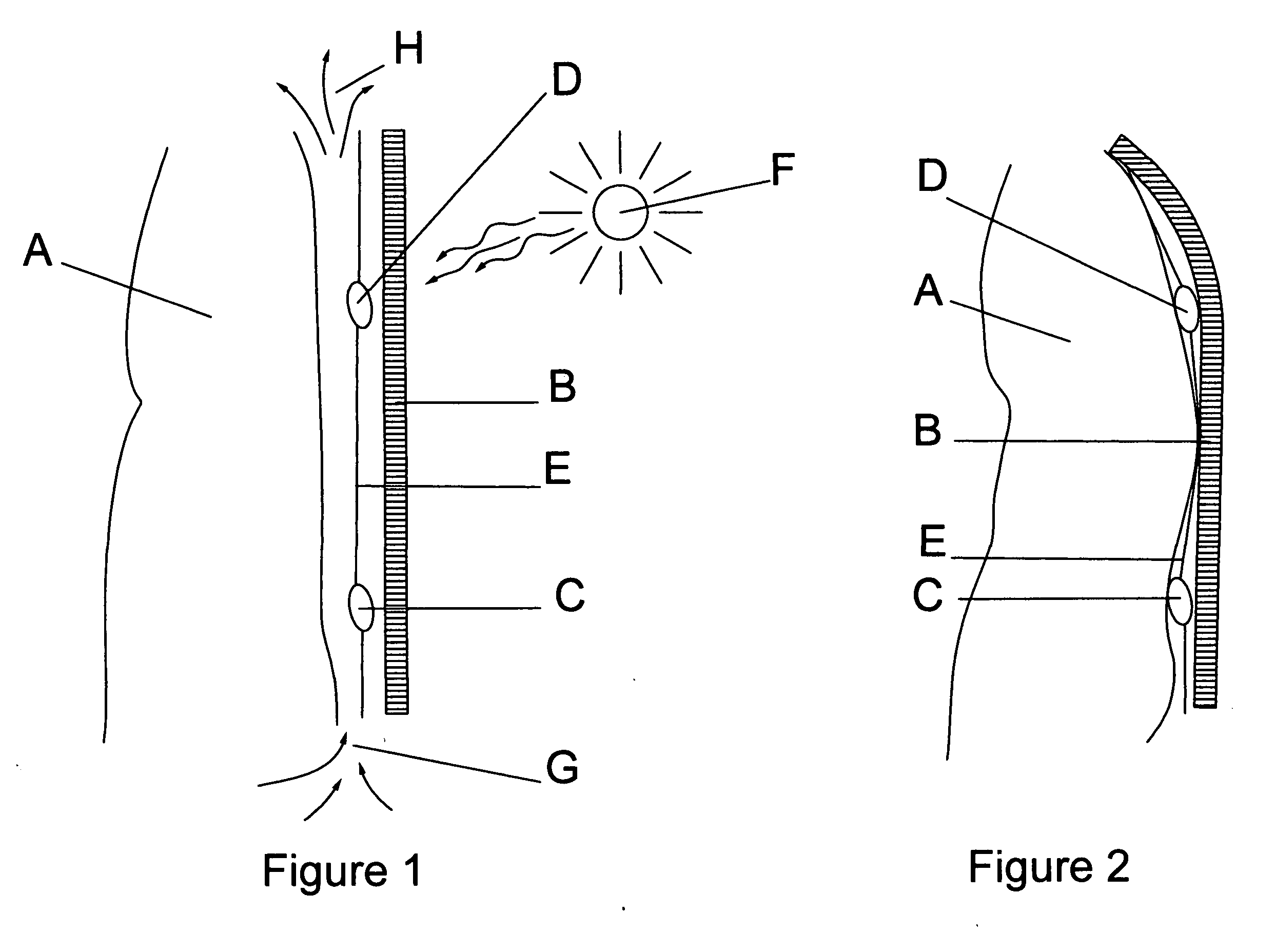

Exhaust hood

InactiveCN102159893ALower energy requirementsSmall back pressureDomestic stoves or rangesCooking fumes removalImpellerEngineering

The invention relates to an exhaust hood (2) comprising a first fan wheel (4) for the intake and removal of indoor air and a plurality of guide vanes (8) arranged externally around the first fan wheel (4) to redirect the air current discharged from the first fan wheel (4). The aim of the invention is to improve said exhaust hood in such a manner that the energy losses through indoor air being blown out are reduced. For this purpose, a second fan wheel (6) for the intake of outdoor air is arranged in the exhaust hood (2) axially offset from the first fan wheel (4) and the air currents discharged from the first and second fan wheel (4, 6) are guided past each other and separately from each other through the guide vanes (8) which are designed as a hollow space (32) and which define air ducts, the walls of the guide vanes (8) defining respective surfaces (34) for the heat exchange between the two air currents.

