Nanospray capillary high pressure liquid chromatographic column and its preparation method

A high-pressure liquid chromatography and capillary column technology, applied in the field of analytical chemistry, can solve the problems of large back pressure, low flow rate, and the separation efficiency of difficult peptide samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

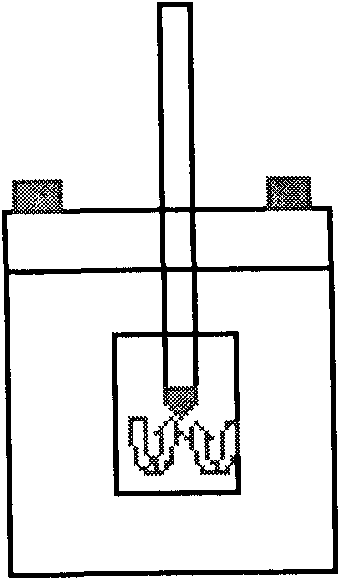

[0017] A 2 mL ampoule containing 0.5 mL of 100% methanol, a magnetic stir bar, and 50 μg of 10-15 μm particle size glass microspheres (Michrom Bioresources, Auburn, CA) was placed in a pressure injection cell, Next Advance Inc.24Prospect Avenue, AverillPark, NY 12018), placed on a magnetic stirrer, suspended. A quartz tube (Polymicro Technologies, Phoenix, Ar) coated with polyimide (Polymicro Technologies, Phoenix, Ar) with an outer diameter of 360 μm and an inner diameter of 200 μm and a length of 25 cm was fitted with an M-130 end-fitting with SST filter , IDEXhealth & Science, 619 Oak Street, Oak Harbor, WA) filter was fixed, and the other end was inserted into the turbid liquid containing glass microspheres, and fixed on the pressure vessel. Pressurize so that the glass microspheres are packed into the quartz tube to a length of 15 cm ( figure 2 ).

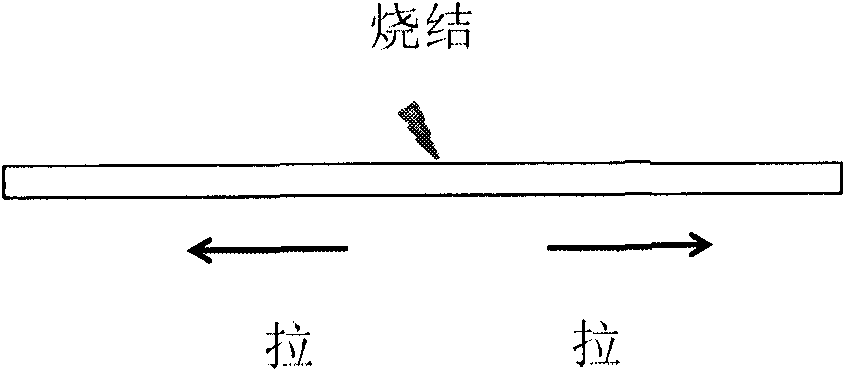

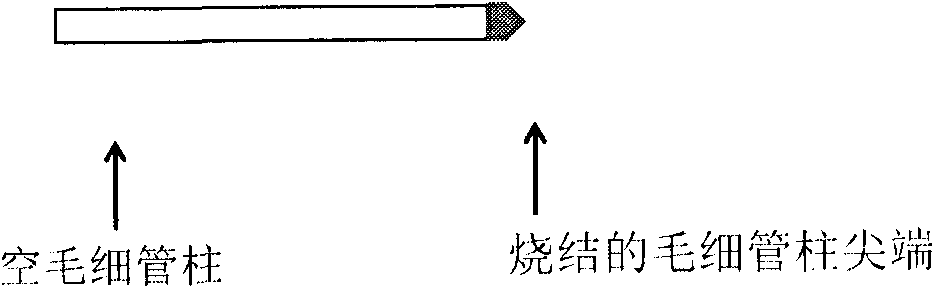

[0018] Burn the 1 cm wide part of the quartz tube filled with glass microspheres on fire for about 30 seconds to remove t...

Embodiment 2

[0021] The method is the same as in Example 1, except that a polyimide-coated quartz tube (Polymicro Technologies, Phoenix, Ar) with an inner diameter of 150 μm and an outer diameter of 360 μm is used; the thermal adjustment of the laser needle pulling instrument is set at 380 degrees Celsius, and the speed is set at 40. In this way, an empty nanospray capillary high-pressure liquid chromatography column with an inner diameter of 150 μm and a low back pressure and high flow rate was prepared.

Embodiment 3

[0023] The method is the same as in Example 1, except that a polyimide-coated quartz tube (Polymicro Technologies, Phoenix, Ar) with an inner diameter of 100 μm and an outer diameter of 360 μm is used; the thermal adjustment of the laser needle pulling instrument is set at 390 degrees, and the speed is set at 40, repeat twice. In this way, an empty nanospray capillary high-pressure liquid chromatography column with an inner diameter of 100 μm and low back pressure and high flow rate was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com