A check valve

A check valve and inner hole technology, applied in the direction of sliding valve, control valve, valve device, etc., can solve the problems of delayed overload drop, production damage, high check valve failure rate, etc., to reduce back pressure and reduce turbulence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

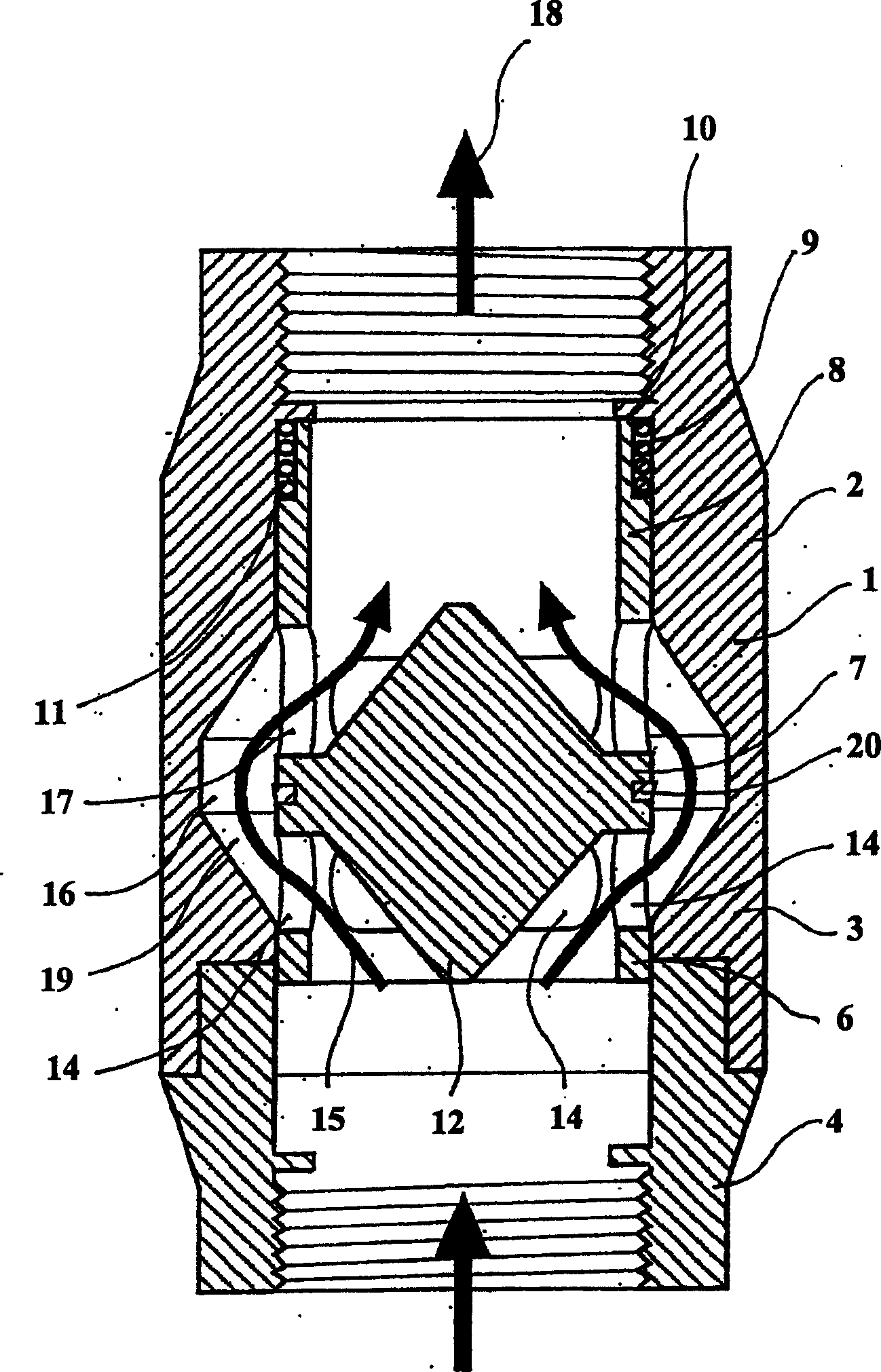

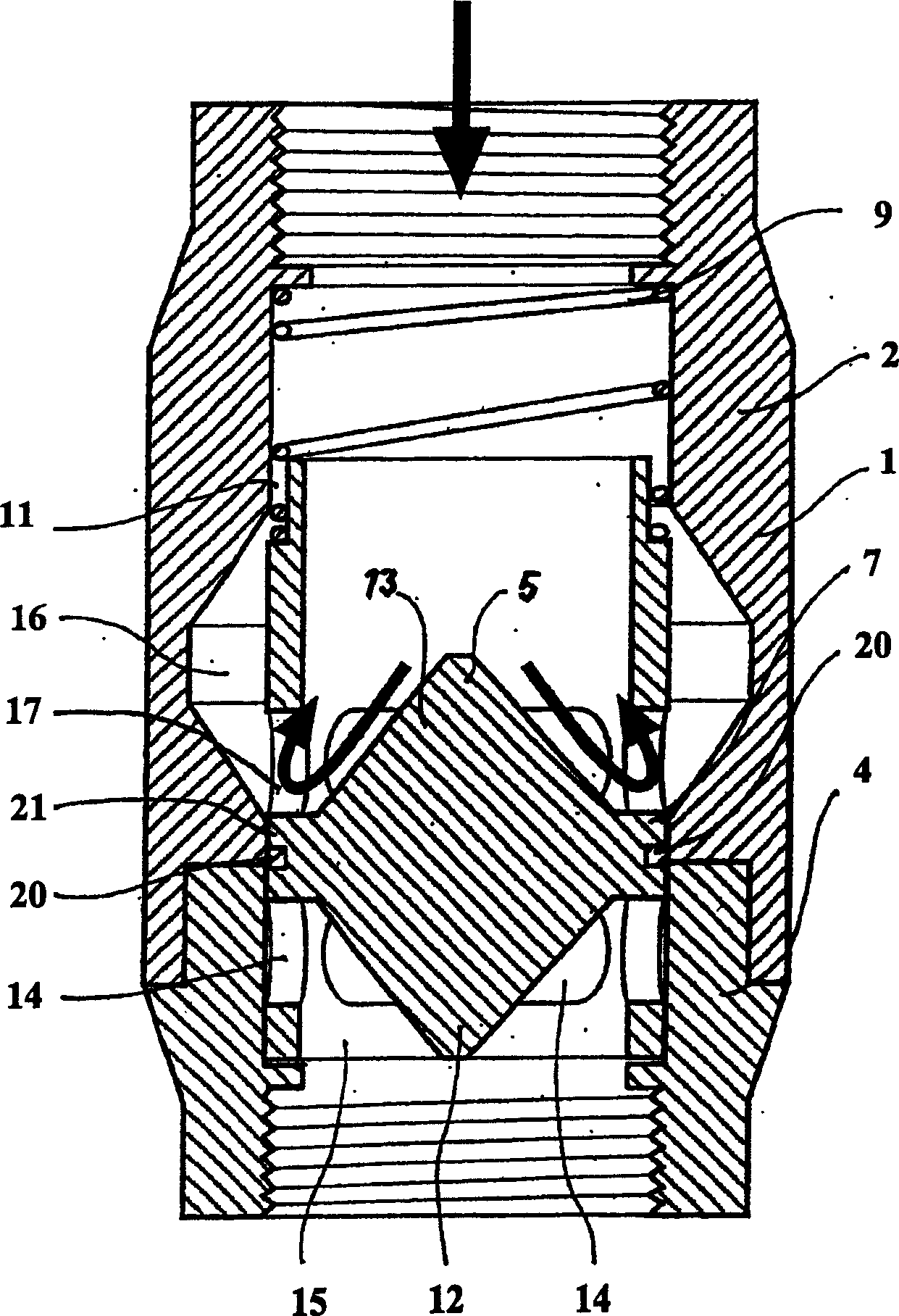

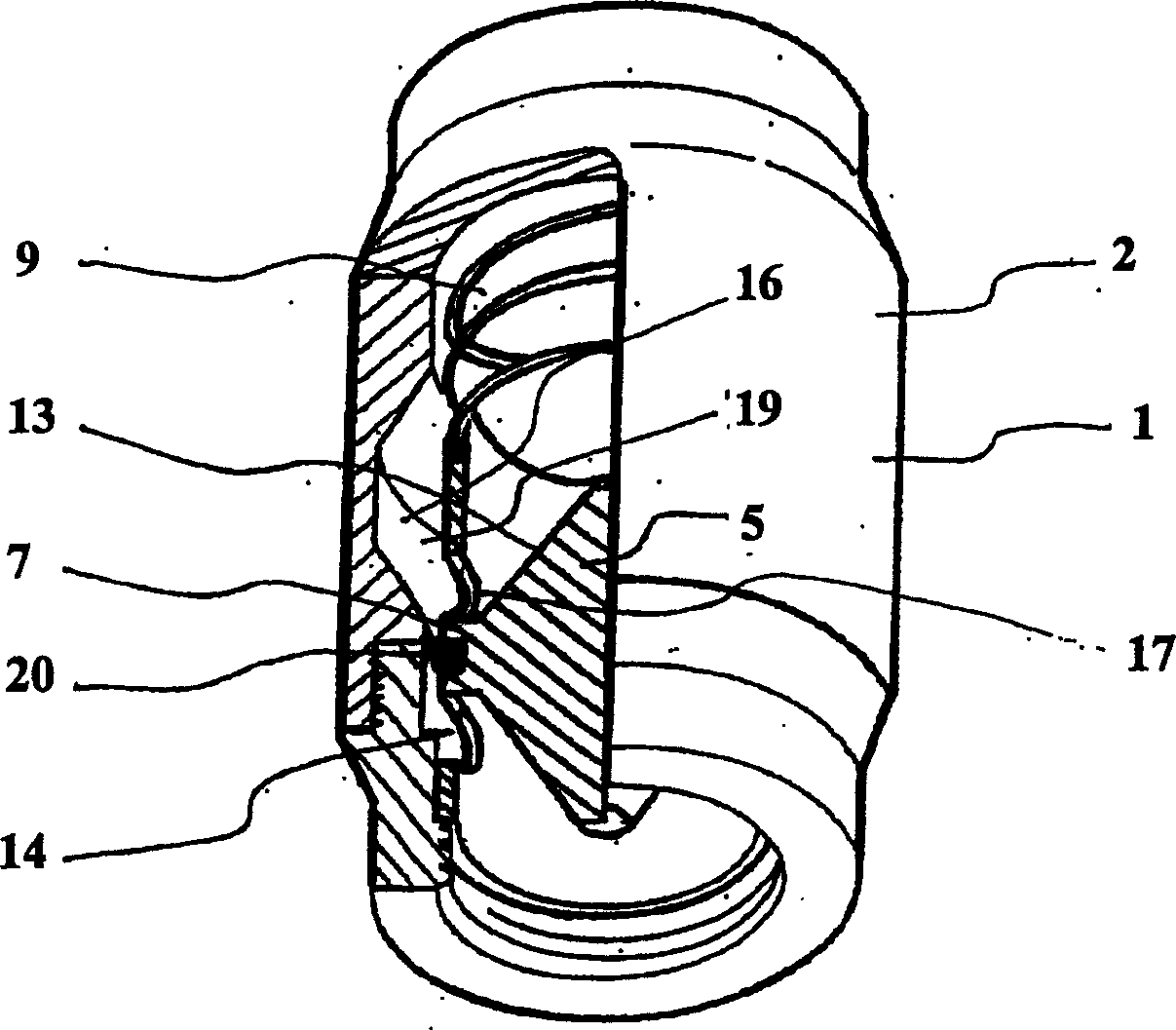

[0048] now refer to Figure 1 to Figure 5 The first embodiment shown, the figure shows a check valve 1, which comprises a main body 2, the main body 2 mainly has an inner hole with a circular cross-sectional shape and consists of two parts, one part is the main body part 3, and the other part is made of threaded Partially connected to this body part is an end portion 4 which enables a reciprocating slide 5 to enter into the body.

[0049] The complex slide 5 in the body 2 has a downstream part 6 , an intermediate part 7 and an upstream part 8 .

[0050] Each of these parts is adapted to slide freely in a respective bore of the body 2 .

[0051] In other words, the reciprocating slider 5 can be figure 1 open position shown and figure 2 It is free to move between the closed positions shown, but is biased by the coil spring 9 held between the stop 10 and the downstream portion 8 of the reciprocating slide 5 .

[0052] As in the figure, especially in the figure 1 As seen in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com