Owner:BERLING

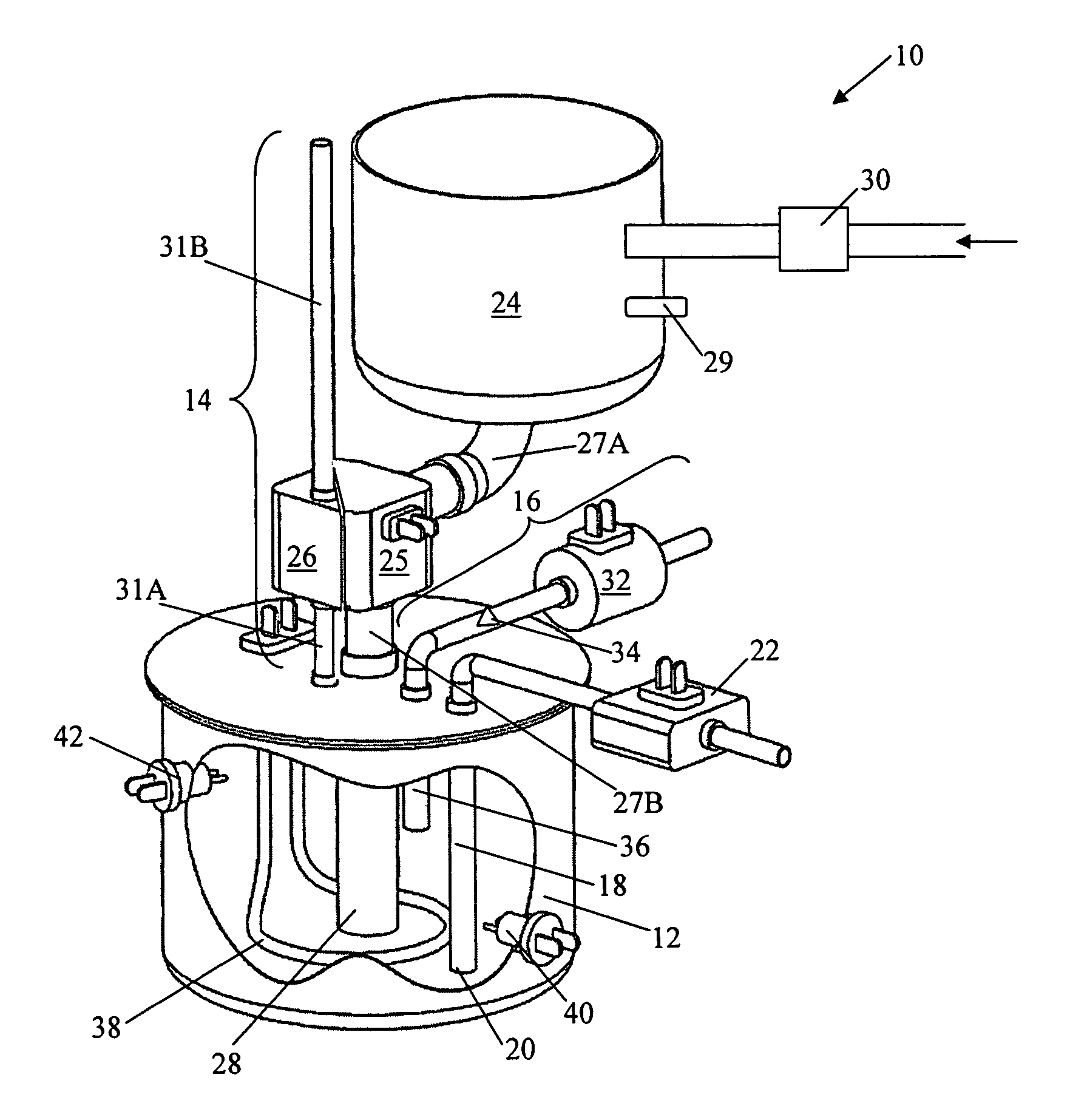

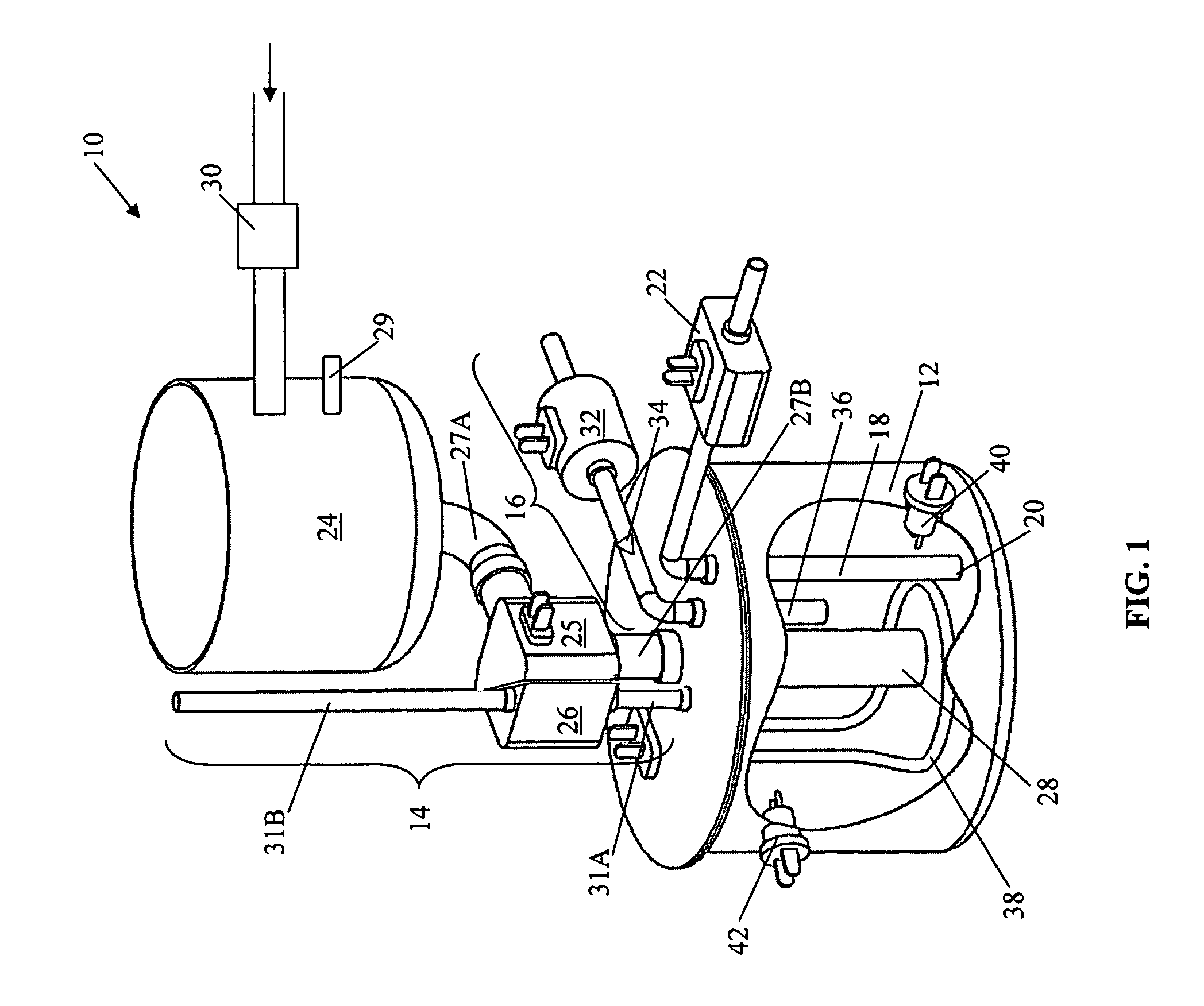

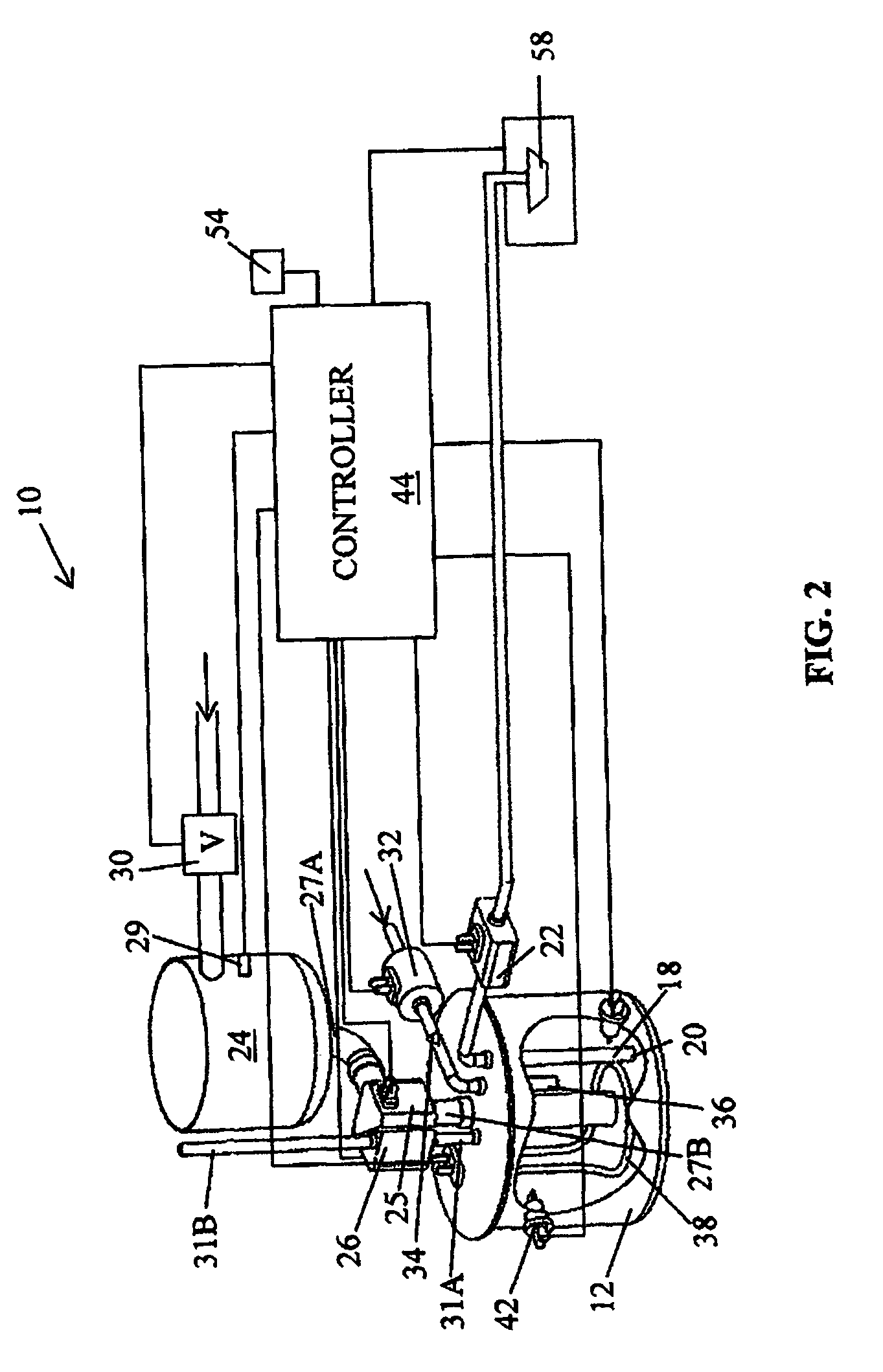

Method and apparatus for dispensing liquid in a beverage brewing machine

ActiveUS7819284B2Increase water flowGreat volumeOpening closed containersBottle/container closureMechanical engineeringAir Pump Assembly

A liquid dispensing apparatus for use in a beverage brewing machine, the liquid dispensing apparatus, includes a dispensing chamber, a liquid delivery and venting arrangement in communication with an interior of the dispensing chamber for delivery of liquid thereto and for venting air therefrom, an air pump assembly in communication with the interior of the heating and dispensing chamber for pumping air into the dispensing chamber, a liquid discharge conduit in communication with the interior of the heating and dispensing chamber for discharging liquid therefrom, an end of the discharge conduit located at a predetermined level of the dispensing chamber, and a liquid pump connected to the liquid discharge conduit for pumping liquid out of the heating and dispensing chamber. During liquid dispensing, the liquid delivery and venting arrangement is closed.

