Preparation of porous integral material immobilized enzyme micro-reactor

An integral material, microreactor technology, applied in the field of enzymatic hydrolysis of protein samples, to achieve the effects of small back pressure, good permeability and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

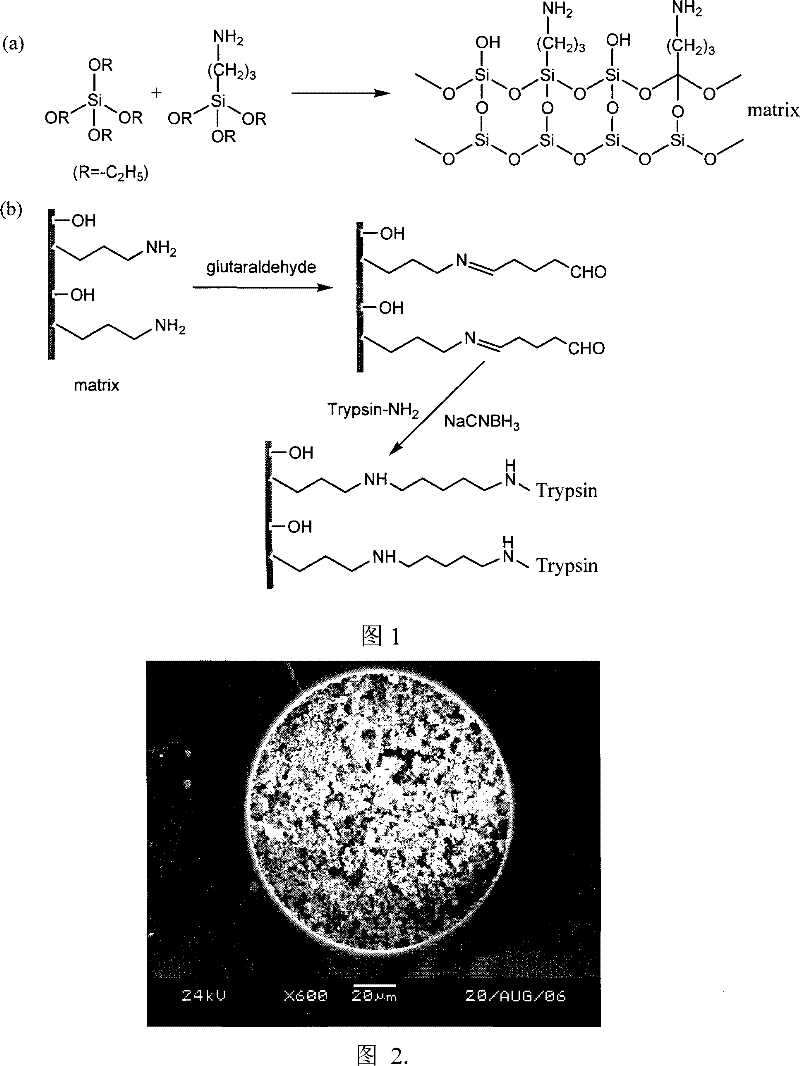

[0024] The organic-inorganic hybrid silica gel monolith immobilized enzyme reactor was prepared according to the following steps.

[0025] 1) Take a certain amount of TEOS, APTES, absolute ethanol, water and CTAB according to the ratios listed below and mix them thoroughly, and then introduce them into a pretreated capillary with an inner diameter of 10-300 μm through a syringe. The introduction process is after the raw materials are mixed. completed within 2 minutes. Seal with silicone rubber, and polymerize at 25-80°C for 12-24 hours; an organic-inorganic hybrid silica gel monolithic material carrier was prepared by sol-gel method and supramolecular template method; the specific parameters of the synthesis example are as follows 1 shown;

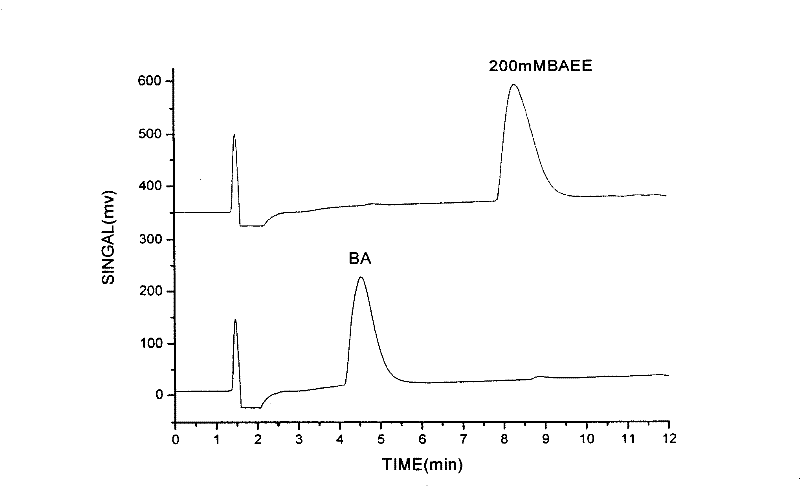

[0026] 2) Activation: The prepared monolithic material was first washed with ethanol to remove CTAB through a constant flow pump, and then washed with water and 100 mM phosphate buffer (pH 8.0) for 30 min. Then, 100 mM phosphate buffer (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com