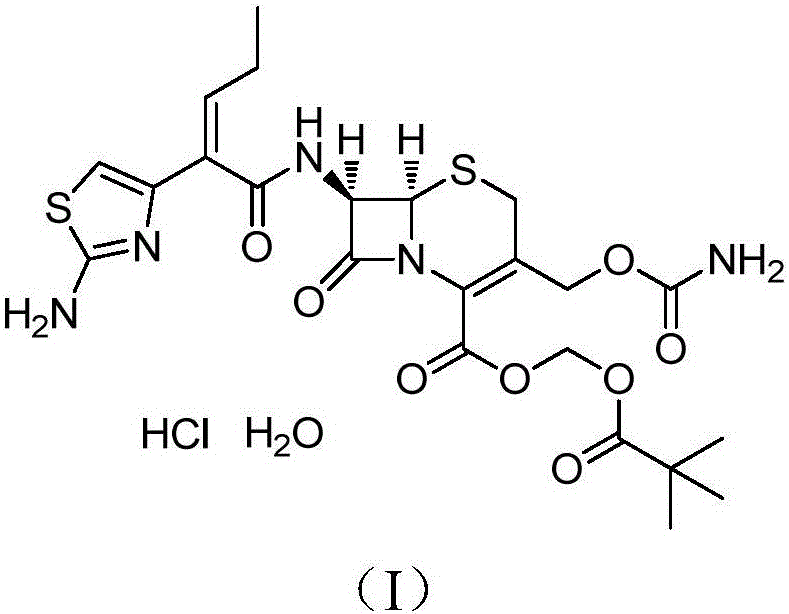

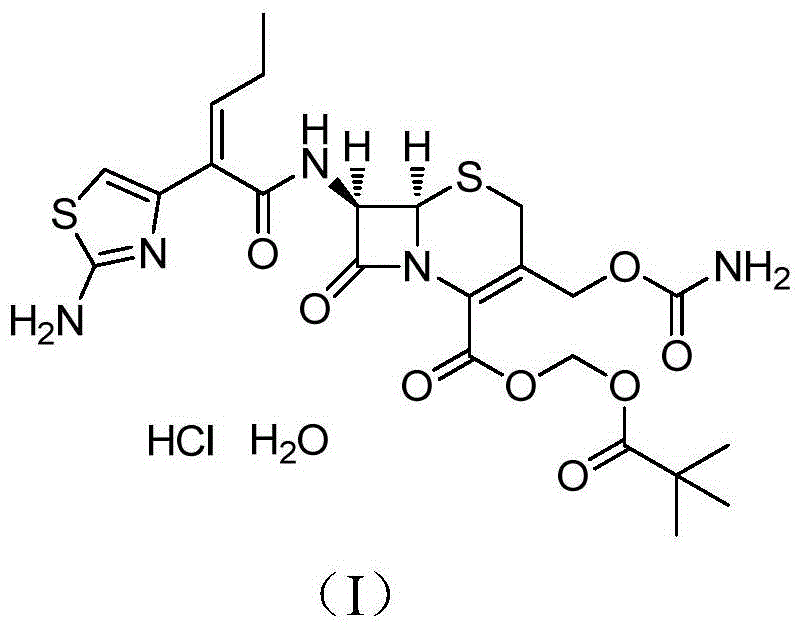

A kind of preparation method of cefcapene hydrochloride

A technology for cefcapine hydrochloride and cefcapine axetil, which is applied in the field of preparing monohydrate hydrochloride, can solve problems such as industrial scale-up production, difficult handling, unstable materials, etc., and achieves reduction of long-term storage and high conversion rate , the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

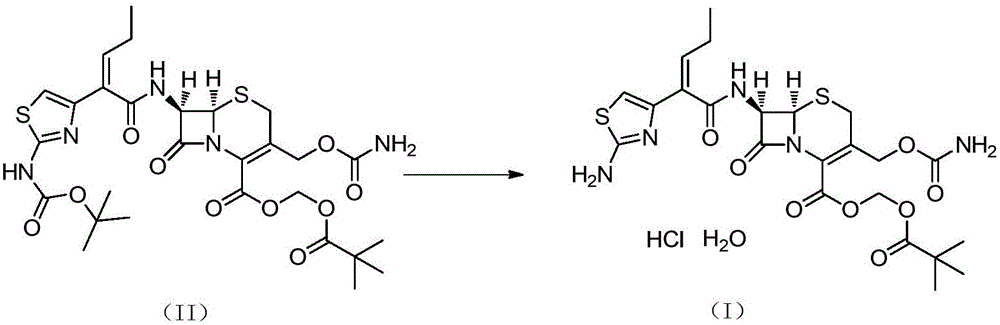

Method used

Image

Examples

Embodiment 1

[0021] Add ethyl acetate (1500mL) and aluminum trichloride (75g) to the reactor, stir to dissolve and cool down to -5~5°C, add compound of formula (II) (75g), and stir at -5~5°C React for 45 minutes. Water (1500 mL) was then quickly added to the reactor, stirred for 30 minutes, allowed to stand for 30 minutes, and the aqueous layer was drained. Wash with 10% sodium chloride solution (750mL), drain the water layer, control the temperature at 15-25°C, add 4mol / L hydrochloric acid (56.3mL) into the reactor, stir for 30 minutes, add acetonitrile (300mL), and stir for 3 hours . After centrifugation, the crude product was washed with water (500 mL×3), and dried for 16 hours to obtain the fine product of cefcapene hydrochloride monohydrate (60 g).

[0022] 1 H NMR (400MHz, d 6 -DMSO, 25°C): δ: 1.022 (t, 3H), 1.157 (s, 9H), 2.192-2.266 (m, 2H), 3.445-3.501 (d-d, 1H), 3.563-3.628 (d-d, 1H), 4.597(d, 1H), 4.828(d, 1H), 5.231(d, 1H), 5.783-5.811(m, 2H), 5.891(d, 1H), 6.353(t, 1H), 6...

Embodiment 2

[0024] Add ethyl acetate (1500mL) and aluminum trichloride (100g) into the reactor, stir to dissolve and cool down to -5~5°C, add the compound of formula (II) (75g), control the temperature at -5~5°C and stir React for 45 minutes. Water (1500 mL) was quickly added to the reactor, stirred for 30 minutes, left to stand for 30 minutes, and the water layer was drained. Wash with 10% sodium chloride solution (750mL), drain the water layer, control the temperature at 15-25°C, add 4mol / L hydrochloric acid (56.3mL) into the reactor, stir for 30 minutes, add acetonitrile (300mL), and stir for 3 hours . After centrifugation, the crude product was washed with water (500 mL×3), and dried for 16 hours to obtain the fine product of cefcapene hydrochloride monohydrate (55 g).

Embodiment 3

[0026] Add dichloromethane (1500mL) and aluminum trichloride (75g) into the reactor, stir to dissolve and cool down to -5~5°C, add the compound of formula (II) (75g), control the temperature and stir at -5~5°C React for 45 minutes. Water (1500 mL) was quickly added to the reactor, stirred for 30 minutes, left to stand for 30 minutes, and the water layer was drained. Wash with 10% sodium chloride solution (750mL), drain the water layer, control the temperature at 15-25°C, add 4mol / L hydrochloric acid (56.3mL) into the reactor, stir for 30 minutes, add acetonitrile (300mL), and stir for 3 hours . After centrifugation, the crude product was washed with water (500 mL×3), and dried for 16 hours to obtain the fine product of cefcapene hydrochloride monohydrate (55 g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com