Owner:1693778 ONTARIO LTD

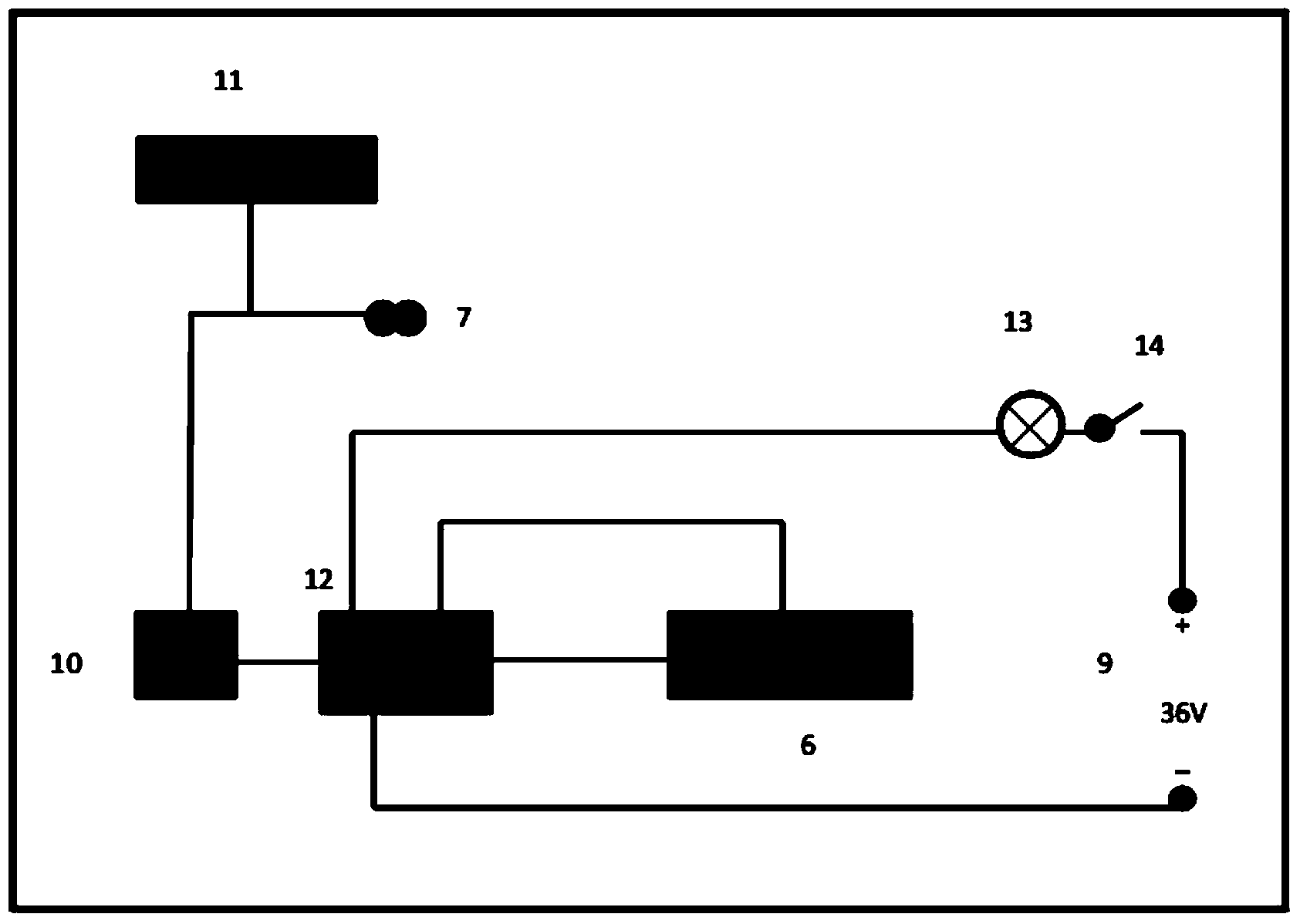

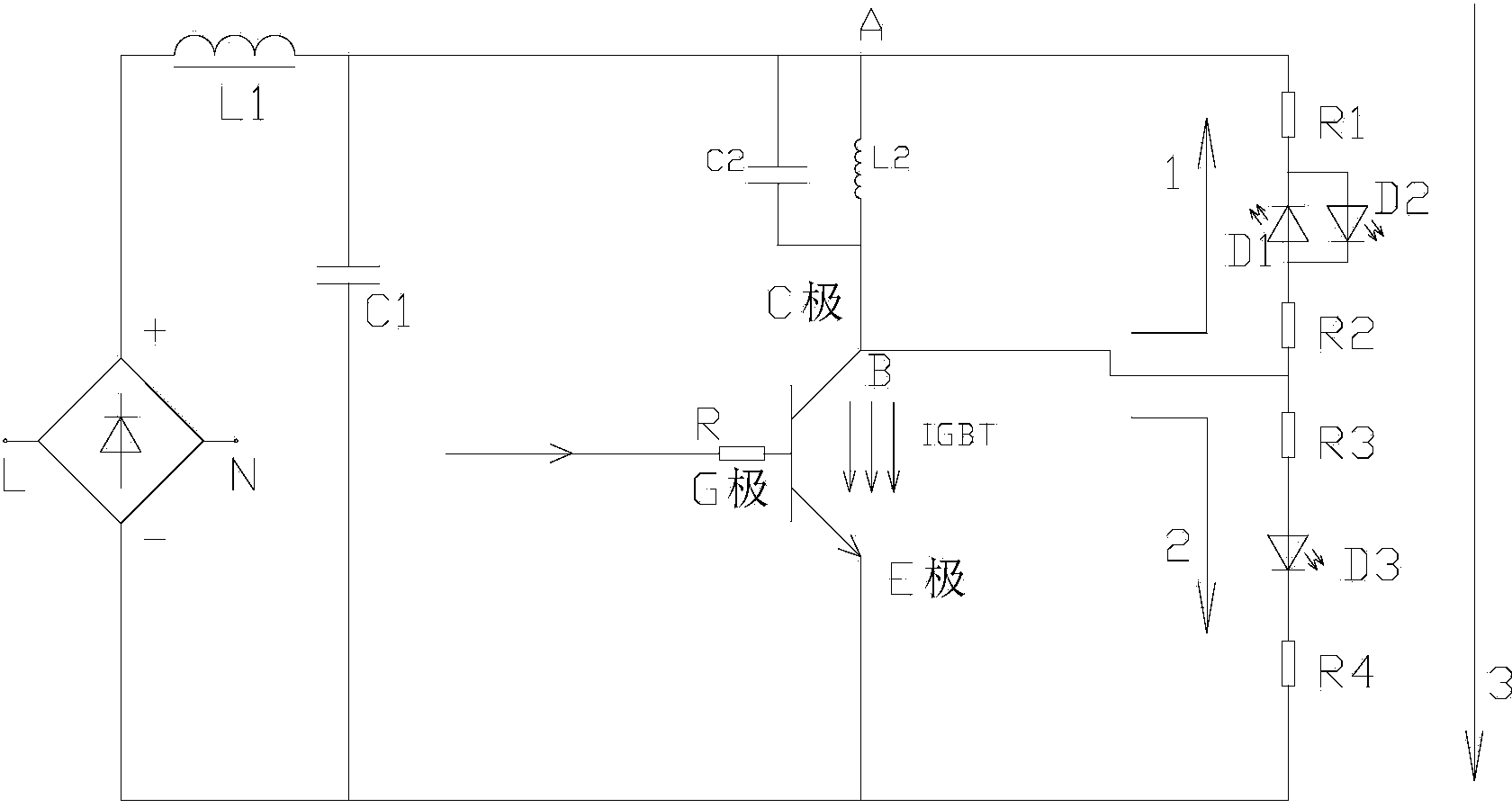

Counter-voltage reducing circuit of induction cooker and induction cooker including counter-voltage reducing circuit

ActiveCN104168680ASmall back pressureExtend your lifeInduction heating controlInduction heating apparatusInduction motorCooker

The invention discloses a counter-voltage reducing circuit of an induction cooker and the induction cooker including the counter-voltage reducing circuit. The counter-voltage reducing circuit of the induction cooker includes a rectifying filtering circuit, an oscillation circuit and an IGBT circuit, which are sequentially connected. The counter-voltage reducing circuit of the induction cooker also includes a first step-down circuit and a second step-down circuit. The two ends of the first step-down circuit are connected to the two ends of the oscillation circuit respectively. A first end of the second step-down circuit is connected to a C pole of an IGBT circuit and a second end of the second step-down circuit is connected to an E pole of the IGBT circuit. The counter-voltage reducing circuit of the induction cooker is capable of reducing a counter voltage of the C pole of the IGBT, improving the security of work of the IGBT and effectively preventing explosion of the induction cooker.

Owner:GREE ELECTRIC APPLIANCES INC

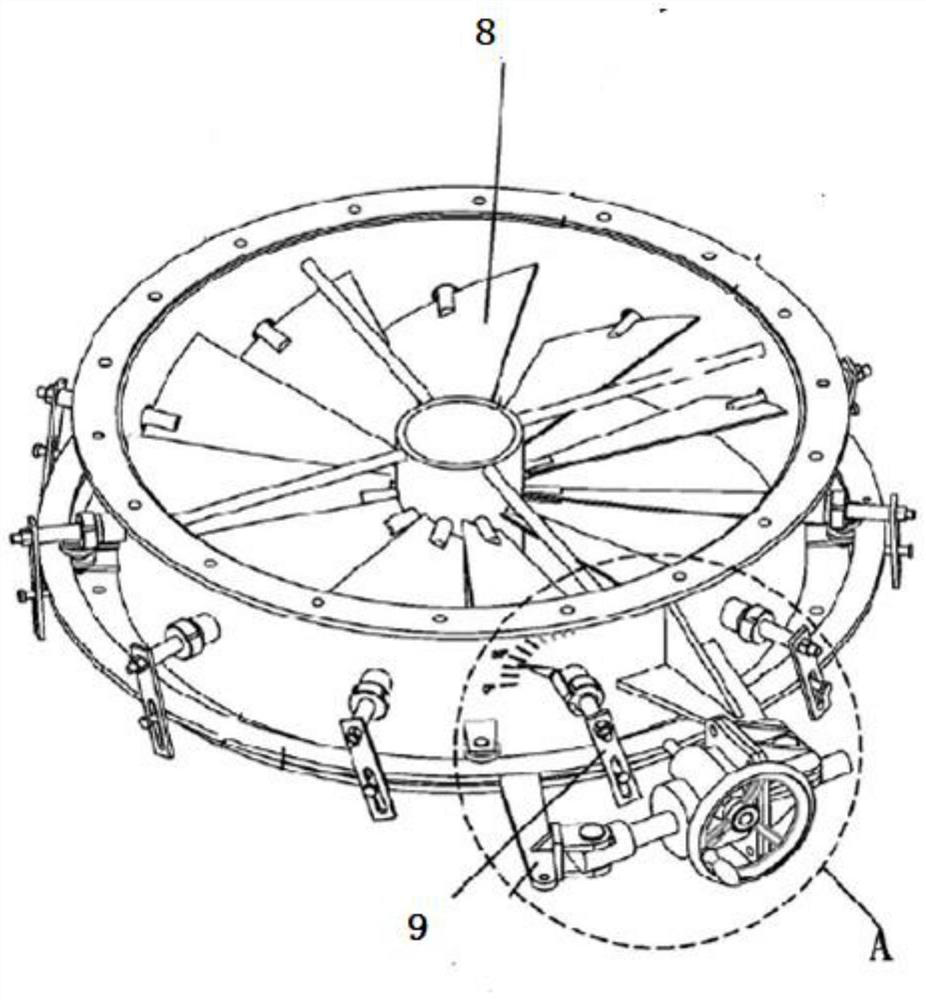

Adjustable swirl blade assembly and flat flame burner comprising same

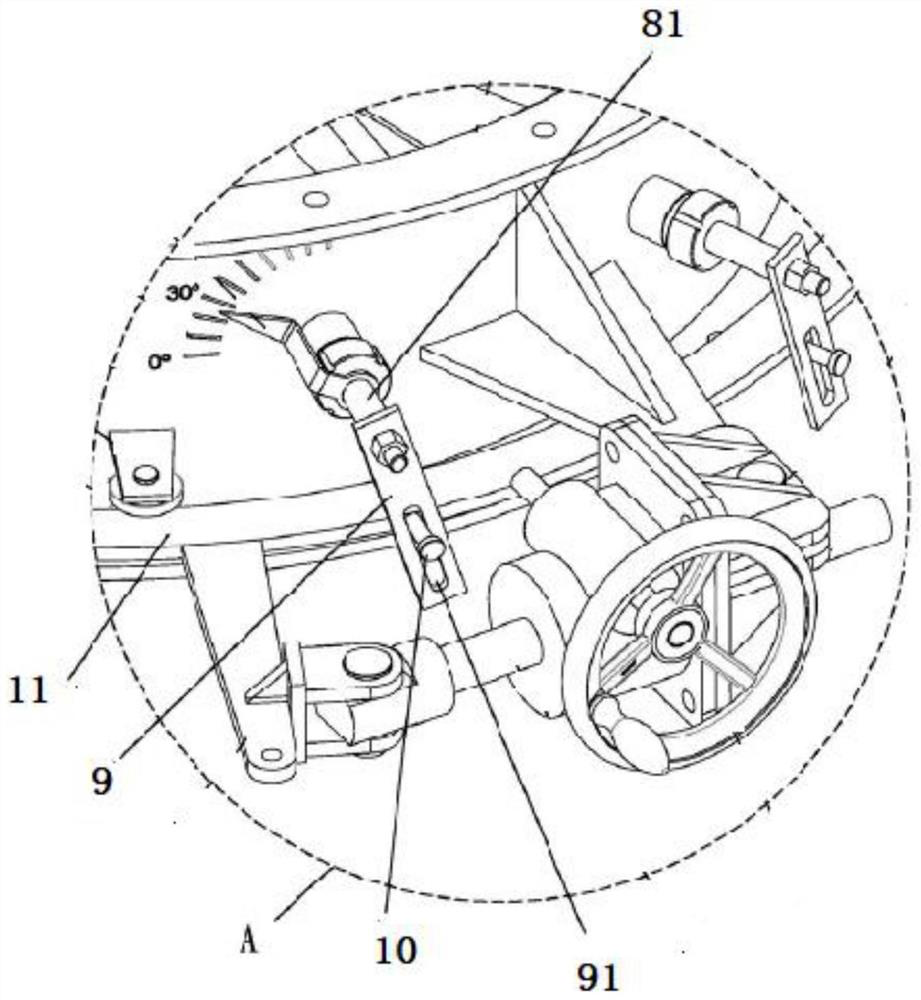

ActiveCN113932220AEasy to adjustLarge adjustment ratioIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorCoaxial line

The invention relates to an adjustable swirl blade assembly and a flat flame burner comprising the same, and belongs to the technical field of combustion equipment. The adjustable swirl blade assembly comprises an adjustable swirl blade assembly body and a blade transmission device, and the body comprises a central rectification body, an outer cylinder, an inner cylinder and a plurality of rotatable blades which are coaxially arranged; the blade transmission device comprises a plurality of blade rotating shafts which are fixedly connected with the blades and are used for controlling the blades to rotate, transmission connecting rods which are fixedly connected with one ends of the blade rotating shafts in a one-to-one correspondence manner, a total connecting ring which is connected with the transmission connecting rods and surrounds the adjustable swirl blade assembly body, and an operating rod which is connected with the total connecting ring and is used for controlling the total connecting ring to move; and each transmission connecting rod is formed by rotationally connecting three rigid connecting rods, and two rotating pairs with non-coaxial lines and non-parallel rotating shafts are formed at the joint. The technical problem that in a traditional device, control over blades is not accurate is solved, a combustor can operate under the small-load working condition, the large air-fuel ratio working condition and the condition that the fuel heat value fluctuates violently, and stable flat flames are formed.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

Melt processable thermoplastic polymer composition

The present invention relates to a melt processable polymer composition and a method of improving the melt processability of the host polymer. Said melt processable polymer composition comprises a thermoplastic non-aliphatic host polymer and a minor but effective amount of a fluoropolymer processing aid.

