A kind of porphyrin mofs film and preparation method thereof, application in electrocatalytic oxidation

A porphyrin and electrode technology, applied in the field of supramolecular metal organic chemistry, can solve the problems of poor binding ability between porphyrin MOFs film and substrate, limited controllability, cumbersome process, etc., so as to improve photoelectric response ability and avoid self- Degradable, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of porphyrin MOFs film, comprises the following steps: with FTO electrode as working electrode, with platinum electrode counter electrode, saturated calomel electrode as reference electrode to constitute three-electrode system, TCPP and Zn(NO 3 ) 2 ·6H 2O was dissolved in DMF one by one and stirred until a uniform solution was formed. As the electrolyte, the working electrode was energized at a constant potential of -0.7 V vs. SCE for 30 minutes, and a porphyrin MOFs film (TCPP@Zn-MOF / FTO composite electrode); wherein, the molar concentration of TCPP in the electrolyte is 0.4 mmol / L, Zn(NO 3 ) 2 ·6H 2 The molar concentration of O is 1.6 mmol / L.

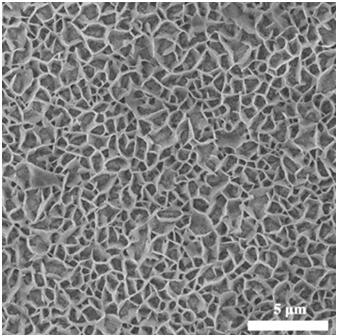

[0045] The porphyrin MOFs membrane prepared above was characterized by scanning electron microscopy, and the results were as follows: figure 1 As shown, it can be seen that the porphyrin MOFs film prepared in the example forms a network structure, the network structure is connected by sheet st...

Embodiment 2

[0047] The porphyrin MOFs membrane was prepared according to the method in Example 1, the only difference being that the constant potential of the working electrode was changed to -0.8 Vvs.SCE.

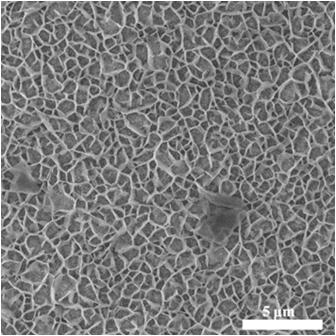

[0048] The porphyrin MOFs film prepared in Example 2 was characterized by a scanning electron microscope, and the results were as follows: figure 2 As shown, it can be seen that compared with Example 1, Example 2 strengthens the negative potential of the working electrode (from -0.7V to -0.8V), which is more conducive to the formation of crystal nuclei, forming a thinner network structure, grid Relatively regular, the edge length is about 200-500 nm. Compared with the porphyrin MOFs film in Example 1, the wall thickness of the porphyrin MOFs film prepared in Example 2 is thinner.

Embodiment 3

[0050] The porphyrin MOFs membrane was prepared according to the method of Example 1, the only difference being that the constant potential of the working electrode was changed to -0.9 Vvs.SCE.

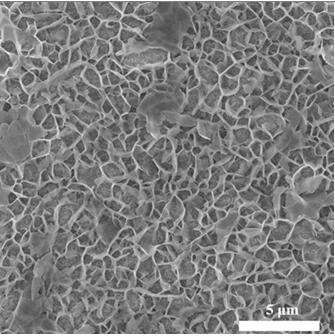

[0051] The porphyrin MOFs film prepared in Example 3 was characterized by a scanning electron microscope, and the results were as follows: image 3 As shown, it can be seen that the morphology regularity of the porphyrin MOFs membrane synthesized in Example 3 is not as regular as in Examples 1 and 2, and there are more sheet-like structures attached to the grid-like structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com