Owner:德弘公司

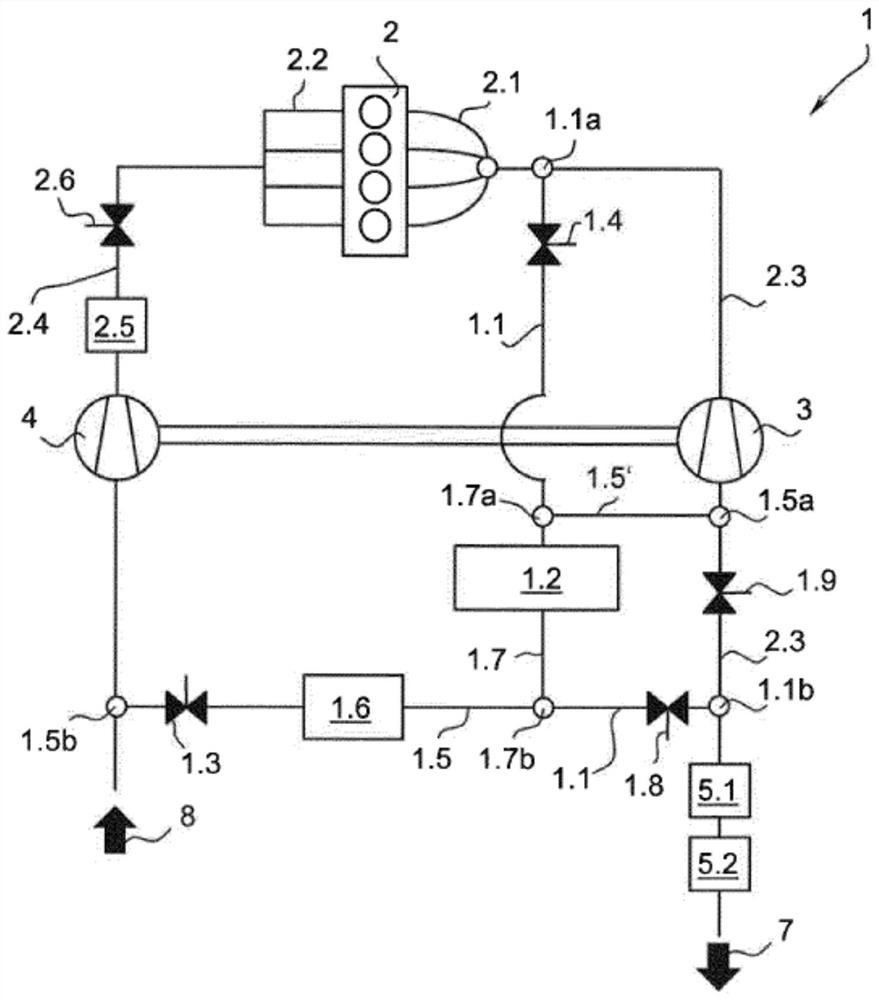

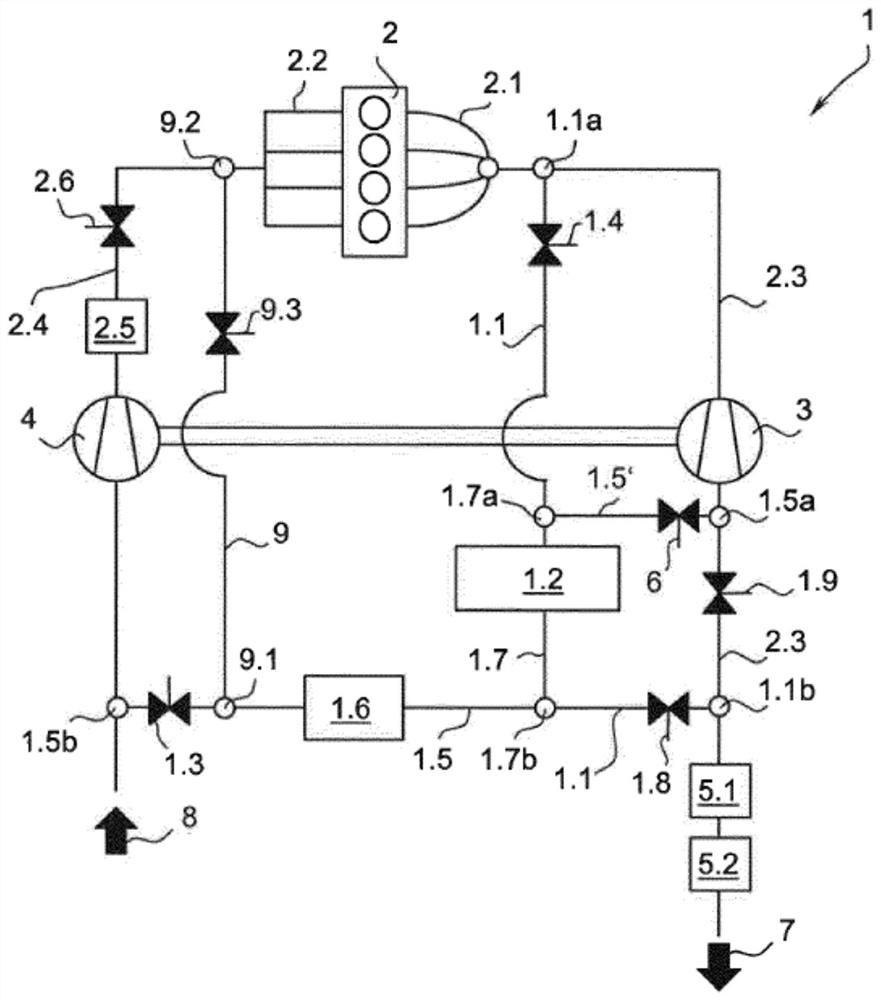

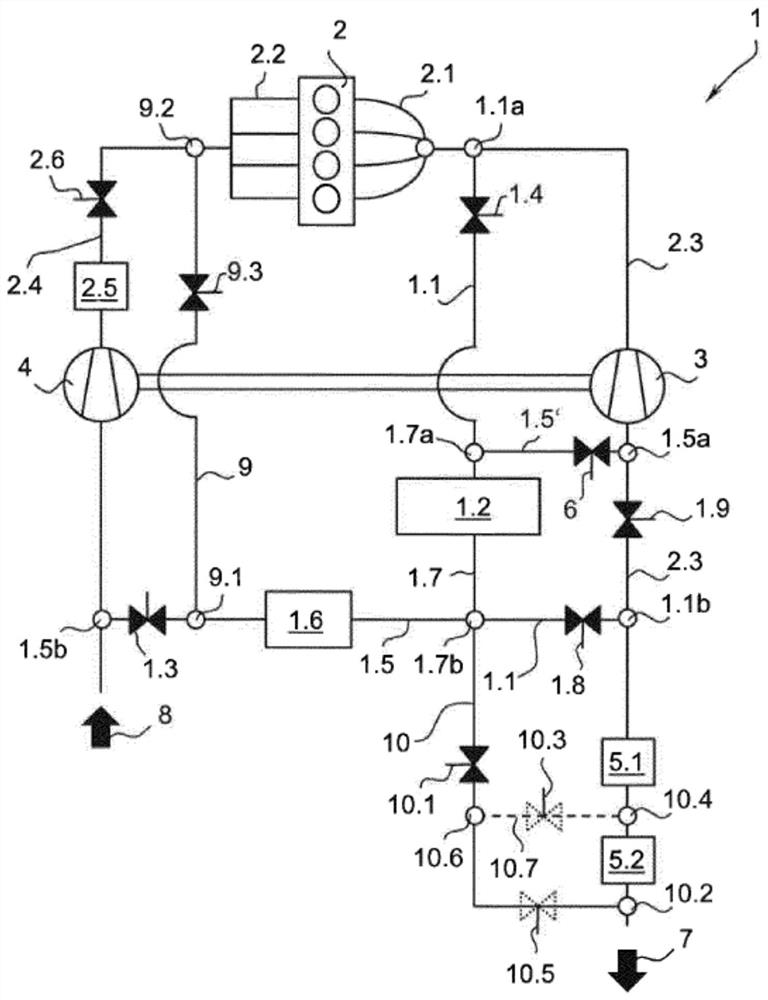

Low-pressure egr system with turbo bypass

ActiveCN111757976AExtensive purificationFree from loadGas treatmentInternal combustion piston enginesCouplingGasoline

The invention relates to a gasoline engine (2) comprising an exhaust gas line (2.3) which can be connected to an exhaust manifold (2.1) of the gasoline engine (2), an intake line (2.4) which can be connected to an intake manifold (2.2) of the gasoline engine (2), a charge air compressor (4) which is arranged in the intake line (2.4), and a turbine (3) which is arranged in the exhaust gas line (2.3). The exhaust gas line (2.3) has at least one bypass line (1.1) with a bypass throttle valve (1.4), the line branching off from the exhaust gas line (2.3) at a branch (1.1) upstream of the turbine (3) and branching back into the exhaust gas line (2.3) at an opening (1.1b) downstream of the turbine (3). At least one exhaust gas recirculation line (1.5) with an EGR throttle valve (1.3) is provided,said line branching off from the exhaust gas line (2.3) at a branch (1.5a) and opening into the intake line (2.4) at an opening (1.5b), wherein a coupling line (1.7) with a first node point (1.7a) and a second node point (1.7b) is provided, the bypass line (1.1) and the EGR line (1.5) being combined in some sections in said coupling line; at least one particle filter (1.2) is arranged in the coupling line (1.7); and the first node point (1.7a) is arranged downstream of the branch (1.5a) and downstream of the branch (1.1).

Owner:TENNECO

Capillary column system capable of increasing open tubular column sample loading quantity by variable-diameter packing column

InactiveCN104849378ALarge amount of sampleLoading GuaranteedComponent separationMicrometerDead volume

The invention relates to a capillary column system capable of increasing the open tubular column sample loading quantity by a variable-diameter packing column. The capillary column system mainly comprises the variable-diameter packing column, a connecting piece and an open tubular column. The capillary column system is characterized in that the variable-diameter packing column is fixed on an internal fingertight fitting of the connecting piece, the open tubular column passes through an external fingertight fitting to be in seamless connection with the tip of the packing column, a dead volume is zero, the internal diameter of the inlet end of the variable-diameter packing column is 320-530 micrometers, the internal diameter of the outlet end of the variable-diameter packing column is 10-75 micrometers, and the length of the variable-diameter packing column is 1-5cm. The capillary column system capable of increasing the open tubular column sample loading quantity by the variable-diameter packing column has the advantages that the variable-diameter packing column is used as a sample loading column, and the advantage of large sample loading quantity of the packing column can be used fully for increasing the sample loading quantity of the open tubular capillary column system; a short variable-diameter packing column can be adopted, so that detecting sensitivity and repeatability are improved while the sample loading quantity is increased; zero connecting dead volume can be guaranteed by the aid of a special structure of the connecting piece and diameter varying of the packing column.

Owner:EAST CHINA UNIV OF SCI & TECH

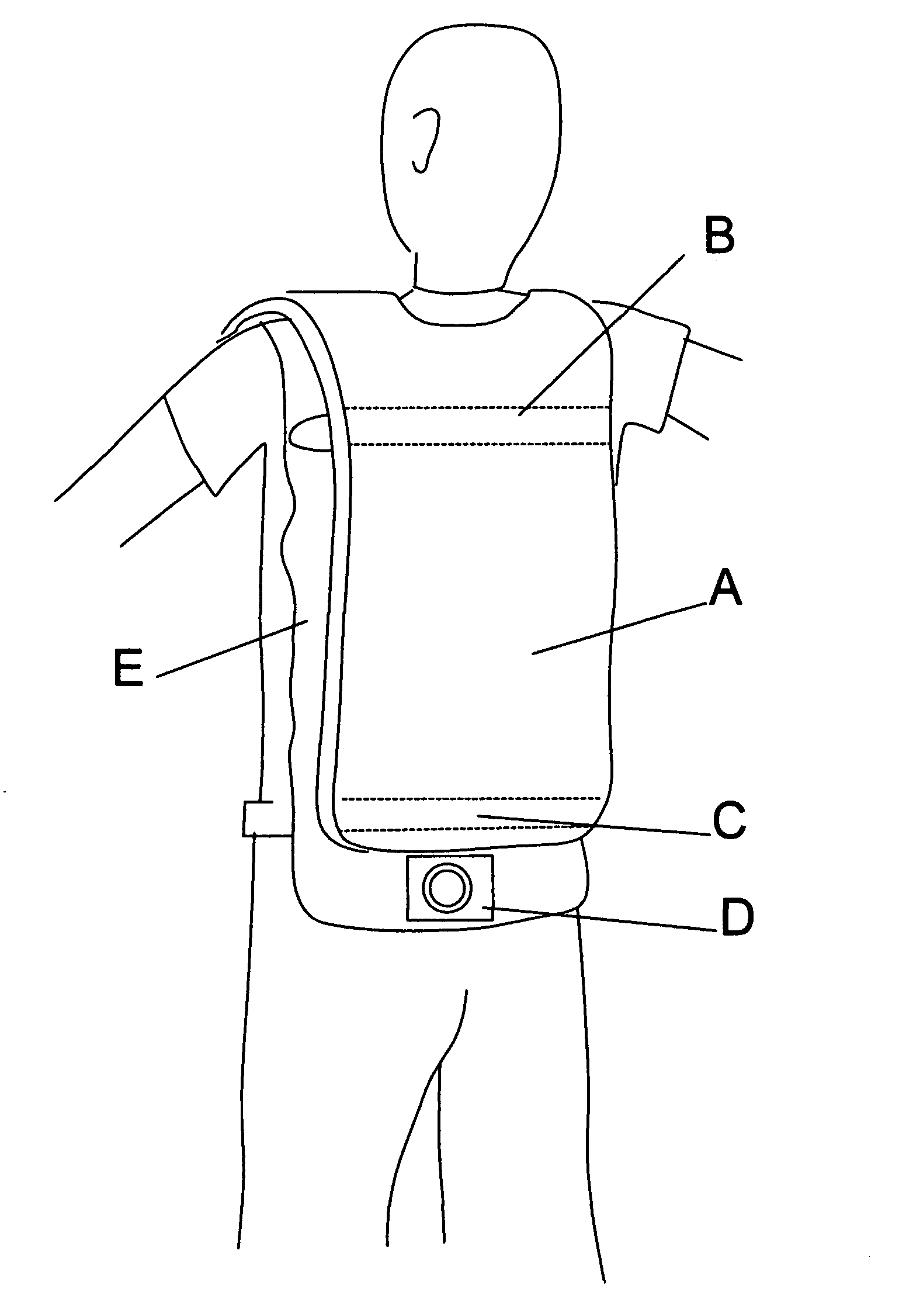

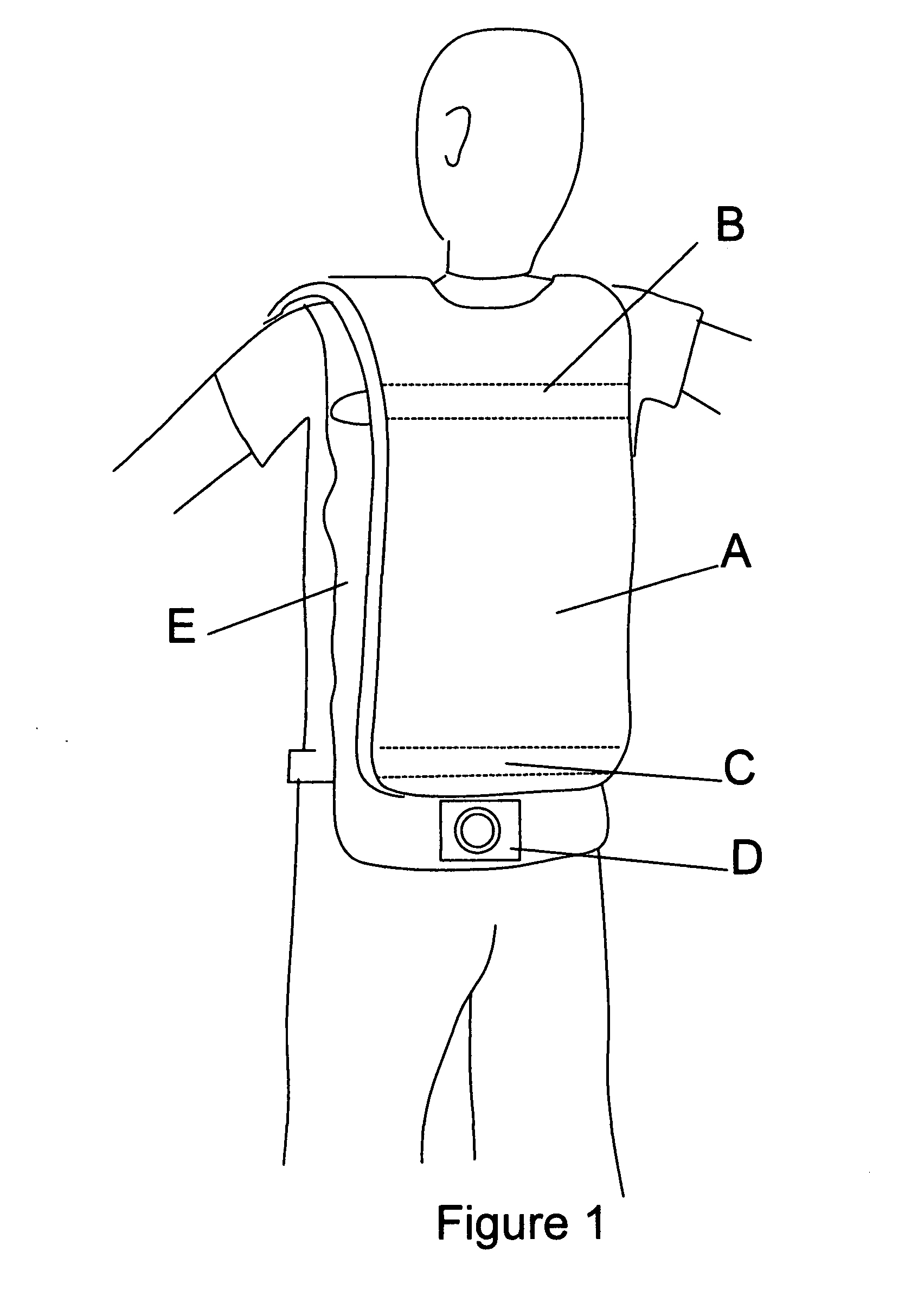

Enhanced evaporative cooling system

InactiveUS20080307567A1Enhance evaporative coolingAvoid environmentChemical protectionHeat protectionEngineeringMoisture

Owner:HORN STEPHEN T +1

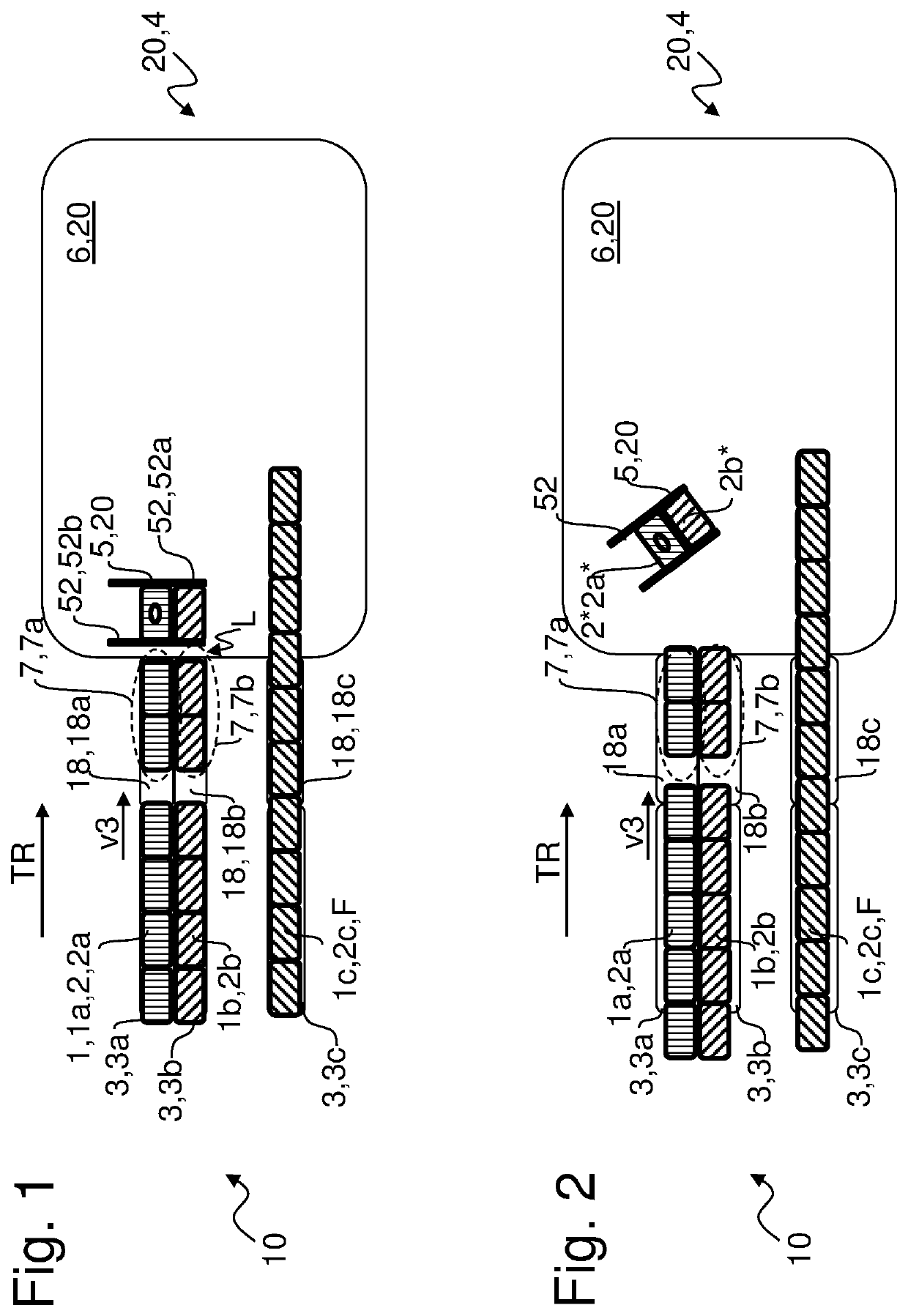

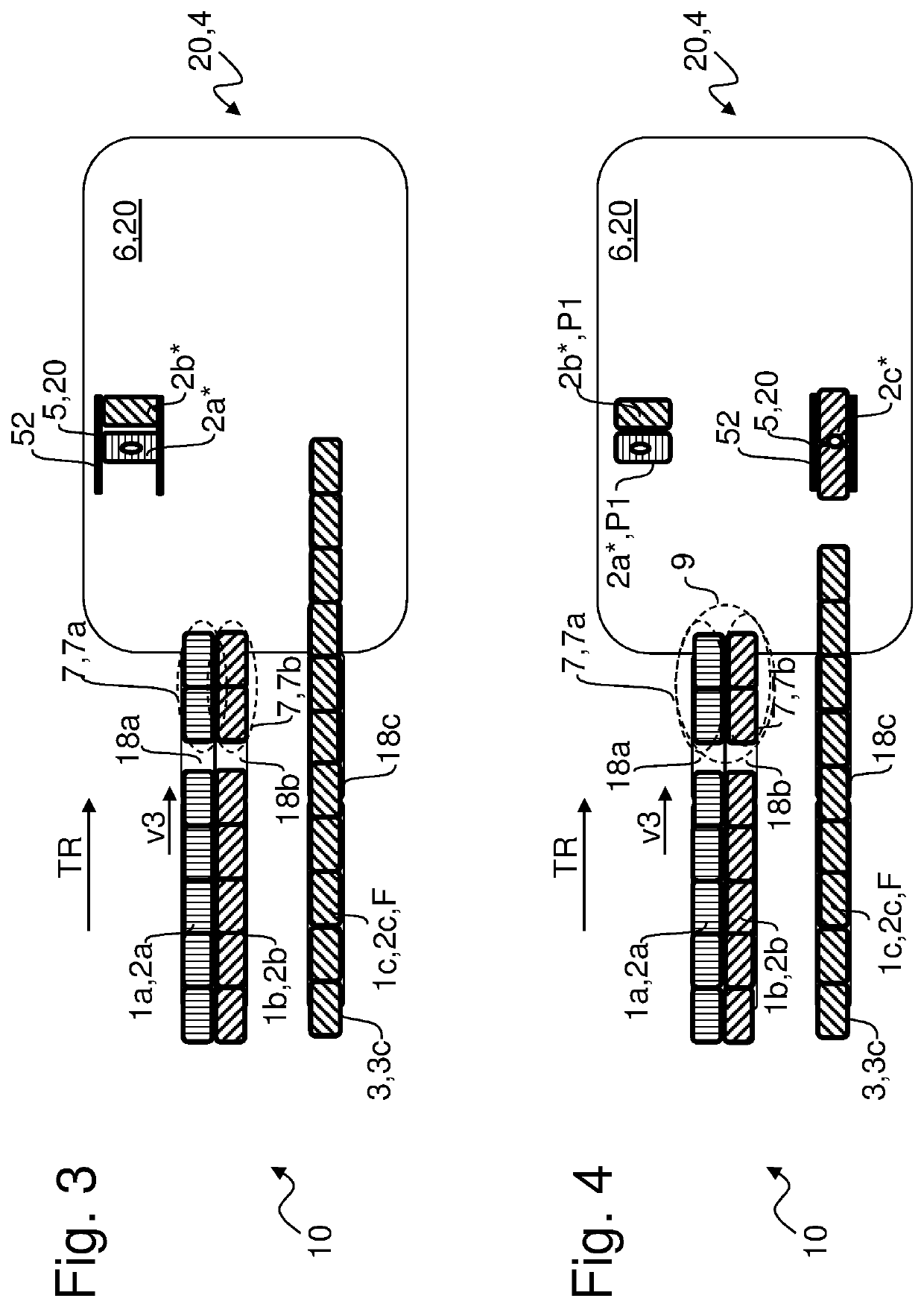

Method and apparatus for handling piece goods moved in at least two parallel rows

ActiveUS10882702B2Prevent slippingNo back pressureProgramme-controlled manipulatorGripping headsEngineeringStructural engineering

The invention relates to a method and apparatus (10) for handling piece goods (2) for forming a palletizable layer or partial layer, with the piece goods (2) being moved in at least two parallel rows (1) and the layer comprising a plurality of piece goods (2). At least two piece goods (2) that are transported beside each other in parallel rows (1) are seized in a clamping and / or force-locking and / or form-locking manner, are then spatially separated from the at least two parallel rows (1) and are then brought into a specified relative target position (P1, P2) and / or target alignment in relation to subsequent piece goods (2). The apparatus (10) comprises at least one manipulator (5) for piece goods (2), and at least one transport device (3), where the piece goods (2) arranged in at least two parallel rows (1).

Owner:KRONES AG

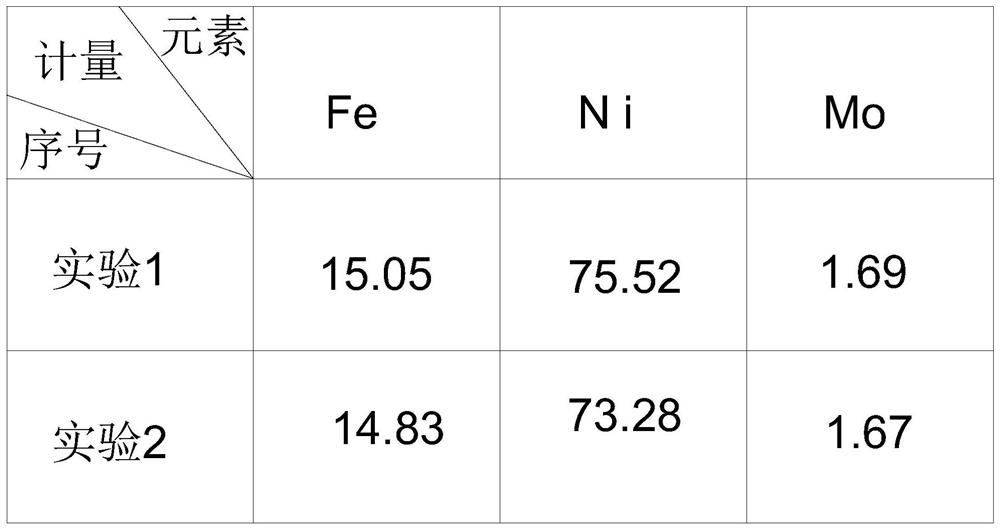

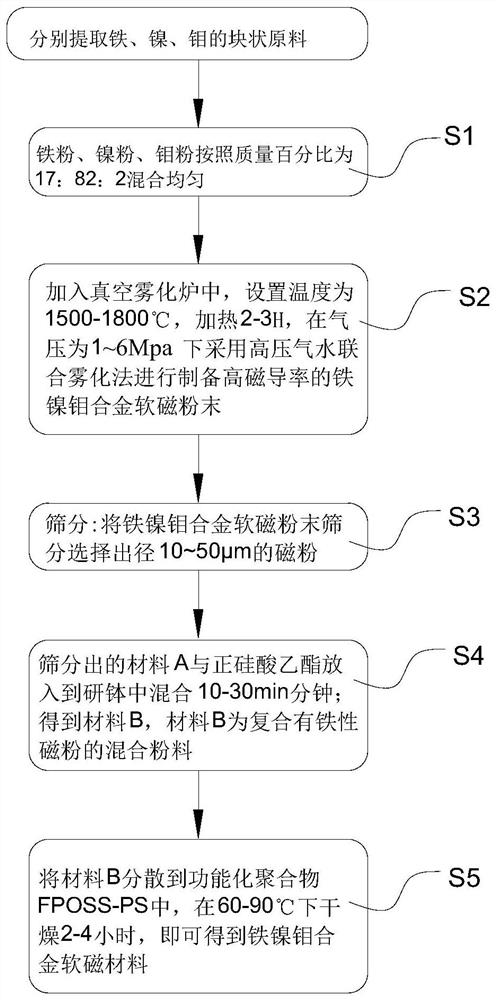

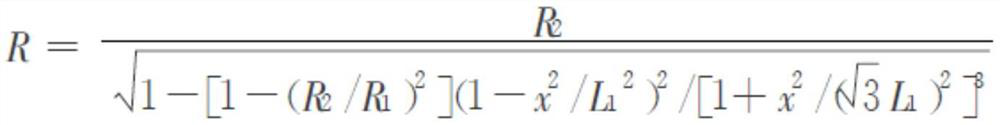

Insulation treatment method of iron-nickel-molybdenum alloy soft magnetic material

PendingCN113674978AMaterial particle size is smallFlat surfaceInorganic material magnetismInductances/transformers/magnets manufactureTetraethyl orthosilicateMagnetic powder

The invention discloses an insulation treatment method of an iron-nickel-molybdenum alloy soft magnetic material, belongs to the technical field of magnetic materials, aims to solve the problem of high eddy current loss caused by large particle size of powder prepared by an original material preparation technology, and provides an insulation treatment method of an iron-nickel-molybdenum alloy soft magnetic material. The method comprises the following steps: mixing an iron block, a nickel block and a molybdenum block according to a mass percentage; adding the raw materials into an atomizing furnace, and presetting a preset temperature and a heating duration; preparing iron-nickel-molybdenum alloy soft magnetic powder with high magnetic conductivity by adopting an atomizing method in the atomizing furnace; and putting tetraethyl orthosilicate into a mortar, mixing for 10-30 minutes, and drying at 60-90 DEG C for 2-4 hours to obtain the iron-nickel-molybdenum alloy soft magnetic material. According to the invention, the atomizing angle of the nozzle of the gasification furnace is designed, the effect is to accelerate airflow while it is guaranteed that the airflow at an outlet of a contraction section is uniform, straight and stable, the nozzle generates the laminar flow effect, the particle size of atomized powder is finer, water atomization is designed to impact a film and gas atomization is designed to conduct secondary homogenization and shaping, and the high-magnetic-conductivity annular magnetic powder core is prepared.

Owner:SOUTHWEST INST OF APPLIED MAGNETICS +1

Filter elements

InactiveCN102089059ASmall back pressureLow running costGas treatmentDispersed particle filtrationFiberFiltration

Owner:NV BEKAERT SA

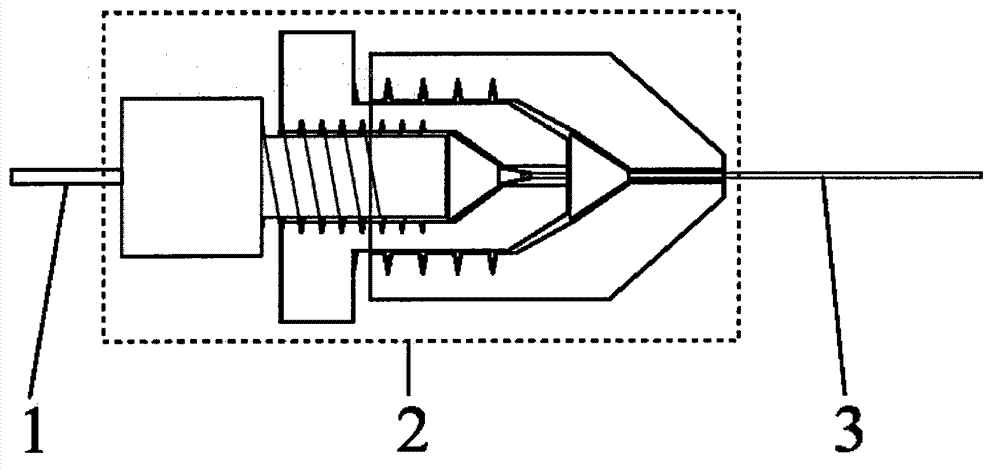

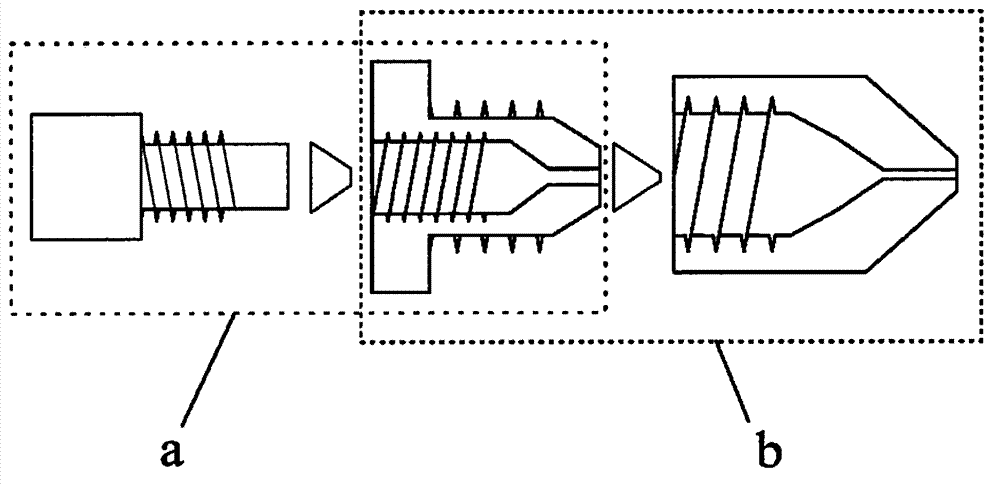

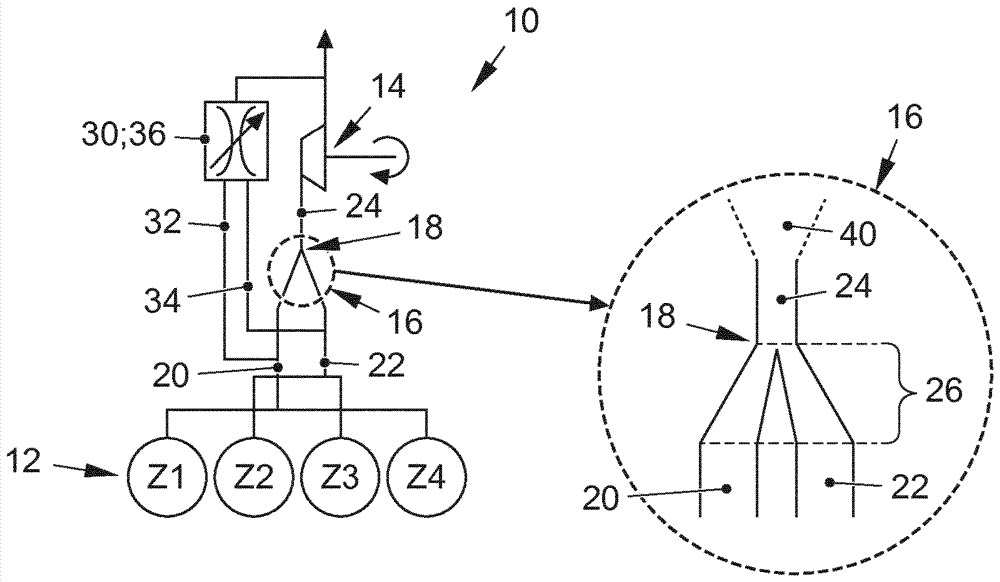

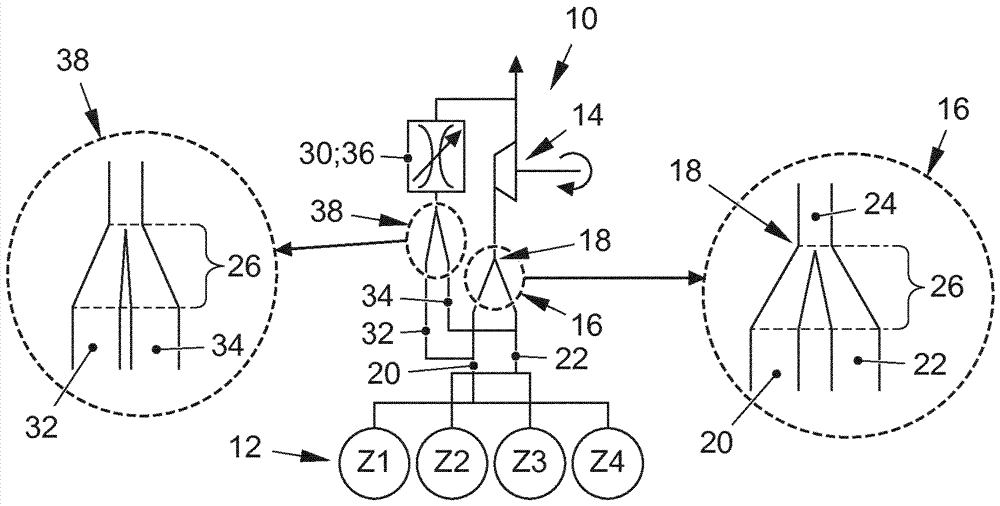

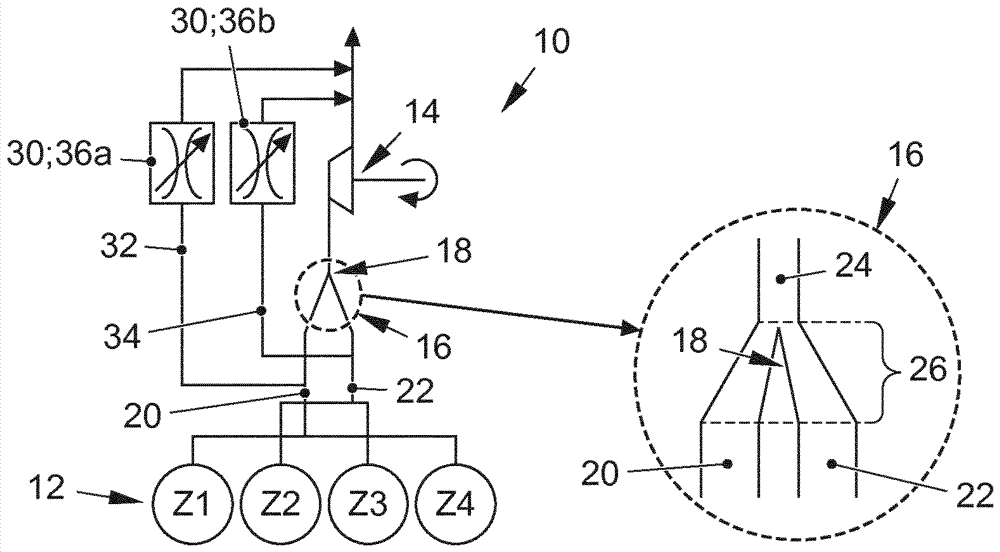

Arrangement for an internal combustion engine having a plurality of cylinders and exhaust turbocharger, exhaust gas pressure transformer having a mixing tube and a wastegate, and method for operating and configuring such an arrangement

ActiveCN107407193AApparent injector effectLow costInternal combustion piston enginesSilencing apparatusWastegateTransformer

The invention relates to an arrangement for an internal combustion engine (12) having a plurality of cylinders and an exhaust turbocharger, an exhaust gas pressure transformer (16), arranged between the internal combustion engine (12) and a turbine (14) of the exhaust turbocharger, and having a mixing tube (24) and a wastegate surrounding the turbine of the turbocharger for discharging exhaust gases without said exhaust gases flowing through the exhaust turbocharger. The problem addressed by the invention is in particular the providing of such an arrangement (10) by means of which the residual gas rate and the exhaust gas counter-pressure can be kept as low as possible over the entire speed range of an internal combustion engine (12). An arrangement (10) for an internal combustion engine (12) according to the invention, having a plurality of cylinders and an exhaust turbocharger, comprises an exhaust gas pressure transformer (16) arranged between the internal combustion engine (12) and a turbine (14) of the exhaust turbocharger and having a downstream mixing tube (24), and a wastegate (30) surrounding the turbine (14) of the exhaust turbocharger. The arrangement (10) has a first exhaust diverting section (20) for separate diverting of exhaust from a first partial volume of the cylinder to the mixing tube (24) and at least one second exhaust diverting section (22) for diverting exhaust from a second partial volume of the cylinder to the mixing tube (24), wherein there is one nozzle-like section each in the first exhaust diverting section (20) and in the second exhaust diverting section (22) in a respective end region (26) before the mixing tube (24), wherein there is a first bypass channel (32) circumventing the exhaust turbocharger from the first exhaust diverting section (20) before or in the nozzle-like section, wherein there is a second bypass channel (34) circumventing the exhaust turbocharger from the at least second exhaust diverting section (22) before or in the nozzle-like section, and wherein there is at least one control and / or regulating element (36) by means of which the flow volume through the first bypass channel (32) and / or through the second bypass channel (34) can be controlled or regulated.

Owner:VOLKSWAGEN AG

Method and apparatus for handling piece goods moved in at least two parallel rows

ActiveUS20200180870A1Prevent slippingNo back pressureProgramme-controlled manipulatorGripping headsStructural engineeringMechanical engineering

The invention relates to a method and apparatus (10) for handling piece goods (2) for forming a palletizable layer or partial layer, with the piece goods (2) being moved in at least two parallel rows (1) and the layer comprising a plurality of piece goods (2). At least two piece goods (2) that are transported beside each other in parallel rows (1) are seized in a clamping and / or force-locking and / or form-locking manner, are then spatially separated from the at least two parallel rows (1) and are then brought into a specified relative target position (P1, P2) and / or target alignment in relation to subsequent piece goods (2). The apparatus (10) comprises at least one manipulator (5) for piece goods (2), and at least one transport device (3), where the piece goods (2) arranged in at least two parallel rows (1).

Owner:KRONES AG

Mixer for an exhaust gas duct system of an internal combustion engine

InactiveCN105736095AReduce shareImprove the mixing effectInternal combustion piston enginesFlow mixersExhaust fumesInternal combustion engine

A mixer for an exhaust gas duct system of an internal combustion engine includes a flow channel element (16) with a flow channel (14), through which exhaust gases can flow in a main direction of flow (S). At least one mixer element (12) in the flow channel element (16) is movable in the flow channel element (16) to change a mixing effect.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

Preparation of porous integral material immobilized enzyme micro-reactor

ActiveCN101497879BAvoid self-degradationReduce consumptionOn/in organic carrierOn/in inorganic carrierSilanesFree solution

The invention relates to a zymohydrolysis method of protein samples, in particular to a porous organic-inorganic hybrid silica bulk material carrier which is prepared and obtained by using tetraethoxy silane and aminopropyl triethoxysilane as precursor molecules, using cetyltrimethylammonium trimethyl bromide ammonia as template molecules, using absolute ethyl alcohol as cosolvent through a sol-gel method and a template molecule self-assembly method. Hybrid silica bulk materials are activated by glutaric dialdehyde. After trypsinase is fixed, an organic-inorganic hybrid silica bulk material immobilized enzyme reactor is prepared. The invention has the advantages of simple and convenient preparation method, good permeability of the enzyme reactor, little counter pressure, high mechanical strength and high zymohydrolysis activity. Compared with free solution zymohydrolysis, the invention largely shortens reaction time, avoids the self-degradation of enzyme, can be repeatedly used, and also can be combined with an HPLC-MS / MS or CE-MS / MS system, thereby the on-line analysis of samples is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

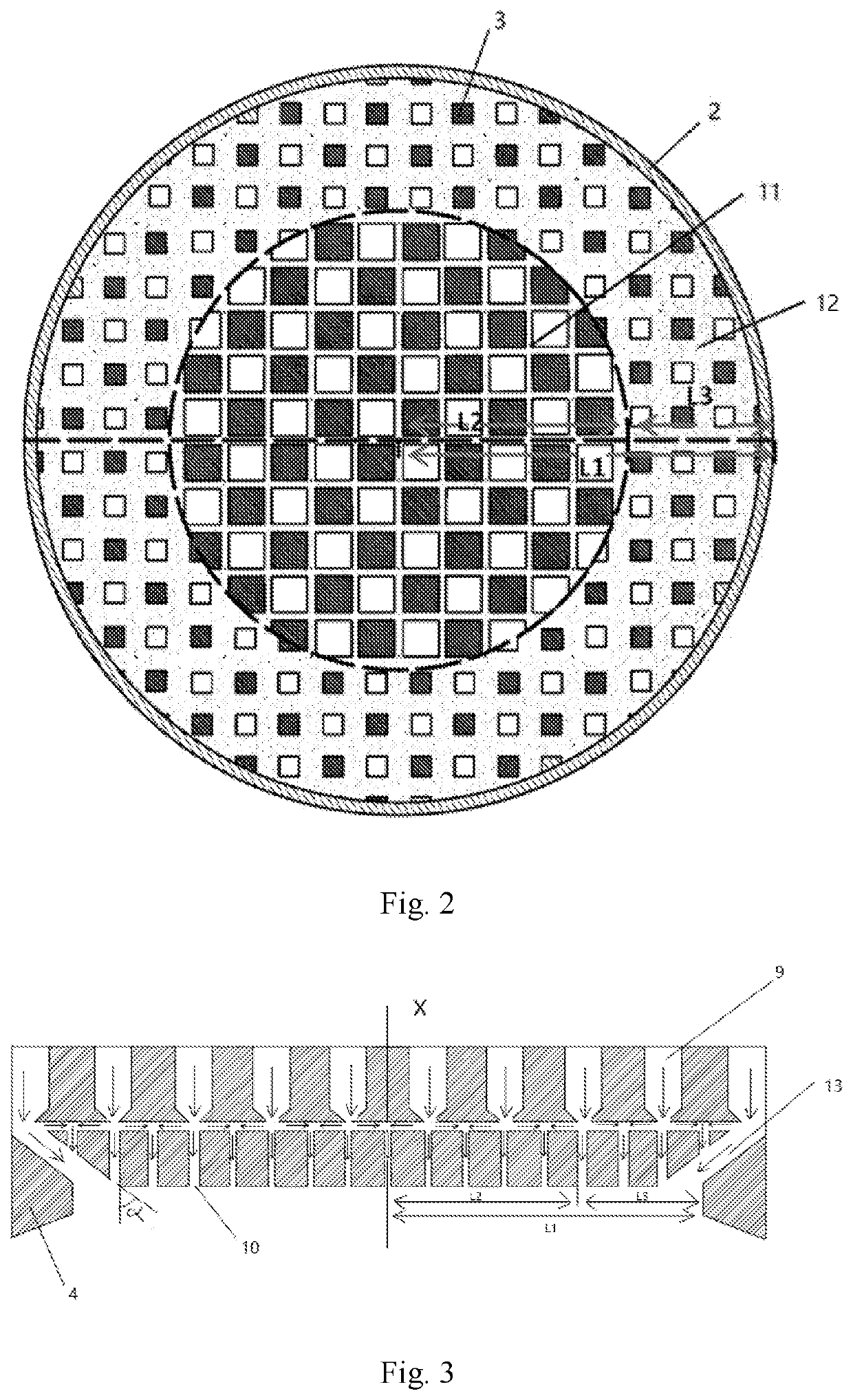

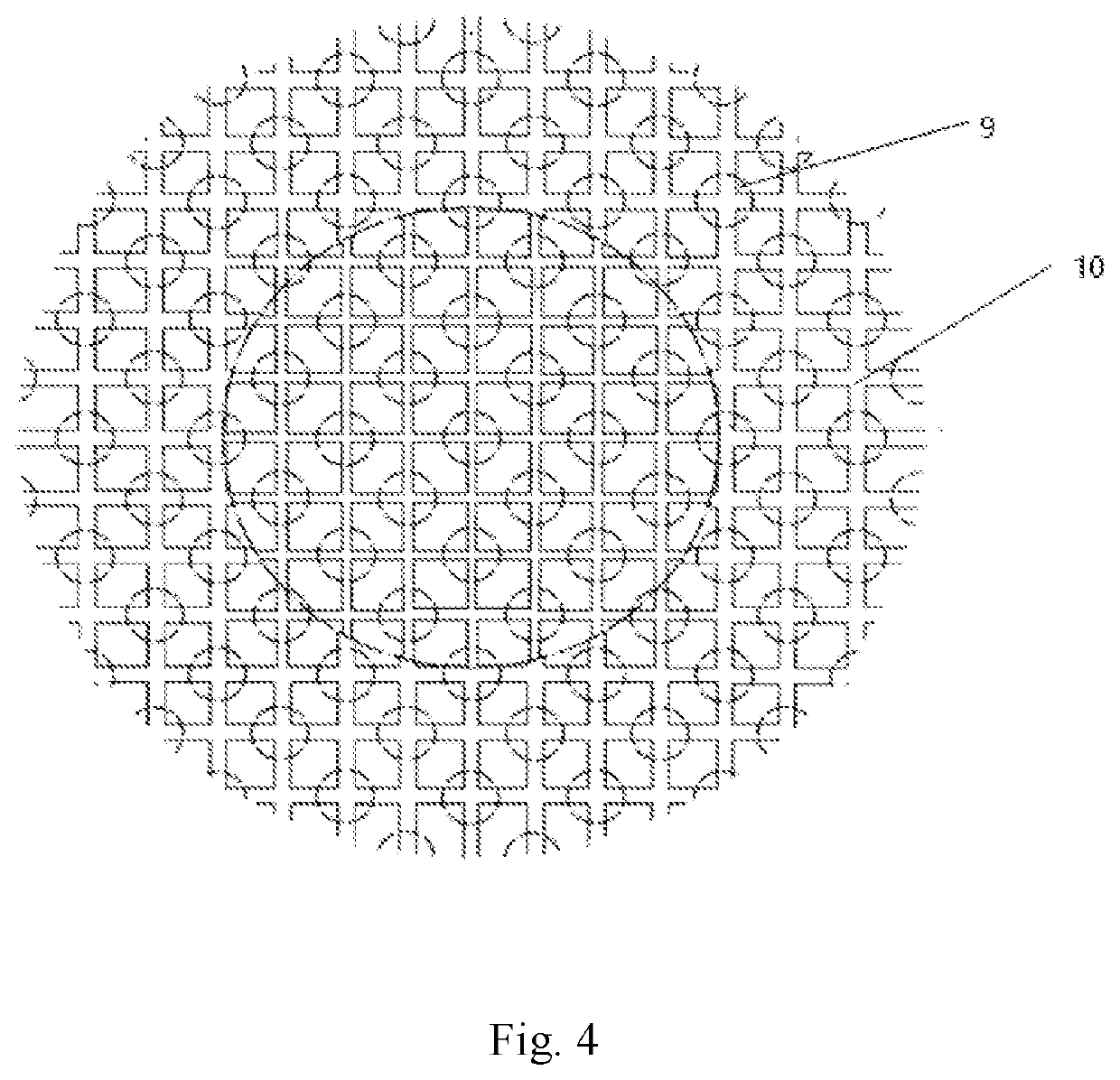

Honeycomb structure body, honeycomb structure filter, and extrusion molding die

PendingUS20220241715A1High strengthImprove thermal shock resistanceGas treatmentDispersed particle filtrationHoneycomb structureThermal shock

Disclosed are a honeycomb structure body, a honeycomb structure filter and an extrusion molding die for a honeycomb structure body, which belong to the field of vehicle exhaust purification materials. The honeycomb structure body includes a honeycomb body and a skin layer around the honeycomb body, the honeycomb body including axially-extending channels defined by a porous wall, wherein a radial path of a radial section of the honeycomb body from a central axis to the skin layer consists of a porous wall inner section and a porous wall outer section in sequence, an average wall thickness of inner porous walls provided in the porous wall inner section is smaller than an average wall thickness of outer porous walls provided in the porous wall outer section, and a length of the porous wall inner section in the radial path accounts for 71%-95%. The arrangement of the specific structure of the honeycomb structure body of the present application not only increases the strength of the honeycomb structure body, but also ensures good thermal shock resistance and small back pressure of the honeycomb structure body; and the honeycomb structure body of the present application is prepared by integral molding, thereby achieving high production efficiency and low preparation cost.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com